Primer: types and properties

The main purpose of using a primer is to give the surface strength and increase the service life of the coating applied to it in the future.

The primer on the walls is indispensable before gluing wallpaper - it is able to penetrate deep into the surface to be pasted and mask defects (cracks and holes).

Wallpaper primer can prevent damage to the roll and the appearance of mold or mildew under it.

A properly applied mixture can improve the adhesion between the wall and the coating, which will lead to a decrease in the cost of finishing materials.

There are several types of primers - acrylic, oil, contact, concrete contact.

Let's analyze each of them in detail:

- acrylic is a universal mixture of deep penetration, capable of imparting strength to a weak base. Most often used in living quarters for leveling walls. However, it can be used on ceilings and floors. Penetrates to a depth of 1 centimeter and, when cured, forms a durable coating with excellent adhesion properties. Not recommended for work on ferrous metals;

- contact primer with the addition of quartz sand enhances the adhesion of the surface and, due to its composition, penetrates deeply into the walls, effectively filling cavities;

- an alkyd or oil primer mixture is used to treat wood or metal surfaces. It can be applied to rust, as it combines the properties of paint and anti-corrosion properties;

- drying oil or alcohol primer is perfect for working on wood - if you preheat the surface to be treated, you can significantly reduce the drying time;

- concrete contact is ideal for walls and ceilings of an ordinary apartment.

Video:

There are also mixtures less popular among ordinary residents, which are most often used only by professionals:

- on concrete or lime-sand walls, they work with a silicone solution, which hardens in 5 hours;

- areas with poor absorbency - utility rooms and workshops - are treated with a polyurethane compound;

- to obtain a neutral color that does not shine through the wallpaper, a pigmented primer is used on the surface.

The drying time of the primer depends primarily on the type. So, the oil, contact and primer mixture of deep penetration freeze for about a day. Acrylic primer dries in just 10 hours.

Therefore, before buying a mixture, read the label - the manufacturer always indicates the drying time of the primer mixture.

If we talk about average values, then the mixture dries completely after about 4 hours at a temperature of 25 degrees Celsius and a humidity of 65%.

Remember that the higher the humidity in the room, the longer it will take for the deep penetration primer to harden, so this process can be accelerated simply by opening the windows, of course, if the weather is clear without rains outside.

If the room has increased humidity, and there is no opportunity to ensure the flow of air, then the time indicated on the box can be doubled.

How long should the primer dry before wallpapering?

There are several factors that affect the drying rate:

- the mixture will solidify slowly if the room temperature is extremely low or, conversely, high temperature;

- the thicker the layer is applied, the longer it will take to dry;

- how much the newly applied primer will dry is also influenced by its composition - the deeper the mixture penetrates, the longer it will take to solidify.

Do not forget about the duration of the action of the primer solution - the interval until the mixture retains its adhesive properties.

Use the primer immediately after preparation, otherwise it will lose its effectiveness.

The primed surface also plays an important role.

If the primer mixture is applied in 2-3 layers on cement-lime plaster, then you will have to wait about 6 hours.

If the primer is applied to a regular wall before the putty, then it will take 2 - 3 hours for the mixture to harden.

After a visual assessment, run your hand over the wall - a smooth and dry surface will indicate a successful priming.

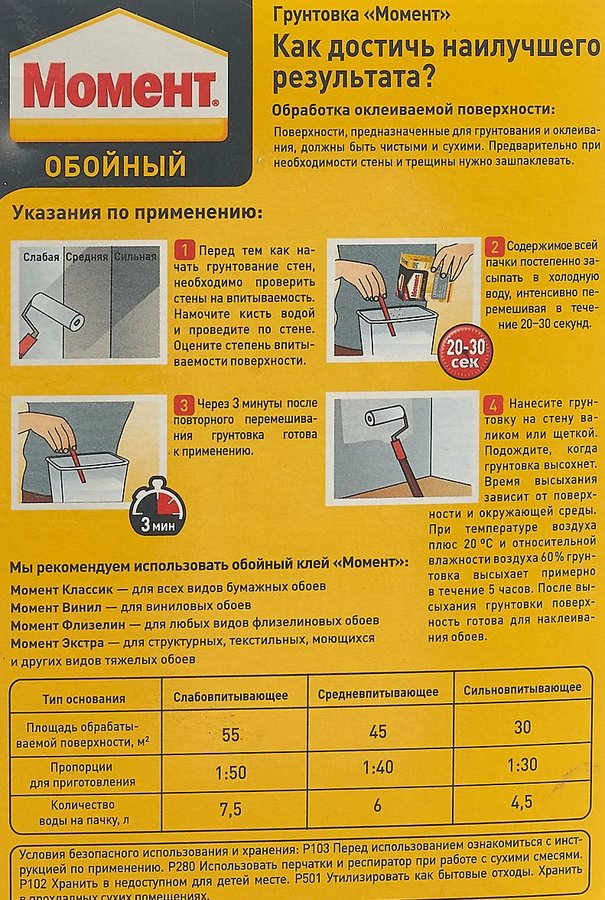

Do not forget to read the instructions for use before starting work. The manufacturer always indicates the optimal working conditions and material consumption for obtaining the best result.

How long does the putty dry

Drying time depends on the temperature and humidity in the room, on what type of mixture is used, the thickness of the applied layer, the use of a primer also plays a role.

A draft must not be allowed in the room.

On a wooden wall

For woodwork, several types of mixture are used. The main thing in this process is to follow all the recommendations.

Types of putty:

- plaster;

- anhydrous alkyd;

- waterproof;

- non-shrinking;

- colorless;

- acrylic.

For wood, the drying time of each layer is approximately a day, but in different rooms it may differ. It depends on the temperature and humidity in the room.

The solution is applied in two stages:

- The first layer is no more than 3 mm. After drying, which you need to walk along the walls with wide sandpaper.

- The second is half the thickness of the previous one and the procedure is repeated with emery.

On concrete and brick

On concrete and brick walls, the drying process is slightly longer than on others. The fact is that concrete has low adhesion. And the bonding mixture penetrates the upper layers of the surface for adhesion. This applies to cases where the layer is applied more than 3 millimeters. To get a quality result, you need to use a primer.

It is easy to determine whether the putty has dried or not - it becomes light and monochromatic. If dark spots are visible, wait a little longer. The hair dryer can only be used in extreme situations.

What determines the time of complete drying?

The drying process depends on certain factors:

- room temperature. The soil takes a long time to dry if the room is too hot or cool;

- the thinness of the applied layer accelerates the drying process;

- the primer mixture contains special additives that quickly evaporate from the wall surface;

- the drying time is influenced by the structure of the walls. If the primer penetrates deep into the pores, it takes longer to dry.

In most cases, manufacturers indicate data on the constituents and the time required for the final drying of the mixture. In addition, the type of material used affects the drying speed. Acrylic compounds dry for at least five hours; for an alkyd mixture, it will take much more time - up to a day. Gryftal compositions dry for a long time - you have to wait more than twenty-four hours. The least time required is a water-based primer - after applying it, it is allowed to continue working after twenty minutes.

Continuing to figure out how long after the primer can be putty, we will give several rules that must be followed:

- a stable optimum air temperature is maintained in the room;

- drafts are excluded.

Why is it necessary to prime the walls?

If you carefully examine the surface of the walls being prepared for painting or pasting from a close distance, you can see depressions and roughness on them.

Due to their presence, the quality of adhesion to the finishing material may deteriorate, and the smooth surface of the wallpaper may also suffer.

The working properties of the primer depend on the type of primer.The reinforcing composition provides adhesion of microparticles of the surface structure, resulting in a smooth, dust-free surface. This makes it easy to apply glue or paint to it.

Deep penetration primers fill the microscopic pores of the substrate, giving the working surface additional strength.

The use of a primer for treating walls has a number of positive aspects:

- the surface acquires a homogeneous smooth structure and becomes more durable;

- the smell of paint is eliminated;

- the glossy surface becomes more shiny;

- the risk of mold and rotting is reduced;

- paint and glue adhere well to the surface, which at the same time absorbs less material.

Types of primers

On the shelves of hardware stores, you can see many types of primers:

- universal;

- acrylic;

- alkyd;

- shellac;

- mineral:

- narrow profile.

Universal

One of these means is the universal deep penetration ST 17 CERESIT primer. This aqueous dispersion of synthetic resins impregnates and strengthens loose hygroscopic foundations of indoor building structures.

The liquid is applied on all types of substrates except for waterproof concrete and plastered surfaces with gypsum, cement and lime compositions.

Emulsions from manufacturers such as Vixen, Prospectors, Knauf, Liotokol and Polirem have proven excellent. How long the primer dries on the wall is usually indicated on the emulsion package. This process takes about 4-6 hours.

Acrylic

The tool is intended for widespread use. Acrylic wall primer is applied to drywall, chipboard, fiberboard, concrete and plaster before wallpapering.

Acrylic primer is produced in two modifications:

- organic composition;

- water-soluble emulsion.

The organic acrylic blend is more suitable for the treatment of façade surfaces. The composition is resistant to negative atmospheric influences.

Water-soluble emulsion is used for interior work. The basis of the soil is water. The product can be easily applied to any surface with a brush, roller or sprayed on with a spray gun. On the canister with the ready-made solution, you can read how long after the primer the walls can be putty. Acrylic primer usually dries in about 2 hours. After that, you can glue the wallpaper.

If it becomes necessary to apply 2 coats of priming, then after the first coat the next coat can be applied with a more liquid mixture. However, drying of the coating will take longer than usual.

Alkyd

An alkyd coating is used for concrete, metal and wood surfaces. This type of primer should not be used on drywall. The paper casing may swell and the gypsum base may collapse.

Polymer primer belongs to the group of alkyd coatings. Alkyd composite mixture creates a matte finish on the treated surface. It is used to prepare wooden walls and other fences before painting and plastering.

The primer forms a base with high adhesion for acrylate, acrylic putty, wallpapering, painting with latex, acrylic and nitro paints. On a container with an alkyd mixture, the manufacturer indicates how much the alkyd-based primer dries before the putty. It usually dries out within 24 hours.

Shellac

It is used only for processing wooden structures of walls, floors and ceilings. An important property of a shellac coating is that it becomes an insurmountable barrier to the release of resin from coniferous wood into the room.

One of the best shellac coatings on the Russian markets is supplied by the German company Kradezeit. Basically, the soil is supplied in cans of 0.375 l and 2.5 l. The applied product on the tree dries up completely in a day. Shellac is available in a wide range of colors.Natural ingredients used to create shellac are absolutely environmentally friendly and harmless to human health.

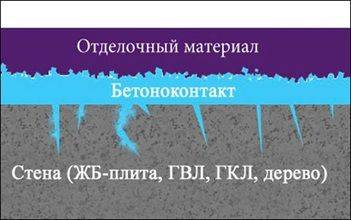

Mineral

It is used to cover concrete walls indoors. The primer is applied on silicate brick masonry... It is made on the basis of a mixture of lime and cement with various additives. Usually the primer is kneaded by hand in a suitable container.

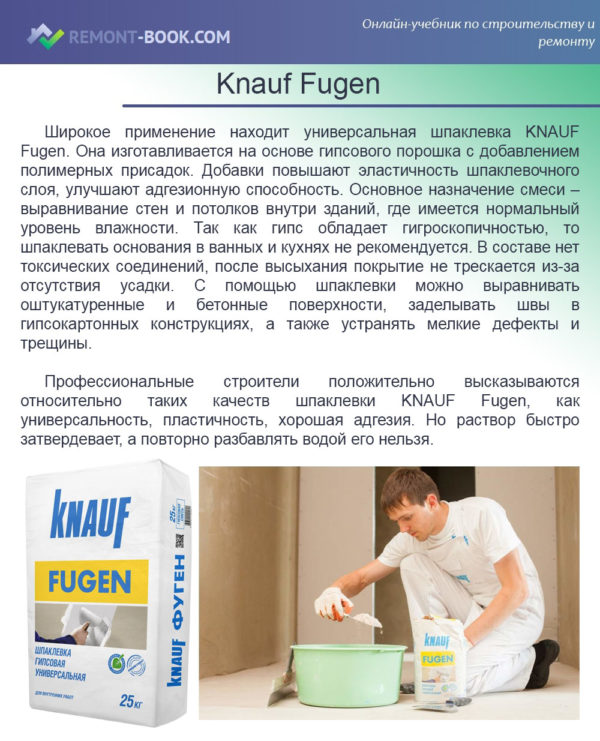

On sale you can find such a tool as "Betonkontakt". The high quality primer is produced by the German company Knauf. The product is intended for coating concrete substrates. The adhesion of the primer to the concrete is ensured by means of fine-grained sand that is resistant to the action of an alkaline environment.

You can find out what the "Beskontakt" primer is by watching the video

Any surfaces are treated with the mixture. Such a primer for walls is indispensable for fixing decorative stucco elements on vertical planes.

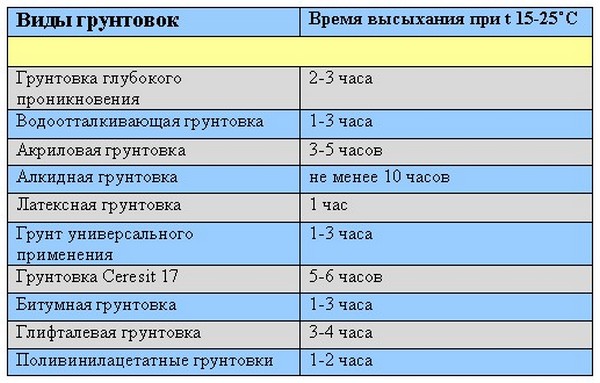

How much the primer should dry before wallpapering, painting, plastering, can be seen from the table.

Drying time table for different types of primers

4 Types of primers - universal and acrylic

Various types of wall primers are suitable for a particular function. First of all, I would like to note the universal compositions that are suitable for finishing work in rooms of any type. The material adheres perfectly to surfaces with high porosity and fine pore structure. This type is designed to work even with old walls that are already dilapidated and are gradually crumbling. The primer is made on the basis of acrylic plastics, to which various resins are added to enhance the quality of the finished product. The substance is quite concentrated, therefore dilution with water is required. After contact with the universal primer, the walls acquire such qualities as a high level of adhesion and moisture resistance.

The substance consumption is very low, which allows significant savings when choosing a universal soil. So, about 120 grams of primer concentrate will be required per square meter. Due to the high quality, it is not necessary to apply many layers - as a rule, two layers are more than enough to give the surface to be treated with the necessary qualities.

Acrylic wall primer is also a very popular and demanded product. The substance is produced on the basis of a styrene-arylate dispersion, while polymer binders are used as additives and fillers. Unlike universal, acrylic primer is suitable exclusively for interior finishing work. When working, there is no release of unpleasant odors, moreover, the material dries very quickly compared to other analogues. After two to three hours, the wall will be ready for wallpapering or other topcoat.

Acrylic primer boasts many positive qualities, among which they are especially distinguished:

- 1. Increasing the useful life of the wallpaper

- 2. Prevention of new damage to the wall, including cracks, notches, dents, chips

- 3. Reducing the level of hygroscopicity of the wall

- 4. Increasing the level of resistance to moisture, as well as temperature drops

- 5. Reducing the consumption of wallpaper glue.

You can work with a regular roller, but you may also need a small brush if you need to process hard-to-reach places, for example, the space near the radiator, corners, and the like. After letting the primer dry, after a couple of hours you can start working with the wallpaper. Thus, acrylic primer can save not only money, but also your time.

Acrylic primer can be applied in one coat

The primer is very reliable, which allows you to apply only one layer before gluing the wallpaper. In some cases, for example when the walls are old enough, a second coat can be applied. It is also recommended to apply several layers of the substance.This is due to the fact that when wallpaper is removed, the top layer of drywall is often disturbed. Several layers of acrylic primer will not allow harm to the gypsum board sheets in the future.

Application of primers

Working with a primer is extremely simple. The main thing is to know what tools you need, the right choice of solution. Such work is within the power of any person. The workflow itself can be split into several periods.

Working with a primer is extremely simple.

Preparation of the primer composition

The preparation of the solution is always clearly spelled out in the instructions, mainly on the sealed packaging. This is followed by the following steps:

- Shake, mix the solution, pour into any container convenient for work. Construction utensils can be as follows: enameled, wooden, plastic. Metal is subject to destruction (sometimes it is smeared, in several layers, with oil paint, each must dry).

- We dilute the primer in accordance with the instructions.

- We also transform dry mixtures in accordance with the rules.

- We mix the solution thoroughly, you can do this with a construction mixer.

We mix the solution thoroughly, you can do this with a construction mixer.

To be more specific, we can single out primers for a specific purpose: lime, adhesive paint, universal. You can prepare them as follows:

- Calcareous. For ten liters of material: fatty lime dough (two and a half kg), table salt (fifty or one hundred g) or aluminum alum. Stir the dough in cold water (5 liters). Dissolve salt in a boiled hearth (2 liters). Then pour it into a container with dough. Remains - three liters of water, add. The next mandatory procedure is filtering through a sieve or other product (one to one mm);

- Adhesive painting. Ten liters of water: the so-called - aluminum alum (one hundred fifty g), forty percent household soap (two hundred g), hard animal glue (two hundred g), drying oil (twenty five to thirty g), chalk (two to three kg). Alum is added to three liters of boiled water, glue is in two liters of the same water. A soap solution is added to the glue (for two liters of boiling water - all the soap), mix, add drying oil. Then add alum, chalk, mix, allow to cool. They are filtering.

If a person loves experiments, you can cook it yourself, but it is better to buy soil from a well-known manufacturer.

If everything is done exactly, according to the instructions, a single mixture without lumps appears.

Surface preparation

Before work, you need to carefully prepare the walls:

- Surface paint. It all depends on the type of paint, for today it is mainly water-based. It can be removed with a simple spatula; it is better to moisten the walls with soapy liquid. The enamelled walls are removed with emery;

- Wallpaper. Removal takes place with a spatula, after wetting the wallpaper with water (or a soapy solution with wallpaper glue). Washable wallpaper is cut in free order. Then moisten with soapy liquid and remove. If not removed the first time, moisten the paper - and try to remove them again. You can also use a heated iron. It should be applied to the wall through a wet cloth. After removing the wallpaper, you should wash the wall and walk again with a spatula;

- Mold, mildew. To clean these microorganisms from the walls, specialized means are used. You can prepare the solution yourself, based on bleach;

- Checking the plaster. The main thing is that the cement surface does not have cracks and does not crumble. You can check its strength by light tapping. You can hear where there is emptiness in the walls;

- Drywall. It is advisable to putty before work;

- Cleansing from dirt, dust.

Before work, you need to carefully prepare the walls.

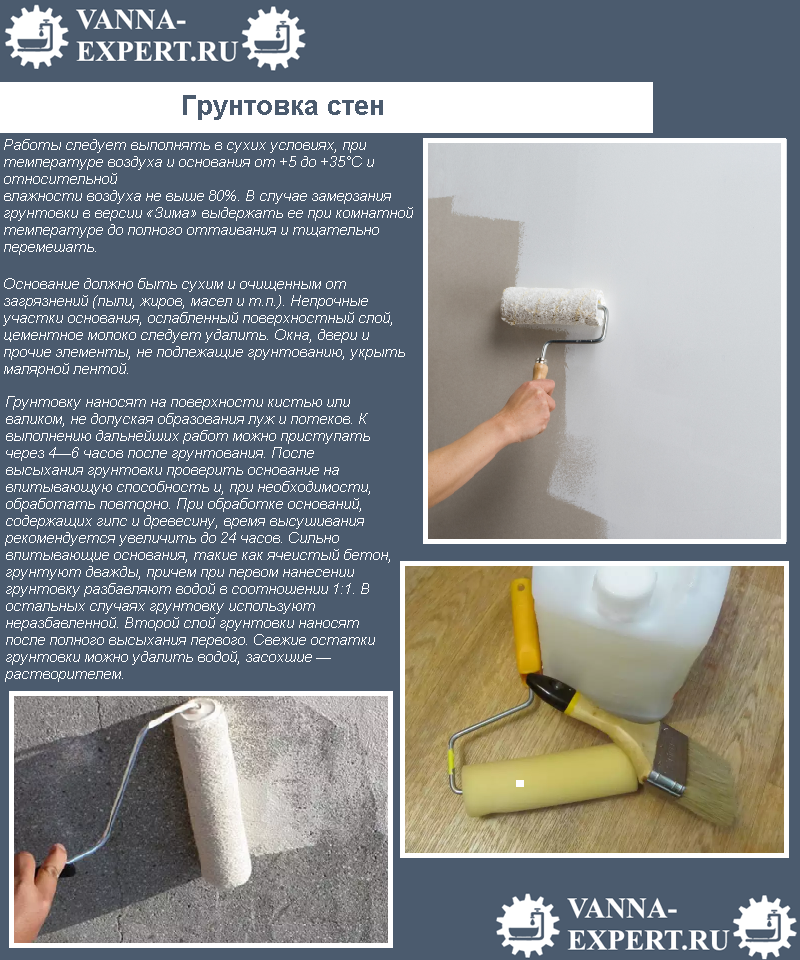

Surface application

A primer for walls under putty - the technological component is extremely simple:

- Consider the air temperature. Better if +30 -5.

- Working tools: roller, brush, tray, telescopic rod or pull-out product, stepladder, gloves, mask, overalls.

- Follow the previous two steps: clean the walls, dilute the concentrate.

- Add material to the tray.

- Moisten a roller or brush in the solution. Apply primer to the wall, observe that the liquid does not spread. It is applied from bottom to top, in a thin layer.

- Work carefully. There should be no dry areas. Remember to clean your work supplies.

- Use the brush in places where it is difficult to roller.

- After processing, you need to wait until it is completely dry.

- Then apply a second coat.

- This is the best way for all types of work: wallpapering, painting, etc.

All the work can be done using a specialized sprayer, it is used if the object is quite extensive.

All the work can be done using a specialized sprayer, it is used if the object is quite extensive.

Features of using a quick-drying primer

When performing certain repair work on priming surfaces, it should be borne in mind that in any case, such a composition should be selected that will best meet existing requirements and is suitable for the subsequent laying of the material or the application of another substance.

This accelerated drying process is due to the fact that special modifiers are included in the primer.

This quick-drying primer is ideal for metal surfaces, as it forms a reliable anti-corrosion and protective film. In addition, such a primer is resistant to temperature extremes in a fairly wide range from -45˚C and + 60˚C, and it can be applied at -10˚C.

If using normal mortar, you can apply a brush, spray or roller. In this case, the surface to be coated should be thoroughly treated, cleaned and degreased with a solvent.

What determines the drying time

It was wrong to start the article without familiarizing you with what the primer is and what types it is. After all, knowledge of such information will help to better cope with the task at hand. Primer - a composition that serves for reliable adhesion (adhesion) of the covering layers of the coating to the treated surface. It is applied as the first layer on the wall previously prepared for painting and pasting. It has binding and strengthening properties that prevent damage to the base and help to better absorb the applied finishing materials: paint, putty or plaster. Has antiseptic properties - prevents the appearance of fungus and mold.

There are several types of primer mix: acrylic mix is designed to seal weak areas. Contact materials have the same properties as acrylics, but differ in composition: finely ground quartz sand is added to them. Alkyd mixes are suitable for working on wood and metal surfaces. Alcohol primers are also suitable for wood. Also, do not forget about drying oil. It should be noted that all types have excellent adhesion.

So what determines the drying time of the primer? Primarily from the surface to which it is applied. If the work surface is too dry or porous, it will dry very quickly and the procedure will have to be repeated more than once.

The room temperature also affects. Too high or too low temperatures are not suitable, as the drying time will increase under these conditions. The same applies to air humidity. Another criterion for the drying of the soil is the applied layer itself. The thicker it is, the longer it dries. The base of the mixture. Usually, it is from easily volatile compositions that impregnations are made from various structures. The material will dry quickly if it contains a large amount of solids and solvent, which evaporates quickly

Such materials are extremely disadvantageous, since organic solvents leave the mixture earlier than necessary.

It is also important to pay attention to the "pot life" of the primer mixture. That is, the viability in this case is the optimal time of work, the interval when the primer does not lose its adhesion properties and can be coated on it with other materials.

Otherwise, the surfaces will not adhere, you will have to repeat the procedure.

My advice: drying too quickly does not lead to the long-awaited result, but quite the opposite, the surface of the base will crack and adhesion will not occur.