How long does the sealant dry

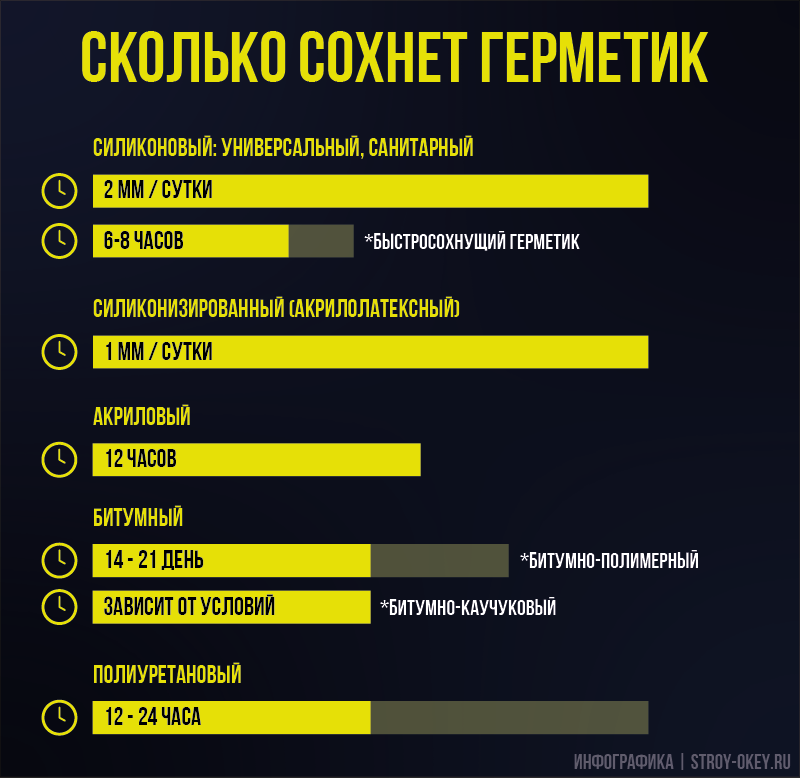

In order for the result of the repair work to be excellent, you can not start using the surfaces until the sealant has completely dried. The exact polymerization time of the composition depends on many factors. The curing process takes place in stages:

- in 15-25 minutes, the uppermost layer is set, a thin film is formed, while the sealant stops sticking to the skin when touched;

- the deeper layers of the agent freeze at a rate of about 2-3 mm per day.

Thus, the time of complete polymerization strongly depends on the layer thickness: the larger it is, the longer the period before the start of operation should be. Knowing the thickness of the seam made, you can roughly calculate the drying time. During the drying period, the surface must be protected from dust, temperature extremes, and mechanical stress.

Acidic and neutral compositions

Acidic compositions set faster under the influence of water and steam. When sealing a small product, you can put it in a bag, put a piece of damp cloth in the same place, place it on a battery or in another warm place. In this case, the acid sealant will vulcanize in a couple of hours. In standard situations, it takes 4-9 hours for the acid composition to dry.

Neutral sealants take longer to dry. If the room temperature is positive, and the surface has been previously cleaned of dirt, dust, grease, then drying will last about a day. When the air temperature rises more than +40 degrees, the structure of the seam may be disturbed, since the evaporation of alcohol from the neutral sealant under such conditions occurs too quickly.

Drying depending on the application

In order for the sealant to dry faster, you need to choose the composition according to the manufacturer's recommendations - it must correspond to the operating conditions. All funds can be classified into the following groups:

- for rooms with high humidity;

- for outdoor work;

- for interior work.

Different sealants contain different additives, plasticizers and modifiers that can change the drying rate. In hard-to-reach areas where there is no free air movement, the seams take longer to dry. Most sealants can be used at + 5 ... + 40 degrees, and the drying time at + 30 ... + 40 degrees will be much shorter than at +20. In winter, it is better not to work with sealants on the street - most products are not able to form a high-quality seam in such conditions.

Features of drying sanitary sealant

In the bathroom, it makes sense to use only a sanitary sealant - a composition into which fungicidal additives are introduced to prevent the appearance of mold. When sealing the joint between the wall and the tub, the seal joint is usually thick, wide, so it will take a long time to dry. Despite the manufacturer's instructions that the composition dries for about a day, it is better to wait at least 48 hours - only during this period the product will undergo complete polymerization.

Characteristics and drying rate of Moment brand sealant

A transparent sealant of the Moment brand is made on the basis of silicone and is used for repairing windows, plastic and glass doors, and for tiling the bathroom and kitchen. This product is very resistant to temperature changes, moisture, atmospheric factors, and hardens under the influence of air.

The main technical characteristics of the composition are as follows:

- specific gravity - 0.99 g / ml;

- extrusion speed - 320 g / min;

- drying time to the third degree (to touch) - 15 minutes at +23 degrees, humidity 50%;

- recommended operating temperature –40… + 150 degrees;

- the approximate polymerization speed for a layer of 2 mm is 24 hours.

To understand whether the "Moment" is dry or not, you can use the feature of this product to emit a slight specific odor, which disappears after polymerization. If there are no extraneous "aromas" in the seam area, then it is most likely dried out well.

Drying speed of silicone neutral sealant "Moment Herment"

This product is a one-component, neutral sealant based on a silicone polymer. It can be used for external and internal work, it is suitable for gluing products and sealing any joints, cracks. The manufacturer notes that a 3 mm layer dries for about a day, if the temperature is close to +23 degrees, humidity - to 50%. In this case, the surface film appears in 10–20 minutes, and the top layer of the sealant stops sticking. In order not to damage the seam, do not subject it to any mechanical stress until complete polymerization.

MS polymer sealants

A newly emerged type of sealant that is rapidly gaining popularity due to its excellent properties. They combine the qualities of silicones and polyurethanes, reliably protecting against leakage, forming elastic and reliable joints.

VS polymers - excellent qualities for bathrooms and other wet areas

Properties and scope

The main advantage of sealants based on MS polymers is that in addition to the properties of the sealant, they still have a high adhesive ability, therefore their polymers are also called adhesive sealant. They have the following properties:

- Excellent adhesion to all building materials without the need for primers.

- Solvent free, safe and virtually odorless.

- They dry quickly and harden even at sub-zero temperatures (only slower).

- When dry they do not harden, they remain elastic (elasticity range 25%).

- After drying, you can paint.

- They do not crack or change color under the influence of the sun.

- Waterproof, can be used in fresh and salt water.

-

When applied, they do not spread, a neat seam is easily formed on vertical and horizontal, inclined surfaces.

Excellent properties. There are also disadvantages. The first is a high price, but it is justified, since the seam does not crack and does not leak for a long time. The second - after a while, the surface of the white sealant may turn yellow. This does not affect the quality of the seam, but it looks ugly. You can remove yellowness by wiping the seam with refined gasoline. The third minus - after hardening, the composition is removed only mechanically. No solvents act on it.

Manufacturers and prices

Almost every major manufacturer has MS sealants, and they also have various additives that give special characteristics, so that you can choose exactly according to the situation and for a specific type of work.

| Name | Colour | Special properties | Skin formation | Release form | Price |

|---|---|---|---|---|---|

| Bisin MS Polymer (adhesive sealant) | white / transparent | Glass, mirrors, plastics, bricks, natural stone, concrete, wood, iron and many other metals. | 15 min at + 20 ° C | Tube for pistol (280 ml) | 490-600 rub |

| BOSTIK MS 2750 | White black | Metal, wood, glass, expanded polystyrene, etc. | 30 min at + 20 ° C | Tube for pistol (280 ml) | 400-450 rub |

| BOSTIK SuperFix | White gray | Suitable for underwater, swimming pools and rooms with high humidity | about 15 minutes | Tube for pistol (280 ml) | 400-550 rub |

| TECFIX MS 441 | transparent | Resistant to seawater, chlorine, mold and fungi | 10 min at + 23 ° C | Aluminum film sleeve (400 ml) | 670-980 rub |

| 1000 USOS | white, transparent, gray, blue, green, tiles, black, brown | For bathrooms and kitchens with anti-mold action | 15 min at + 20 ° C | Tube for pistol (280 ml) | 340 rbl |

| SOUDALSEAL High Tack | White black | For sanitary rooms and kitchens - resists the formation of fungus |

10 min at + 20 ° C | Tube for pistol (280 ml) | 400 rbl |

| SOUDASEAL 240 FC | White, black, gray, brown | For sanitary rooms and kitchens, fast curing | 10 min at + 20 ° C | Tube for pistol (280 ml) | 370 rbl |

| SOUDASEAL FIX ALL High Tack | White black | For sanitary facilities, super strong initial hold | 10 min at + 20 ° C | Tube for pistol (280 ml) | 460 rbl |

Despite the fact that this type of sealant has appeared recently, the range is solid, since the combination of high adhesive ability and sealant properties is very convenient and the product is in demand.

The main advantage of MC sealants is elasticity after drying, tolerance of prolonged direct contact with water, and resistance to the growth of fungi and bacteria. Therefore, this type of sealant is used to seal the junction of the bathroom or shower stall with the wall. In the case of a shower cabin, it is also good because it does not slip when applied vertically.

Another positive point - most of the formulations have a pasty consistency, which lays down evenly, does not bubble. After application to the initial curing (skin formation), the applied sealant can be easily leveled to the desired shape.

The agony of choice: which type of sealant is best for the bathroom?

The breadth of the assortment makes your head spin when you look at the shelves of a hardware store. In fact, the task is not that difficult, especially with a competent approach. First of all, you need to choose the appropriate type of sealant from those that are most often used in the repair of bathrooms.

Types of sealants for bathrooms

Silicone. It has a high degree of adhesion to most materials, which makes it the most popular sealant, but negatively affects the cost. Resistant to ultraviolet radiation, moisture, high and low temperatures, due to which it has a long service life. Slight shrinkage, which does not exceed 2%, makes it the best choice for sealing moving joints. Due to its high elasticity, the finished seam is easily deformed and is not able to hold the paint.

Acrylic. It is practically not inferior to silicone in terms of adhesion, immunity to ultraviolet light, temperature fluctuations and high humidity. At the same time, it has a more affordable cost if you compare the prices of one company. Its use is limited by the low elasticity of the seam, which is not suitable for surfaces that may be subject to deformation. Acrylic sealants can be painted, varnished or plastered.

Polyurethane. It is most often used to replace an old sealant layer, since it is not so critical to surface preparation, and fits well on difficult-to-clean silicone residues. As with acrylics, the finished seam can be opened with varnish or paint.

Silicone acrylic. It occupies an intermediate position between the two types, differing in good indicators of elasticity and strength. Another area of application of this group of sealants is the bonding of surfaces.

Choosing the best

If you have to seal the joints in the bathroom with a sealant, the best choice is a silicone sealant, which, in turn, is divided into two types:

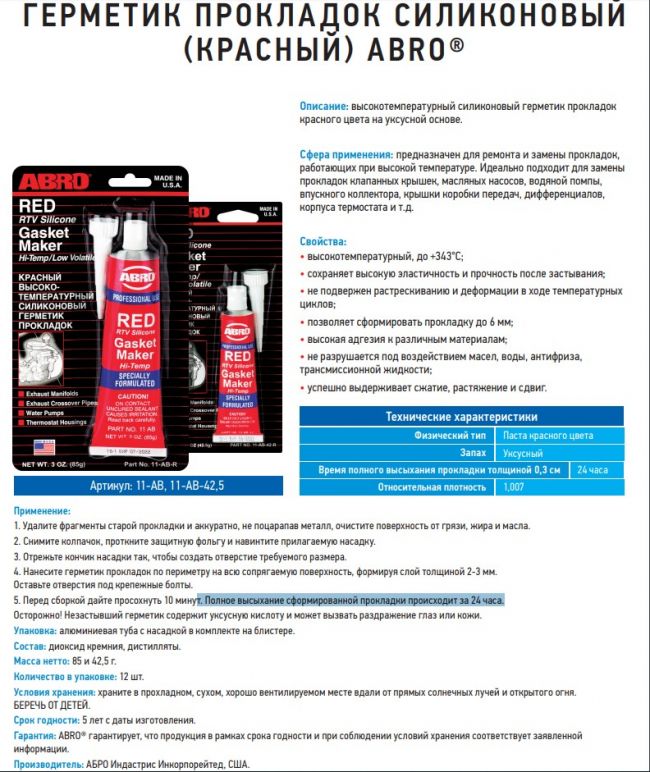

Acid. They perfectly cope with their tasks, but the acetic acid included in the composition adversely affects metal, stone, marble, mirror and lime plaster surfaces. Due to their affordable cost, it is acidic silicones that are commonly used by employees. If your bathroom requires sealing the seams of acid-unstable materials, check this moment. You can find out if an acidic sealant is being used by the characteristic vinegar smell or the “A” mark on the package.

Neutral. Due to the fact that the components of these compositions do not enter into chemical reactions with alkalis and metals, they are used for any surfaces.Such versatility negatively affects the cost of sealants, but for the sake of the safety of finishing materials or plumbing, it makes sense to pay more. An indication that a neutral sealant has been used is the absence of a strong odor and the “N” marking on the tube.

Prevent mold

The warmth and humidity in the bathroom are favorable conditions for the development of fungi. To keep black mold-resistant mold from spreading around the bathroom, choose a sealant marked “sanitary”. It contains antifungal agents that will prevent mold spores from developing.

For plumbing fixtures made of acrylic, it is better to choose the sealant of the same name. Due to the similarity of the compositions, the connection will be stronger and more durable

Additional properties

All sealing mixtures on the market contain various additives that give them certain qualities:

Extenders - provide a significant expansion of the material, indispensable for filling wide joints, for example, around sewer pipes.

Fillers (quartz dust or chalk) - improve adhesion and reduce the cost of production.

Fungicides and antibacterial components - prevent the development of pathogenic microflora.

Organic solvents, mineral oils - serve as a tribute to environmental friendliness and safety of vapors for humans.

Pigments - Provides an extensive color palette that makes it easy to match a sealant to colored plumbing fixtures or tiles.

How long does it take for different brands of silicone sealant for bathroom and other areas?

Considering the different popularity of domestic and foreign brands of sealant, we offer a small summary table. Basically, it will contain data on universal and sanitary types of material, including information on how long the Moment silicone sealant dries.

| Type of sealant | The foundation | Brand | Primary setting time, minutes | Full solidification time, hours |

| Universal | Acid | Titan | 15…25 | 2 mm / hour |

| Universal | Acid | KIM-TEC Silicon 101E | 9 | 3 ... 12 hours |

| Universal | Acid | Ceresite CS 23 | 10…15 | 2 mm / hour |

| Universal | Neutral | Ceresit CS 16 | 8…12 | 24 |

| Universal | Acid | Кrass | 15…25 | 2 mm / hour |

| Sanitary | Acid | Makroflex SX 101 | 15…20 | About 24 |

| Sanitary | Acid | Ceresit CS 25 | 10…15 | 2 mm / hour |

Important: when describing their products, manufacturers sometimes do not directly indicate the setting time and full curing of the sealant. Often this data can be obtained from indirect data - for example, the Ceresit company indicates that it is necessary to smooth the material in the seam no later than 6 ... 8 minutes from the moment of application

Thus, already after 10 minutes the initial setting is possible.

Often this data can be obtained from indirect data - for example, the Ceresit company indicates that it is necessary to smooth the material in the seam no later than 6 ... 8 minutes from the moment of application. Thus, the initial setting is possible after just 10 minutes.

Nobody indicates the exact time of complete solidification! These data are so individual that it is unrealistic to establish them without admission at 3 ... 12 hours.

Types of sealants

The sealant is an adhesive based on polymers, hardeners and fillers, targeted additives and plasticizers, which, after drying, forms a tight elastic seam. Depending on the composition, sealants are divided into several types.

Silicone

Bathroom silicone sealant is the most requested option because of its many benefits. Products from this group are characterized by a high degree of adhesion to ceramics, tiles, natural enamel, glass, and other building materials. Sealants do not allow moisture to pass through, they are not afraid of ultraviolet radiation, they can easily withstand temperature drops in the range of -50 ... + 200 degrees, they serve for several years and practically do not shrink.

By the type of base, silicone sealants are divided into:

Acidic (acetic). They have a characteristic odor. They differ in low price, availability, wide assortment. Acidic compounds damage metal, some types of plastic, and are not suitable for stone, mirrors, surfaces covered with lime plaster. These sealants are marked "A" on the packaging. Neutral. At cost, they are more expensive than acidic ones, but they do not enter into a chemical reaction with metals, alkalis, and other materials, therefore they can be used on any grounds without restriction. Some sealants from this group can withstand heating up to +500 degrees, therefore they are considered heat-resistant

Acrylic

Acrylic bathroom sealant usually costs less than silicone, but has a slightly lower degree of adhesion to ceramics, glass, metal, and other materials. The disadvantage is also less high elasticity, therefore, acrylic should not be used for deformable bases - it is better to give preference to silicone. If you ignore this rule, over time, the sealant layer will be covered with microcracks, through which water will seep.

The advantages of acrylic compounds are:

- resistance to UV radiation;

- no burnout;

- tolerance of temperatures within –25 ... + 80 degrees;

- the possibility of painting, varnishing, plastering;

- lack of smell.

Among acrylic sealants, there are moisture-resistant and non-moisture resistant, and the latter are not suitable for the bathroom, which must be clarified when buying.

Polyurethane

Despite the highest strength, excellent adhesion, resistance and durability, such sealants are used less often in the bathroom. They have a toxic composition, emit an unpleasant odor, and therefore require long-term and thorough ventilation of the room. With polyurethane compounds, you must work with a mask, gloves.

On top of the finished seam, if necessary, you can paint or varnish. If a polyurethane sealant is available, it can also be used to fix various decorative elements and mirrors.

Silicone-acrylic

They are products based on acrylic and silicone, combining the best properties of both components. They are not afraid of water, smooth out the thermal expansion of materials, have a long service life, do not react to the influence of ultraviolet radiation. Silicone-acrylic compounds are suitable for indoor and outdoor use and are widely used for sealing joints in the bathroom.

MS polymer sealants

They are an improved form of polyurethane sealants. They appeared recently in the course of experiments on polyurethane, into the structure of which a silanol (organosilicon) group was introduced. After contact with moisture in such compositions, the polymer is vulcanized, which additionally acquires the stabilizing properties of silicone.

Initially, due to the high cost of MS polymers, they were not used in large quantities and were only used for the repair of military equipment. Now they are used mainly in industry, although they are also suitable for domestic purposes.

The advantages of sealants are obvious:

How to speed up the drying of silicone sealant

There is not always the possibility of a long wait. Sometimes it is necessary to speed up the hardening process of the material. We offer several proven ways to help you do this.

- Raise the temperature in the room. Silicone cures faster at 30-40C. To do this, you can turn on the heater or use a heat gun. But you need to keep an eye on the thermometer. If the heating is more than 40C, this will adversely affect the properties of the composition.

- Provide air circulation. Normal airing significantly speeds up the drying of the material.

- Increase the moisture content of the air. Direct contact with water during the hardening period is unacceptable. You can spray the sealant with a spray bottle or steam it.

Instagram @tmkmetiz

Instagram @tmkmetiz

It is necessary to accelerate the curing process of the sealant correctly, otherwise the material will collapse

Acidic agents react particularly well to high humidity and steam. If the part is small, the silicone preparation can be dried very quickly. To do this, it is placed in a plastic bag together with a cloth soaked in water, it is sealed and placed on a battery or in another warm place. In contrast, neutral pastes "prefer" dry air and good ventilation.

Types and characteristics

All sealants today are divided into only 2 main types:

- One-component composition. This type is sold in any hardware store and is one of the most common. Compounds of this type are sold in metal or polyethylene tubes. This component hardens due to the presence of moisture in the air. The main disadvantage of this type is high-speed hardening, but only if the surface is treated with a thin layer. And if the layer is more than 1.2 cm, then the sealant hardens for a long time.

- Two-piece type. Such mixtures freeze in any layer, but the cost of such a composition is higher, since they are mainly used for industrial purposes.

Moment sealants are one-component types, as they are intended for domestic use.

The Moment manufacturer produces two types of sealants. The first type is silicone based sealants, and the second type is made from acrylic water dispersion.

Acrylic-based sealants are more resistant to frost and various adhesions of the processed surfaces. The main disadvantage of acrylic compounds is the impossibility of using in an environment with constant moisture. As for the color of this sealant, it is mostly white.

Silicone sealant is made on the basis of a rubber polymer. Such a component makes the mixture more elastic and makes it possible to solidify in a short time, even at room temperature. Due to this characteristic, Moment silicone sealants are sold in special plastic tubes, which retain its liquid and plastic state for some time after production. The tubes can be produced in volumes from 85 ml to 250 ml.

If you divide the compositions, starting from the scope of use, then they are construction, automotive and special.

According to their composition, they are divided into two types:

- Neutral. Alcohol is added to the composition of such a material instead of acetic acid and thus a less pungent odor is obtained. They can be used outdoors and indoors. Such mixtures are used in the field of shipbuilding, to seal freezers, they can be transparent and white.

- Universal sealants. The manufacture of such a composition takes place with the addition of a vinegar mixture, which gives an unpleasant and pungent odor, and when interacting with non-ferrous metals, cement and similar materials, which include alkalis, causes corrosion. This type of sealant is produced in white or transparent color. It can be used for interior processing, that is, indoors, and for outdoor use, as it is moisture and heat resistant. The cost of such a composition is lower than that of a neutral one.

And also the Henkel company produces the Moment Herment sealant, it can be used both for domestic use and for professional use. Such a sealant is divided into several types:

- Premium white, which is highly resistant to moisture, and consists of silicone. This type can be called the most heat-resistant.

- The next type, which is made on the basis of silicone and sodium silicate, copes well with oil, gasoline, high temperatures, which can reach 300 degrees. It dries quite quickly, and its color may even be red.

- The type of sealant Sanitary is used for the manufacture of glazing for shower stalls and bathtubs, but it cannot be used for processing stone and rusty surfaces, its curing speed is about 15 minutes.

- Aquarium look, used for the treatment of painted and glass surfaces that are subject to frequent vibrations. It is popular, since it has an increased level of moisture resistance, and the color of such a composition is extremely transparent.

The same series of materials "Moment" includes a gray sealant, which is made on the basis of polyurethane. It is often used as a grout for moving joints and as a tile adhesive. It is resistant to moisture, acids, alkalis, water and similar negative factors. But it has a drawback, since it burns out in direct sunlight and loses its elasticity over time.

Scope of application

The seal is considered a universal sealant. So, it is used for both indoor and outdoor work. When finishing the front side of buildings, sanitary sealant is in high demand for various purposes:

- they fill up the cracks in the window frames;

- reliably fix the stone tile, which comes off the base;

- seal the drain and glass structures;

- close the seams on the roof;

- form the joints of the vinyl facade.

In addition, indoor sanitary silicone sealant has also found a wide range of applications:

- Sealing joints between the ceiling and drywall.

- As thermal insulation for sealing the seams of window sills.

- Sealing joints on pipes and other parts that can reach high temperatures.

- Fixing seams at the junction of plumbing.

- Sealing the joints between the shower stall and the wall. Durable mounting of mirrors.

This is an incomplete list, because there are a lot of uses for the sealant. Professional craftsmen find new ideas for the use of this substance.

Time of initial drying and full curing

It is impossible to accurately predict the drying time, since in each case there are nuances associated with temperature, humidity in the room, layer thickness and other parameters. However, based on the experience of builders and repairmen, one can roughly say how long it will take to wait before starting work with a frozen mass.

| Type of sealant | Application feature | Application conditions | Curing time | Properties |

|

Silicone

They are transparent and colorless, do not stain with paints, give an elastic seam. Resistant to moisture and temperature extremes |

Universal | On any surface | The top layer "grabs" in 5 ... 30 minutes. In the future, it dries up 2 mm per day (on average).

Fast drying varieties can completely cure in 6 ... 8 hours |

Often acidic, can be corrosive to metal and concrete, has a characteristic vinegar odor |

| Sanitary | For damp surfaces, including water communications | Contains additives to prevent the development of mold and mildew, usually without acidic components | ||

| Heat-resistant (silicate) | For areas with high (up to 1200 degrees) temperatures | Contains glass silicates | ||

| Auto repair | Work in difficult conditions - with vibration, heating, exposure to active substances | Neutral, with increased elasticity and resistance to dynamic loads | ||

| Siliconized (acrylatex) Moisture-resistant, gives a tight and elastic seam | To be stained | Sealing in slightly damp and dry places | Initial setting 60 min, complete drying 1 mm / day | Applies to dry surfaces |

| Acrylic Good adhesion, resistant to low temperatures, deformation and dynamic load resistant | Water resistant | Is universal | Fully cured within 12 hours under favorable conditions. In unfavorable cases - up to 1 month | Not afraid of water, but only applied to dry surfaces |

| Not waterproof | It is used for the repair of furniture, wood products | Applies only to dry surfaces, dissolves with water | ||

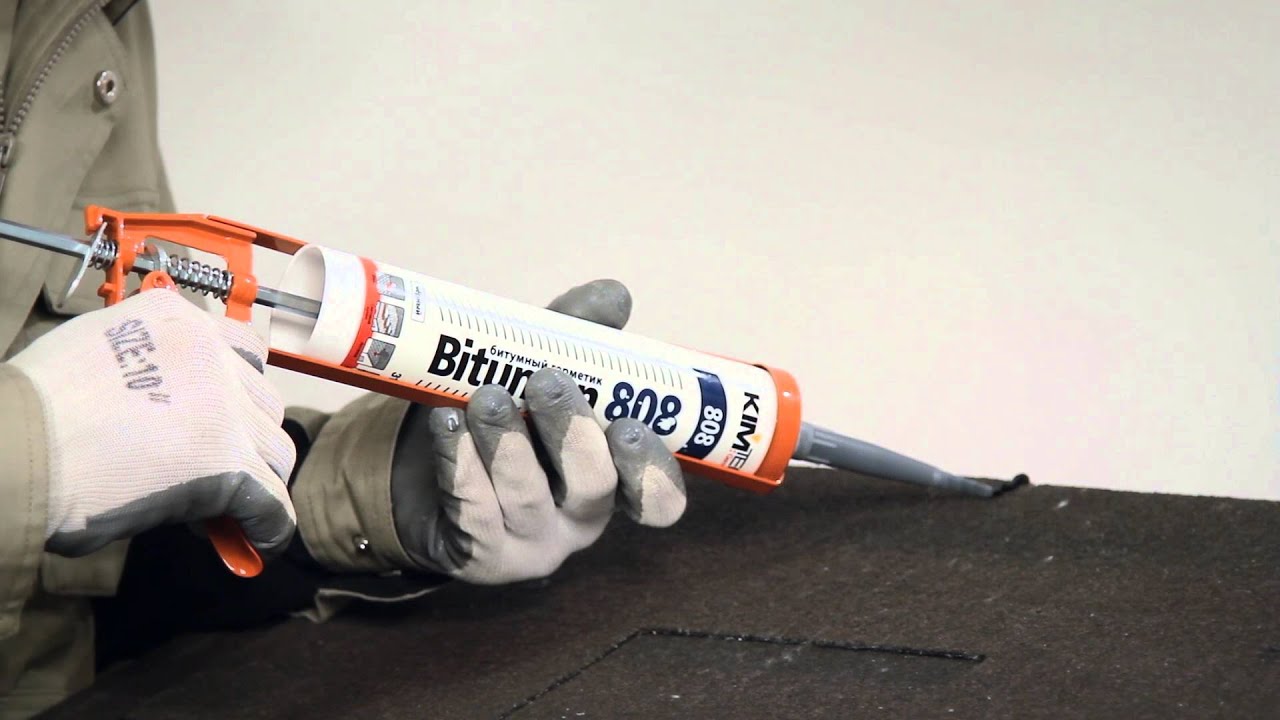

| Bituminous Water resistant, excellent adhesion | Bituminous-polymer | For outdoor use, roof waterproofing, bonding of coatings | Complete cure in 14 ... 21 days | It is applied on dry surfaces (preferably), at positive temperatures, often in a heated form |

| Bituminous rubber | The surface film hardens in an hour, the time for complete drying depends on the layer thickness and conditions | |||

| Polyurethane High adhesion, elasticity, strength, durability up to 20 years | Visually and in terms of characteristics, it is similar to polyurethane foam | Corrosive composition, used for outdoor use | Initial setting 15 ... 30 minutes, full curing 12 ... 24 hours | Apply to a dry, grease-free surface |

Important: the table contains approximate (average) data for each type of sealant. For specific products, it is necessary to clarify the data.

What type of sealant to choose for the bathroom

It is impossible to save on this material - penetrating water will spoil the adjacent materials, provoke the appearance of fungus and mold

When choosing a product, pay attention to the adhesion and strength indicators indicated on the label. As a rule, one package is enough for sealing.

As for the type of silicone used, the sanitary subspecies are almost always used for bathrooms and toilets. Fungicides (substances that kill the fungus on the root) are added to it. With this tool, it is convenient to seal up the seams, seal the joints between the plumbing device and fasteners, pipe inlets, the wall, and the constituent elements of the structure.

However, if the bathtub is metal, then a neutral material will be the best choice. For acrylic - special acrylic, similar in structure to it.

Now you know how long different types of silicone sealants take to dry, and you can calculate the duration of the repair work based on this. Remember that the correct choice and application of this material will significantly increase the comfort of using plumbing and extend its service life.