Curing speed

In conclusion, it is worth paying attention to the question of how quickly the epoxy glue hardens. Some, in order to speed up this process, think that more hardener can be added.

Thanks to this, the composition will quickly harden. However, this is a delusion. If you want to achieve rapid hardening of two surfaces, it is necessary to artificially increase the temperature.

Conclusion So, here we have considered all the features of epoxy glue. Which one is better to choose it is up to you. You can purchase a proven domestic manufacturer

When choosing, be sure to pay attention to the shelf life of the composition on the package

Choose the glue that fulfills its main purpose. We hope this material was helpful to you. You have learned about the main properties of epoxy glue. Additionally, we suggest watching the video: How to mix the epoxy resin correctly.

Solidification stages

The mixture of epoxy and hardener does not rise all at once, the formation of continuous and ultra-long (on a molecular scale) polymer chains in the entire mass of the epoxy composition does not occur. Polymerization takes place in separate fragments, which only then, over time, merge into a single polymer mass.

Good to know> What varnish can be applied to epoxy resin

The process of solidification, thickening and drying of a product made of epoxy resin mixed with a hardener goes through several stages:

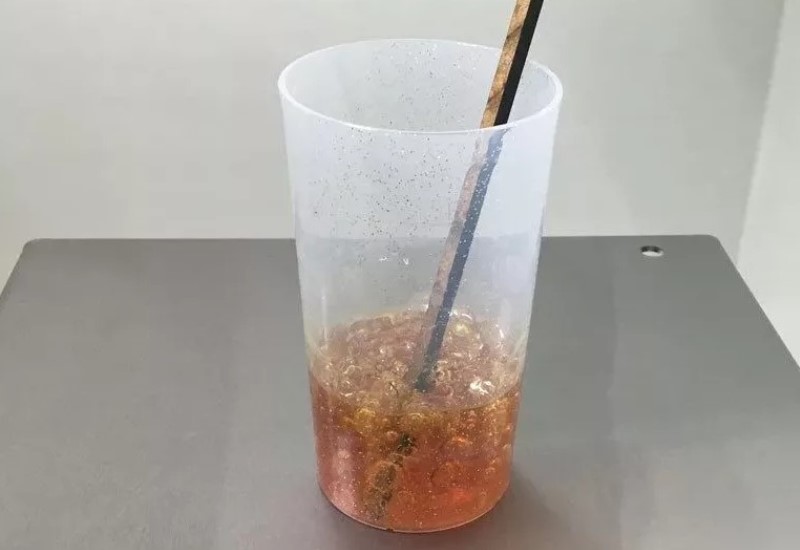

- A liquid flowing consistency that allows, due to this fluidity, to fill in the smallest irregularities in the cavity of the material being poured.

- Thickening of the mixture to the state of cold buckwheat honey. In this form, the mixture is no longer able to completely fill surfaces with a complex and pronounced relief.

- The density is already such that it slides out of the overturned vessel at a speed of no more than a centimeter per second. Suitable only for gluing large parts.

- So thick that when trying to separate at least part of the total mass, a long train of resin stretches behind this part, freezing before our eyes.

- "Rubber stage", no longer sticks to your hands, you can bend, stretch, twist the casting from the composition.

- The product is made of plexiglass or plastic to the touch. Solid, durable, little susceptible to external influences.

How much epoxy dries, is it possible to speed up this process

Curing or drying time of epoxy, whether it is an epoxy for jewelry, fill-coating for flooring or epoxy adhesivedepends on many factors. The key role is played by the age of the composition or how many years have passed since the epoxy was released by the manufacturer, the shelf life related to the date of production. Among the factors affecting the rate of polymerization, significant quantities will be:

- Composition of the hardener reagent.

- The amount of hardener added to the epoxy or adhesive.

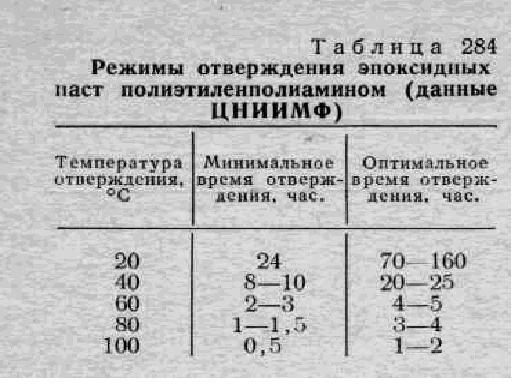

- The temperature at which the components are mixed and the finished composition hardened.

- The area of the surface to be poured or its volume.

Expert opinion Oleg Vasiliev Master in the manufacture of furniture and interior items from epoxy resin. Creates unique custom-made items in his production. Asking a question to the master It is impossible to refrain from saying that the terms "dries" or "freezes" are practically not correct and are used only for everyday conversation. The mixture of epoxy resin and hardener goes through the curing stage.

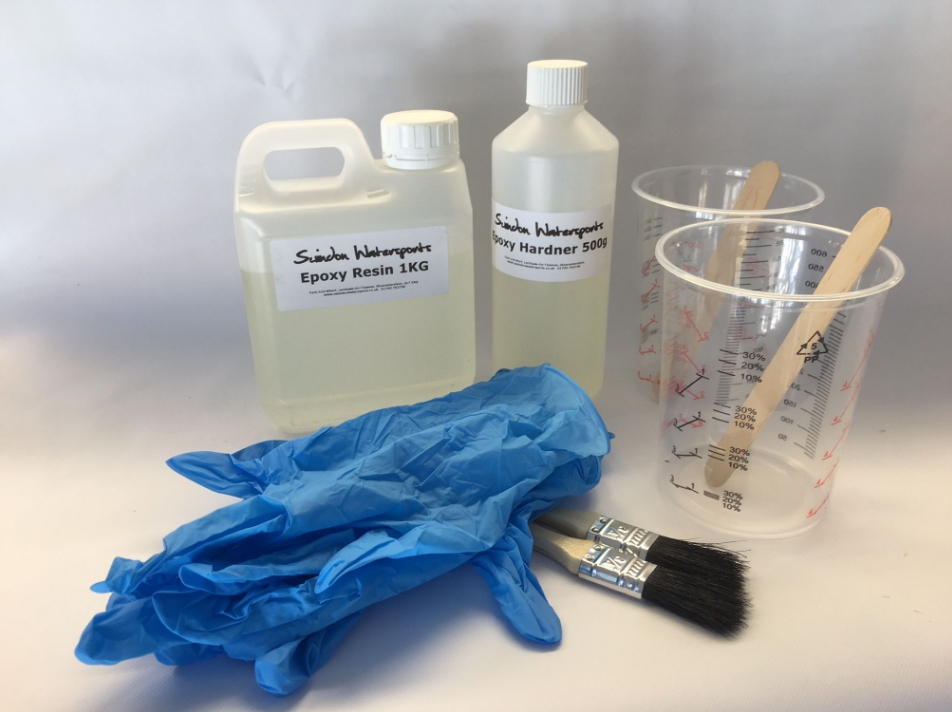

How to properly dilute epoxy with hardener?

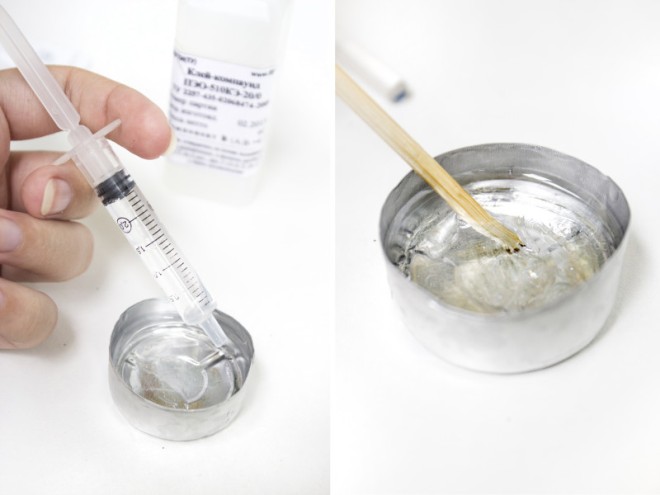

It is necessary to prepare everything that is needed during the work on the connection of components.To dilute the epoxy, use containers, a mixing tool. It should be borne in mind that materials are toxic, therefore, safety precautions should be followed. When the composition is stirred during the development of a chemical reaction, a homogeneous mass is obtained.

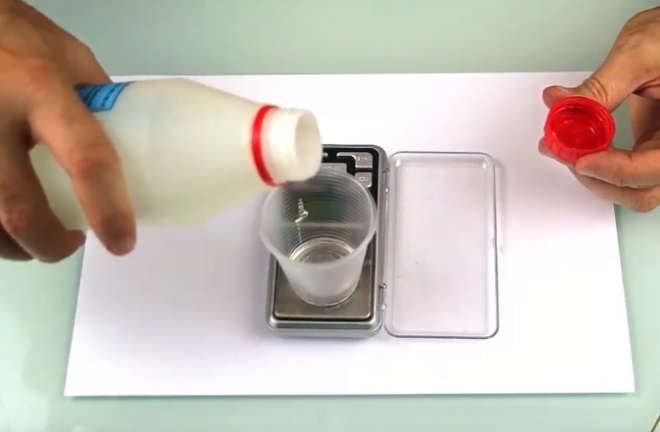

Small volume epoxy preparation

In this case, the technology of cold connection of components is used. Air temperature - no more than + 25 ° С. In addition, the mixing process begins with a test reaction. A small amount of materials are used at first. If the finished sample meets the requirements, is characterized by the necessary properties, the process of making the mass is continued.

Resin production in large volumes

In this case, the main feature of the mixing process is considered to be the intense heat release during the reaction. Used in large quantities, epoxy solvent increases the temperature of the material, causing it to boil. This is a consequence of a thermal reaction. It proceeds more intensively due to the use of a significant amount of components.

Due to boiling, the composition becomes white and foams, then becomes cloudy. This material is not suitable for construction, finishing works, waterproofing. In addition, if a large number of toxic additives are used (for example, a hardener), an effective supply and exhaust ventilation must be organized. In a domestic environment, such work can be performed using the heating method in a water bath.

How to mix the ingredients correctly?

If the work is carried out in conditions of a higher air temperature (above + 25 ° C), the rate of hardening of the composition increases. As a result, the duration of work with such material is reduced. For this reason, it should be applied to the surface within half an hour. The ratio of hardener to resin may vary. It depends on the preparation technology of the material. The standard scheme is 10: 1, with less resin used. The hardener is added in a larger volume. The composition also includes a plasticizer. This component makes the material elastic.

It is necessary to ensure that no drops of water get into the resulting mass. This will cause the resin to lose its adhesive power. The recommended amount of plasticizer is no more than 10% of the total weight. First, combine this component and the resin. Then the hardener is added in a thin stream. If you need to get a denser mass, the amount of the component is regulated. Add the hardener to the mixture slowly over 10 minutes. If this component is introduced quickly, the material will boil and become unusable.

Resin curing time

The parameter depends on the environmental conditions. At extreme temperatures, the material hardens quickly. If the main components are mixed at room temperature, and the ratio of additives is 1:10, the solidification time of the material varies within 30-60 minutes. As the hardener decreases, the composition retains a viscous structure for up to 2 hours.

Instructions for preparation and use

It is better to work in a well-ventilated area so as not to irritate the respiratory system with fumes from epoxy. Wear protective gloves and clothing that you don't mind getting dirty. The place of work can be covered with newspaper or cloth so as not to contaminate the surface. Prepare the application tool and mixing container in advance. You can use disposable tableware.

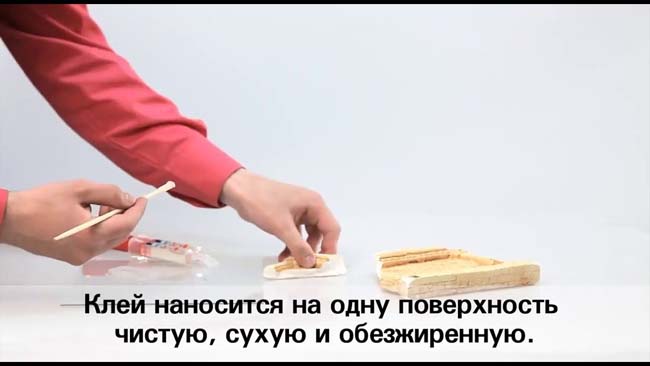

The processing of the product is carried out before mixing the adhesive, since the solution must be applied immediately after manufacture.

Before you start preparing an epoxy mixture with your own hands, you need to study the manufacturer's instructions attached to the package. It indicates the proportions of the resin and hardener components. The ratios of substances differ from manufacturer to manufacturer.In general purpose liquid adhesives, you usually need to mix 1 part hardener and 10 parts epoxy.

If the epoxy is viscous, it will be difficult to mix the components. To easily dilute the resin, it must be heated in a water bath or heating radiator to 50-60 degrees. Using a syringe without a needle, measure a small amount of resin and pour it into a container. Then take the required portion of the hardener and dissolve in the resin, stirring vigorously, to obtain a homogeneous mass.

After mixing the components, proceed to gluing the surfaces. On one side, you need to apply the ready-made glue and press both halves with effort, fixing for 10 minutes without displacement. If a small amount of solution is squeezed out of the seam, it must be immediately removed with a napkin. Until the epoxy is completely cured, do not use the product or subject it to stress.

Sawdust and other fillers can be added to the prepared epoxy mortar, which add additional volume, improve the quality of the finished joint and give the desired color. If you add sawdust to the epoxy, then you need to fill the mold with the finished mixture. You can use a spacer to make a product item. The hardened part can be sanded, painted and drilled.

How to glue with epoxy?

And now step by step. We already have a cap with ready-made glue.

Preparing flowers and accessories.

We prepare accessories and flowers. The surfaces to be glued are degreased with alcohol or acetone. Cold porcelain reacts normally to both substances.

We wipe the gluing sites with acetone or alcohol.

In order to fix the flowers on the fittings, we use the Moment super-glue. We glue them, forming a composition. Super glue is needed as a pre-fixer.

We pre-fix the flowers with the Moment glue.

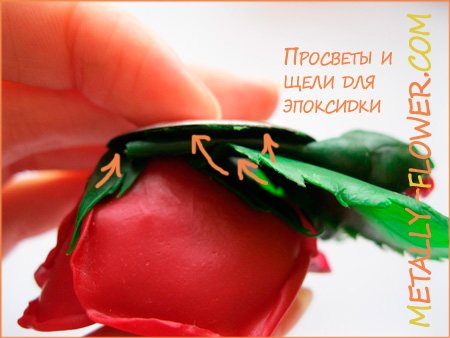

It is important to leave more gaps between the fittings and flowers / leaves, where the epoxy could penetrate - it should capture as many surfaces as possible. Therefore, carrying out preliminary gluing "Moment", you should not make strong pressure

It is enough just to "make" the flowers, leaving room for a magic compound that will fix this beauty already tightly.

We leave the gaps into which the epoxy must penetrate.

When the product is assembled, and the epoxy glue has reached the stage at which it is convenient to hook it with a match / toothpick, proceed to pouring.

We pick up a drop of epoxy and use a toothpick to transfer it to all the gaps left between the flowers and fittings. So, drop by drop, fill in all the cracks. If the glue has already started to flow out, wipe it off with a dry (and only dry!) Napkin. We try not to drip epoxy onto the flowers themselves. If you get dirty - again, a napkin to help, you can then wipe it with Johnsons oil or vegetable oil so that there is no trace left.

Pour epoxy glue a little into all the cracks.

After all the cracks are filled, we leave the product to dry in a stationary position, making sure that the glue does not leak out (after half an hour or an hour it will stop doing this, but at first the filling may "float").

After 12 hours, we will see that the glue has hardened.

Cured epoxy

Main features of epoxy resin

When figuring out how much epoxy glue dries, one should take into account the main technical features of such substances. Epoxy, regardless of the modification of the product, is an oligomeric thermoactive compound. In a resinous substance, the transition from a liquid to a solid state occurs only when a special hardener is exposed to the mass.

The resin hardens only when using a special compound

The resin hardens only when using a special compound

Various diliamines and amines, rubber, organosilicon resinous substances, etc. act as a hardener.According to experts, for household repair work, it is better to give preference to epoxy compounds with polymeric and oligomeric plasticizers, oligosulfides and oligoamides included in the composition. The presence of these substances increases the bonding performance and improves the quality of the final work.

How long does the composition freeze

Specifying how much epoxy dries, it is necessary to take into account a number of additional factors. The following indicators influence the polymerization time:

- the age of the glue (the period of use at the current shelf life), the fresher the resin, the faster the drying time will come;

- composition and type of hardener used;

- the proportions of mixing the catalyst with the resinous substance;

- the volume of the treated surface;

- the thickness of the poured layer;

- temperature at which polymerization occurs.

In the overwhelming majority of cases, epoxy hardens within 1–1.5 days. If it is used too much, the final hardening time can take up to 6-7 days (at room temperature). The polymerization time can change dramatically if the dosage of the added hardener is not observed correctly.

For quality work, the proportions of resin and hardener must be observed.

For quality work, the proportions of resin and hardener must be observed.

The full hardening time is usually indicated in the enclosed instructions. Polymerization usually takes place in several phases:

- Liquid consistency. Observed immediately after adding the hardener. At this stage, the resin flows easily into all cavities and quickly fills the cavities.

- Thickening to the state of honey. The mass is already difficult to pour and is not suitable for use on surfaces with complex relief.

- Increase in density. At this stage, the resinous substance, when the vessel is overturned, slides down at a speed of about 2 cm / second. This resin can also be used for gluing large, even parts.

- Rubber stage. The substance no longer sticks to the hands and has a "rubber" shape, it can be stretched, bent and twisted.

- Complete polymerization. Or hardening. In the final stage of the process, the epoxy becomes similar to sturdy plastic or plexiglass.

Are there fast-setting resins

All epoxies existing in modern industry fall into two broad categories. Depending on the number of components included in the composition, resins are:

- One-component. When used, they are already completely ready to work. The polymerization process takes place at room temperature or with a slight increase.

- Two-component. The kit consists of a resin and a hardener supplied with it. Such formulations are more popular. Polymerization begins only when the two components are mixed.

Many craftsmen are interested in the accelerated curing process and are wondering if there is a quick-drying epoxy resin. Such compositions are produced under the brand name "jewelry" resin (or "decorative"). They are two-component masses used for creativity and design. The features of such substances include their complete transparency after solidification and increased cost.

Cured resin is a very durable material

Cured resin is a very durable material

There are areas of optical distortion in the resin

Possible

reasons and advice

V

the coating or surface has foreign

inclusion. Wrong applied

abrasive material

-

Capacity

and the mixing tool should be

clean. Avoid using containers

with traces of fat. -

Surface

must be carefully prepared. For

sanding epoxy use

sandpaper with grain No. 80. -

Surface

must be clean of any kind

dirt, oils, fats and water. For

dust can be removed from the surface

use a clean rag,

soaked in isopropyl alcohol or

clean water. Do not use for these purposes

acetone and dirty rags. -

The coating must be applied in

within a few hours. After

wet sanding and rinsing

it should not roll off with water

beads - this indicates pollution

surface. Wipe with suitable

thinner and rinse again with water

before they disappear

Purpose of epoxy adhesive

What is epoxy glue, every craftsman, builder-installer, technical worker knows. It is an adhesive with an epoxy resin (epoxy) in the composition, a polymer material with excellent adhesion to various surfaces. Even with the advent of more modern adhesives on the construction market, epoxy does not lose its popularity.

Most often, the adhesive composition is used in construction. It is ideal for concrete and for metal, wood and glass. Like cold welding, epoxy-based material is used to bond plastics (PP, PC, and many other types of plastics). The versatility of the glue makes it suitable for working with rubber, ceramics, it is intended for stone (granite, marble, artificial materials). Epoxy resin is used for pouring floors, it is part of primers, putties, mixtures for tiles, mosaics.

The main rules for working with eposkid

- The surfaces that will be glued must be cleaned, sandpaper treated, degreased.

- The epoxy components must be measured with maximum precision.

- The ambient temperature should not be lower than what is indicated on the packaging as "curing temperature" (but not "operating temperature").

- It is possible to add third-party substances (dyes, etc.) to the resin and hardener if you do not count on the high strength of the product. "Left" components can greatly affect the course of the reaction and the final characteristics. If you add oil paint, the glue will become less hard and ductile (and color at the same time).

- It is better to put a little more hardener than to be greedy (too much is also not allowed). Although there is always less of it in the package than you need. Therefore, when it ends, the resin still remains (bitter experience!).

- Do not allow water to enter the epoxy adhesive!

- If you are gluing two surfaces, the glue layer between them should be thin. After applying the epoxy, the surfaces must be strongly pressed together for the next 12 hours.

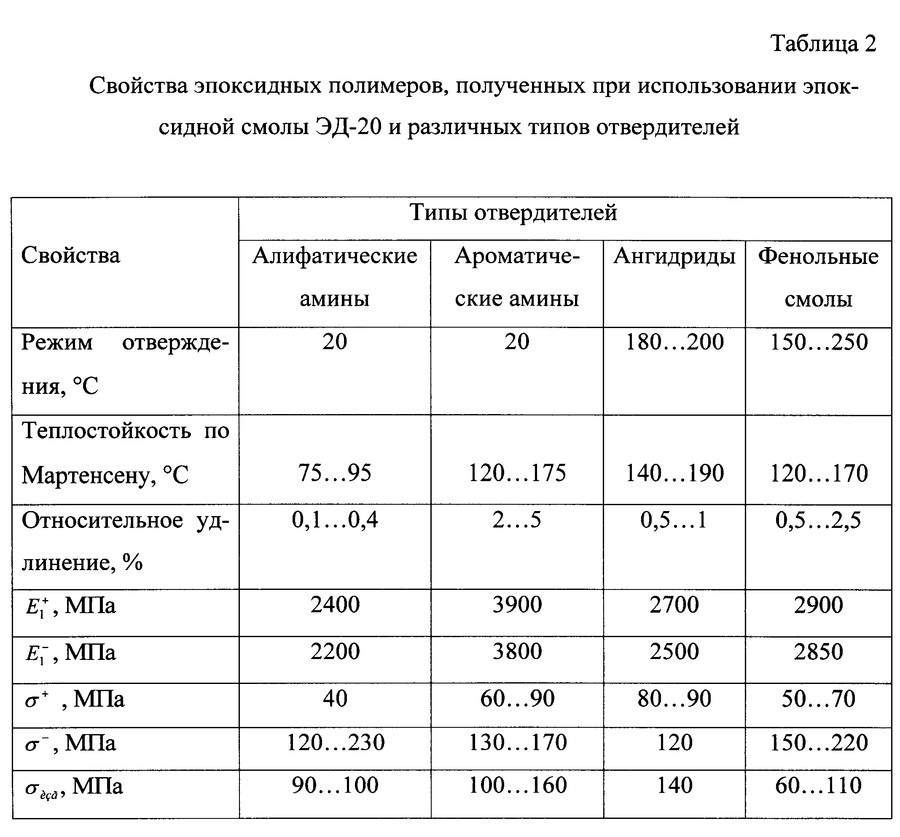

Types and characteristics of glue

For practical use, several easy-to-use modifications are produced. There are no special differences between ED-5, ED-6, ED-20 and EDP. By agreement, even under the USSR, different designations were introduced in order to know the manufacturer. Currently, there are only two types on the Russian market: ED-20 and EDP. Everything else is just variations of the original samples.

Common brands

Glue Moment Industry also produces special types that are used in purely special areas. The characteristics of the glue depend on the purpose and form of release.

- Many people know Moment glue on an epoxy basis. It is sold in tubes of 50 g. Bonding takes place within a few minutes, the strength is high. In this way, glass is glued to metal.

- In the form of plasticine, the "Contact" mass is realized. With its help, pipes and sanitary ware are repaired and connected. You can glue small shelves, for example, in the bathroom. The drying time of epoxy glue in the composition of this plasticine is 2 ... 4 minutes. Adhesive Cold welding

- Cold welding is an adhesive used to join metal fragments. The strength of such a joint is at the weld level. Used in the repair of aluminum parts that are really impossible to weld. Fast drying effective adhesive.

- EDP is the most widely used. It is always present among motorists. Helps in solving any problems that may arise along the way. Glue Epoxylin

For what reasons does the epoxy resin not harden?

Epoxy is a resinous, viscous substance. Epoxy resin exhibits all its declared qualities only when it interacts with a special hardener additive. Thanks to the hardener, the polymerization process takes place and further strong adhesion of the glued surfaces, and the creation of exclusive products.

You should know and understand the polymerization processes in order to simplify the work with such a material. If you do not find out why the epoxy does not freeze, what to do in this case, creative ideas are not realized, and the resulting products will be of poor quality.

Epoxy resin is used in the creation of various products

Epoxy resin is used in the creation of various products

Mixing error

The most common problem is that epoxy does not harden and may not cure at all. If, when the hardener was introduced into the resin, the proportions of the substances were violated, the epoxy will remain in a liquid state. If the sticky layer remains only on the surface and lasts for more than 1.5–2 days, it must be carefully removed and wait until the remaining mass has completely cooled.

For a perfect end result, be careful when mixing the resin with the hardener. In the classic version, 1 part of the hardener is taken for 10 parts of epoxy. If the ratio was correct and the proportions were maintained, this happens due to the poor quality of the hardener itself. The only way out is to carry out the work again, with a fresh composition and strictly according to the instructions attached to it.

Incorrect pour point

Typically, epoxy cures at normal room temperature. If the epoxy does not dry for a long time, the temperature conditions can also tell what to do in this case. When the environment is heated, the mass polymerization procedure is faster. But when the air temperature drops, the resin will harden much longer.

One of the reasons for uncured resin is a violation of temperature conditions.

One of the reasons for uncured resin is a violation of temperature conditions.

What to do in such a situation? Try the following tips in practice:

- leave the product to harden at a constant room temperature;

- if there was a decrease in the temperature regime, provide air heating with portable heaters;

- if it is not possible to maintain a stable temperature, use special hardeners designed for low temperatures during work.

Experienced craftsmen recommend using a hardener of proven brands. And if you need a product for working in low temperatures, stop choosing a hardener brands AF-2 and DTB-2.

Bad stirring

One of the most common mistakes novice masters make. The reason for the poor curing of epoxy lies in its insufficient stirring. In this situation, the hardener simply cannot fully combine with the resin and activate the polymerization procedure. To achieve the desired effect, you should not only use a quality hardener, but also mix it well with the resin.

Experienced masters advise to stir the ingredients gently, slowly, tightly and deeply stirring the layers of substances. Too active actions are not needed, otherwise air can get into the composition, which will then remain in the resin as ugly bubbles and make the product fragile and fragile. Stirring is done with a long stick, better than a wooden or plastic one.

Resin requires proper and gentle stirring

Resin requires proper and gentle stirring

Illiterate selection of used components

The question is in the correct choice of the required hardener. Usually, a suitable product is already included with the epoxy. But sometimes the catalyst runs out too quickly. It is worth purchasing it additionally, taking into account the brand and type of epoxy used. When choosing a hardener, it is better to get advice from the store, indicating the brand of resin with which the work is done.

How to speed up the drying process: tips and tricks

What needs to be done to make the polymerization process faster? There are some tips that answer the question of how to dry epoxy quickly. These are the following guidelines:

- increase the temperature to + 25-30⁰С;

- during operation, install a miniature heater next to the surfaces to be treated;

- maintain an elevated temperature regime during the first days after the end of work.

A separate point should be made to highlight several common mistakes that beginners make when they want to speed up polymerization. Remember not to increase the recommended proportions of the hardener. Violation of the recommended proportions will lead to a reverse reaction - the resinous substance will remain sticky for a long time or will not harden at all.

Coating with ugly yellow spots on the epoxy surface is the result of additional exposure to high temperatures. Keep in mind that the resin itself generates heat when the hardener is mixed in it. Therefore, you should not additionally try to accelerate the polymerization, but calmly wait for the natural end of the process.

Drying rate versus pouring area

We figured out the temperature, although there is another interesting nuance, but it is completely related to the next topic. Sometimes resins with amine hardeners such as TETA do not need to be heated, it occurs spontaneously, and this is due to the form into which the feedstock is poured.

The following dependence can be traced here: the more compact the filling form, that is, the closer it is in shape to the cube and the more to the ball, the faster and more intense the self-heating process will take place, up to boiling and even smoke, which can certainly ruin the workpiece.

If a small amount of epoxy resin with a hardener is taken, then at room temperature 100 g of the composition will completely polymerize after 5-6 hours. But the same volume of resin is poured over an area of 100 sq. cm, it will harden for a day already, that is, a certain critical mass is formed in the resin with the TETA hardener, depending on the volume that such an epoxy mixture occupies, and this critical mass is less, the more the volume it occupies tends to a spherical shape.

A complete analogy with plutonium: in the form of a cylinder, it needs, say, 5 kilograms to start a spontaneous chain reaction of nuclear fission, and in the form of a ball, only 2 kilograms. In the form of a flat sheet, the mass of metal can be even up to a centner, and nothing will happen.

Only in the case of epoxy do chemical processes take place, affecting the outer shells of the atoms of a substance and its molecular bonds, and with fissile materials like plutonium or uranium-235 pure physics enters into action, where intranuclear processes are already involved. But the mechanism is similar: the formation of a critical mass, depending on the compactness of the placement.

Expert opinion Oleg Vasiliev Master in the manufacture of furniture and interior items from epoxy resin. Creates unique custom-made items in his production. Asking the foreman We are talking about the heat transfer area of such a "critical mass". The larger the area, the less the mixture heats up and the longer its curing time. For a ball, this area is minimal and, accordingly, the heating is greatest.