Specifications

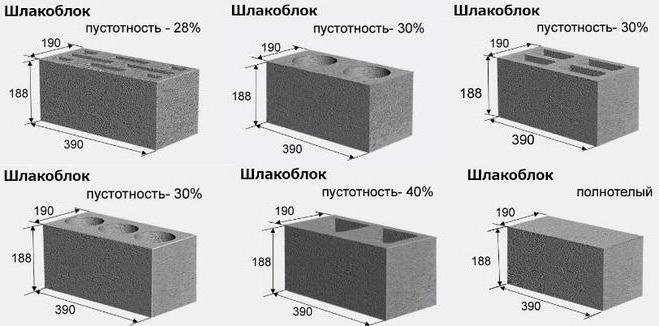

What size cinder block do builders use? The factory standard product has the following dimensions:

In case of self-production, the dimensions can be changed up to ± 5 mm, however, it is better to adhere to the standards corresponding to the modules of wall thicknesses used in masonry from ordinary clay or silicate bricks.

Cinder blocks can be solid or void. The volume occupied by the voids can vary from 25 to 40%. By the number of voids that the cinder block contains, the weight of 1 piece is from 30 kg / piece. up to 15 kg / piece

Stones with a greater voidness, having a lower weight of the cinder block, facilitate the work of laying them, have better thermal insulation properties, but their strength (grade) is lower than that of solid products.

An example of calculating the number of cinder blocks

If a standard cinder block (390x190x188) is used, the calculation is as follows:

- Wall in 190 mm or in the floor of the block. The width and length are converted to centimeters, obtaining values of 0.188 and 0.39, then the lateral area is calculated, that is, S = 0.188 * 0.39 = 0.073. Since the dimensions were converted to centimeters, the resulting value is already calculated in square centimeters, which allows us to proceed to the final calculation, that is, finding N = 1 / 0.073 = 13.64 blocks. If we take into account the seams, then it turns out that when laying in the floor of the block, about 13 pieces of cinder block are required for each square centimeter.

- Wall in 390 mm or in one block. The calculation algorithm is similar to the previous version, but the values, of course, are different. In other words, S = 0.188 * 0.19 = 0.036, that is, the side area is completely different from the first option, N = 1 / 0.036 = 27.77 or approximately 27 pieces, if we take into account the thickness of the masonry mortar. Consequently, the wider the wall, the more blocks to purchase.

These calculations can be applied to absolutely any building being erected, erected from a cinder block.

Why calculate the amount of cinder block in one square meter?

This initial stage of calculation is necessary to determine the exact amount of material required for the construction of a particular building. Thus, knowing the consumption per 1 sq. m., it is not difficult to calculate the total cost of the material. If a garage is being built with masonry in the floor of a block whose wall area is 51 square meters, it means that you need to purchase 663 cinder blocks. This number will double if the building is built with 390 mm thick walls. In addition, you always need to remember that the material should be purchased with a small margin, taking into account the possible marriage or damage to the blocks directly during masonry.

Calculation of the number of cinder blocks per house

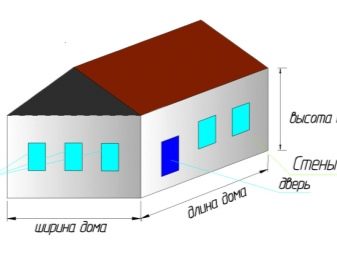

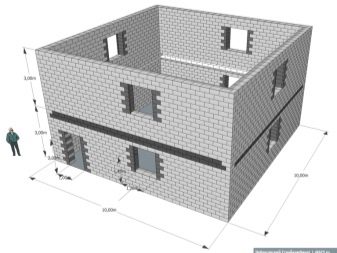

We take as the basis for the calculations:

- The standard dimensions of the unit are 390x190x188 mm.

- The mass of the block with two voids is 17 kg.

- The dimensions of a one-story house are 8x8x3 m (Length x Width x Height).

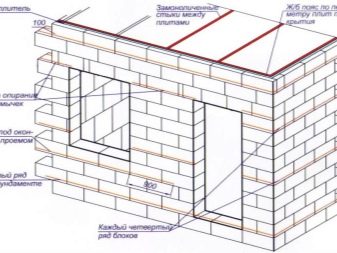

Counting by rows of masonry - how many units of wall stone fit in one row. To do this, you need to know the size of the block and the size of the house. Then we calculate how many cinder blocks are per 1 sq. m. will be needed to build a carrier box.

- To do this, we calculate the perimeter of the house: Phouse = 8 * 4 = 32 m.

- To find out the number of units of products in one row, you need to divide the perimeter of the house by the length of the block: N pieces in 1 row = 32 / 0.39 = 82.05 pieces.

- Next, we calculate the total number of rows. The height of the walls is divided by the height of the building block: N rows = 3 / 0.190 = 15.78 rows.

- We find out the total number of blocks per house by multiplying: Ntotal = Npieces in 1 row * N rows = 82 * 16 = 1312 pieces.

Based on the results, you can calculate the weight of the building, which will put pressure on the foundation: weight of 1 piece. - 17 kg is multiplied by the total number of units, we get 22304 kg. Since the preliminary calculation was carried out without taking into account window and door openings, they should be subtracted in the process of a more accurate calculation, as well as their weight should be subtracted from the total weight of the load on the foundation.

To calculate the amount of mortar or glue for laying the cinder block, you should proceed from the thickness of the seam. For glue, the joint thickness is 2-3 mm, for mortar - 5-10 mm.

Since the cinder block is usually stored on pallets, it is recommended to calculate the required number of pallets before purchasing it. One pallet holds 60 items. Therefore, based on the example above, an 8x8x3m house will require approximately 20 pallets.

For the foundation, blast-furnace slag will be the most optimal material; any filler can be used for the walls - ash slag, brick or stone quarry, crushed stone or gravel. To obtain a full-bodied product, 0.011 m3 of working solution will be required to manufacture one unit of building stone. That is, from a bag of cement, 36 units of a standard size will be obtained with a bag weight of 50 kg.

The more precisely the equipment is configured, the less mortar will be consumed for stacking blocks in rows, and the more products will be obtained from one bag of cement.

Verified suppliers

- PalletTrade - production since 1996

- BusinessPallet

- Detinets - production and sale of pallets

Usually, the number of foam blocks is counted in cubic meters and is supplied in pallets, tied with tape and packed in cellophane to protect against moisture.

But there are often cases when it is necessary to calculate the amount of material not in cubic meters, but in pieces.

So, how many pieces of foam blocks are there in a pallet? In order to correctly calculate the quantity, you need to know the size of the pallet and the size of the supplied unit.

Mainly due to generally accepted shipping standards, foam block manufacturers use standard pallets.

Standard pallets are made of plastic or wood and vary in size:

- 800 × 1200 mm - Euro pallet;

- 1000 × 1200 mm - standard pallet;

In addition to standard pallet sizes, they have generally accepted recommendations for laying foam blocks on them for shipment. For Euro pallets, it is recommended to stack standard blocks of two blocks long and four wide, five rows per pallet.

For a standard pallet, the stacking recommendation is two blocks long and five wide, with five rows per pallet.

The most common standard foam block has a size of 200x300x600 mm;

The volume of one standard block is 0.036 cubic meters. meters. Based on this information, you can easily count the number of blocks on a pallet. To do this, you need to multiply the number of blocks in one row by the number of stacked lines on the pallet.

You can find out how to choose the best pallet for a warehouse by comparing the technical characteristics of several types in this informative article.

In our case, these are:

- 2 * 4 * 5 = 40 pieces on a Euro pallet (1.44 cubic meters);

- 2 * 5 * 5 = 50 pieces on a standard pallet (1.8 cubic meters);

Payment

For the construction of any object (house, garage or other auxiliary structure), information on the number of cinder blocks is required. Excess building material is useless, and a shortage can lead to downtime and additional costs for loading, transporting and unloading the cinder block. In addition, different batches, even from the same manufacturer, may differ slightly. What can we say about buying missing blocks from another supplier!

Problems with the construction of a building due to a lack of basic material are guaranteed not to be, if you first calculate the need for cinder blocks with maximum accuracy. Of course, you will have to buy more. First, because you always need a supply. And secondly, the blocks are not sold by the piece. Manufacturers stack them on pallets and fasten them so that the goods do not break upon delivery to the buyer, and it is convenient to load them into vehicles.

If necessary, you can purchase material and piece by piece. However, the lack of reliable fastening is fraught with chips and even complete destruction. In order to calculate the need for building blocks, for example, for a house, you need to know the dimensions of this building.

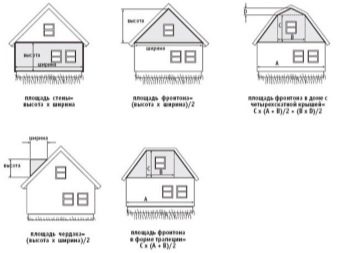

First of all, you need to remember the school curriculum, more precisely, the definition of areas and volumes. The task is simple, accessible to everyone and does not require any engineering knowledge.

The number of cinder blocks required can be calculated in two ways.

- By volume. The volume of the walls of the building is determined, the number of bricks in 1 m3 is calculated. The volume of the building in cubic meters is multiplied by the number of blocks in one cube. It turns out the required number of slag bricks for the whole house.

- By area. The area of the walls of the house is calculated. The number of blocks per 1 m2 of masonry is found. The area of the walls of the house is multiplied by the number of pieces of cinder blocks in one square meter.

If you need to count the number of standard blocks in a square meter, two sizes are taken into account: length (390 mm) and height (188 mm). We translate both values into meters and multiply among themselves: 0.39 mx 0.188 m = 0.07332 m2. Now we find out: how many cinder blocks are there for each square meter. To do this, divide 1 m2 by 0.07332 m2. 1 m2 / 0.07332 m2 = 13.6 pieces.

Similar calculations are performed to determine the amount of building material in one cube. Only here all block sizes are involved - length, width and height. Let's calculate the volume of one cinder block, taking into account its dimensions not in millimeters, but in meters. We get: 0.39 mx 0.188 mx 0.190 m = 0.0139308 m3. The number of bricks in 1 cube: 1 m3 / 0.0139308 m3 = 71.78 pieces.

Let's consider the calculation of the material requirements for the house in a "volumetric" way.

- Let's say the house is planned to be built square, with each wall 10 meters long. The height of the one-storey building is 3 meters. The thickness of the outer walls is the thickness of one cinder block, that is, 0.19 m.

- Let's find the volume of all the walls. Let us take two parallel walls equal in length to ten meters. The other two will be shorter in length by the thickness of the already counted walls: 10 m - 0.19 m - 0.19 m = 9.62 m. The volume of the first two walls: 2 (number of walls) x 10 m (wall length) x 3 m (wall height) x 0.19 m (wall thickness) = 11.4 m3.

- Let's calculate the volume of two "shortened" walls: 2 (number of walls) x 9.62 m (wall length) x 3 m (wall height) x 0.19 m (wall thickness) = 10.96 m3.

- Total volume: 11.4 m3 + 10.96 m3 = 22.36 m3.

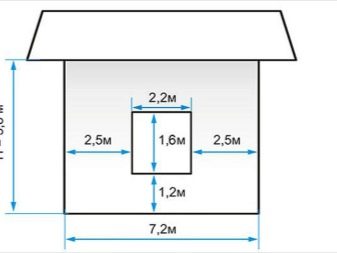

- Suppose that the house has two doorways 2.1 m high and 1.2 m wide, as well as 5 windows with dimensions 1.2 mx 1.4 m. We need to find the total volume of all openings and subtract it from the previously obtained value.

Volume of door openings: 2 pcs. x 1.2 mx 2.1 mx 0.19 m = 0.9576 m3. Volume of window openings: 5 pcs. x 1.2 mx 1.4 mx 0.19 m = 1.596 m3.

The total volume of all openings in the walls: 0.9576 m3 + 1.596 m3 = 2.55 m3 (round to two decimal places).

- By subtracting, we obtain the required volume of cinder blocks: 22.36 m3 - 2.55 m3 = 19.81 m3.

- We find the number of blocks: 19.81 m3 x 71.78 pcs. = 1422 pcs. (rounded to the nearest integer).

- Considering that there are 60 pieces on a pallet of standard cinder blocks, you can get the number of pallets: 1422 pieces. / 60 pcs. = 23 pallets.

The same principle is used to calculate the need for building material for internal walls. With other dimensions, for example, a different wall thickness, the calculated values must be adjusted. It should be understood that the calculation gives an approximate number of cinder blocks, the fact almost always differs from the calculation in one direction or another, but not much at all. The above calculation was performed without taking into account the seams, which account for 8 to 10 mm and a margin of approximately 10-15% of the calculated value.

How to calculate how many cinder blocks are in 1 m3, see the video below.

Measurement and calculation system for the selection of building materials

First of all, it should be noted that an elementary knowledge of such subjects as mathematics and geometry will help to answer any question related to measurements and quantities. For this, there are special formulas and calculation methods.

However, when asking the question of how many cinder blocks in 1 cube, it is worth remembering that a unit of this material can have completely different sizes, which depend on its manufacturer.

How much material in a cube when buying

-

Before ordering a cinder block from the manufacturer, it is necessary to clarify the dimensions of one unit of the product

... In the standard version, they look like 40 cm x 20 cm x 20 cm, in length / width / height ratios. - Based on this, it can be concluded that one block occupies a volume of 0.016 cubic meters.This is calculated by multiplying the length, height and width by each other, converting all values to meters.

- (0,4 * 0,2 * 0,2 = 0,016)

- Thus, in order to find out how much cinder block in a cube, you need to divide 1 by 0.016.

- The result is a value equal to 62.5, but considering that half of the product can be omitted, it turns out 62.

However, it should be noted that during the transportation and installation of this material, its integrity is often violated. This is due to the fact that one hundred cinder block is quite fragile and unstable to moisture. That is why the installation instructions recommend ordering a cinder block with a 10% margin.

How many meters of the wall

Having decided how much a cinder block cube costs and how many of its units in a given volume, you can determine the length and height of the future wall.

- To perform such calculations, you need to know the height of the structure.

- For a reference point, you can take the most optimal size equal to 2.5 meters.

- Further, approximately determining the thickness of the seam at 1.5 cm.

- After that, we divide the wall height of 2.5 m by the block height of 0.2 m and in the end we get 7. This number will be equal to the number of rows.

- Then we divide the number of cinder blocks in the cube by 7 and get the number 8.8, which will be equal to the number of units of material in the row. In this case, it is worth rounding up this value to 8.

- Next, we multiply the amount by the length of the material, and we get a wall with dimensions of 3.2 x 2.5 meters.

- (8 * 0,4 = 3.2)

- However, if you take into account the thickness of the seam, then you can build a structure measuring 2.5 by 3.5.

However, it should be noted that such calculations are very approximate.

Brick calculator

To simplify all construction calculations, a special program was invented, which is called a brickwork calculator. Using it, you will not need to do calculations with your own hands, for which it is enough just to enter all the initial data that will be processed and the corresponding result will be given.

The main feature of such a program is that it not only calculates the volume of masonry, but also takes into account the presence of windows and doorways. She can also work with any type of material, from ordinary bricks to blocks. In this case, such a calculator can take the thickness of the seams as primary data, and as a result, display the amount of mortar.

It should be noted that the price of such a program is usually low, although there are also quite expensive versions installed on portable devices. However, on our website you can download it absolutely free.

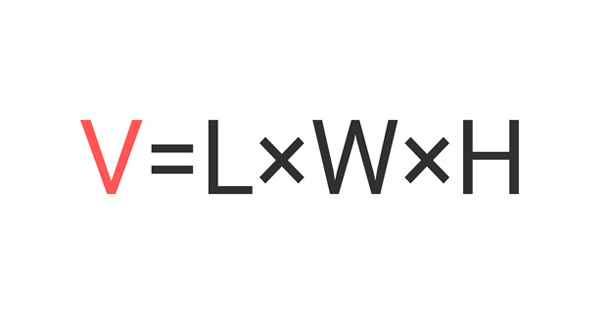

How to calculate a cinder block

To perform the necessary calculations, you need to know what volume is. Calculating this value is absolutely not difficult. We present to your attention a simple formula, guided by which, you will get the desired result: V = L × W × H.

- L - (length) - length;

- W - (width) - width;

- H - (height) - height.

According to the formula, it is necessary to measure the length, width and height of the product, and then to multiply them. For reference - 1 m³ = 1.000.000 cm³.

Consider an example: we have a block with parameters 390 × 190 × 188 mm. Therefore, - 39 × 19 × 18.8 = 13930.8 (cm³). Now you just need to split:

1.000.000 (cm³) ÷ 13390.8 (cm³) = 74.67814 (piece). For convenience, let's round up - 74.5 pieces.

So we found out how many cinder blocks are in 1 cubic meter - 74.5 pieces. But these calculations relate to those elements that are used for the construction of external walls. Now let's count how many pieces of cinder block intended for the construction of partitions in 1 cube.

The dimensions of this "comrade" are 390 × 120 × 188 mm. Next, we calculate the volume: 39 × 12 × 18.8 = 8798.4 (cm 3). Now - you need to split:

1,000,000 (cm³) ÷ 8798.4 (cm³) = 113.657 (pcs). Rounding up, we get 113.5 pieces.

Actually, that's all the calculations that we need to perform in order to find out how many cinder blocks one cubic meter contains. As a rule, cinder blocks are transported on pallets, where their exact volume must be indicated on the label.

Another frequently asked question: "How many cinder blocks are in the pallet?" Now we will answer it for you. The fact is that the quantity on a pallet is determined by the size of the products themselves. Their number may vary. For the convenience of calculations, we have rounded off the indicators of standard sizes (390 × 190 × 188 and 390 × 120 × 188):

- wall 400 × 200 × 200 - 71pcs;

- partition walls 400 × 120 × 200 - 142 pcs.

But these figures are approximate. The error can be up to 15 pieces. Much depends on the size. The fact is that to lay the blocks on a pallet so that there is no gap between them - firstly, it is rather difficult, and secondly, it is not functional: when stacked in this way, they can break during transportation.

By the way, in case of rejection - blocks must be purchased with a margin. And this stock, as a rule, is 10-15% of the total

When calculating, this should also be taken into account.

Now there is one more uncovered question: "How many cinder blocks are in 1m 2?" To find the answer to it, we will also do some calculations. To be precise, according to GOST 6133, the dimensions of a standard cinder block product are 390 × 190 × 188 mm. And if in our previous calculations regarding pallets, we, for convenience, could round off these indicators, then this is not necessary here. To find out the result, we can use two solutions. These decisions depend on the thickness of the wall itself. Now everything will become clear to you.

Option 1. The wall thickness is half of the whole block - 190 mm.

Knowing that the height is 188 mm and the length is 390 mm, we will calculate its lateral area. We will preliminarily translate the indicators into the SI system:

S = 0.188 × 0.39 = 0.07332 m². Rounding up, we get just 0.73 m². This is the lateral surface area of one block.

Owning this figure, we can find out how many elements are needed to build one square meter of the wall:

X = 1 ÷ 0.073 = 13.698630137pcs. Do not be intimidated by this figure, since the calculations were made without taking into account the thickness of the mortar joint. And if we take it into account, then we need 13 pieces of blocks, provided that the seam we have will have a thickness of 8 to 10 mm.

Option 2. The wall thickness is one whole block - 390 mm

In this case, our calculations will follow the same algorithm. First you need to calculate the S (area) of the side surface.

S = 0.188 × 0.19 = 0.03572 m². Rounding off, we get the value - 0.036 m².

Now let's find out how many blocks one square meter of masonry will contain:

X = 1 ÷ 0.073 = 27.77778pcs. And, taking into account the thickness of the masonry seam, we come to the value of 27 pieces.

These calculations, of course, are approximate, therefore minor errors are possible. And during construction, it would be good to find out how many cinder blocks are needed to build a house - in general. In this way, it will be easy to clear up the value of your entire enterprise. That is, not only find out how much the cinder block costs, but also find out how much you will spend on cement and sand, and on laying work in general. Unless, of course, you decided to build a house with your own hands. Just remember to stock up on building materials in case of rejection.

We have learned how to count cubic meters. Now let's talk about the material itself and find out what its strengths and weaknesses are.

Why do you need to count the number of cinder blocks?

Having correctly calculated how many pieces of cinder block are in a cube, you can proceed to the economic part of construction, and calculate how many cubes of material will be required to erect an object under construction.

The specified formula for calculating the amount of building material in one cube is used for a wide variety of materials sold in cubic volumes. The formula allows you to calculate the required amount of materials for construction, with an accuracy of one.

Given the rather high cost of modern building materials, such a careful calculation of the number of cinder blocks required for construction is a mandatory and very important procedure that allows you to save the owner's finances.

Cinder block is a building stone produced by artificial pressing or natural laying into a mold from a cinder-concrete mixture. The standard dimensions of one unit are 400x200x400 mm. Such blocks are made both in industrial production and at home.

Fine-grained crushed stone, broken brick, expanded clay, granite screening, hardened cement breakage, cullet and a number of other industrial wastes are used as a filler for them. The bonding material in the production of the material is cement.

Such a building material is universal, therefore the question is often asked: "How many cinder blocks are there in a cube?" It is used in almost all construction industries.

Why do you need to know how many cinder blocks are in 1 cube? The volume of the walls is measured in m 3. Therefore, in the project, the houses indicate that in the future there will be n blocks. This number is not always round. Therefore, in order not to be mistaken when purchasing, it is necessary to calculate the exact amount of building materials based on your needs.

Let's calculate how many blocks are in one square meter of masonry and the area of one block

We have brought together the most popular block sizes in one table, in which you will find the information necessary for further calculations. If you do not find any sizes, you can use the most suitable for your choice for a preliminary calculation.

For example, in Novosibirsk, blocks for masonry walls are produced in the size of 198x295x598. Such block sizes are not presented in our table, but for preliminary calculations, you can use the calculation results for a block with a size of 200x300x600 (300x200x600).

How do I use the table? For example, you have opted for gas silicate blocks 300x200x600 in size.

Let's use Table 1:

when laying load-bearing walls, we will lay the block in such a way that the width of the wall is 300 mm, respectively, the height of the block is 200 mm. Then for laying a wall with an area of 1 m2 it will be required - we take the data from the table - 8.3 pcs. blocks. Here you do not need to round the value to the nearest integer, otherwise large errors are possible for calculating large areas. If the total area of the walls of your house, taking into account the window and door openings, is 100 square meters, then 100 X 8.3 = 830 pcs.;

from the same table we take number of blocks in a cube - 27.8. Then 830: 27.8 = 29.87 or rounded to the nearest integer - 30 cubes of blocks are needed;

we check the calculation as follows: the wall thickness is 0.3 m, the wall area is 100 square meters, then 100 X 0.3 = 30 cubic meters. blocks will be required for masonry walls with a thickness of 0.3 m and a total area of 100 sq. m.

Block size: length - 600 mm, width - 200 mm Table 1

| Block dimensions, HxWxL, mm | Block volume, H * W * D, cubic meter | Number of blocks in cubic meters, pcs. | Block area at H * D, sq.m. | Number of blocks in 1 sq.m. at H * D, pcs. | Block area at W * L, sq.m. | Number of blocks in 1 sq.m. at W * L, pcs. |

| 50x200x600 | 0,01 | 166,7 | 0,03 | 33,3 | 0,12 | 8,3 |

| 75x200x600 | 0,01 | 111,1 | 0,05 | 22,2 | ||

| 100x200x600 | 0,01 | 83,3 | 0,06 | 16,7 | ||

| 125x200x600 | 0,02 | 66,7 | 0,08 | 13,3 | ||

| 150x200x600 | 0,02 | 55,6 | 0,09 | 11,1 | ||

| 175x200x600 | 0,02 | 47,6 | 0,11 | 9,5 | ||

| 250x200x600 | 0,03 | 33,3 | 0,15 | 6,7 | ||

| 300x200x600 | 0,04 | 27,8 | 0,18 | 5,6 | ||

| 375x200x600 | 0,05 | 22,2 | 0,23 | 4,4 | ||

| 400x200x600 | 0,05 | 20,8 | 0,24 | 4,2 | ||

| 500x200x600 | 0,06 | 16,7 | 0,30 | 3,3 | ||

Block size: length - 600 mm, width - 250 mm Table 2

| Block dimensions, HxWxL, mm | Block volume, H * W * D, cubic meter | Number of blocks in cubic meters, pcs. | Block area at H * D, sq.m. | Number of blocks in 1 sq.m. at H * D, pcs. | Block area at W * L, sq.m. | Number of blocks in 1 sq.m. at W * L, pcs. |

| 50x250x600 | 0,01 | 133,3 | 0,03 | 33,3 | 0,15 | 6,7 |

| 75x250x600 | 0,01 | 88,9 | 0,05 | 22,2 | ||

| 100x250x600 | 0,02 | 66,7 | 0,06 | 16,7 | ||

| 125x250x600 | 0,02 | 53,3 | 0,08 | 13,3 | ||

| 150x250x600 | 0,02 | 44,4 | 0,09 | 11,1 | ||

| 175x250x600 | 0,03 | 38,1 | 0,11 | 9,5 | ||

| 200x250x600 | 0,03 | 33,3 | 0,12 | 8,3 | ||

| 300x250x600 | 0,05 | 22,2 | 0,18 | 5,6 | ||

| 375x250x600 | 0,06 | 17,8 | 0,23 | 4,4 | ||

| 400x250x600 | 0,06 | 16,7 | 0,24 | 4,2 | ||

| 500x250x600 | 0,08 | 13,3 | 0,30 | 3,3 | ||

Block size: length - 625 mm, width - 200 mm Table 3

| Block dimensions, HxWxL, mm | Block volume, H * W * D, cubic meter | Number of blocks in cubic meters, pcs. | Block area at H * D, sq.m. | Number of blocks in 1 sq.m. at H * D, pcs. | Block area at W * L, sq.m. | Number of blocks in 1 sq.m. at W * L, pcs. |

| 50x200x625 | 0,01 | 160,7 | 0,03 | 32,0 | 0,13 | 8,0 |

| 75x200x625 | 0,01 | 106,7 | 0,05 | 21,3 | ||

| 100x200x625 | 0,01 | 80,0 | 0,06 | 16,0 | ||

| 125x200x625 | 0,02 | 64,0 | 0,08 | 12,8 | ||

| 150x200x625 | 0,02 | 55,3 | 0,09 | 10,7 | ||

| 175x200x625 | 0,02 | 45,7 | 0,11 | 9,1 | ||

| 250x200x625 | 0,03 | 32,0 | 0,16 | 6,4 | ||

| 300x200x625 | 0,04 | 26,7 | 0,19 | 5,3 | ||

| 375x200x625 | 0,05 | 21,3 | 0,23 | 4,3 | ||

| 400x200x625 | 0,05 | 20,0 | 0,25 | 4,0 | ||

| 500x200x625 | 0,06 | 16,0 | 0,31 | 3,2 | ||

Block size: length - 625 mm, width - 250 mm Table 4

| Block dimensions, HxWxL, mm | Block volume, H * W * D, cubic meter | Number of blocks in cubic meters, pcs. | Block area at H * D, sq.m. | Number of blocks in 1 sq.m. at H * D, pcs. | Block area at W * L, sq.m. | Number of blocks in 1 sq.m. at W * L, pcs. |

| 50x250x625 | 0,01 | 128,0 | 0,03 | 32,0 | 0,16 | 6,4 |

| 75x250x625 | 0,01 | 85,3 | 0,05 | 21,3 | ||

| 100x250x625 | 0,02 | 64,0 | 0,06 | 16,0 | ||

| 125x250x625 | 0,02 | 51,2 | 0,08 | 12,8 | ||

| 150x250x625 | 0,02 | 42,7 | 0,09 | 10,7 | ||

| 175x250x625 | 0,03 | 36,6 | 0,11 | 9,1 | ||

| 200x250x625 | 0,03 | 32,0 | 0,13 | 8,0 | ||

| 300x250x625 | 0,05 | 21,3 | 0,19 | 5,3 | ||

| 375x250x625 | 0,06 | 17,1 | 0,23 | 4,3 | ||

| 400x250x625 | 0,06 | 16,0 | 0,25 | 4,0 | ||

| 500x250x625 | 0,08 | 12,8 | 0,31 | 3,2 | ||

Now, knowing how to use the data from the tables presented, you can correctly and quickly calculate how many blocks for load-bearing walls and partitions you will need to build a country house.