Step-by-step instructions for making concrete by hand

Now, when concreting, concrete mixers are most often used. But not all developers work with equipment yet, especially if it is necessary to quickly prepare a small amount of concrete for urgent repairs. The mass is stirred with a shovel or hoe in a special trough. If you do not have it, then you can make concrete on a solid flat area, often large sheets of thick iron are used for this purpose. Mixing is much easier and easier with a hoe, attach a long handle to it so that you can get it all over the trough from one place.

Trough and hoe for manual concrete mixing

Trough and hoe for manual concrete mixing

Step 1. Pour dry cement into the container, pour in water and mix everything very thoroughly. Your task is to turn the composition into a milk consistency. A bucket of cement requires about half a bucket of water. Below we will describe in detail what caused this proportion.

Cement is poured into a dry trough, then water is poured

Cement is poured into a dry trough, then water is poured

Step 2. Mix the composition thoroughly with a hoe.

Stir the cement with water until the lumps dissolve.

Stir the cement with water until the lumps dissolve.

In such a container, you can prepare a composition from one bucket of cement, three buckets of sand and the same amount of crushed stone. It is not necessary to do more at one time - it is very difficult to mix the increased volumes of concrete. It is much easier to make two small batches than one big batch. In addition, the quality is also much better, the positive effect is achieved through more thorough mixing.

Step 3. Pour rubble into the trough. He will completely break the remaining small lumps of cement. You can pour all three buckets of material at once, it is advisable to evenly distribute it over the entire area of the container.

Crushed stone can be added immediately in full

Crushed stone can be added immediately in full

Step 4. Start mixing. This is already somewhat more difficult than working with cement alone.

Mixing with rubble will require more physical effort

Mixing with rubble will require more physical effort

Step 5. Add three buckets of sand to the container. In our case, sand and crushed stone are poured into bags, each with three buckets, as required by the recipe. Stir the sand, this is the most difficult operation, it takes quite a lot of effort and time. The chopper should slide along the bottom of the trough and over the entire area.

Stir very thoroughly after adding sand.

Stir very thoroughly after adding sand.

Depending on the actual consistency, add water or sand, how this is done and what you need to pay attention to, we have already described above. Prepare as much mixture as you can use within thirty minutes

After this time, the rates of chemical reactions of the cement increase critically. Concrete hardens, it is categorically not recommended to add water to it, the material as a result of such actions greatly deteriorates the strength parameters.

Ready concrete must be used within half an hour

Ready concrete must be used within half an hour

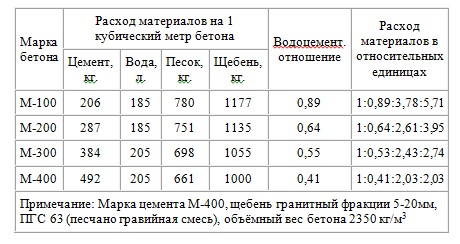

Composition of conventional heavy concrete, page 3

Ц, В, П, Щ - consumption of cement, water, sand, coarse aggregate in kg per 1 m3 of concrete.

Concrete composition by volume:

, where

VЦ, VП, VШ, - the volume of cement, sand and coarse aggregate.

, where

rH.C., rH.P., rH.SC. - bulk density of cement, sand, coarse aggregate.

When expressing the composition of concrete by volume, W / C is indicated separately by weight.

6.

The resulting concrete composition is called laboratory, since aggregates are taken in the calculation in a dry state. In manufacturing, virtually all aggregates contain the greatest amount of water. Therefore, when assigning the production composition of concrete, the moisture contained in the aggregates is taken into account, and their consumption is greater by the amount of moisture, and the water consumption is correspondingly less.

7.

When making a concrete mixture, its volume will be less than the total volume of the initial components by the amount of compaction of the mixture during mixing. The decrease in the volume of the concrete mixture is taken into account by the concrete yield factor b:

The coefficient of concrete yield, depending on the voidness of the aggregates and the composition of the concrete, is in the range of 0.60-0.75.

Knowing the coefficient of concrete yield and material consumption, determine the dosage of materials for one batch of a concrete mixer with a capacity of V according to the formulas:

,where

TsV, PV, VV, ЗV - the amount of cement, sand, water and coarse aggregate for one batch of a concrete mixer with a capacity of V, kg.

An example of calculating the composition of concrete

Calculate the composition of concrete grade 200 (300) at the age of 28 days of normal hardening, intended for the manufacture of slabs for coating industrial buildings. The operating conditions of the plates are normal. The slump of the concrete cone is 2 cm, the compaction method is vibration.

Material data.

| Concrete component | Density, kg / m3 | Humidity, W% | Note | |

| True r0 | Bulk rН | |||

| Quartz sand | 2620 | 1460 | 3 | MCR = 2.1 |

| Granite crushed stone | 2600 | 1490 | 1 | DNAIB = 40mm |

| Portland cement | 3100 | 1100 | — | RC = 380kg / cm2

M400 D10 |

| Water | 1000 | — | — |

The calculation of the composition of concrete is carried out in the following order:

1.

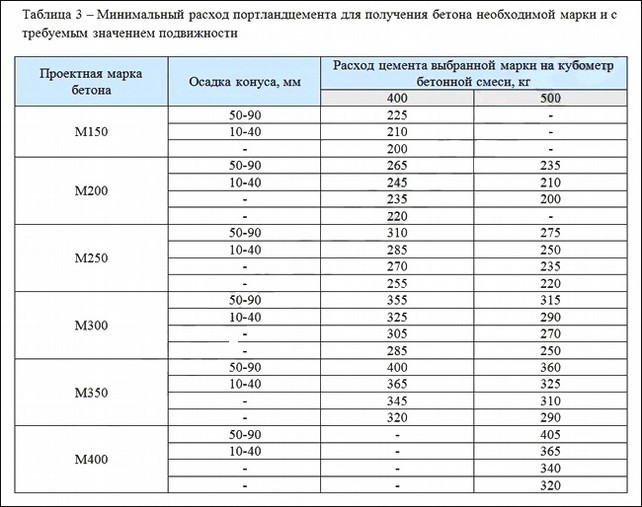

According to Table 3, the water flow rate B = 170 l / m3 is found.

2.

Determine the value of the cement-water and water-cement ratio:

coefficient A is taken according to Table 4 equal to 0.60 (for aggregates of ordinary quality).

3.

Determine the cement consumption:

kg / m3.

4.

Calculate the consumption of crushed stone. The KRAZD coefficient according to Table 5 is 1.32.

Volume of voids determined by the formula:

kg / m3.

5.

Calculate the consumption of sand:

kg / m3.

Thus, the consumption of materials for the preparation of 1 m3 of concrete is:

- cement, kg - 226

- water, kg - 170

- sand, kg - 694

- crushed stone, kg - 1280

Calculate the approximate density:

kg / m3.

6.

The composition of concrete (nominal and production) in relative units is determined after adjusting the mobility of the concrete mixture. Nominal composition of concrete by weight in relative units:

To express the composition of concrete by volume, the volumes of materials are first calculated:

Nominal composition by volume:

7.

Determine the coefficient of output of the concrete mixture:

at V / C == 0.75

8.

Students, on the instructions of the teacher, determine the production composition of concrete.

2.Test batch preparation and adjustmentconcrete mix

Trial mixes establish the correspondence of the calculated composition of concrete to the given conditions of the mobility of the concrete mixture and the strength of the hardened concrete. A test batch is usually done in a volume of 10 liters, i.e. dry materials are weighed in the amount of 1/100 of their estimated consumption per 1 m3 of concrete. Weigh the required number of components and prepare the mixture.

The mixture is prepared in the following order:

¨ moisten the baking sheet in which the mixture is to be prepared;

¨ pour in sand, add cement and mix until a mixture of uniform color is obtained;

¨ a coarse aggregate is added to the cement-sand mixture and mixed until the coarse aggregate is evenly distributed in the mixture;

¨ in the middle of the mixed mixture, a depression is made, where half of the required water is poured, after carefully mixing, collect the mixture in a heap and pour in all the remaining water, after which the concrete mixture is intensively shoveled until smooth. The duration of mixing from the beginning of mixing should be 5 minutes;

Calculation of the composition of the concrete mixture

The classification of concretes is based on the compressive strength index. In accordance with the requirements of SNiP2.03.01-84 "Concrete and Reinforced Concrete Structures", the marking of concrete on the ogs, as well as from a mixture of sand and crushed stone, contains the letter "B" and numbers indicating the load in MPa. This is a relatively new designation.

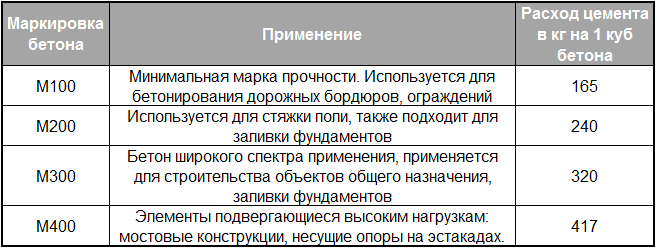

The more familiar marking with the letter "M" and strength, measured in kg / cm2, has not lost its relevance either. By the way, cement is marked in exactly the same way. Concrete grades from M100 to M500 are used in construction.

The strength, density and other characteristics of the final product are influenced by the ratio of cement and the proportion of pgs in concrete, as well as the content of aggregates from grains of various sizes in the mixture. For specific purposes, the following grades of concrete are used:

- M 150 - it is recommended to prepare for the construction of foundations for light buildings on one floor;

- M 200 - used in the construction of tape and low-power slab bases;

- M 250 - for foundations in the form of a monolithic slab for medium loads;

- M 300 - for monolithic foundations of any design;

- M 400 - on high-quality cement is used for the construction of especially powerful foundations under heavy loads.

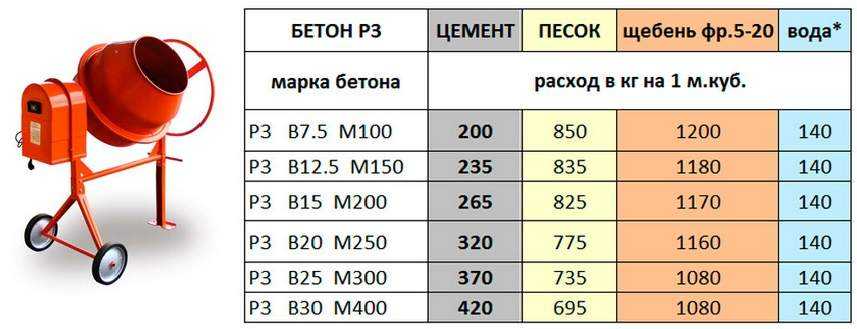

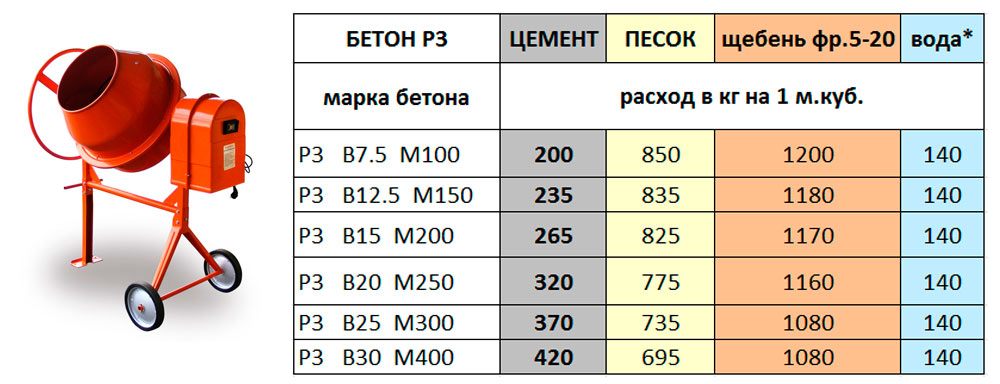

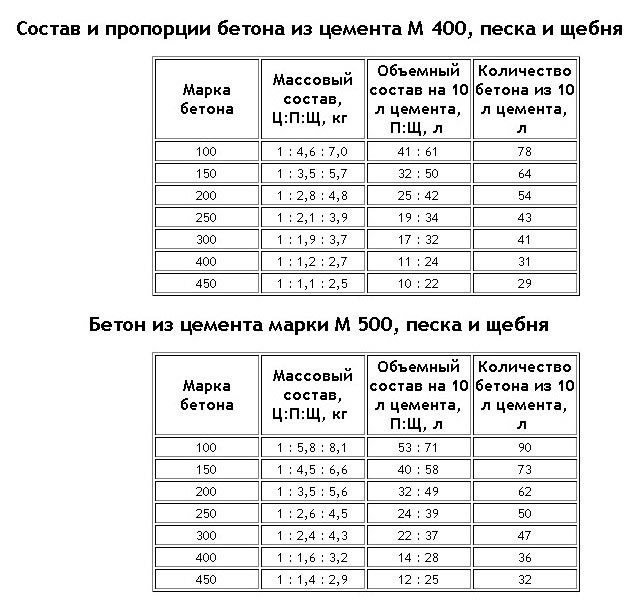

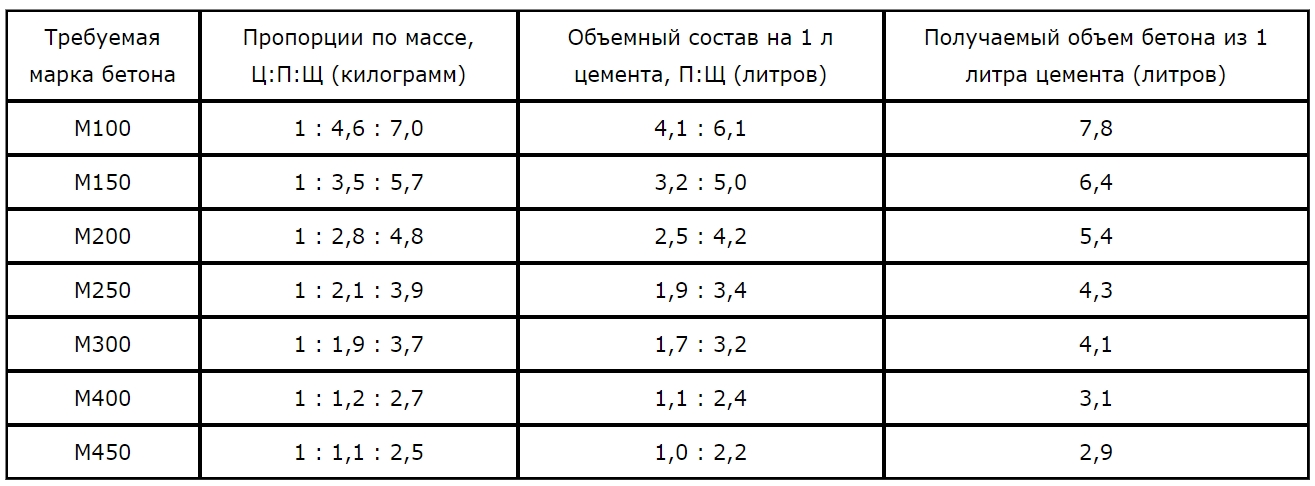

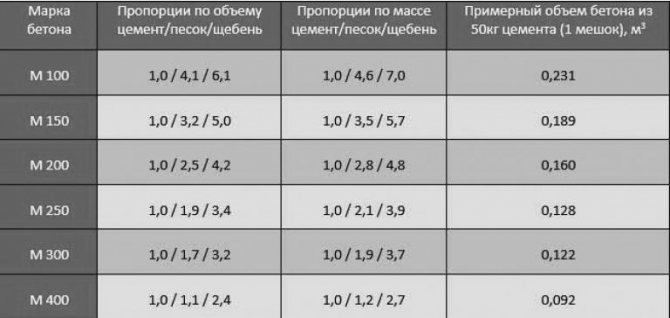

For the convenience of calculating the consumption of materials, we will combine the proportions of PGS and cement for concrete of different grades into a table.

| Concrete grade | OGS consumption per 1 kg of Portland cement, kg | OGS consumption for 10 liters of Portland cement, l | The amount of concrete obtained from 10 liters of cement, l | |||

| M 400 | M 500 | M400 | M500 | M400 | M500 | |

| 100 | 11,6 | 13,9 | 102 | 124 | 78 | 90 |

| 150 | 9,2 | 11,1 | 82 | 98 | 64 | 73 |

| 200 | 7,6 | 9,1 | 67 | 81 | 54 | 62 |

| 250 | 6,0 | 7,1 | 53 | 63 | 43 | 50 |

| 300 | 5,6 | 6,7 | 49 | 59 | 41 | 47 |

| 400 | 3,9 | 4,8 | 35 | 42 | 31 | 36 |

| 500 | 3,6 | 4,3 | 32 | 37 | 29 | 32 |

According to the table, it can be understood that from 10 liters of M400 cement, you can get M 300 concrete in an amount of 41 liters. If you measure the proportions in buckets, then for the preparation of concrete you need to measure out one bucket of cement and almost 7 buckets of sand and gravel mixture.

Using the available proportions, you can easily calculate the need for materials for the preparation of 1 m3 of concrete. We compose simple equations:

- Cement M400 will need: 1000 * 10: 41 = 244l or 24.5 buckets.

- ASG for 1 cube of concrete must be taken: 1000 * 49: 41 = 1195 liters or 119.5 buckets.

Calculation of materials: without the invention of the bicycle

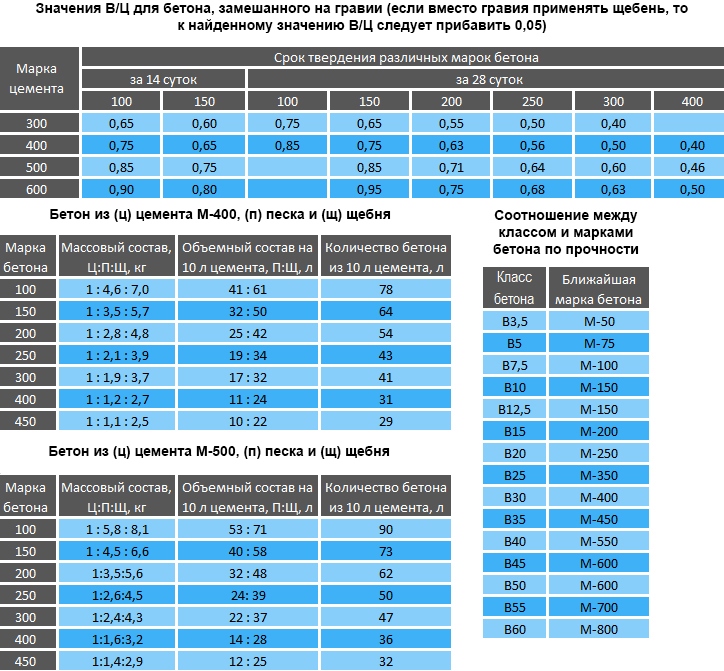

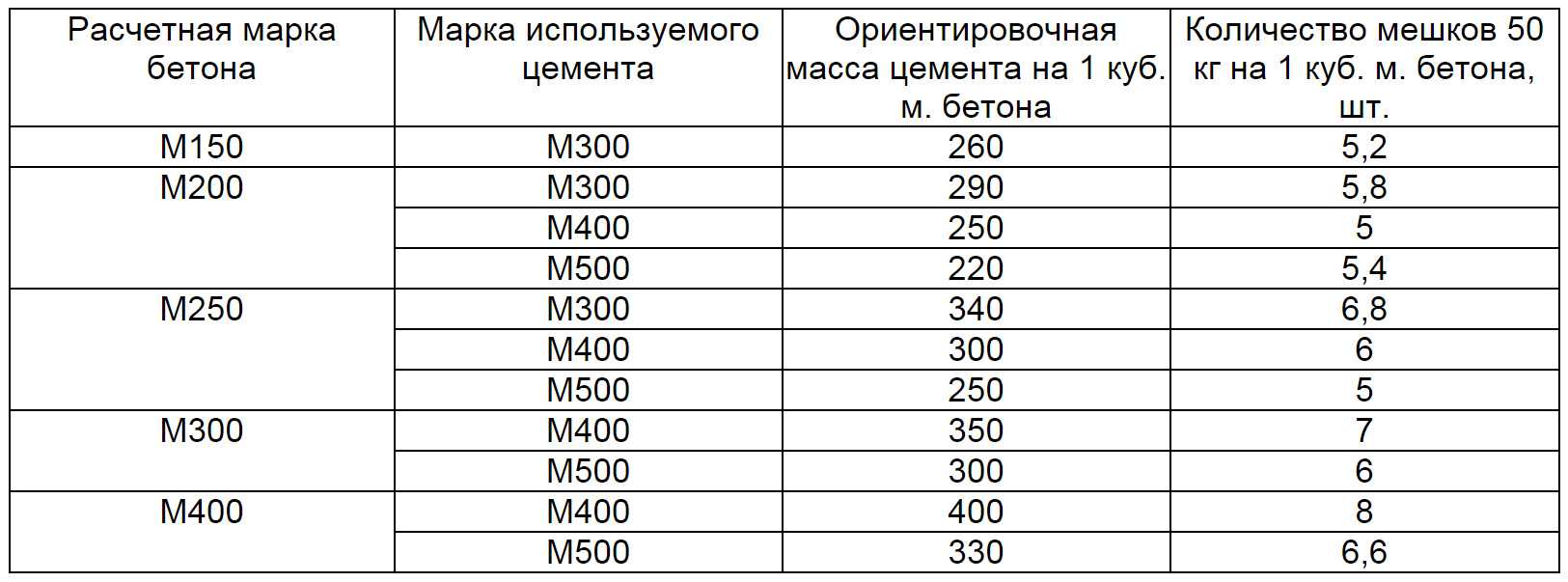

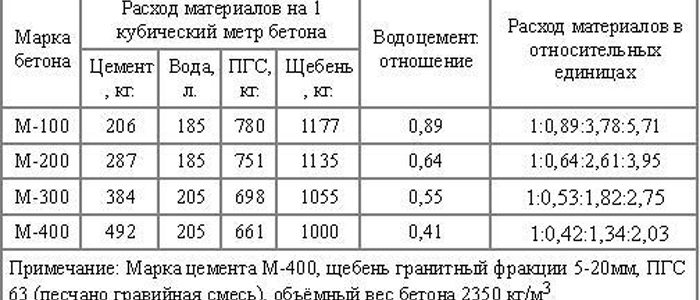

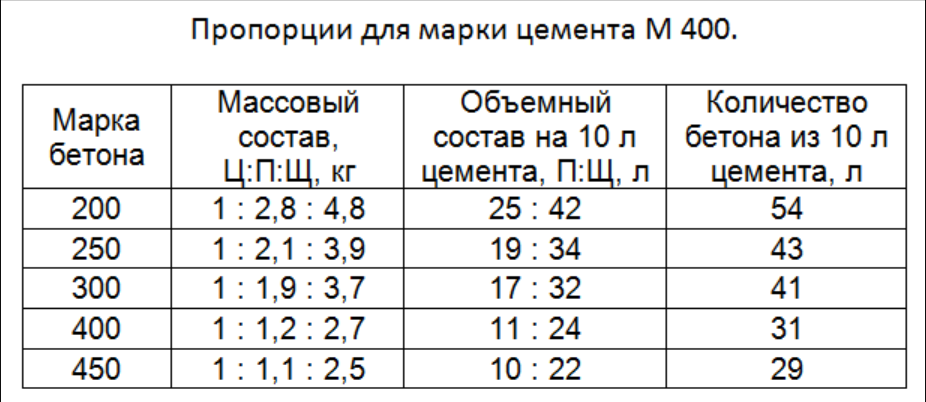

How to calculate cement for foundation? For the accuracy of the results, it is necessary to take into account the brands of concrete and cement, as well as the ratio of water and cement, which is called for short - VC. The table below is illustrative and does not require a person to have a degree in mathematics.

The table is easy to use. For example, we need to prepare 2 m3 of M250 grade concrete:

- It needs M500 cement, which means we multiply 297 kg by 2, we get - 594 kg. Now this number must be divided by 50, since this is the weight of one bag of cement: 594/50 = 11.88. The result is rounded up towards a larger value - we get 12 bags of M500 cement.

- Crushed stone with a grain of 20 mm for our concrete will be calculated as follows: multiply 1188 by 2, we get 2376 kg. If you chose a different faction, then all calculations will have to be done again.

- Sand is calculated in the same way as crushed stone: 1188 * 2 = 2376 kg.

- We find water like this: we multiply 205 liters by 2, we get 410 liters as a result.

Indeed, the calculations should not cause any difficulties, you just need to decide on the required characteristics of your raw materials. If plasticizers are used for the foundation, then adjustments must be made to the calculations, the coefficients can easily be found in reference books.

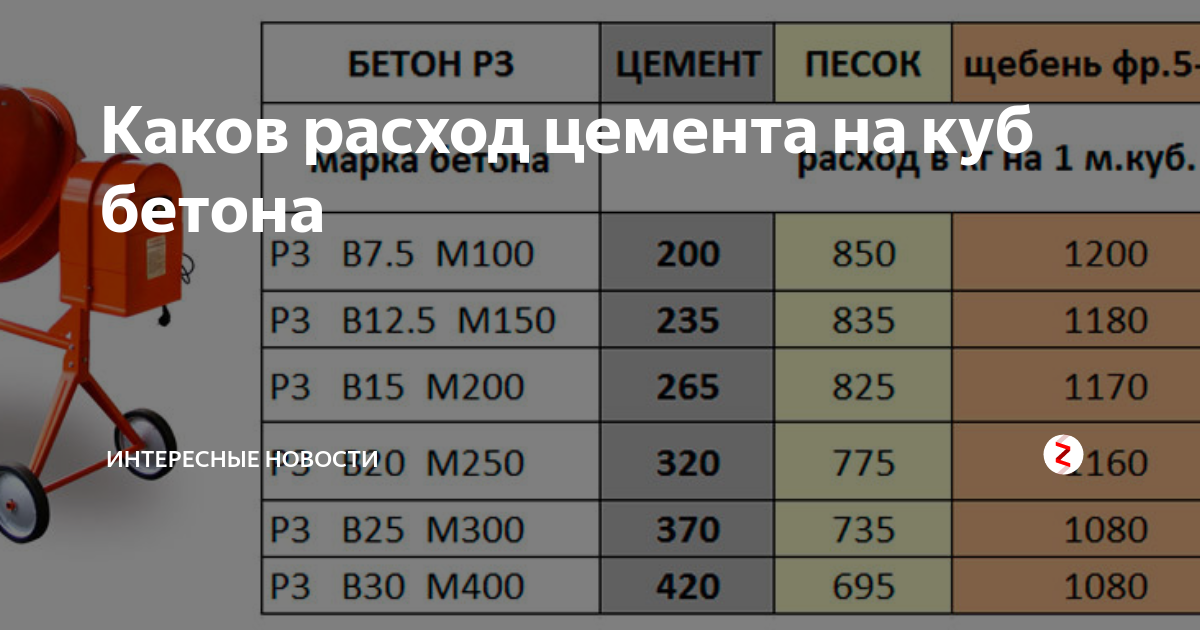

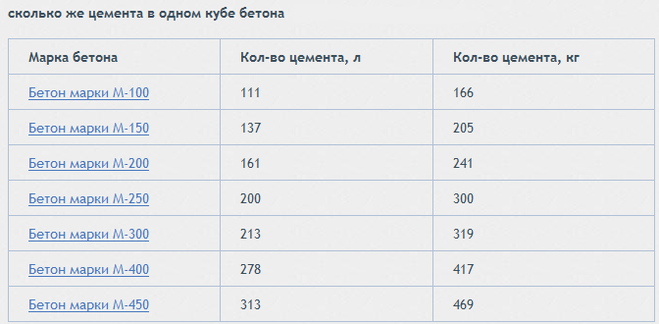

Features of calculating the consumption of cement for 1 cubic meter of concrete

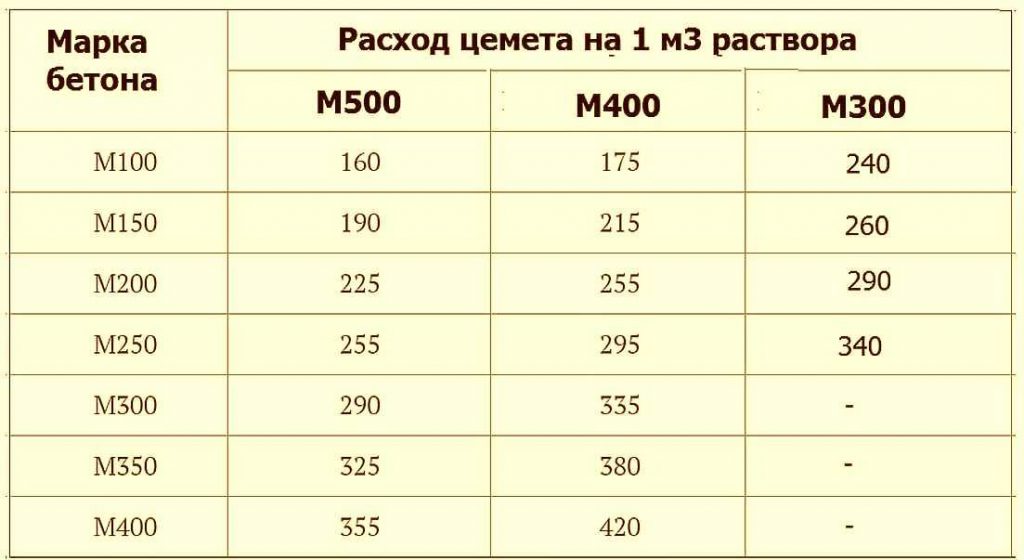

Consumption of cement for 1m3 of concrete is a reference information (when using cement M500), which for the main grades of concrete is displayed in the consumption table:

| Concrete marking | Application | Consumption of cement M500 in kg per 1 cubic meter of concrete |

| M100 | Lightweight concrete used in the preparatory stages prior to concrete work | 166 |

| M200 | Concrete for a wide range of applications, most often used for pouring foundations | 241 |

| M300 | Concrete for a wide range of applications with good strength properties | 319 |

| M400 | Medium concrete, characterized by its fast setting, is most often used in the construction of hydraulic structures. | 417 |

In order to obtain high quality concrete, which will ensure a long service life of the structure, it is important to use the components in the right proportion. The amount of cement affects the flow of concrete

Therefore, when preparing concrete, the accuracy of placing the components must be observed in the following volumes:

The amount of cement affects the flowability of the concrete. Therefore, when preparing concrete, the accuracy of placing the components must be observed in the following volumes:

- Cement - up to 1 kg.

- Sand - up to 3 kg.

- Crushed stone - up to 5 kg.

You can read more about these proportions in the article The ratio of crushed stone, sand and cement in concrete.

In this case, subject to the required proportions, high-quality concrete will be produced, that is:

- Lasting;

- With the required rigidity;

- Plastic.

If a large error is allowed, for example, in the direction of reducing the amount of cement, then the binder will not hold the filler, which means that the concrete under the impact of external negative factors will become unusable in a short time.

Consumption of cement for 1 cubic meter of concrete depends on what grade of concrete mix is planned to be made. And it depends on what the concrete is planned to be spent for. In household low-rise construction, the following are most often used:

- Concrete marked M200 with high compressive strength. It is used when arranging various types of foundations, pouring sites and forming paths. It is also often used in the construction of stairs and as a concrete cushion when installing curbs.

- Concrete marked M300. It can be used for pouring monolithic foundations, but is most often used in the construction of walls and the formation of floors in buildings.

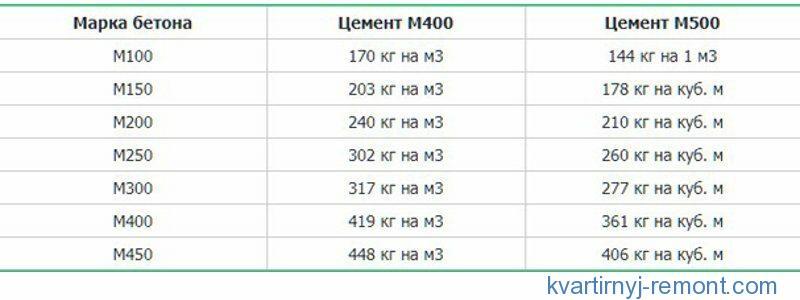

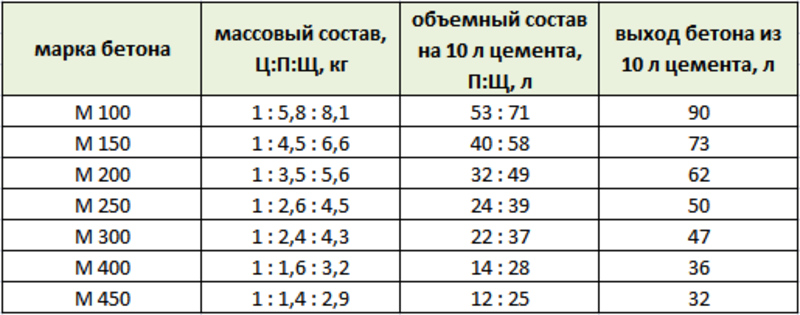

The grade of cement used in the preparation of concrete is always 1.5 or 2 times higher than the grade of concrete prepared from it. So, for example, for the preparation of concrete M200, it is necessary to use cement marked M300 or M400.

For the convenience of preparing concrete, it is recommended to purchase bagged cement 50 kg. The use of such a measuring instrument will make it easy to prepare a concrete mixture. So, for the manufacture of 1 cube of the most popular concrete with the M200 marking, 4 bags and 41 kg of cement grade M300 or M400.

Calculation of cement for 1 cubic meter of concrete (m³)

The proportional ratio of cement to other binders affects the flowability of the concrete mix. In order to prepare high-quality building materials, the following ratios should be adhered to:

- cement up to 1 kg;

- sand up to 3 kg;

- crushed stone up to 5 kg.

Failure to comply with all component ratios leads to a decrease in the strength characteristics of the future building coating. This will lead to rapid wear and surface cracking. Quantitative consumption of cement per 1 m³ of mortar directly depends on the brand of concrete mixture planned by the manufacturer. Under different climatic conditions and construction zones, different grades of material are used.

Concrete marking classifier

Table of the ratio of classes and grades of concrete.

With various requirements for the stability and reliability of a building object, the following marking classifier of concrete mixtures is mainly used:

- M100. It is used at the initial (preparatory) stage of construction work.

- M200. Has a wider range of applications. Most often used when pouring fundamental surfaces.

- M300. This building material has great strength characteristics. Fundamental laying with such a concrete monolith is used in industrial construction.

- M400. It is used in the construction of structures of a hydraulic nature. It has high strength and differs from other grades of concrete by its fast hardening.

Decoding of building material: the letter M with a number that indicates the arithmetic mean of the strength characteristics of the sample, for compression in kgf / cm².

How many cubes of concrete are needed for a foundation?

When building a civil or industrial facility, two types of fundamental coatings are used: strip and slab bases. For the convenience of the calculated indicators, a reinforced concrete (reinforced concrete) foundation 10 by 10 is taken:

- Strip foundation. The required amount of mortar is determined by the total volume of the base. The calculation is carried out by multiplying the metric values: height, length and width of reinforced concrete tape. Initial data: height - 1.5 m, width - 0.5 m, total length of the tape - 55 m. Multiplying the values and rounding the value to an integer, we get 41 cubic meters of concrete.

- Slab base. The amount of concrete mix is determined very simply for a slab foundation. For example, the thickness of the slab is 40 cm. Multiplying the initial data, we get: 10 mx 10 mx 0.4 m = 40 m³.

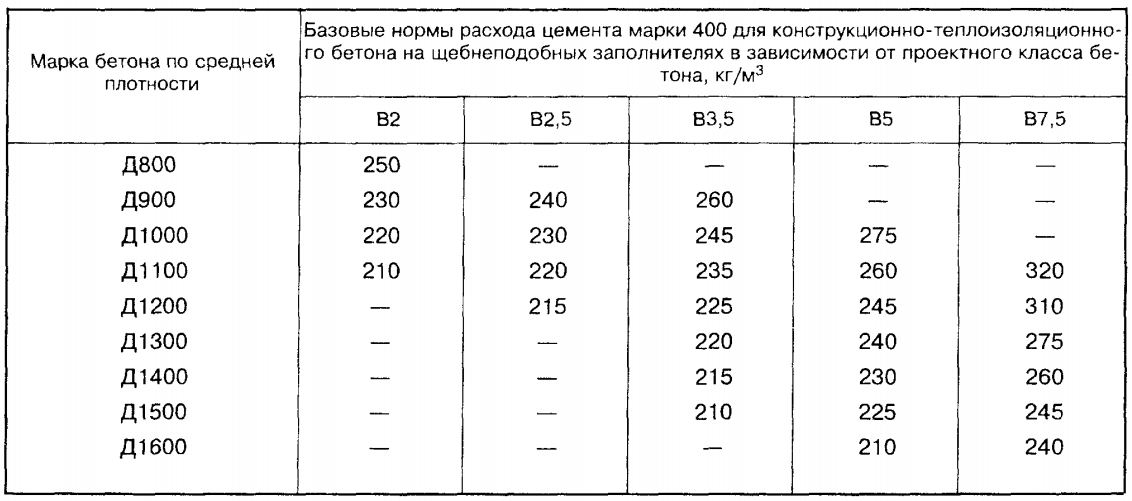

Weight of 1 m³ of concrete mix

The specific gravity of the binder building material is variable.

The mass of concrete weighs differently, depending on its structural components, that is, on the type of aggregate. In civil and industrial construction, a heavy type of concrete monolith is usually used. Gravel and crushed stone of large fractions are used as filler. Thanks to this basis, the fundamental coating has a special strength and stable surface. The weight of one cubic meter of concrete mix is from 1.7 to 2.5 tons.

Calculation Basics

Cement is the main component in the composition of the concrete mixture, since it has the property of tightly binding the rest of the components. Such material affects the main indicators - moisture and frost resistance, strength. If deviations are allowed in the mixing of the solution, then the errors will negatively affect the composition. This will lead to poor quality raw materials.

After a while after production, the cement powder begins to lose its useful properties. For this reason, it cannot be bought long before the start of construction work.

For their implementation, it is important to know how much cement is needed for a cube of concrete, based on the selected type and grade of material.

To get a high-quality batch, they also add:

- sand;

- water;

- crushed stone.

Without these two components, the solution will not have all the necessary properties. Crushed stone is a fairly strong stone, therefore it is able to more firmly hold the composition together. Thanks to him, concrete does not crack, regardless of weather conditions. For the preparation of 1 cube of concrete, 1.08 tons of crushed stone must be taken. Moreover, for the best fraction of the composition, it is recommended to add stones with a diameter of no more than 20 mm. They are usually sieved through a sieve with special cells.