Number of bricks in one pallet

Despite the abundance of fundamentally new building materials, traditional brick is still one of the most popular and relevant options for laying walls and building individual houses. Bricks are sold in pallets, which greatly facilitates their storage, transportation and handling. But the majority of private developers prefer to calculate the purchase volume by the piece. In addition, quite often manufacturers set the price not per unit of goods, but per pallet. Therefore, in order to know the total cost, it is necessary to correctly calculate how many bricks are in the pallet.

Brick and its varieties

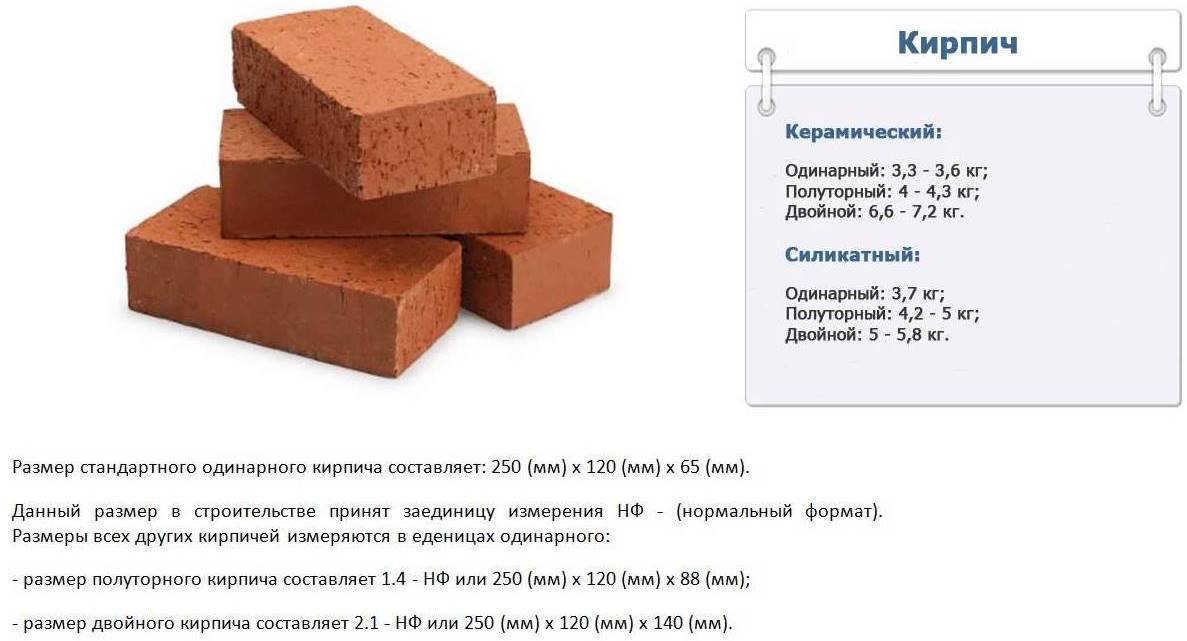

In order to calculate the amount of material that fits in one pallet, you should understand which of its types you need to buy in a particular case. Depending on the raw materials used, a distinction is made between silicate and red bricks. By its structure, it can be:

1. Red.

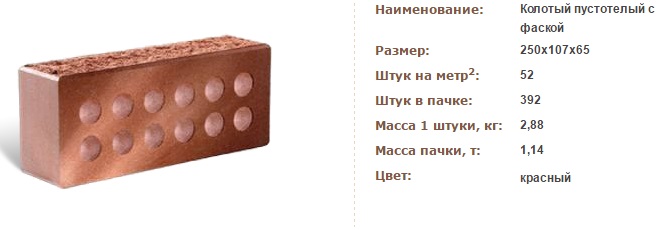

Red brick is mainly used in the construction of houses and cottages. It is made from various types of clay using firing. It is strong enough, not too heavy (full-bodied weighs about 3.6 kg, hollow - 2.5 kg) and successfully withstands harmful atmospheric influences. The standard size is 250 x 120 x 65mm.

No less popular is the silicate briquette, which is autoclaved from sand with various additives. This species has excellent heat and sound insulation properties, as well as high frost resistance. The weight of the product is slightly more - corpulent weighs 5 kg, hollow - no more than 4.

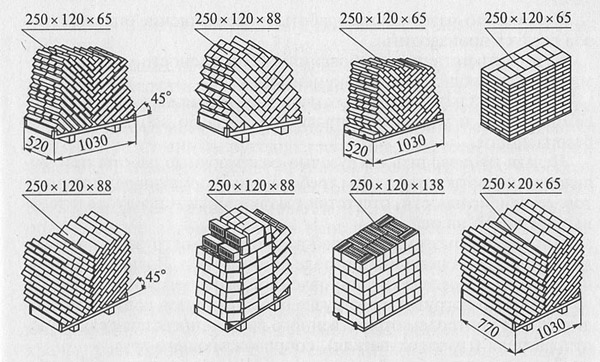

Number of blocks in a pallet

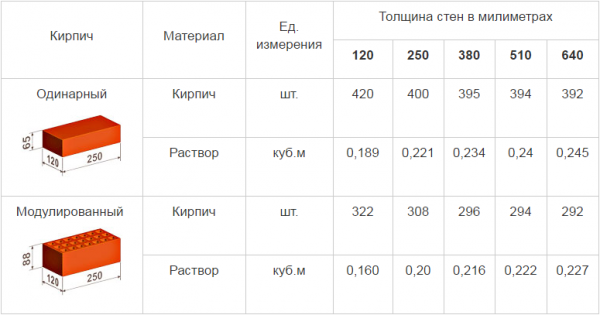

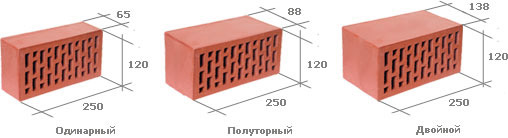

The capacity of the platform depends on the size of the bricks placed on it, as well as on the dimensions of the platform itself. There are single, one and a half and double bricks. In all cases, the dimensions of the product remain unchanged, only the height differs:

- for single - 6.5 cm;

- for one and a half - 8.8;

- for double - 10.3.

As for pallets, they are of two types:

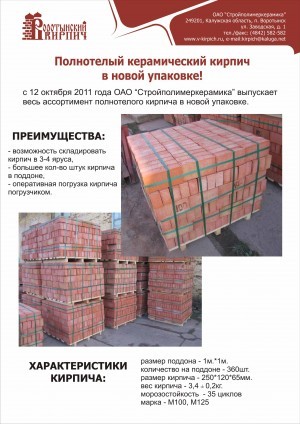

- standard - 103 x 52 cm, carrying capacity - 750 kg;

- reinforced - 103 x 77 cm, carrying capacity - 900 kg.

Knowing the weight of the material, as well as its basic parameters, you can calculate how many pieces the platform can hold. For this, the base area is divided by the area of one product. Multiplying the resulting number by the number of rows on the pallet, we find the total amount:

- no more than 420 pieces, if it is a single brick;

- about 390 units, if it is one and a half;

- up to 200 doubles.

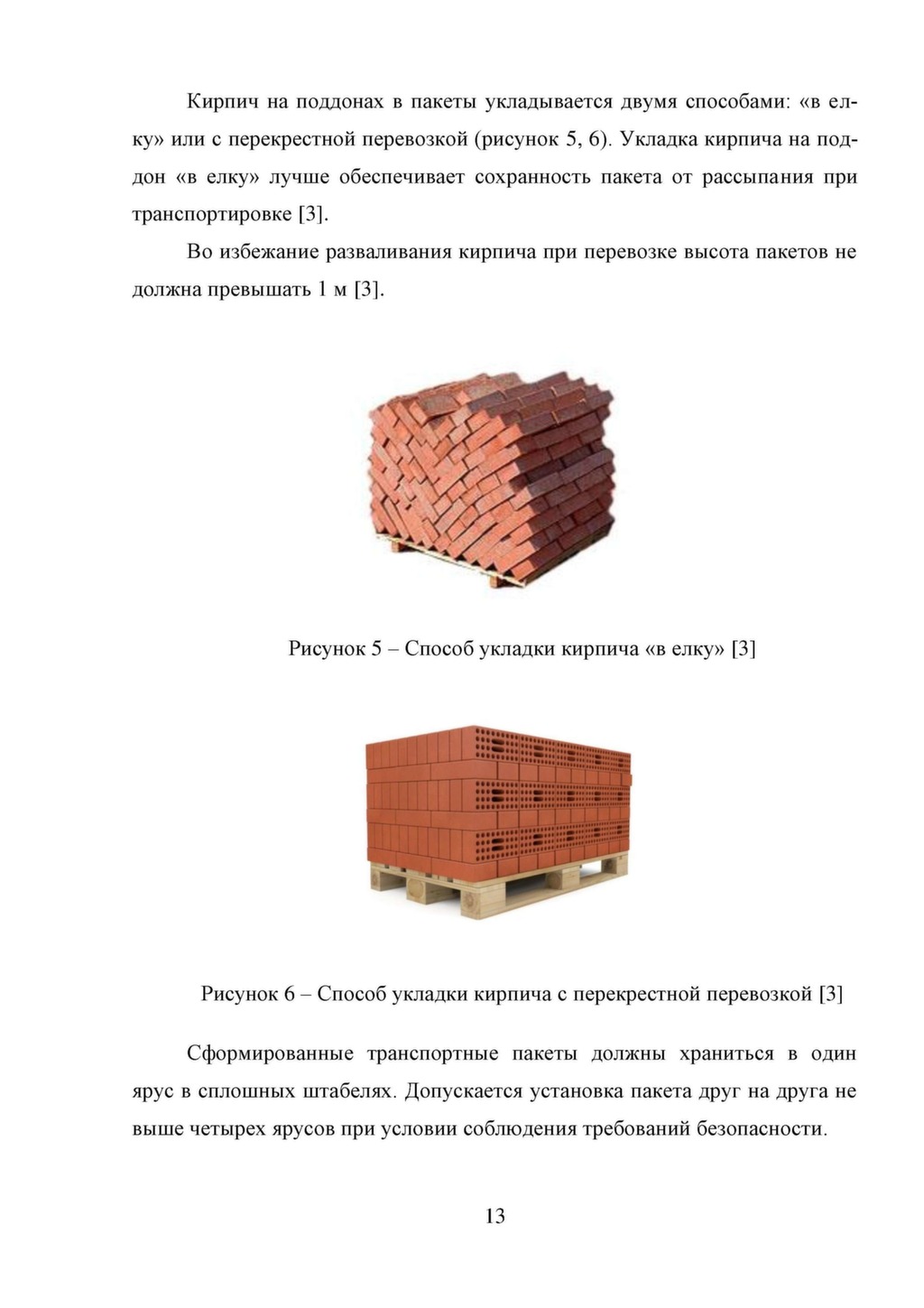

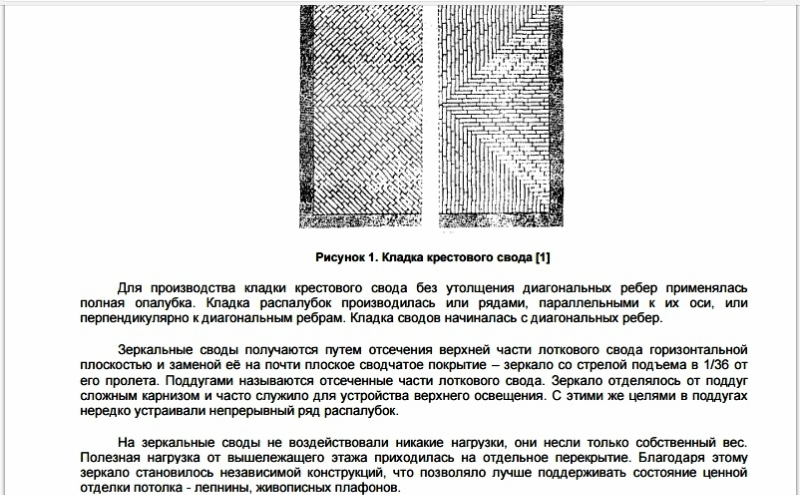

Such calculations will not work if the laying on the base took place at an angle of 45 degrees - "herringbone". In this case, you can find out the number of blocks using simple geometry, namely, by counting in one cubic meter.

The information obtained allows you to optimize costs. The price of wall material, which accounts for a significant proportion of the total cost of building a house, does not allow buying it "just in case." In addition, an excessive amount will increase the cost of transport and handling.

Pricing is influenced by the following points:

1.brand and country of origin;

2. specifications and dimensions;

3. strength and ability to withstand multiple freeze cycles;

4. remoteness from the construction site.

Varieties and brands of bricks

There is a huge variety of bricks and, in accordance with domestic state standards, products are divided into different groups depending on their scope and technical characteristics.

By appointment, there are the following types.

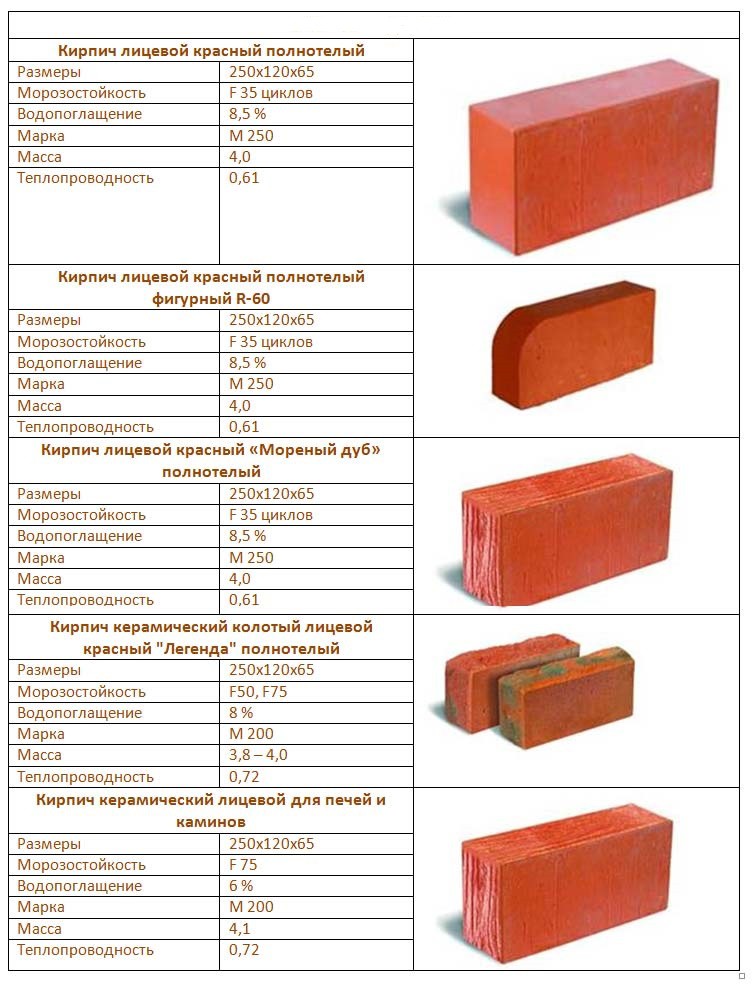

- Structural - designed to make walls for various purposes (load-bearing, interior), both inside and outside the room. They also include a basement brick, ordinary.

- Facial - required for final finishing. Blocks can be made from natural or artificial materials, there is a huge variety of colors, different sizes. The facing brick can be used as a construction material.

The structure can be distinguished:

- hollow, in the production of which forms are used, in which there are holes in the blocks to ensure low thermal conductivity, respectively, this type of brick is more energy-saving;

- full-bodied, that is, there are no voids inside the brick, this can be a standard furnace block;

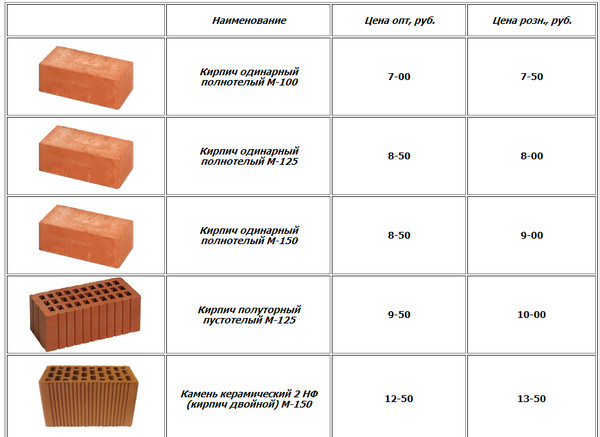

- several grades are distinguished by strength - from the least dense M-75, M-100 and M-150 to the most dense M300;

- for frost resistance there are markings from F15 to F50.

One of the types is fireclay bricks, which are made from special durable clay with the addition of certain impurities, including sand. The blocks are obtained by processing under high temperature (firing) refractory dust and special powder. There is general purpose fireclay bricks (ША, ША-5, ШБ-5, ШБ8), cupola, double-sided facing and many others intended for specialized construction.

There are also other types of this facing material - acid-resistant, backing, silicate and ceramic blocks.

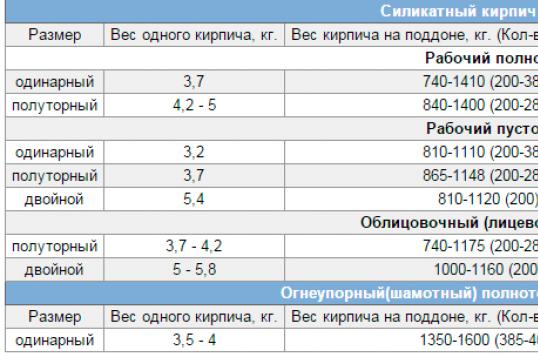

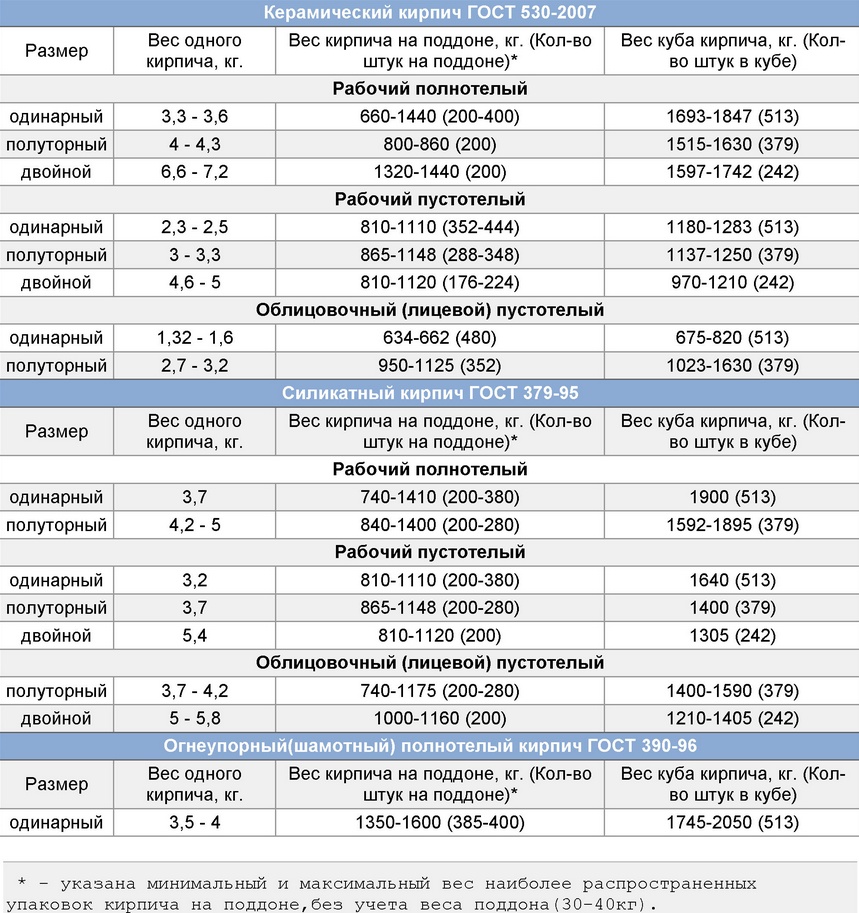

How much does a silicate brick weigh?

Silicate brick belongs to the category of artificial building materials for the construction of vertical enclosing structures. The characteristics are excellent, the scope of application is wide, but do not forget that the type of foundation or supporting elements depends on such a parameter as the mass of white brick. Therefore, even for the simplest calculations, you need to know the weight.

Types and characteristics

White brick is produced by a non-fired method from a mixture of lime binder, silica filler (quartz sand, fly ash, sludge, etc.) and a small amount of water to moisten the mixture. In production conditions, raw materials are pressed and autoclaved. Due to this, the finished block gains the required parameters:

1. The compressive strength is marked with the M75-M300 brand.

2. Thermal conductivity - up to 0.87 W / m * K.

3. Frost resistance: withstands from 15 to 50 complete freeze-thaw cycles when fully immersed in water.

4. Density: porous or lightweight up to 1500 kg / m³. Products with an index exceeding this indicator are called dense.

5. Water absorption - 6-16%.

Plants produce a silicate block of the following dimensions:

- Single: 250x120x65 mm.

- One and a half or thickened: 250x12x88.

- Double: 250x120x103.

- Embossed: 250x90x65.

By the field of application, a distinction is made between working or ordinary brick and facing. The latter is used for finishing facades, foundations, basements, fences.

The structure for all sizes is typical:

- full-bodied or monolithic product;

- hollow products, with a void content of up to 15% (3-void), 25% (11-void) and 31% (14-void).

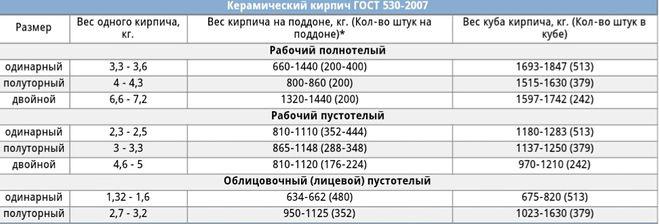

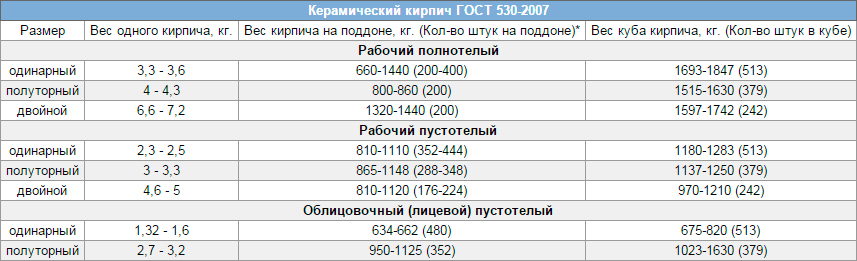

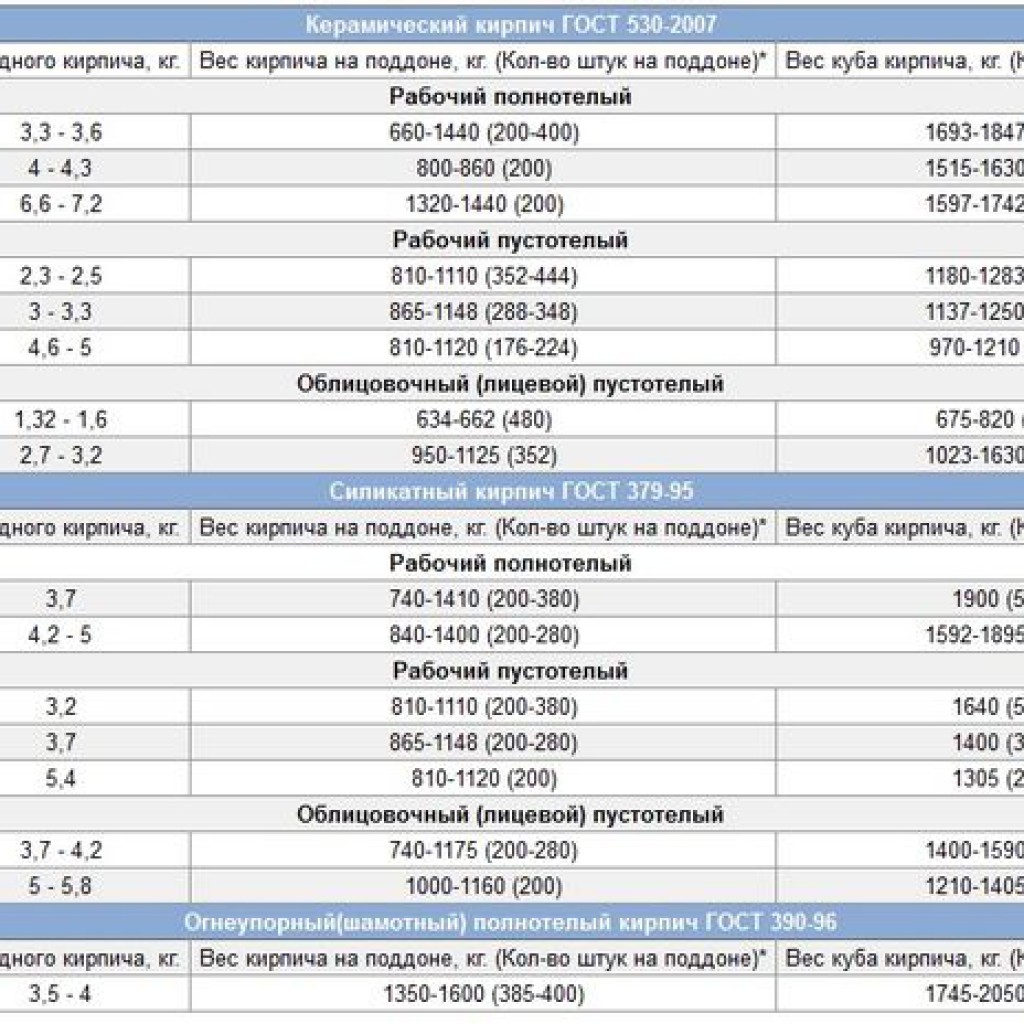

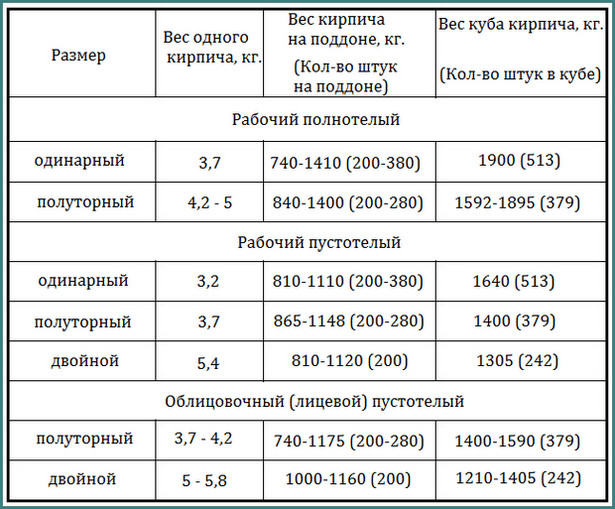

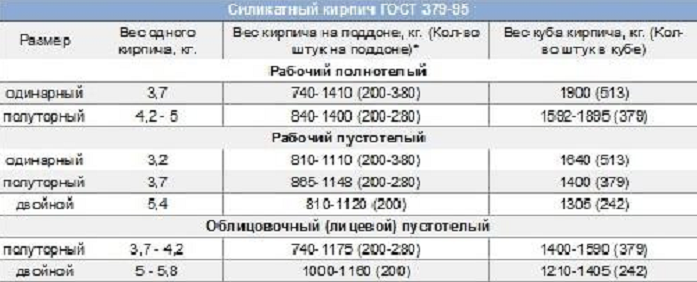

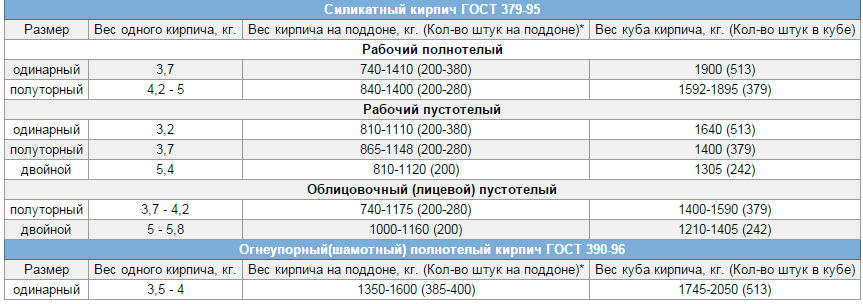

White brick produced in accordance with GOST 379-95 "Bricks and silicate stones" must have a standard weight according to the table below.

The data from the table are corrected for the weight of auxiliary materials. That is, for example, the weight of one one-and-a-half solid silicate brick made according to the basic recipe from lime and sand is 4.2 kg / pc. The total weight of the building material laid on the Euro pallet is 840 kg, but the pallet itself, protective film and fixing straps are added to this. Accordingly, the cargo prepared for transportation will weigh approximately 846 kg.

The weight of a hollow silicate block 250x120x88 is less than a solid analogue precisely due to the cracks, but during the construction process they will be filled with mortar, so the total mass of the masonry will increase significantly.This must also be taken into account when calculating the project plan.

Before buying, you need to carefully inspect the proposed product. The surface must be firm, even, free of chips, chamfered corners, cracks and cavities. If the product crumbles in the hand, slightly crumbles, it means that it was overdried or underdried, therefore it is not suitable for the construction of walls - it will quickly collapse.

White silicate bricks, along with red ceramic bricks, occupy a worthy place in the category of building materials for fencing.

Before starting any type of construction, you need to accurately calculate how much consumable material, including.

With the advent of new building materials, which significantly speed up and reduce the cost of construction of buildings, but do not have.

Running meter capacity

You can use ready-made data to determine the amount of material in a 1-meter cross-tie structure. So, when laying on the "bed" (the largest edge) of a single brick in a pallet 520x1030 will fit 240 pieces, on "spoons" (edge) - 256 pieces.

Pallet 770x1030 contains 360 single construction products when laid on the bed or 384 pcs. when placed on "spoons". One and a half, respectively, 176 and 192 pcs. for a small pallet, 264 and 288 for a large one. However, one should not forget about the load on the platform. In order not to overload it, a stack of solid bars is formed lower, since 1 single product weighs about 3.3-3.4 kg.

The thickness of the double is slightly more - not 136, but 138 mm. However, the parameters of the material with a decorative surface may differ significantly. So, for cladding, handmade ceramic products 188x88x63, narrow long clinkers 528x108x37, euro 250x85x65 mm can be used. Since there is no single standard for this type of product, it can be from 336 to 672 pieces in one pack.

To calculate the exact amount, you should use the previous formula: determine the cubic capacity of the package, measure the bar and divide the first value by the second, remembering to bring both indicators to a single measurement system before that.

The nuances of packaging and consumption of silicate bricks

How many pieces in 1m2

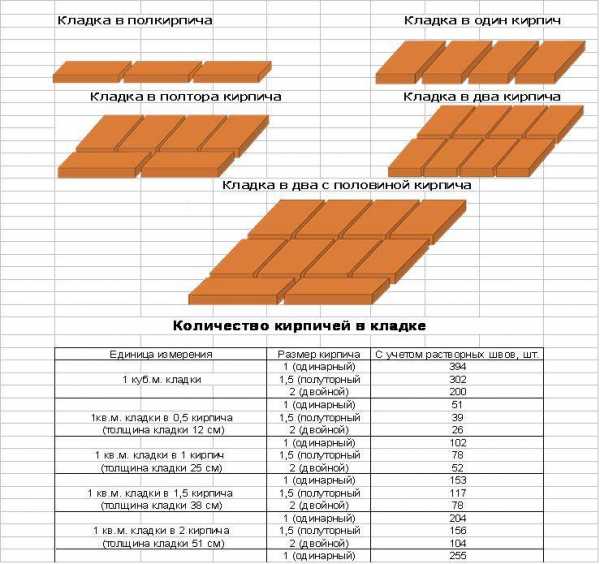

During construction, it is important to accurately calculate the amount of material in order to avoid unnecessary costs. Brickwork is calculated according to two parameters: area and volume

Therefore, let's figure out how many bricks will go to 1 meter of the wall in each case.

For 1 m2 of silicate brick masonry, a different amount of material can be used. Much depends on the size of the product. For example, to erect a wall one brick thick, the material consumption will be as follows:

- Single - 204 pcs.

- One and a half - 156 pcs.

- Double - 104 pcs.

If the wall is standard (2.5 bricks), the consumption will be as follows:

- Single - 255 pcs.

- One and a half - 195 pcs.

- Double - 130 pcs.

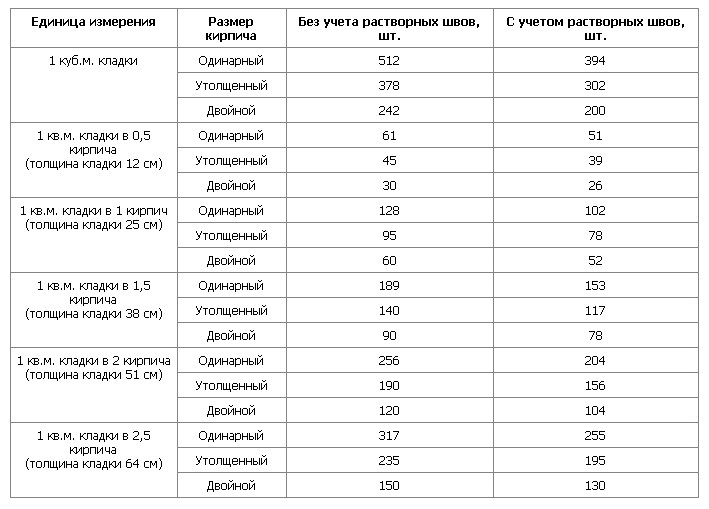

How to calculate the quantity in a cube (1m3)

Calculating the volume will be a little trickier. As an example, let's take a standard sand-lime brick with dimensions 250 * 120 * 65 mm. To find out how much material will go for 1 m3 of masonry, you need to calculate the volume of one unit of building material. To do this, translate the size into meters and multiply the sides.

After simple calculations, we get 0.00195 m3 - this is the volume of one brick. After that, we divide the cubic meter by the volume of one brick. On average, 512 blocks are used for 1 m3 of masonry.

Note that in both cases, the actual material consumption will be less: when calculating, you need to take into account the thickness of the mortar joint.

How many bricks are in the pallet

When ordering a brick, you need to take into account the number of pieces in a package. It looks like this:

On a pallet - depending on the size, 240-380 pieces of single and one-and-a-half bricks can be accommodated, respectively.

The amount of building material in one pack

In a pack - a standard form of polyethylene packaging can contain 480-560 pieces of hollow and monolithic bricks.

Note that there are no special requirements for the packaging of the material.Therefore, the number of bricks on pallets and in bundles may vary depending on the manufacturer.

Advantages of brick material

- The main advantage of bricks is strength, this indicator is denoted by the letter M, and the subsequent numbers indicate the load that the material can withstand.

- Also, the material has a long service life, such structures are considered the most durable, the facade may not require repair work for about 100 years.

- The material is resistant to low temperatures and can withstand a large number of freeze cycles. This indicator is denoted by the letter F, and the number after it indicates the number of cycles. The frost resistance index affects the durability of the structure.

- Brick is considered an environmentally friendly material, it contains clay, water, and sand, no chemical additives are used. Thus, the material does not emit substances that are harmful to health and polluting the environment.

- The product is called breathable, as it allows air to pass through, mold and fungi do not form on the walls. The material is not susceptible to damage by insects and rodents, and also does not lend itself to decay.

- Thanks to the brick walls, the humidity level in the room is not exceeded, thus creating a microclimate favorable for comfortable living. With proper wall construction, even in the wettest or coldest weather, the interior will remain warm and dry.

- The cost of the material is affordable, moreover, the work can be done independently, this will help save on costs.

- The brick facade has an aesthetic appearance. Such material is used not only for the construction of walls, but also for facing work.

Number of single bricks in a pallet

If the partition is interroom and the masonry is "2-layer 2x1 / 2" with an interval of 7-8 centimeters, it was filled with sound insulation, if the interroom is "single-layer" 1/2 brick. "

a source

scan from the old manual:

indicates a great bearing capacity of such masonry.

Purely intuitively, such laying seems to be more stable than usual. At least the occurrence of such vertical cracks seems less likely to me:

But why did they abandon the diagonal masonry during the massive construction of the same five-story buildings?

This secret is great.

Although in the form of a curiosity and design they sometimes put:

but in ancient Rome, diagonal masonry was used quite widely. These parts of the masonry have just been preserved better than the horizontal ones:

Pallet types

In order to ensure the safety of bricks during transportation and storage, as well as to facilitate loading and unloading operations, special pallets (pallets) are used. Design features and technical characteristics of pallets intended for storing and transporting bricks are regulated by GOST 13843-80 dated 01.01.1981. The use of pallets provides:

- significant time savings during loading and unloading;

- almost 100% safety of building material at all stages, from storage to unloading at the construction site;

- the possibility of using forklifts.

Features of the pallet design

A pallet for transporting and storing bricks is in many ways similar to conventional pallets, however, it has a number of significant differences:

- increased carrying capacity;

- availability of special fasteners for the use of special equipment;

- the possibility of using forklifts is provided.

Varieties

For the convenience of using pallets, the following designations are adopted:

NS

- pallet;

O

- the pallet is equipped with supports;

TO

- the pallet has special hooks;

D

- the pallet is made of wood;

M

- the pallet is made of metal.

Classification

Depending on the design features and materials used, the following modifications of pallets for transportation and storage of brick blocks are distinguished:

UNDER

- the most common modification (a pallet equipped with wooden supports), used for transportation by road and rail;

POM

- reinforced version on supports with a metal base;

MPCM

- a pallet with a wooden base, reinforced with metal elements. It is equipped with special hooks to facilitate loading and unloading operations.

Modifications POD and POM have additional transverse beams to increase the bearing capacity. For fixing brick blocks during transportation, triangular stops are provided.

Dimensions and load capacity

For the transportation of bricks, three types of pallets are used, the dimensions and carrying capacity of which are regulated by GOST 9078-84:

| Modification | Dimensions, mm | Carrying capacity, kg |

| Standard | 1030x520 | 750 |

| Reinforced | 1030x770 | 900 |

| Euro pallet | 1200x800 | 1500 |

Capacity

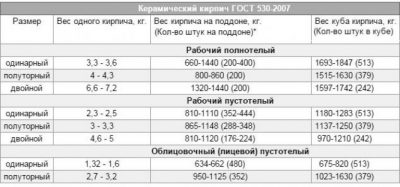

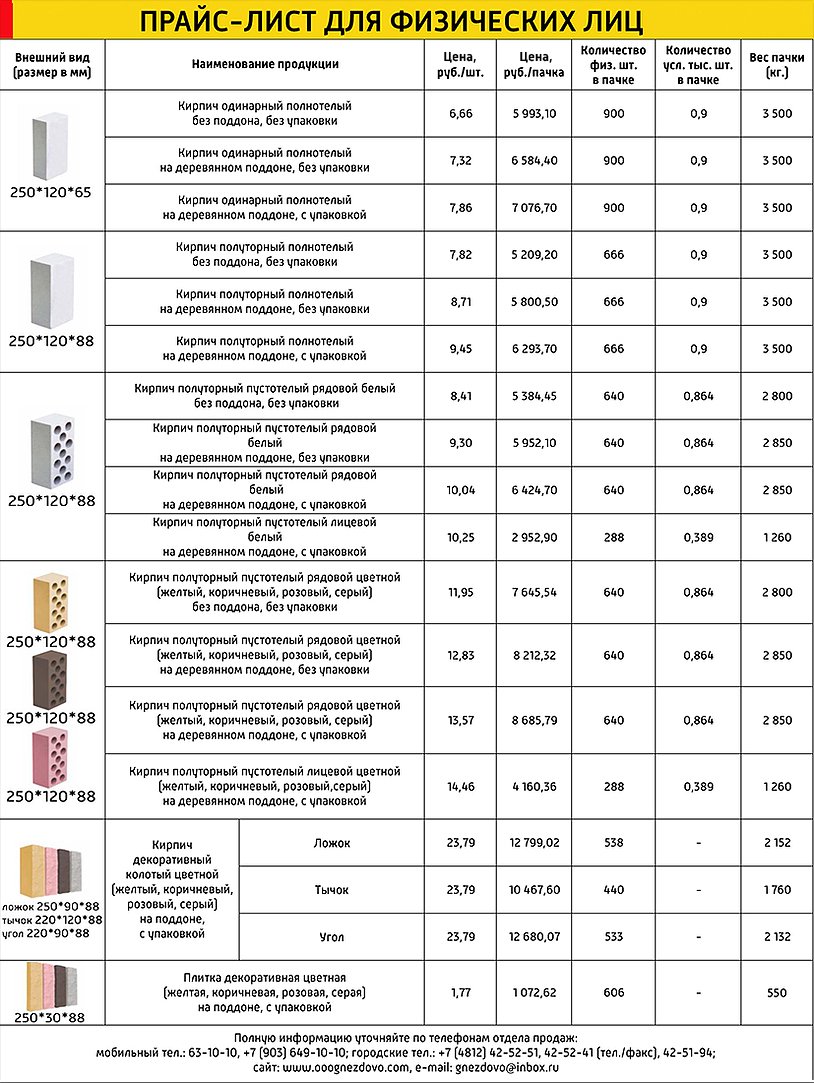

Red

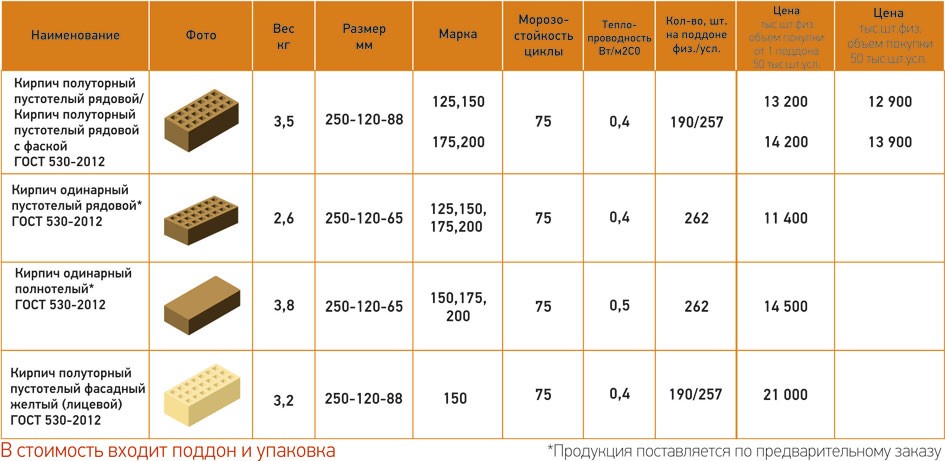

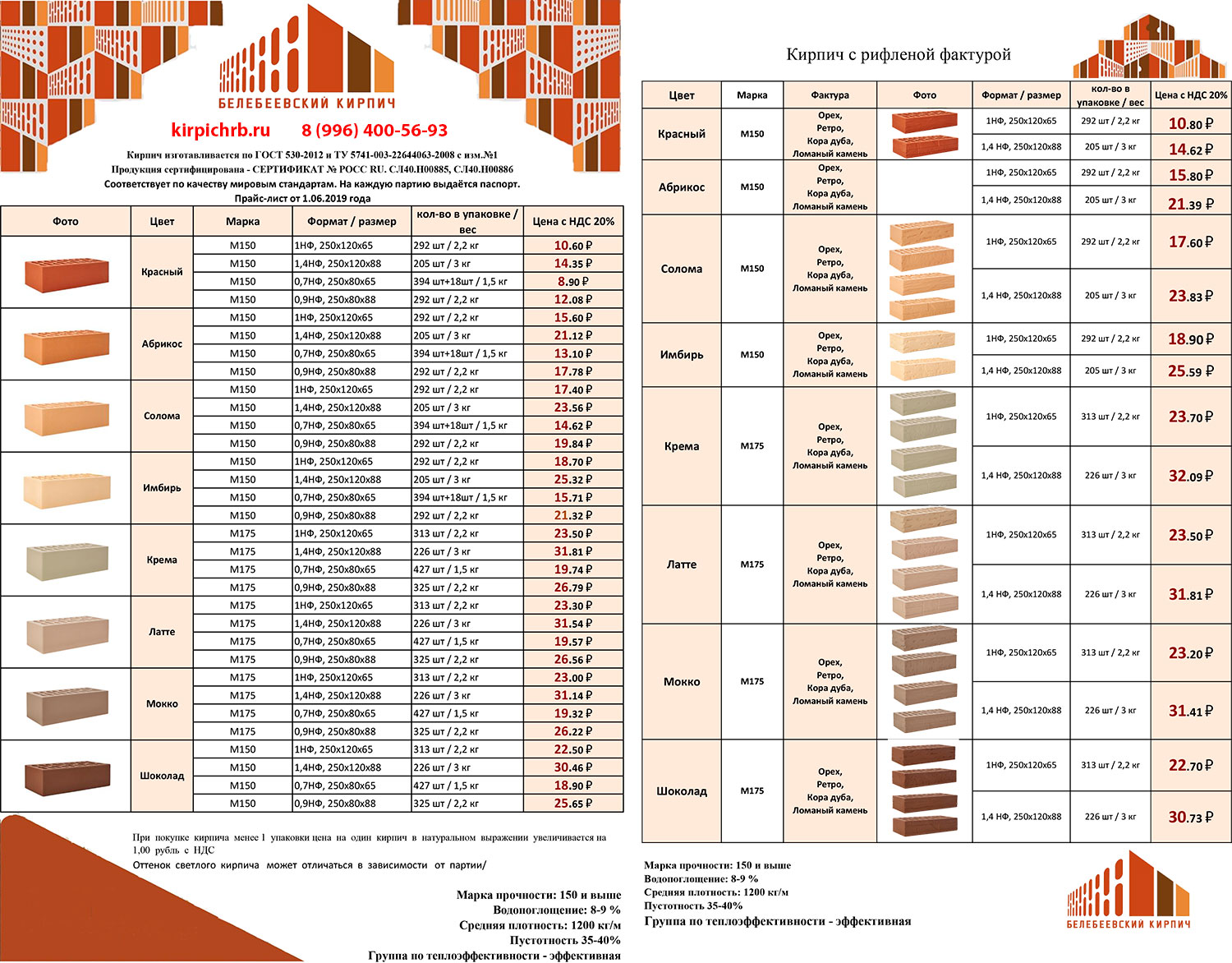

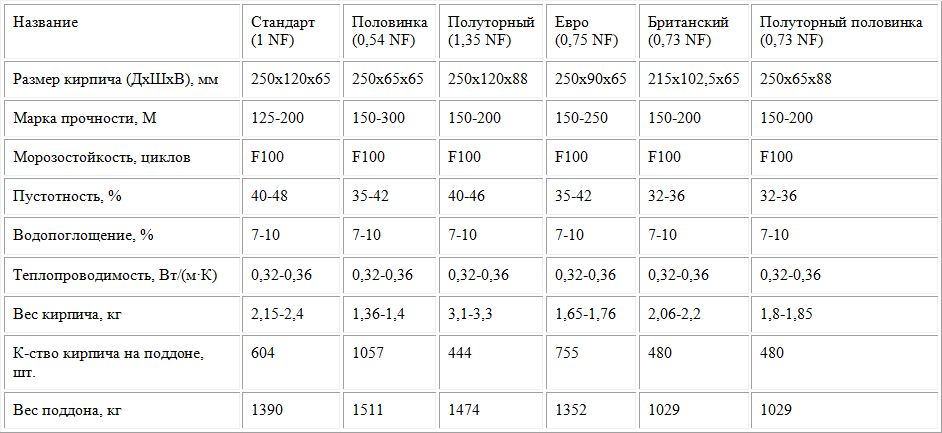

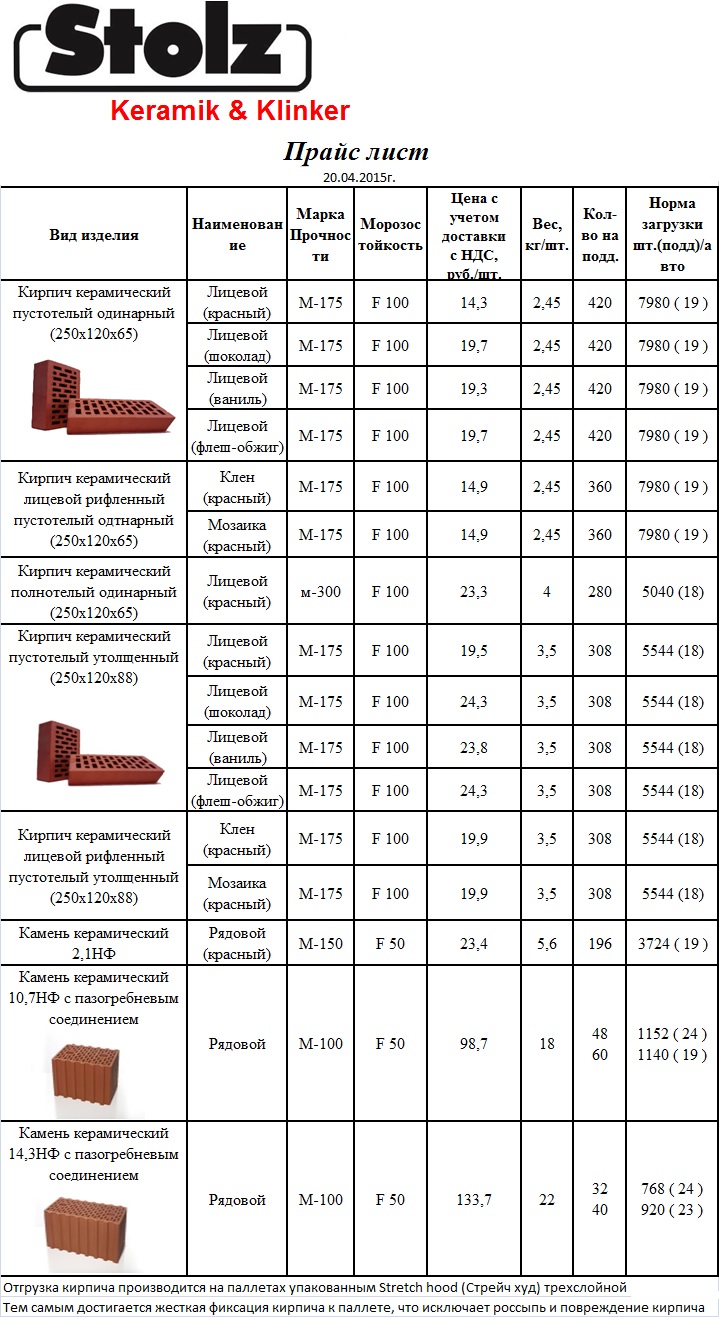

The capacity of bricks in a pallet, depending on the size of the product.

How many bricks are included in one pallet of regular size? Usually, the unit of measurement is taken as a pallet of 103x77 cm. In this case, in 1 stack per meter in height (standard), the amount of backing or ordinary material will be quite standard. You just need to clarify the specific parameters. For example, a hollow ceramic block will be placed on a large pallet in the amount of 420-480 pieces. On a small one it will fit from 308 to 352 pieces. Let's consider in more detail the data on the most popular types of bricks.

|

Solid brick type |

250x120x65 |

250x120x88 |

worker |

stove |

basement |

M100 |

facing |

|

number of pcs. in a pallet 130x77 cm. |

420 |

390 |

200–400 |

420 |

420 |

420 |

360 |

White

In a standard size pallet, the amount of white sand-lime bricks usually depends on what type of product you plan to transport. It is worth adding that the platforms themselves will also be reinforced - due to the greater mass of the elements. On wood-metal pallets with the size of 1915x600 mm or 1740x520 mm, 240-300 pieces are placed. single sand-lime brick. For a one-and-a-half product, this figure will be 350-380 pieces, but the manufacturer can also ship half-packs of 180 units. For the facing option, the number of bricks per pallet will be 670-700 pcs. For slotted - from 380 to 672 pcs. Hollow double bricks are placed on a special pallet in the amount of 448 units. All these indicators are relevant exclusively for packaged products. In its absence, the number of pieces of goods available for delivery will depend on the stacking method. But with such transportation, the volumes of damaged and broken building material will be much higher.

Shamotny

For kiln or fireclay blocks, the number of units per pallet is also of great importance.

Here you should definitely pay attention to the product labeling. Among the most popular options are end wedges, which are placed on wooden pallets of 415 pcs.

In addition, the brand ШБ-5, measuring 230x114x65 mm, is stacked and transported on pallets of 385 pcs. If you buy fireclay bricks ШБ-8, with dimensions of 250x124x65 mm, 625 pieces are stacked on a standard pallet. Standard standards are not the only correct ones, and it is imperative to take into account the dimensional characteristics of the selected pallet option. Fireclay bricks of any brand are placed on a more spacious Euro pallet in the maximum volume.

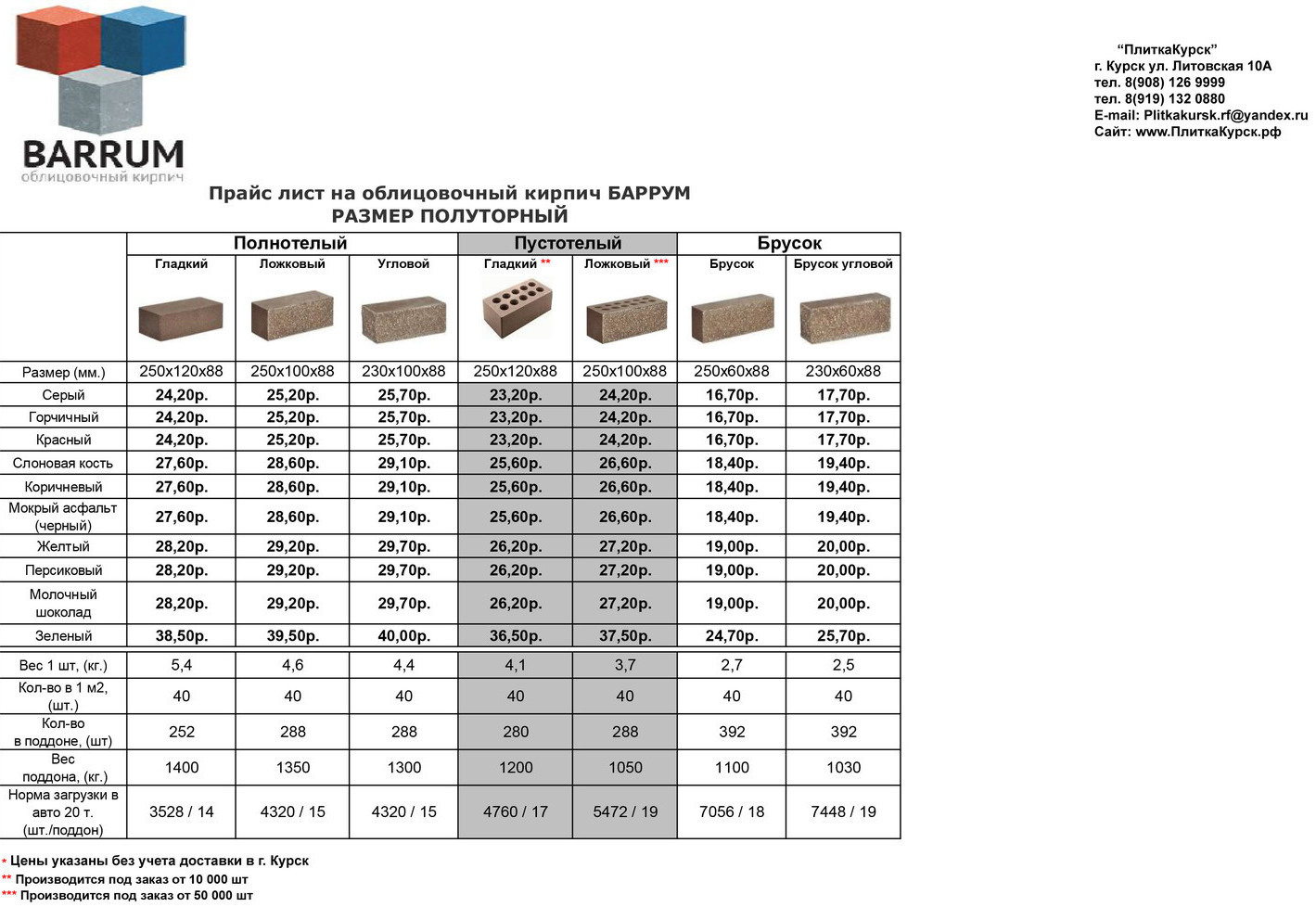

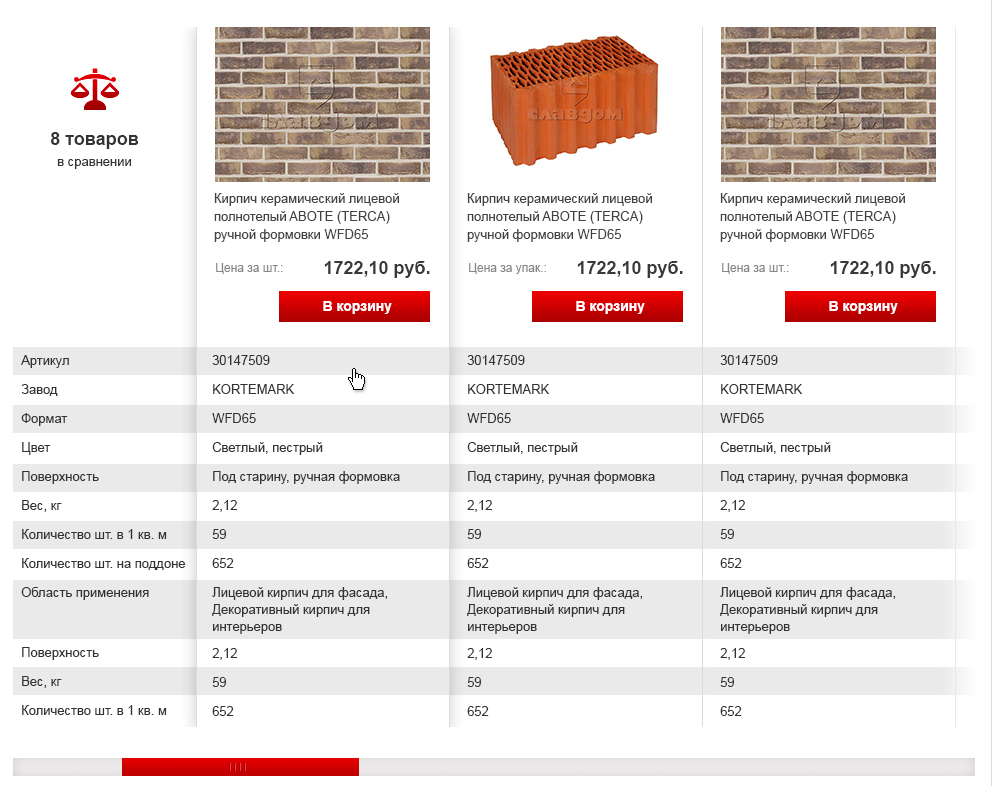

Facing

For facing bricks, the calculation of the number of products fit into the pallet also implies obtaining information based on the size of the product. With a standard size of 250x130x65 mm, 275 units of products are placed on the pallet. A single ceramic hollow body will fit 480 pcs. Silicate and yellow 200 pcs. in a single version. For the clinker variety, this figure will be 344 units. All specified data must be carefully checked, taking into account the standard according to which the product is manufactured, the carrying capacity of the pallet. In addition, when purchasing from a manufacturer, you need to clarify its individual parameters used during transportation. Only taking into account all these factors, it will be possible to accurately calculate the number of pallets and select the mode of transport for their delivery to the object.

How many bricks are in a pallet?

First, you need to consider the dimensions of the pallet, the usual form is 52 * 103 centimeters, and the maximum has a width of 77 centimeters and a length of 103. After that, you need to find out the parameters of the brick, the standard indicators of the element are 250 millimeters in length and 120 millimeters in width. But the thickness depends on the type of brick, a single element - 65 millimeters, one and a half - 88 millimeters, and a double - 103.

Now you can calculate the number of elements in the first row on a pallet, for this you need to divide the area of the pallet by the area of one brick. This number is multiplied by the number of rows. Thus, you can calculate the amount of material in one pallet.

In order not to carry out calculations, you can use ready-made data for the 75 and 150 mark of bricks, which is located on a standard pallet.

2. Number of non-standard facing bricks: 360 pieces

According to GOST, a pallet with red brick should have a weight of no more than 850 kilograms, but not everyone adheres to this indicator. Some manufacturers may use containers that can transport up to 3 tons of material. The brick can be laid in rows or at an angle, the weight of the pallet with the material depends on it. To calculate the weight of the pallet with bricks, it is necessary to add the total mass of all elements to the mass of the carriage. To do this, you need to find out the mass of one brick, and multiply this indicator by the amount of material stacked in the pallet.

A few words about volumes

A situation may well arise when it is required to determine not the number or even the weight of the material, but its volume that fits into the pallet. The need for such information, in particular, is due to the peculiarities of the estimated standards, where the masonry is measured precisely in cubic meters, but not in pieces.

The easiest way to start your calculations is to determine the number of products that fit in a unit of volume - in most cases, it will be the cubic meter that will be of interest. This can be determined by dividing the unit by the volume of the brick, expressed in cubic meters. What is the volume of one brick? This can be easily determined by calculating the value of the product of length and width, and then multiplying the resulting figure by the height of the brick - all parameters are entered into the calculation in meters. For example, the volume of a standard ceramic red brick can be calculated as follows:

250х120х65 = 1,950,000 mm3 = 0.00195 m3

Accordingly, the following quantity will fit in one cubic meter (taking into account rounding):

1 / 0.00195 = 510 pieces

In order to determine how many cubes of material are placed in a standard pallet, you need to determine the ratio of the number showing how many pieces are in the pallet to their number in one cubic meter. Consider a single red brick as an example:

420/510 = 0.82 - it turns out that one conventional platform holds approximately 0.8 cubic meters of material.

Thus, by simple calculations, the following values are obtained for the standard type of bricks:

| Variety | Volume of one piece, m3 | Quantity in 1 m3 | How many bricks are in the pallet, m3 (including rounding) |

| Single | 0,00195 | 510 | 0,8 |

| One and a half | 0,00264 | 380 | 1 |

| Double | 0,00414 | 242 | 0,8 |