Plexiglass adhesive options

Speaking about the popular compositions that can be used to glue plexiglass, it is worth dwelling on the following:

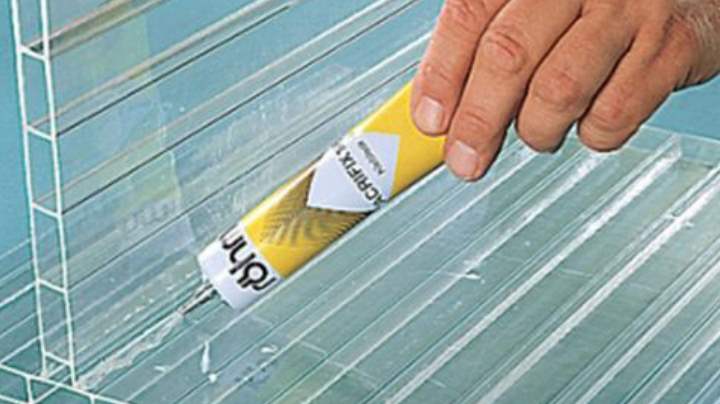

- formulations of the Acrifix family, specially formulated for acrylic-based materials;

- mixtures based on dichloroethane;

- acetic acid and its essence;

- Colacril family compounds;

- Cosmofen glue. It is also used to hold wood and plexiglass together;

- adhesives produced by Era-Henkel: Moment, Moment - seconds and others.

Acrifix 117 glue

One of the most popular formulations for gluing plexiglass has a long and well-deserved popularity among home craftsmen.

It has the following advantages:

- excellent bond strength;

- high transparency of the suture material;

- short setting time;

- low toxicity, especially compared to dichloroethane;

- high penetrating power makes it unnecessary to squeeze the parts hard.

Unfortunately, Acrifix 117 also has disadvantages that make it difficult for DIYers to access it:

- packing in liter cans;

- high price.

Acrifix 117

Experts recommend adding one tenth the volume of Acrifix 116 to Acrifix 117. This contributes to better filling of microroughnesses and increased adhesion.

Acrifix 116 glue

In composition, it is close to grade 117, but differs in greater density and viscosity. It is packaged in convenient 100 ml tubes, which makes it easy to use in home workshops.

They can glue rough surfaces that do not have perfect smoothness.

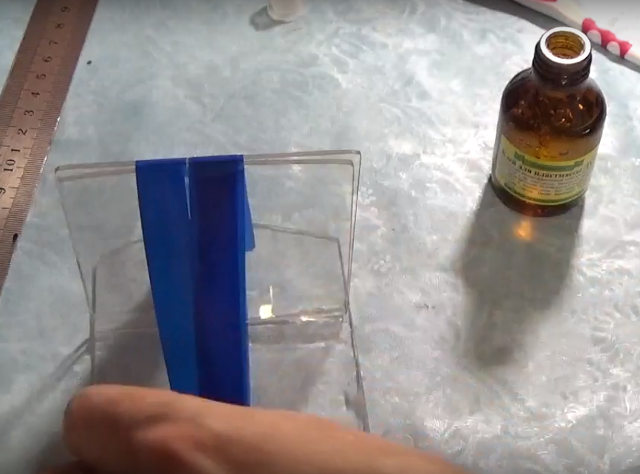

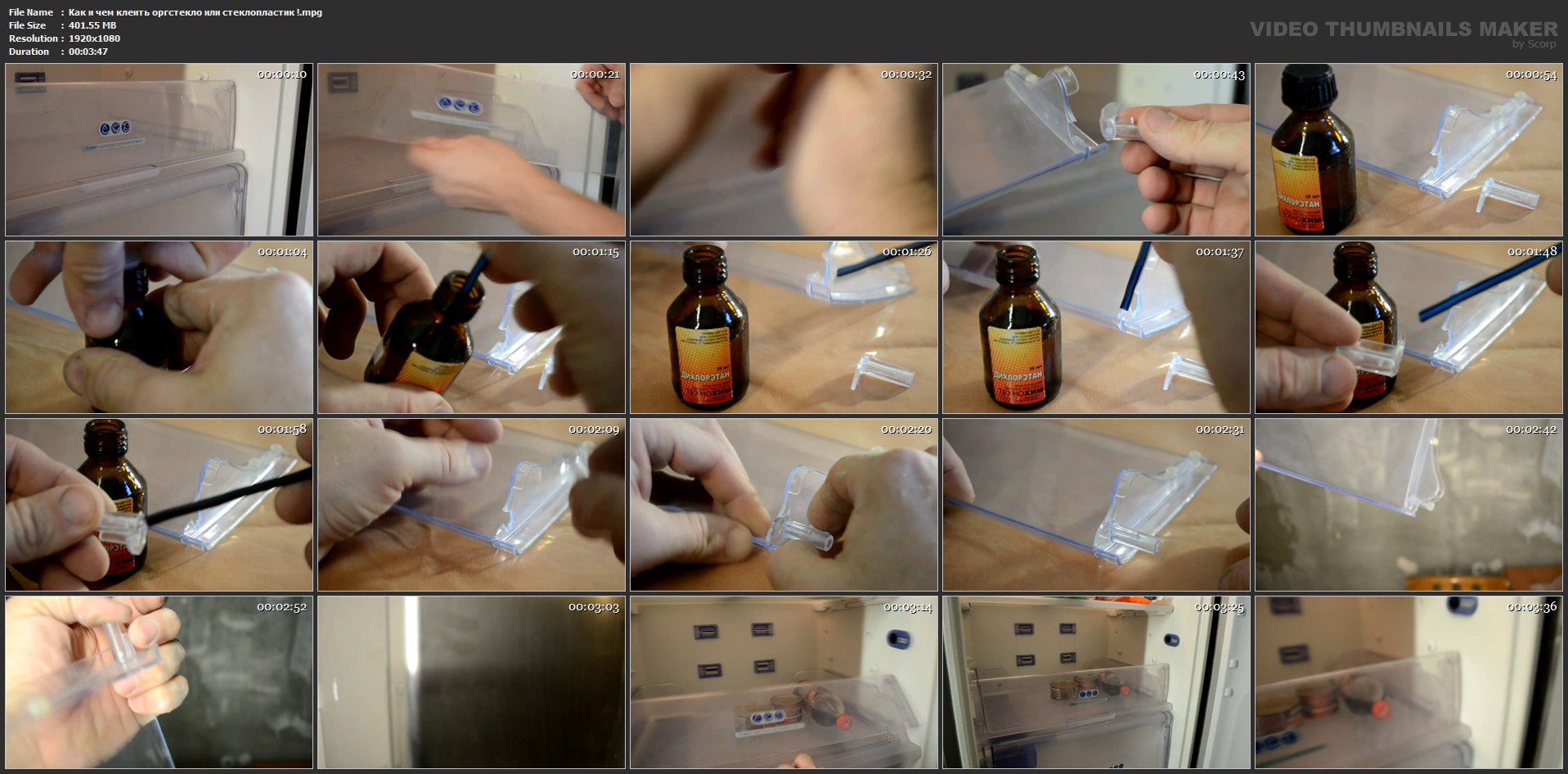

Dichloroethane

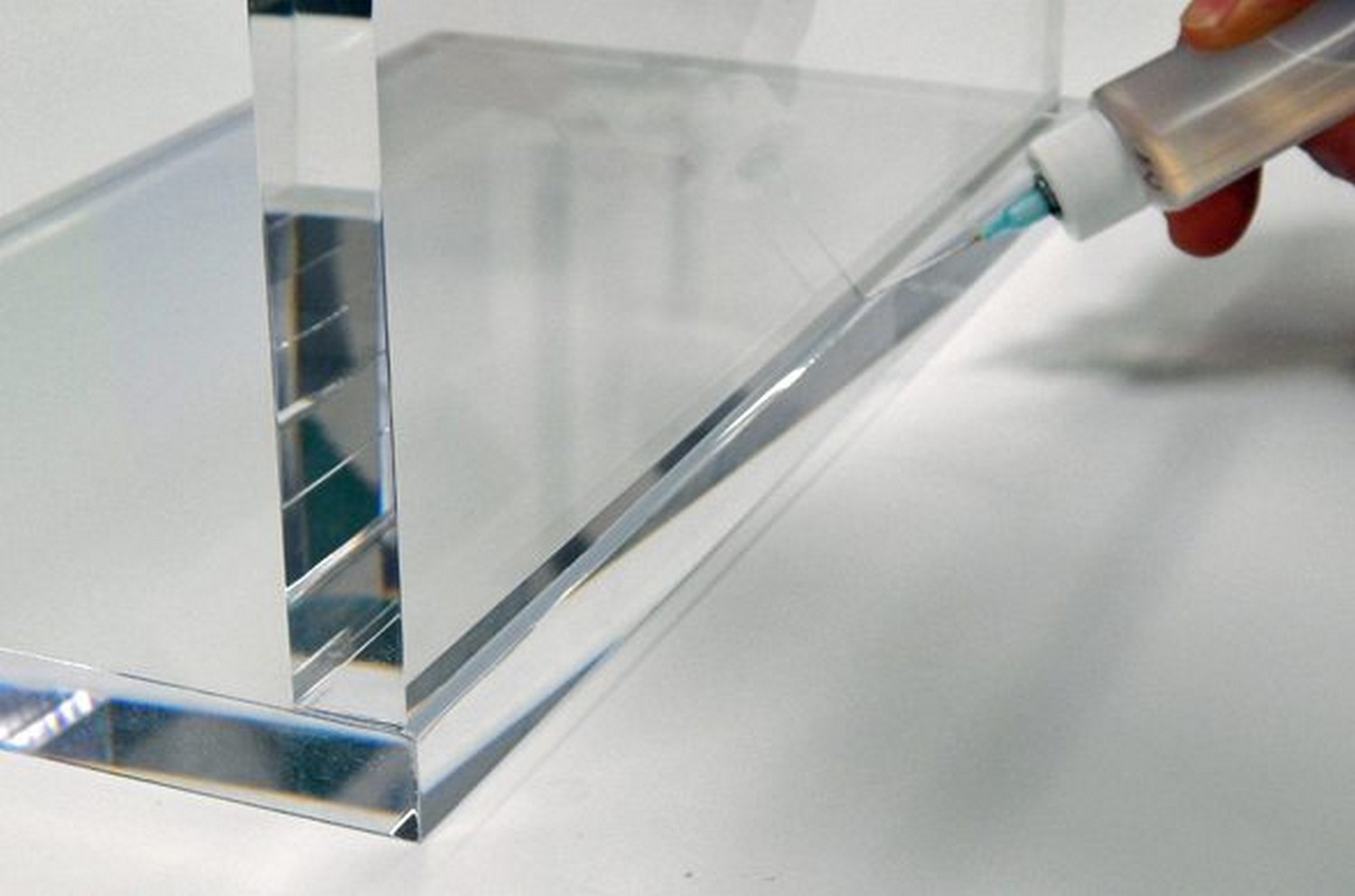

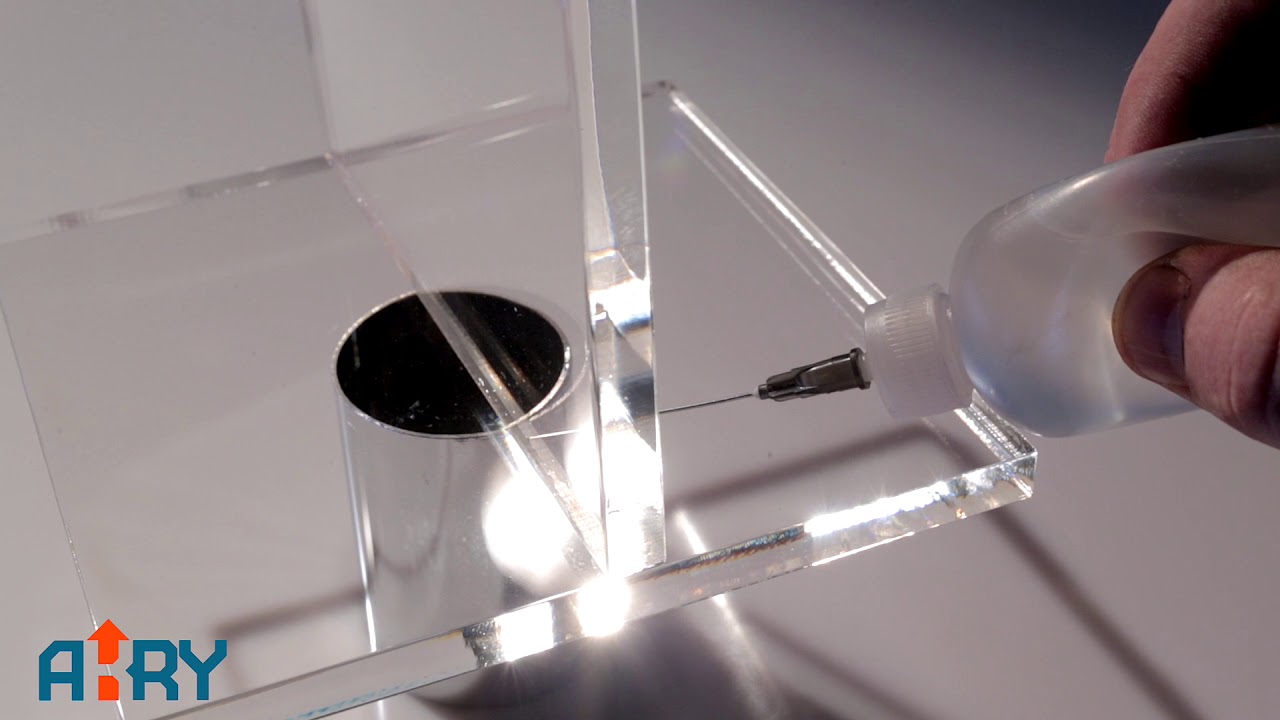

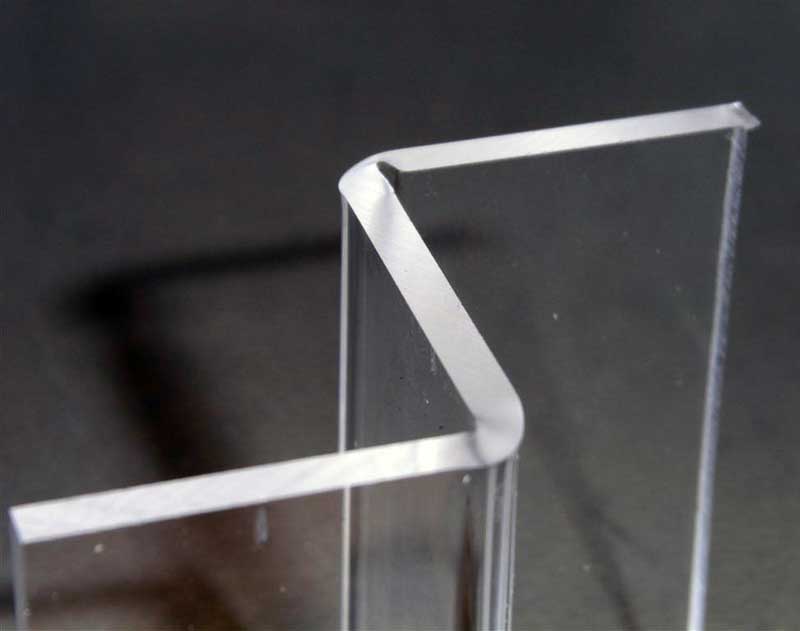

Budget replacement for expensive formulations. It is sold in stores of chemical components and stores of radio components. If the surfaces are perfectly smooth and even, they can be glued with dichloroethane without any additives. It is applied using a medical syringe into the gap between the parts to be connected. The seam turns out to be perfectly smooth, high transparency. If the surfaces are properly prepared, the seam will be bubble-free.

If the surfaces are not perfectly smooth, then there is another way to glue them together. A little plexiglass shavings (sawdust) are poured into a bottle with dichloroethane after dissolution, a thick composition is obtained, which can be applied with a spatula or wire.

Dichloroethane

In the room where they work with dichloroethane, it is imperative to have high-quality ventilation.

Vinegar essence

It is another inexpensive substitute for commercial pro formulas. Allows to glue plexiglass firmly enough.

Serious internal mechanical stresses occur on the folds of the parts, which can lead to cracking of the plexiglass.

Experts recommend using vinegar essence to glue small items that are not subject to heavy loads.

Colacril 20 and colacril 30 glue

The Colacril family serves as a functional replacement for the expensive Acrifix family of adhesives.

Colacril 20 is highly fluid and Colacril 30 is viscous.

Experts blend them to obtain the optimal consistency for each specific compound.

Compositions allow you to glue the parts and get a beautiful and even seam, transparent and without bubbles.

The disadvantage of the Colacril family in comparison with Acrifix is the formation of small cracks at the point of bending of the plexiglass, caused by internal mechanical stresses. At the same time, the appearance deteriorates, but the strength remains.

Seconds glue moment and Cosmofen

Most instant adhesives are cyanoacrylate based. Regardless of the type of packaging - in metal, plastic tubes or bottles with a narrow spout for application - they are very similar in their properties.

The general property is that they do not dissolve plexiglass, but create an intermediate adhesive layer.

Therefore, experts do not recommend using them for joints subject to any stress. The most they can do is to grab a small piece to a toy or decoration.

The adhesive layer is opaque, the junction is very noticeable.

Cosmofen

Dangerous! "Moment" can glue the skin of your fingers so that you have to see a doctor. Use of protective gloves is mandatory.

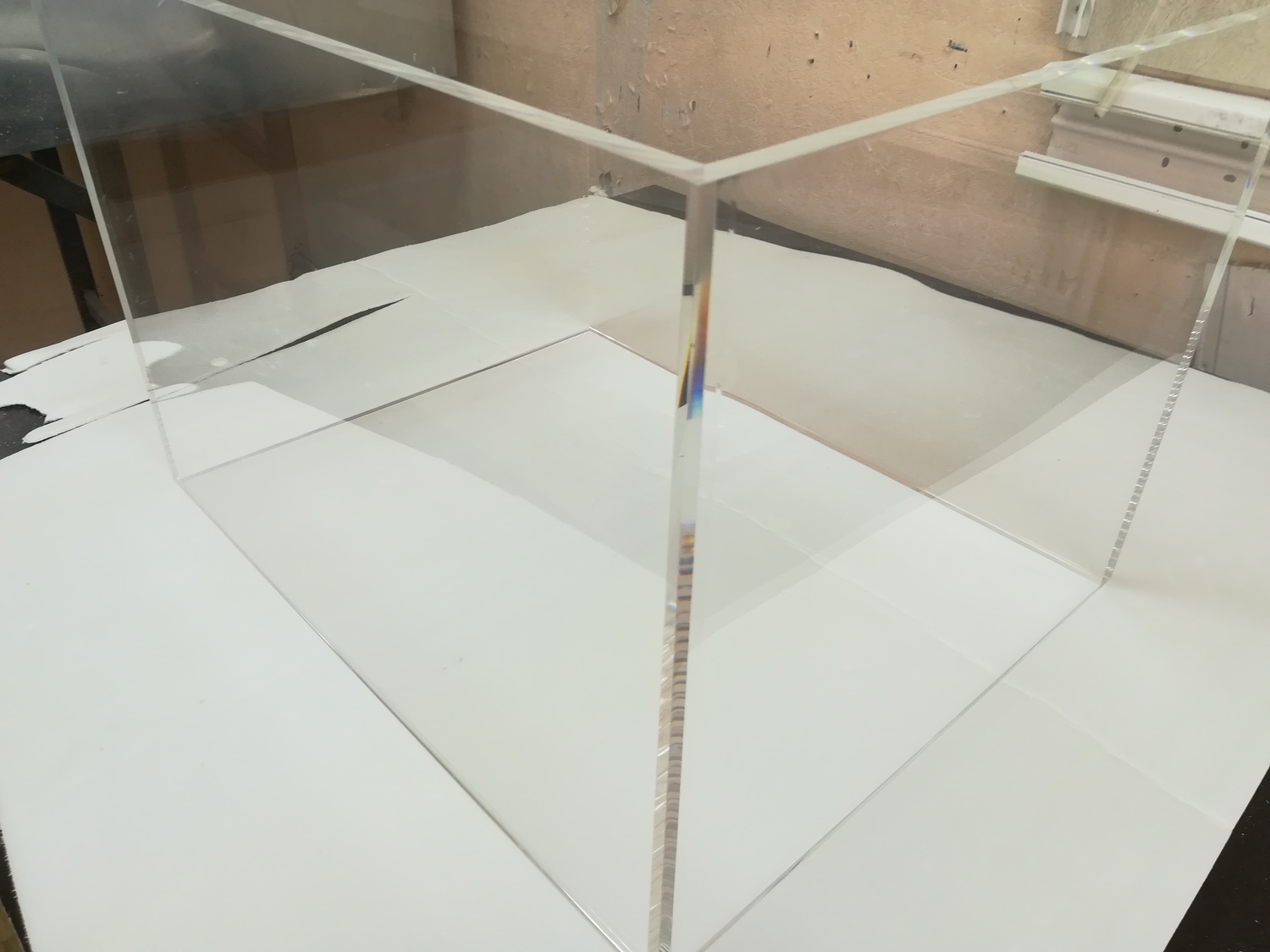

How to glue plexiglass together

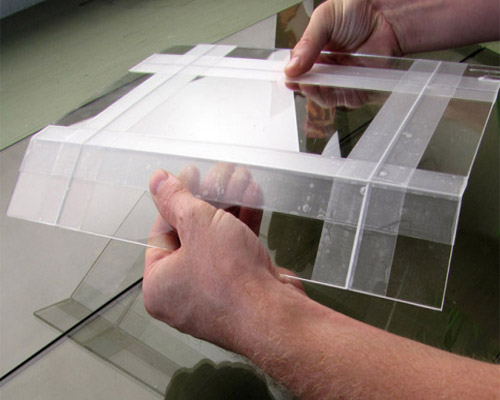

To glue plexiglass together, you need to study the important features of this process. You should first prepare the material, wipe it with ethyl alcohol and degrease the surface, this will provide better adhesion. The product must be clean and smooth.

Standard way

Plexiglas is usually glued using popular adhesives containing acrylic, solvent or epoxy. But to get a strong and durable seam, you need to do everything correctly.

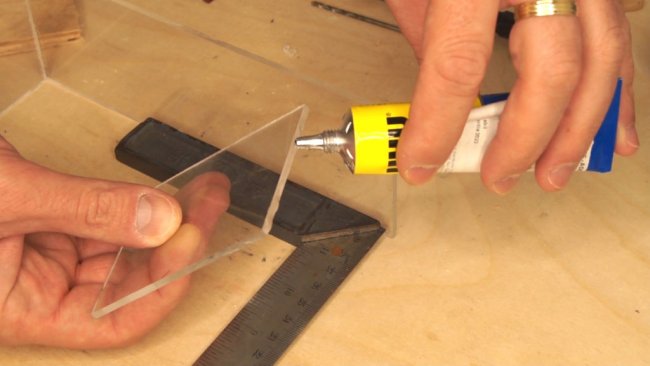

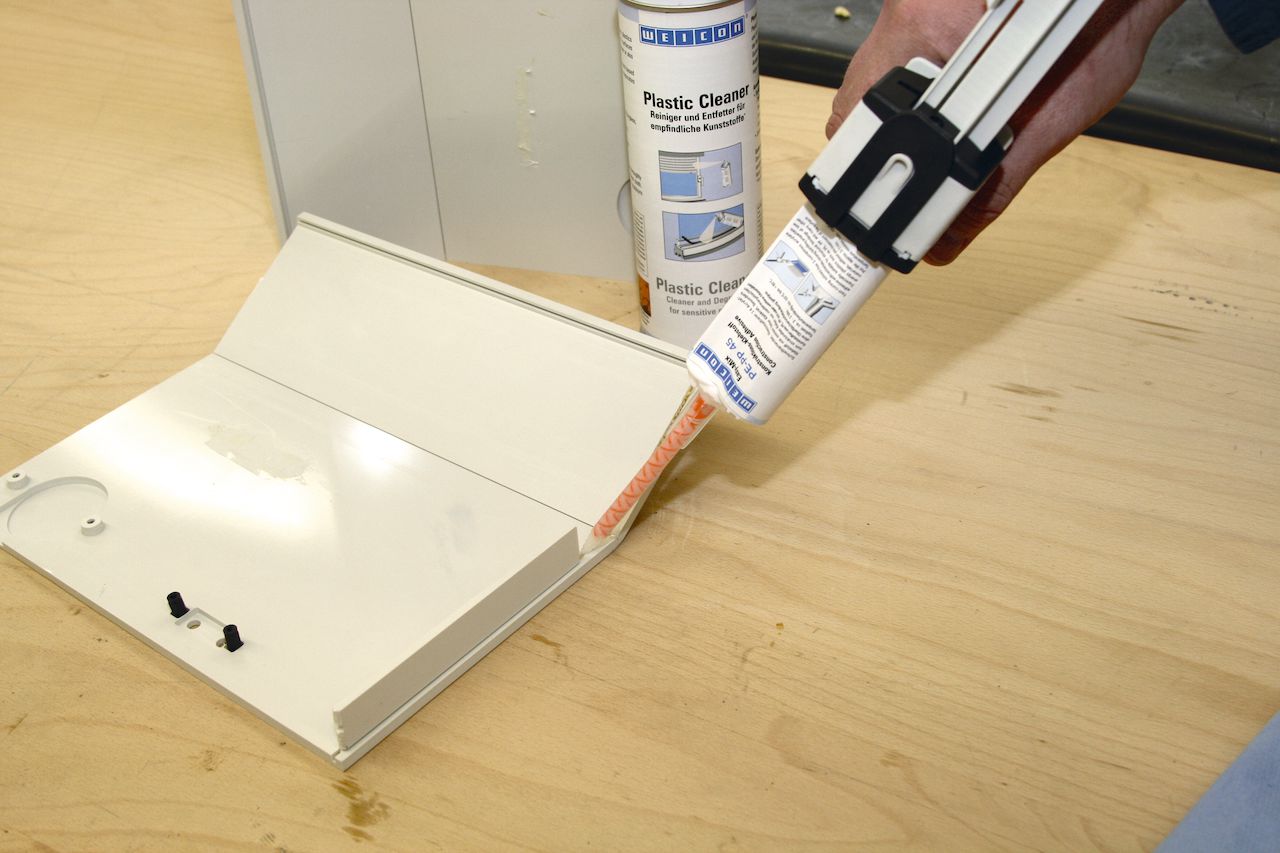

So how to glue plexiglass at home? The following instruction will help with this:

- The surface is degreased beforehand. A cloth or napkin is moistened with solvent or gasoline, and after the plane on which the glue will be applied, they are well wiped;

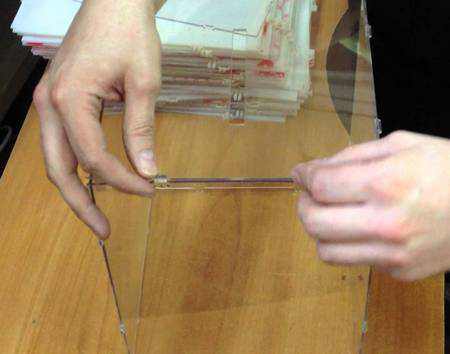

- Further, the elements of the product must be fixed, there must be a gap between them;

- The adhesive is applied to both parts in the form of a uniform layer. To make it convenient to apply the product, you can use a medical syringe. It is better to cut the needle a little so that the composition does not splash;

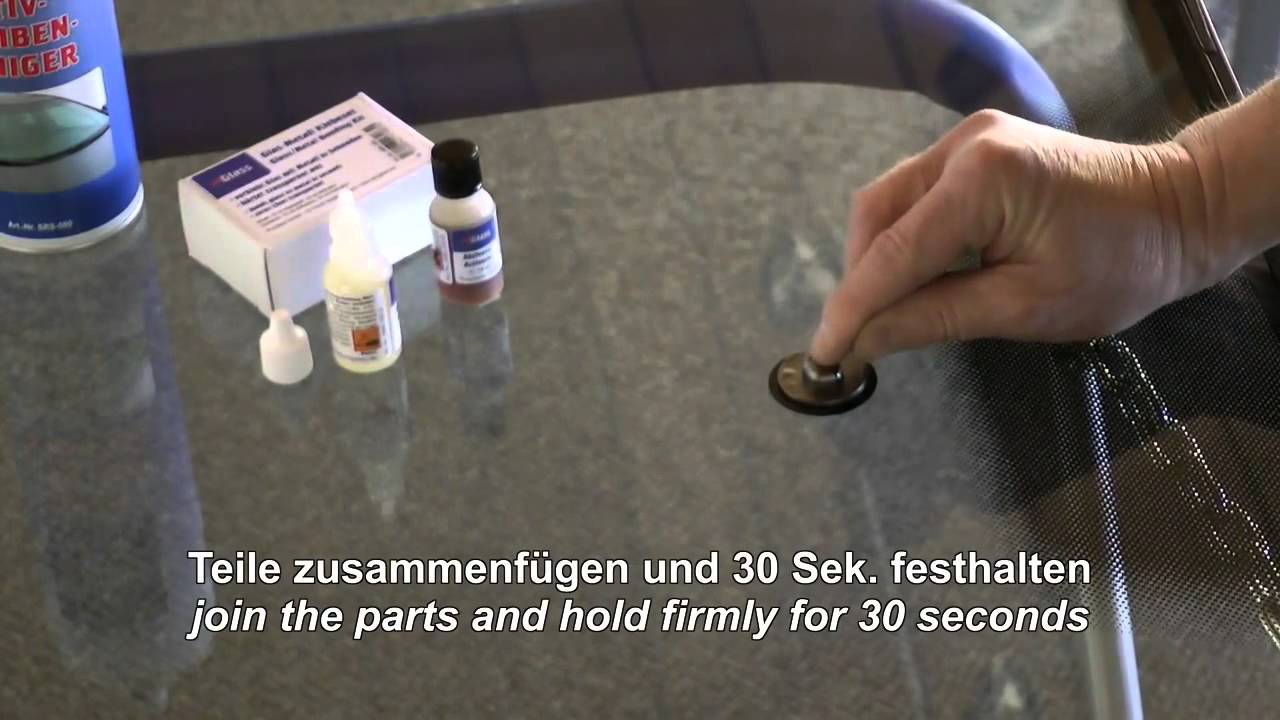

- Then the components are connected, tightly compressed until they are fully connected. For better fixation, you can install a load;

- In the squeezed position, the product should be kept from 1 to 30 minutes.

Vinegar bonding

At home, for fixing products, you can use an affordable and inexpensive tool - vinegar essence. Only concentrate is suitable for gluing, but even it cannot create a strong and transparent seam.

Plexiglas gluing with vinegar is carried out as follows:

- The liquid must be applied to the area of the edges of the product;

- After the edges are tightly compressed;

- The top layer softens, this is what allows you to create a solid seam;

- The products to be glued should be pressed down with a load and left for a day.

2> Types of adhesives

The variety of plastics used in everyday life corresponds to an equally wide variety of manufactured compositions and methods of their use.

How to glue plastic

To dissolve the surface layer of a material, it is necessary to break the chemical bonds between the molecules. For this, special substances are used, strong solvents. Each solvent is suitable for its own group of plastics, and it may not even leave a trace on material from another group. Each adhesive is based on such a solvent. In addition, the composition may include:

- a hardener to help dry it;

- filler - dissolved molecules of the substance for which the glue is intended.

One of the strongest solvents is dichloroethane. It is used to bond polystyrene and plexiglass.

Dichloroethane

Depending on the method of application, the funds are divided into several groups:

- liquid;

- contact;

- reactionary;

- hot melt adhesives.

Liquid

Liquids are widespread in everyday life, they are easily and simply used at home for gluing plastic with a porous structure. They are available in both organic solvent and water based. They are applied to surfaces that are pressed against each other for a time sufficient for the base to evaporate. After that, the adhesive layer hardens, forming a connecting seam. A typical example is PVA glue, which can be used to glue not only linoleum, but also wood at home.

Contact

Bonding takes place in two stages:

- the surfaces to be glued are lubricated with a thin layer, which dissolves the surface layer of the plastic, softening it and facilitating contact with another surface;

- after a few minutes, the parts are pressed against each other with force, the softened layers are mixed, the solvent evaporates and a seam is formed.

Moment for plastic

This is how Moment, BF-2 and others work. They can be used to glue polystyrene and other plastics at home.They contain toxic substances, so you need to work in a well-ventilated area and do not allow drops to get on the skin or mucous membranes.

Reactionary

One-component reactive agents dissolve the material to be bonded very quickly and harden just as quickly. These are such well-known brands as Secunda, Superglue and their analogues. The seam is strong and tough.

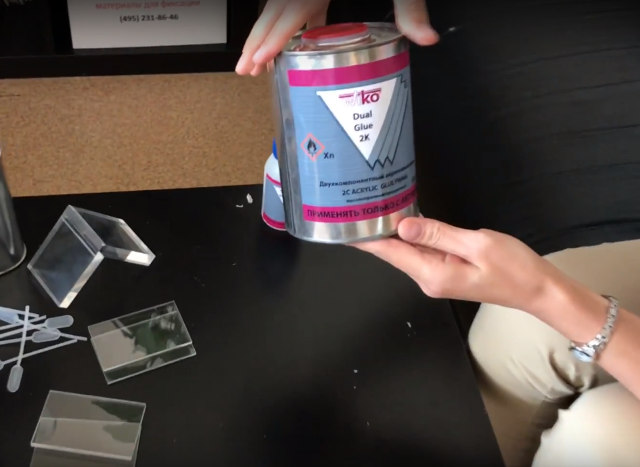

Two-component components consist, respectively, of two components stored separately from each other:

- hardener;

- fixer.

Two-component adhesive

The components are mixed immediately before use and applied to surfaces where the mixture hardens to form a compound. The base is epoxy or polyester resins. The seam at home is very durable. A characteristic feature is that complete hardening takes a long time, and the seam gradually increases both strength and fragility.

Hot melt adhesives

This group includes substances that show their properties when heated to 110-120 ° C. For use, a special glue gun with a heating element is required. Differs in the accuracy of application. In addition to plastic, they can glue wood, fabric, paper at home.

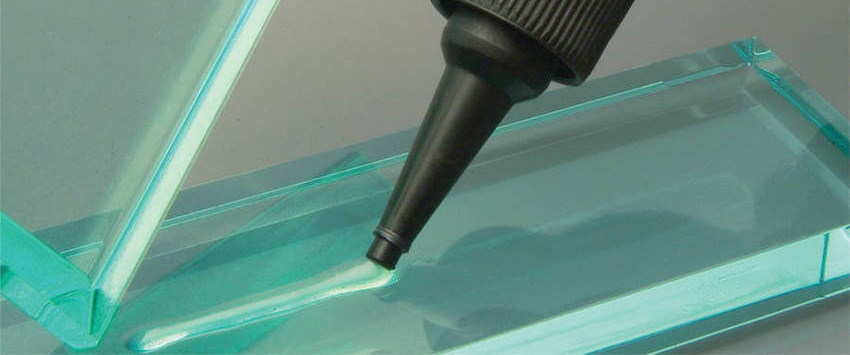

Glass Adhesive Requirements

Almost any type of adhesive can be used to glue glass at home. But it should be borne in mind that a number of requirements are put forward for the glue used to solve such a problem:

- Formation of a strong connection that can withstand significant loads.

- The transparency of the junction.

- Fast fixing in air.

- Good viscosity.

- Moderate fluidity of the composition.

- Elasticity.

- Wide temperature range of bonding.

- Good resistance to moisture.

- Environmental friendliness.

- Possibility of long-term storage.

Such requirements must be met by a good adhesive for glass, which will ensure a reliable connection.

How to choose a glue for glass

Glass has low adhesion properties. Therefore, the connection of such surfaces is difficult. The fragility of the material further complicates the task. For gluing glass objects, you need a special substance that has certain qualities:

Glass has low adhesion properties. Therefore, the connection of such surfaces is difficult. The fragility of the material further complicates the task. For gluing glass objects, you need a special substance that has certain qualities:

- High adhesion for connecting objects that experience significant mechanical stress in everyday life.

- Transparency so that the resulting joint becomes invisible. When joining parts of small size, this quality is even more important than strength.

- The ability to dry in a short time.

- Increased density so that the resulting joint acquires elasticity.

- The ability to withstand significant temperatures, as well as frost and heat.

- The ability to repel moisture when in a humid environment or when operating products in atmospheric conditions.

- Environmental friendliness and safety for nature.

It is optimal to choose transparent means for work. They can be used to easily neatly connect small parts of the decor. It is also worth considering the physical parameters: transparent compositions are suitable for combining smooth objects, but if the surface is corrugated, a stronger formula is required. When you need to connect parts of the aquarium, choose a product that does not contain antibacterial components that will not harm the fish. For the connection of painted surfaces, strong compounds are chosen.

Polymer glue

The hardening of such a composition is carried out by exposure to ultraviolet radiation. In this case, gluing is possible only if at least one of the parts to be joined is light. To improve the process, a special lamp is applied to the aligned planes until the seam hardens. When glued with this substance, a transparent joint is obtained that can withstand temperature changes, moisture and mechanical stress.

The hardening of such a composition is carried out by exposure to ultraviolet radiation. In this case, gluing is possible only if at least one of the parts to be joined is light. To improve the process, a special lamp is applied to the aligned planes until the seam hardens. When glued with this substance, a transparent joint is obtained that can withstand temperature changes, moisture and mechanical stress.

Important!

Such a substance is used to work with jewelry, shop windows and stained glass windows. The connection is very strong.The only drawback of the glue is the slow hardening rate.

Silicate glue

The main ingredients of this substance are sealants and silicones. It is often used in construction. Due to the large number of shades, the connecting joint is made invisible or, on the contrary, emphasizes its decorative effect. This composition is often used in needlework. In this case, for a high-quality connection, you need to apply a larger layer.

Cyanoacrylate glue

This composition is also called cold welding. It has excellent adhesion and fast drying speed. The result is a strong and very durable seam. Cyanoacrylate glue is used to bond painted objects or to glue glass to other surfaces: metal, wood or plastic. The disadvantage of glue is that it breaks down when exposed to water.

Household adhesives

This group of adhesives includes PVA, "Moment", BF-2 or BF-4. In this case, the bond will be the stronger, the more the surfaces are squeezed after applying the adhesive. It is difficult to connect objects with BF glue, since this product requires a high temperature, and the glass may not withstand it.

This group of adhesives includes PVA, "Moment", BF-2 or BF-4. In this case, the bond will be the stronger, the more the surfaces are squeezed after applying the adhesive. It is difficult to connect objects with BF glue, since this product requires a high temperature, and the glass may not withstand it.

Important!

When using Moment glue, you must first withstand the lubricated surfaces for about 20 minutes and only then connect. If there is no time to wait, use the "Super Moment" tool.

Heat Resistant Glass Adhesive

I use a similar tool if the parts after connection will be regularly exposed to high temperatures. Such connections can be in an oven, electric kettle, or kitchen stove. To prevent the destruction of the glue seam, special reinforcing additives are included in the composition.

Glass glue

Perhaps, you need to start by choosing an adhesive for gluing glass. Here, first of all, it should be taken into account which glass parts are to be joined together. For example, in order to glue the glass for an aquarium, you do not need any glue, but with a good ability to resist moisture.

This criterion is fully met by silicone glue for gluing glass. Only when it comes to an aquarium, then the adhesive composition should be in this case only on a vinegar basis, without the content of harmful substances.

In all other cases, UV glue is quite suitable for gluing ordinary glass parts that will not come into contact with moisture. If you need to glue glass and metal together, then you should know that there are special adhesives for these purposes.

How to make glue

You can also make glue for gluing glass at home and with your own hands, there is nothing absolutely complicated in this. This will require the following components to choose from:

- Ash and bone glue;

- Casein and silicate glue;

- Wood ash and wood glue;

- Chalk, drying oil, rosin, cement and beeswax.

So, first things first. To make the simplest glue for joining two glasses, mix ash and bone glue together.

In this case, it is important to take into account the technology of gluing glass in this case, since its surface must be well heated

A more complex glue for glass can be made by mixing casein and silicate glue in proportions of 1 to 10. Well, if you need to glue glass and wood, then you can't do without a special adhesive, which is made from wood ash and wood glue.

Conversely, in order to glue a glass for an aquarium or a vase, for example, there is a universal homemade glue. To prepare it with your own hands, you will need to make the following composition:

- 10 grams of beeswax with 50 grams of chalk are poured into a small metal container;

- Then 100 gr is added here. rosin and 50 gr. drying oils;

- The whole thing is heated to a boil, after which the mixture is cooled and about 25 grams is added to it. cement.

On this, the glue for glass is almost ready, it remains only to mix it thoroughly, after which you can safely use it in work.

How to glue at home

Recommendations on how to glue plexiglass at home will help to get a high-quality, invisible, reliable and durable seam:

- Thoroughly degrease the surfaces to be glued with a cloth soaked in gasoline.

- Apply adhesive to both bonded areas. It is more convenient to do this with a medical syringe - fill it with glue, having previously grinded off the tip with a bar at an angle of 90 degrees. Grinding is necessary to prevent splashing of the compound towards the bevel of the needle. Pour the glue very carefully into the joint between the slightly pressed together and securely fixed parts.

- Press the surfaces firmly against each other and provide a tight squeeze until the compound sets, this can take from 2 minutes to half an hour, depending on the amount of glue poured in. The main thing is that the product should dry and not spread over the surface after you turn the product over.

In some cases, it becomes necessary to glue plexiglass to metal or wood.

For a high-quality connection of a metal part and plexiglass, the following are suitable:

- glue brand 88;

- dichloroethane;

- "Liquid Nails";

- glue "Moment for iron and plexiglass".

When gluing plexiglass to wood, it is important to get not only a strong seam, but also an inconspicuous one, since otherwise, the attractiveness of the product will be lost. For this reason, the choice of glue must be taken as seriously as possible.

Suitable for gluing wooden parts with plexiglass:

Organic glass (plexiglass) is an artificially produced polymer material that was synthesized at the beginning of the last century. Due to its properties, it is successfully used in various sectors of the economy and industry. One of the most common options in everyday life is a home aquarium, since plexiglass can withstand heavy loads compared to ordinary glass.

The main advantages of organic glass in comparison with the silicate version:

- high mechanical strength (about five times more than that of ordinary glass);

- easy to process and thermoplastic deformation without loss of quality;

- in comparison with standard glass, it transmits ultraviolet and X-rays better;

- about three times lighter than ordinary glass with the same thickness;

- does not crumble into dangerous sharp fragments in case of complete damage.

These properties allowed plexiglass to firmly establish itself as an alternative material to ordinary glass.

How to glue plexiglass: types and brands of the best products

If you do not have reliable information about the type of polymer, we will select an adhesive for plexiglass with the expectation that it is really PMMA. In principle, if you have already dealt with gluing plastic, then there will be no intrigue in the question of how to glue plexiglass for you: the guarantee of the strength of the seam is still in solvents.

A small educational program for those who have not previously dealt with gluing plastics: the most reliable option for gluing polymers is to dissolve the edges to be glued to a viscous state with the help of solvents and dock them until they dry. Thus, the product is essentially monolithic, and the seam holds even when the product begins to crack and break in other places.

How to glue plexiglass so that you are pleased with the result? There are several options here.

Factory glue

Of course, the most convenient formulations for working with plexiglass are various types of factory glue. And really, why look for something to glue plexiglass, and invent something when everything has already been invented for us?

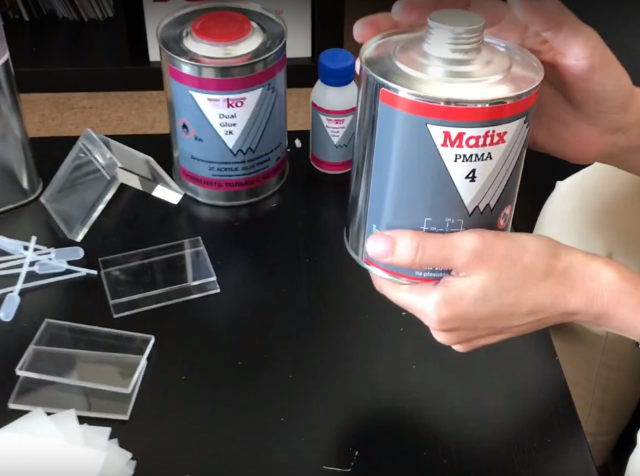

- Artifix is a reactive adhesive, which is currently considered the highest quality and most convenient when working with plexiglass.The seam obtained with its help is strong, transparent and durable, and the toxicity is lower than the toxicity of solvents if there is no dichloroethane in the composition (there are variations without its addition). True, it is better to use this glue for plexiglass if you have a small production: it is not very profitable to lay out about 6-8 thousand rubles per liter package to glue the model. The most commonly used numbers are 116, 117, 106, and 190, depending on the viscosity grade you want.

- Colacril is a slightly more budgetary replacement for the previous glue, but judging by the reviews, Artifix cannot be outdone. The most commonly used numbers are 20 and 30. Different numbers can be mixed to obtain the desired viscosity.

- Cosmofen for acrylic glass is a cyanoacrylate-based superglue, also called liquid plastic. That is, a monolithic connection will be obtained only if the acrylic of the glue matches the acrylic from which the plexiglass is produced. Most often it is used when working with plastic windows: there it fits perfectly. In other cases, you will still get a pretty strong and durable seam, and for not the most money. Please note that Cosmofen may require UV curing!

Solvents

You can make your own glue with a completely identical polymer, and this can be done using solvents. Yes, it will set a little slower, but the result will not be worse!

- How to make the perfect glue at home? Dissolve some of your plexiglass shavings in dichloroethane! Yes, the substance is quite toxic and it is better to work with it in the fresh air, but the parts will stick to each other just tightly!

- If EDC is not found, you can look for tetrohydrofuran. Depending on the nuances of the composition, it sticks together some types of plexiglas even better than the famous dichloroethane.

- In desperate situations, you can glue the pieces together with formic acid, glacial acetic acid, or even ordinary vinegar essence. Not with table vinegar, but with concentrate.

In general, you can glue the parts without diluting the chips - if you apply a solvent to both parts, connect them and fix them until dry, the seam will again turn out to be monolithic.

Contact adhesive

What about the other options? There are a lot of other types of glue, which, no, no, yes, they will advise on some resource. Unfortunately, you shouldn't count on a really high-quality seam and gluing "for centuries" with them, and that's why.

- Sometimes epoxy resin is recommended for gluing plexiglass, because it really holds the joint well, and even completely transparent. But it just connects the two parts of the plexiglass without turning them into a monolith.

- Adhesives like "Super Moment" do not change the structure of the material and create a very fragile seam: they can only be used for gluing together the elements of the product, which is practically unloaded. In addition, when using them, the plexiglass becomes cloudy and the seam becomes very noticeable.

- The usual "Moment" and similar compositions will not last long either: they can only glue what you are not going to actively use, and that will hold up mediocre.

What is the glue for plexiglass

Adhesive for plexiglass is chosen depending on the wishes of the consumer himself.

new one-component Wiko Plexy adhesive for plexiglass (plexiglass)

There are two types of glue used to repair, restore the integrity of products:

An adhesive mixture of acrylic with a solvent, used for extrusive (cast) acrylic (it is also plexiglass, plexiglass). Professional glue. During the connection of two identical components under the influence of the third active substance, a strong connection of the bases occurs due to the dissolution of the surface molecular layer of plexiglass. The gluing is monolithic. There are some nuances.Although this group is intended directly for bonding plexiglass (plexiglass), not all adhesives in this group will be able to bond all types of these materials.

This is very important, there are exceptions, so you need to be careful when choosing a composition for certain brands of PLEXIGLAS, which is the general name of the trademark.

Two-component adhesive based on epoxy resin or cyanoacrylate. With their help, you can quickly glue individual parts

Suitable in some cases, and can be used for a small area of work.

Household adhesives for joining plexiglass are divided into two groups according to the principle of action:

- The former include active substances that are applied to the joints before gluing. The surfaces are melted. The master glues them while the material is liquid. After drying, a monolithic seam is formed.

- Compositions forming a connecting layer between the individual parts. A less durable seam is formed than during the melting of the surfaces to be joined.

In order not to be mistaken during the selection, it is necessary to consider the most popular products for gluing plexiglass.

new two-component adhesive Wiko Dual Glue for plexiglass (plexiglass)

Acrifix 116 glue

Acrilfix plexiglass adhesive, which produces high-quality substances that are used when joining various materials. Product 116 is a transparent formulation, a thick mixture (more viscous than Acrifix 117), which is similar in consistency to a flowing resin. Packaged in 100 ml tubes.

Used for gluing rough parts with uneven edges. Effectively fills in the voids caused by chips, creates a homogeneous surface. One component adhesive. It hardens by evaporation and absorption of solvents by the parts to be joined.

Acrifix 117

If a person does not know how to glue plexiglass, any experienced craftsman will call him Acrilfix 117 glue. This mixture is considered the best for gluing acrylic-based materials. He has a number of strengths and weaknesses.

Advantages:

- High strength of the finished seam.

- Dries quickly.

- The lowest level of toxicity compared to analogues.

- Long shelf life.

- Penetrates small cracks, fills them to the ground.

- The transparent seam is practically invisible on the total area of the glued surface.

Disadvantages:

- Very high price.

- Rarely comes across on the shelves of hardware stores.

- It is impossible to buy a small capacity. The standard package size is 1 liter.

Experienced craftsmen recommend mixing Acrilfix 117 with 116 (10/1) in order to reduce the consumption of expensive glue. In addition to this, the mixture better fills the voids of microcracks. The quality of the seams does not deteriorate.

Colacril 20 glue

When gluing plexiglass, craftsmen often use Colacril products. It costs less than Acrilfix, however, its properties are close to expensive mixtures. Item 20 is a flowable adhesive that can be used to make transparent, strong, durable seams. Similar in its actions to the previous brand, but cheaper.

Colacril 30

It differs from the name 20 - in consistency. It is thicker, so that 30 is mixed with 20 to get the desired thickness of the adhesive. The lack of adhesives from this company is that they crack at the bend. This violates the integrity of the connection, degrades the appearance.

BRAUBERG glue

This transparent adhesive is universal for a large number of different materials, differing in their structure. Sold in a package called a show box. Glues and joins wood, metal, PVC of any hardness, polystyrene, porcelain, ceramics, plexiglass, glass. Also glues rubber, felt and leather.

Advantages:

- Versatility.

- Water resistance.

- Elasticity of the sealed seam.

- Bonds porous materials.

- Glues plexiglass and plain glass.

- A symbolic price.

Execution technology

Now let's look at how to properly glue plexiglass plates with other parts:

- Degrease the surface with a cotton swab moistened with gasoline.

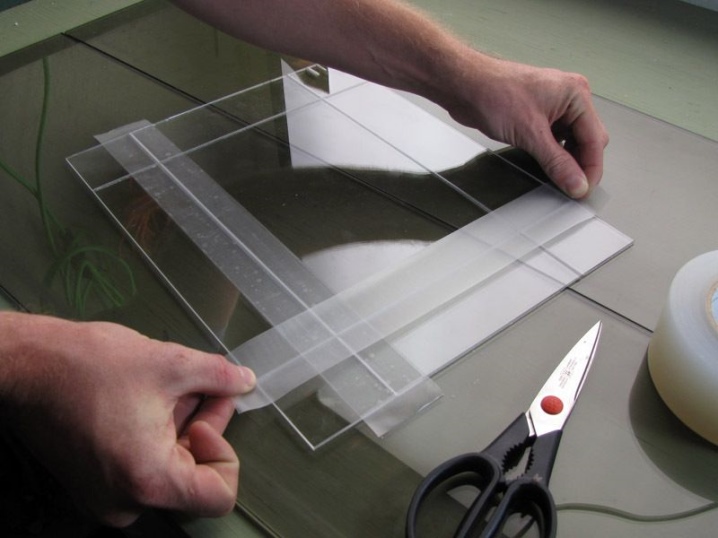

- If you are afraid to stain the plexiglass, cover the entire surface with a film or masking tape, except for the joint.

- Apply glue. To make the seam even and neat, this can be done with a medical syringe. For a wider band, remove the needle. If you need a thin seam, grind off the bevel of the needle with an abrasive bar, otherwise the glue will splatter to the side.

- Connect the parts and fix them securely until the glue is completely dry. Thick plates can be secured with a vice or clamps, thin ones - wrapped with elastic bandages. Drying may take from 2-3 minutes to half an hour, depending on the brand and the thickness of the adhesive layer.

"Dichloroethane" is often used for gluing plexiglass plates. This substance provides the highest bond strength, the glue line is transparent and unobtrusive. A number of experts recommend pre-adding to the "Dichloroethane" shavings of the material to be worked with. This increases the viscosity of the adhesive, but at the same time increases the drying time. It takes about three days for the chips to completely dissolve, after which the substance can be used within a month.

Dichloroethane forms an extremely strong seam on the plexiglass parts

When working with any glue, do not forget about safety rules. Use protective gloves, goggles and a respirator. Depending on the toxicity of the adhesive, carry out the work either in a well-ventilated area or outdoors, away from sources of fire. Try not to store even sealed products in the living area, especially in places where children can find them.

The main problem when gluing plexiglass

When the result of gluing is far from what they would like to see, people in most cases blame the glue for it. Because of this, on the forums for working with plexiglass, you can stumble upon real verbal skirmishes! But the fact that the glue advised by someone did not suit you is the last indication that glue - the only variable that is 100% identical in your cases - is the culprit of the failure.

When we talk about a thing that it is "plastic", in fact, plastic may be one of hundreds of polymers or their mixtures - we have the same situation with plexiglass. Depending on the composition of this plastic, the same glue will give different results, therefore, unfortunately, there is no escape from the share of risk, experimentation and selection of the ideal glue empirically.

How to glue plexiglass, which adhesives are suitable

Before you start gluing plexiglass, you need to understand the features of the material. Depending on the type, the cooking process includes casting or extrusion. It is a synthetic material that is made from acrylic resins by adding a number of other elements to it. The result is a reliable, durable and transparent material. But, despite the high indicators of strength, objects from it can break, due to active use. Therefore, it is worth knowing the better to glue the acrylic.

Plexiglass is a synthetic material that is obtained from acrylic resins, adding a number of other elements to it.

Types and brands of glue

The glue for acrylic glass is chosen based on the needs of the master. There are 2 types of adhesive solutions for gluing plexiglass:

- Mixtures of acrylic with thinner. Suitable for professionals. The composition acts on the material, as a result, the top layer melts and a strong connection of the parts occurs. However, this view is intended only for certain types of material;

- Two-component composition based on epoxy or cyanoacrylate. Helps to glue individual elements, can be used for gluing small items.

If the work is carried out at home, you can choose how to glue the plexiglass from 2 options for the principle of operation:

- Active substances, the principle of their work is to melt plexiglass. And the connection is performed at the moment of its liquid state, they help to glue the parts tightly;

- Adhesives that create a film between parts, this method does not provide as high reliability as the previous one.

The glue for acrylic glass is chosen based on the needs of the master.

Plexiglass can be glued with products of the following brands:

-

Glue "Sekunda" is a two-component solution, components are produced in syringes, before work they must be mixed together. Differs in fast setting and viscosity, it can fill cracks, it does not spread, the composition will not be visible. Withstands exposure to water, acetone, gasoline, oils;

-

Rexant glue dichloroethane, produced in China. It has a transparent consistency, dissolves the material on which the parts are then glued. Does not require preliminary degreasing of the surface, withstands the influence of water, does not change the color of the material;

-

ACRIFIX 1S 0116, when joining, it is not necessary to squeeze the elements to be glued, viscous, cannot cope with filling the entire depth of the crack, air may remain inside the product. The initial setting occurs in a minute and a half;

-

Sika Sikaflex-295 UV is a mastic used for the assembly of acrylate glazing. Cures when exposed to ambient humidity and is used as a sealant for sealing imperfections in maritime transport.