Peculiarities

Moment is a product created by the German company Henkel, which has over 130 years of successful experience in the market of industrial and household chemicals. The latest equipment, technologies, constant modernization of formulations, focus on environmental protection and strict quality control help them to be the first.

Basically, the brand produces adhesives, polyurethane foams and sealants. Most of their products belong to the "Moment" line. Moisture control products are formulated with many components to help you get the most out of your tasks.

General characteristics:

- The main component is rubber, which provides the viscosity of the mass, thanks to which the sealant can be applied to any deformable surface.

- The composition includes all kinds of amplifiers that provide varying degrees of strength, as well as vulcanizers that are responsible for consistency and plasticity.

- For more reliable adhesion to surfaces, adhesion primers are added.

- Various fillers add volume and color to the composition.

- For additional ductility and elasticity, silicone plasticizers are added.

- Antifungal additives protect surfaces from mold growth.

The purpose of the sealant is to protect against moisture and drafts, tight adhesion of parts, to prevent leakage of water or other substances.

Certain factors help Moment sealant in this task:

- Combination with all surfaces, strong adhesion to all materials.

- The sealant tolerates very low temperatures (up to -40 degrees) and high temperatures (up to +100 degrees).

- The service life of the supplied seal is about 10 years.

- High plasticity, which allows the substance to have the dynamics of deformable materials.

- It does not collapse from sudden temperature changes.

- UV resistance, that is, the substance is not afraid of direct sunlight.

Moment, like a protective coating, has some minor drawbacks:

- The sealant cannot be painted over.

- Pungent odor in some products.

- At low or high temperatures, the cooling time of the upper layers can be up to 5 hours.

Despite the combination with a large number of materials and surfaces, the sealant is not recommended for the treatment of metals prone to corrosion, natural stones, plastered surfaces, concrete and cement.

How to accelerate polymerization?

Professional installers know a few tricks to speed up sealant cure. Here are some of the easiest ways to implement:

Provide maximum ventilation of the premises. On fine days - open wide the windows, in cloudy and rainy weather - use the fans

But it is important to ensure that no dust settles on the sealant.

Heat the air in the room to a temperature close to the maximum (+ 40 ° C). An electric heater is suitable for this.

But you should not warm up the joint with a hairdryer. Heating will be uneven, so different parts of the mass will harden at different rates. This will adversely affect the reliability of the seam.

Spray the joint from time to time with a spray bottle. Moisturizing will speed up the hardening process.

If you need to seal the seams on the window frame with a sealant, you will have to dry the composition with the windows closed. To prevent the frames from sticking tightly, after application, the composition is covered with foil. The paste will dry out within 2-4 seconds, but to achieve optimal results you can only wait patiently.

These simple methods can shorten the cure time of the sealant by a few hours.Every hour won will allow you to finish work faster and start enjoying the fruits of your labor.

Peculiarities

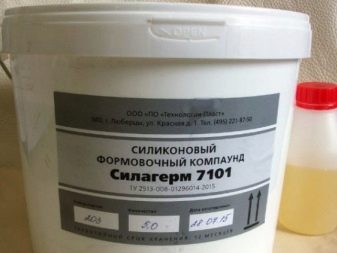

Universal Moment is a popular sealant that consists of many components.

And these are such substances:

- polymer silicone;

- thixotropic silicon oxide additive;

- the composition of such a sealant includes acetoxysilane;

- antifungal component.

In the markets today, you can find a variety of adhesives of the brand "Moment". And also this company produces polyurethane foam and self-adhesive tape.

The main features of Moment sealants are:

- plasticity of the material after solidification;

- increased rate of adhesion with the processed material;

- resistance to temperature changes and resistance to mechanical stress;

- not affected by moisture;

- long term use of the surface after treatment with the composition;

- cost that is low;

- resistance to external influences;

- and also the sealant meets all hygienic requirements and environmental standards.

The advantages of a high-temperature sealant are difficult to overestimate, it has a short drying time, it is colorless, which makes it suitable even for mirrors. Technical characteristics make it possible to use heat-resistant material in the bathroom.

Has "Moment" and disadvantages, but they mainly relate to the very surface treatment, which is not prepared for work.

Peculiarities

On the shelves in the hardware store, you can find a large selection of products from the German company Henkel, which has been dealing with goods for construction for over 130 years. Thanks to the latest equipment and constant innovations, the company has been at the forefront for a long time and produces a large number of necessary and irreplaceable goods.

To date, Henkel has produced about 200 types of products, a significant part of which are Moment sealants and adhesives, polyurethane foam and self-adhesive tapes.

When buying Henkel sealants, you can be sure of their quality. Other manufacturers often supplement their product with various additives. Outwardly, this is not reflected in any way, but the service life when processing with such a product will be much lower. All the company's products have only the necessary ingredients in their composition, so there is no need to fear for the quality of the products, the sealant will not lose its properties during operation.

It is difficult to imagine how it was possible to do without materials such as sealant, because they have a number of advantages:

- have high adhesion to many materials;

- greater elasticity;

- the material is resistant to negative manifestations of the environment, UV rays, it has increased resistance to fungi and mold;

- withstands temperatures from -60 to +350 degrees;

- increased resistance to moisture;

- low cost;

- can be used on fragile parts;

- long service life, have high strength, does not wear off;

- environmentally friendly.

This material has undoubted advantages, but one should also warn about its shortcomings:

- it is difficult to work with a sealant on wet surfaces, it adheres poorly to the surface;

- not all types of silicone are paintable;

- at low temperatures and high humidity, the time for solidification increases;

- it can be difficult to work with certain surfaces, for example, with polycarbonate and polyethylene.

Usage Tips

Before you start using Moment silicone sealant, you should read the instructions, since different types of insulators have their own characteristics. It is recommended to wear gloves to protect the skin from the substance.

Accuracy and consumption depends on correct use, which assumes a standard procedure and some nuances:

- The surface to be applied must be cleaned of dirt and dust.

- When sewing seams, it is worthwhile to limit the edges with duct tape for a more accurate result.

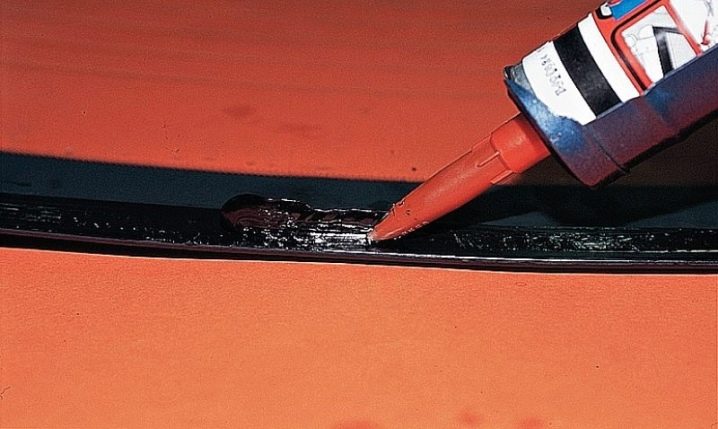

- Put a special assembly gun on the tube.

- Remove the retainer. Punch a hole with the back side.

- The end of the tube can be cut to the desired size based on the size of the seam. It is better to do this obliquely, so the substance will flow out more evenly.

- Begin to gently apply the silicone while holding the tube at a 45-degree angle.

- The thinner the layer of the substance, the faster the silicone will dry.

- The sealant dries completely in 24 hours, and a hard film on the surface can appear in 20 minutes.

It is necessary to apply the substance close to the surface, this will provide maximum adhesion.

It is better to remove excess substance immediately with a spatula or rag.

If the sealant has dried, but its excess remains, you can use white spirit or special substances to remove silicone

You can also try peeling off the cured silicone, but there is a high risk of scratching the surface.

Pay attention to the expiration date of the sealant, if it has expired, the substance will lose its adhesion.

Where is it used?

Any breakdown or minor repairs in the house are not complete without a sealant. In every room there is a job for a given tool. It can be used to seal joints and seams, it is suitable for work in the shower room and pool, an irreplaceable assistant for the bathroom and kitchen. Has antifungal and antimicrobial effects.

It is used for sealing windows, installing mirrors. This is an excellent restorer, it is used when repairing tiles during installation. Moment glue or sealant is used quite often, it is used when sealing joints in an aquarium or when sealing mirrors, in industry.

Due to its qualities, the product is suitable for sealing pipe joints, sealing joints, fixing plumbing fixtures to the wall. Sanitary bathroom sealant will become an indispensable tool.

One-part polypropylene adhesive sealant will help you to bond tough plastic surfaces such as polypropylene. Silicone is used for thermal insulation of any premises.

With this material you can:

- fill the seams and cracks in the bathroom, toilets, in the kitchen;

- to carry out sealing of window structures and doors;

- glue a mirror in the bathroom or other rooms;

- fill in the joints on different surfaces;

- use when installing plumbing equipment;

- use when sealing equipment in the kitchen, other rooms;

- use when filling and sealing joints and roof joints;

- apply when filling joints in concrete structures, wood, PVC tiles;

- use for sealing joints in water tanks, in the pool.

The sealant dries in different ways: the curing time completely depends on what composition was used, the quality of the product, how correctly and efficiently the agent was applied.

When applying an acid sealant, its curing time can be 6-7 hours, when working with an acrylic agent, the curing time will be longer - up to 12 hours. After applying the Moment product, its gradual hardening begins. After 20 minutes, the seam is covered with a film, and after a day, the silicone sealant hardens completely. If you need to speed up drying, you can increase the air temperature in the room or increase ventilation, you can also moisten the seams with cold water.

How does the sealant polymerize?

Silicone sealant is a multi-component mixture. At the time of application, it is in a gel state. Further, upon contact with air, the solvent begins to evaporate, and the components of the composition undergo polymerization. The result is a mass that resembles rubber in properties. This layer becomes a reliable barrier to moisture.It is easy and convenient to apply sealants, which is why they are used in many areas of construction and renovation.

When installing plumbing equipment for a bathroom, a bathroom, a kitchen, deadlines are set rigidly: the less time it takes to dry, the faster you can start using the water supply and sewerage system. At the same time, it is extremely undesirable to use plumbing until the sealant is completely dry: water under pressure will immediately wash the paste out of the joints, and all the work will have to start all over again

Therefore, it is very important to understand how the sealant polymerization occurs and how long these processes take.

Curing takes place in two stages:

- In the first 25 minutes, a film forms on the surface of the composition. When this stage ends, the applied mass stops sticking to the hands. However, under the frozen surface, the material is still in a gel-like state.

- The hardening of the bulk of the applied composition takes a long time. Manufacturers indicate that a sealant on an acidic solvent should dry for 5-7 hours, and on a neutral one - at least a day.

The sealing compound acquires its final strength only after the second stage. In order not to wait a whole day, you need to figure out what factors accelerate polymerization.

Types and characteristics

All sealants today are divided into only 2 main types:

- One-component composition. This type is sold in any hardware store and is one of the most common. Compounds of this type are sold in metal or polyethylene tubes. This component hardens due to the presence of moisture in the air. The main disadvantage of this type is high-speed hardening, but only if the surface is treated with a thin layer. And if the layer is more than 1.2 cm, then the sealant hardens for a long time.

- Two-piece type. Such mixtures freeze in any layer, but the cost of such a composition is higher, since they are mainly used for industrial purposes.

Moment sealants are one-component types, as they are intended for domestic use.

The Moment manufacturer produces two types of sealants. The first type is silicone based sealants, and the second type is made from acrylic water dispersion.

Acrylic-based sealants are more resistant to frost and various adhesions of the processed surfaces. The main disadvantage of acrylic compounds is the impossibility of using in an environment with constant moisture. As for the color of this sealant, it is mostly white.

Silicone sealant is made on the basis of a rubber polymer. Such a component makes the mixture more elastic and makes it possible to solidify in a short time, even at room temperature. Due to this characteristic, Moment silicone sealants are sold in special plastic tubes, which retain its liquid and plastic state for some time after production. The tubes can be produced in volumes from 85 ml to 250 ml.

If you divide the compositions, starting from the scope of use, then they are construction, automotive and special.

According to their composition, they are divided into two types:

- Neutral. Alcohol is added to the composition of such a material instead of acetic acid, and thus a less pungent odor is obtained. They can be used outdoors and indoors. Such mixtures are used in the field of shipbuilding, to seal freezers, they can be transparent and white.

- Universal sealants. The manufacture of such a composition takes place with the addition of an acetic mixture, which gives an unpleasant and pungent odor, and when interacting with non-ferrous metals, cement and similar materials, which include alkalis, causes corrosion. This type of sealant is produced in white or transparent color. It can be used for interior processing, that is, indoors, and for outdoor use, as it is moisture and heat resistant.The cost of such a composition is lower than that of a neutral one.

And also the Henkel company produces the Moment Herment sealant, it can be used both for domestic use and for professional. Such a sealant is divided into several types:

- Premium white, which is highly resistant to moisture, and consists of silicone. This type can be called the most heat-resistant.

- The next type, which is made on the basis of silicone and sodium silicate, copes well with oil, gasoline, high temperatures, which can reach 300 degrees. It dries quite quickly, and its color may even be red.

- The type of sealant Sanitary is used for the manufacture of glazing for shower stalls and bathtubs, but it cannot be used for processing stone and rusty surfaces, its curing speed is about 15 minutes.

- Aquarium look, used for the treatment of painted and glass surfaces that are subject to frequent vibrations. It is popular, since it has an increased level of moisture resistance, and the color of such a composition is extremely transparent.

The same series of materials "Moment" includes a gray sealant, which is made on the basis of polyurethane. It is often used as a grout for moving joints and as a tile adhesive. It is resistant to moisture, acids, alkalis, water and similar negative factors. But it has a drawback, since it burns out in direct sunlight and loses its elasticity over time.

Moment silicone sealant - characteristics of disadvantages and advantages

Silicone sealant "Moment" due to its chemical composition has the following positive features:

- high adhesion to almost all materials;

- high temperature resistant (up to 350 degrees Celsius);

- water resistance;

- elasticity (up to 200 percent);

- resistance to mold, fungi, ultraviolet light and aggressive weather conditions;

- mechanical strength;

- duration of operation;

- low cost;

- environmental friendliness (according to world requirements).

This guarantees the adhesion of the sealant, even on moving parts, while maintaining aesthetic appeal.

But it also has disadvantages: the Moment universal silicone sealant smells unpleasant and harsh, and after sealing the seams cannot be painted, regardless of the agent used.

Important! In case of non-observance of the temperature range recommended by the instruction and excessive humidity, the drying time of the "Moment" increases to 5 hours

Types of "Moment" silicone sealant

The production line of sealing materials "Moment" is represented by:

As you can see from the description, the products of the Moment brand are indispensable in everyday life for almost any occasion. The packaging is optimized for the customer: several weight options - from 0.08 to 0.5 kg as required, a convenient form of release that allows you to adjust the flow rate, and all this at a relatively low price.

Additional Information: Sealant moment silicone universal transparent henkel characteristics

Cut off the top of the cartridge thread and screw on the tip. Cut the tip of the ferrule at a 40 ° angle to match the seam width. Place the cartridge in the applicator gun.

Fill the joint tightly with sealant. Smooth out the sealant with a damp piece of wood or trowel. The silicone surface dries in about 15 minutes.

It is not recommended to paint this sealant, as the paint does not adhere to the flexible silicone surface. Until the silicone has completely hardened, working tools and contaminated surfaces can be cleaned with mineral spirits.

High Temperature Herment is a premium branch of the conventional Moment sealant. Profil universal silicone universal silicone sealant? It belongs to insulators with a rich variety of components.

It is especially heat resistant, it can be used at extremely high temperatures up to +300 degrees and in cold conditions - up to – 50.

Adhesives and sealants are becoming more widespread. They are used in assembling units, various devices, machines, ventilation systems, etc. Popular is the Moment adhesive sealant, which is a waterproof type.

It is used for bonding a wide variety of surfaces - wood, leather, rubber, glass, ceramics, etc. (except for the dishes in which it is planned to serve food).

For sealing and adhesion of various types of seams and surfaces, a universal multi-purpose adhesive based on FLEXTEC polymer is used, in which silicone, polyurethane and acrylic types of sealant are combined. It hardens when exposed to moisture. The composition is neutral (alcohol).

White color. Serves for sealing joints in air conditioning systems, window frames, between building blocks, brick walls, used for laying tiles.

You are viewing Universal silicone sealant "HENKEL Moment", transparent, 280 ml

We would like to draw your attention to the fact that all products are certified. We also offer you to make a purchase Silicone sealant universal "HENKEL Moment", transparent, 280 ml with free shipping on orders over 10,000 rubles, except for large-sized goods and remote areas (check with the operators for details)

Sealant Moment with universal technical characteristics has found its application in various fields, and is also suitable for domestic use. Depending on the selected composition, the type of sealant will determine its scope of use. For example, a silicone-based compound, Premium 300ml or Moment Herment silicone, can be used to seal cracks and seams on glass in shower cabins, baths, saunas, and swimming pools.

An additional function of the adhesive is that it prevents the occurrence and spread of the most common problems for rooms with high humidity - fungus, mold and various bacteria.

Consumption

Any Moment sealant can be used for surface treatment at a temperature not lower than + 6 degrees and not higher than + 40 degrees. It must be applied on a previously prepared surface that is free from rust, dirt, oil, dust and similar elements. Although such sealants do not have adhesion, it is better to degrease the surface for better grip. The seam layer must be at least 5 mm and no more than 1.2 cm.

The consumption of silicone sealant depends on the depth of the gap and the thickness of the layer. In order to find out the consumption of material, you can use online calculators on any construction site. And also on each package it is indicated how much area there is enough funds from one package. For example, if you have a 6 mm wide and 3 mm deep joint, with these parameters you will need an average of 20 ml of silicone sealant per meter of joint.

What does the drying time depend on?

Many factors can affect the rate of polymerization. Let's take a closer look at the most important points that speed up the process.

Solvent type

By the type of solvent, there are three main categories of sealants:

- Acetic acid based formulations. Their main advantage is quick hardening. However, acetic acid has a pungent characteristic odor that will be felt not only during use, but also for some time after application. In addition, this caustic substance can destroy concrete and provoke corrosion of metal products.

- Neutral formulations. Such mixtures do not destroy metals, are not afraid of contact with water. The colorless transparent sealant is almost invisible after drying. This variety is ideal for installing plastic windows, sealing joints on the floor, and sealing an aquarium. The wide range of applications allows us to say that the sealant on a neutral basis is the most versatile of all varieties. But the drying time is 24 hours.

- The sanitary sealant contains bactericidal substances and components that prevent the appearance of mold. This composition is optimal for the kitchen, bathroom, living quarters. As a rule, mixtures of this group harden in 16-24 hours.

The choice of sealant by type of solvent is dictated by the application.

Layer thickness

The thickness of the layer with which the sealant is applied is determined by the specifics of the work. For example, to seal a connection in plumbing, 1 mm of paste is enough, and to seal the joint between the sink and the wall, you will need to lay a much larger volume. Depending on the type of solvent, the polymerization rate is 2-3 mm per day.

Indoor temperature and humidity

Most manufacturers name two requirements for the microclimate in which the sealant will dry:

- The temperature should not fall below + 5 ° C and rise above + 40 ° C.

- The air in the room must be constantly renewed.

In living rooms or on the street, it is easy to achieve the necessary conditions - just open the windows (it would be a fine warm day) or turn on the fan. But when installing a bathtub or toilet, it is much more difficult to ensure constant ventilation of a cramped room in which the air is easily supersaturated with water vapor.

Instructions for use

Before using this tool, you should study the instructions and carry out preliminary preparation to find out how to use the tool correctly.

When working with the sealant, you should take care of special clothing, protective gloves

It is important that the product does not come into contact with the skin.

The place of application of the product is wiped from dirt and degreased. Masking tape is glued to decorative surfaces so that the silicone does not get onto the surface.

Use an assembly gun for application.

How to use it indicated on the package.

The edge of the cartridge is cut obliquely so that the sealant can flow evenly.

Apply the product at an angle of about 45 degrees. You should not make a thick strip so that the material can dry faster, connect both sides, use a spatula to get rid of the excess.

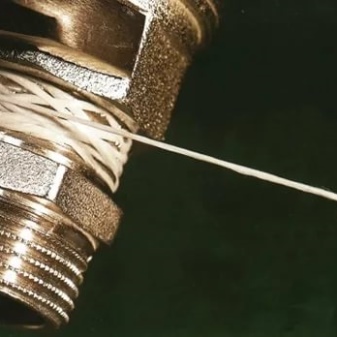

When sealing a threaded connection in a heating system, gas and water supply, a thread sealant is used for threaded connections. The sealing thread is made of polyamide and fluoroplastic and is used to seal pipes made of metal and plastic.

Starting to wind the thread, they hold the part with one hand, and the thread for sealing in the other hand. It should be wound from the beginning of the thread, make the layer thicker, then continue along the thread. The thread is wound in a clockwise direction, thereby an even distribution of the product will be achieved.

Henkel's products have repeatedly shown how much easier it has become to carry out construction work, installation, and other types of work. The brand is recognizable in many countries, the company's products have many advantages, the main of which are: reliability, quality and durability.

See below for an overview of Moment sanitary sealant.

Advice

The main criterion for the correct choice of sealant is a comparison of different manufacturers by the property of the composition and a preliminary determination of the scope of its application. But experts advise to build on some more criteria:

- From the presence or absence of a coloring agent in the sealant. If there is no colorant in the sealant, then after complete solidification it becomes transparent. This type of sealant can be used as an adhesive.

- Sealant packaging volume. If you need to process windows, then it is relevant and better to purchase a sealant with a capacity of 85 ml, this volume is quite enough to process 1 window, and if you have more windows, then it is more expedient to purchase a sealant whose packaging is 280 ml than to purchase 4 small packages. Thus, you significantly save money.

Since every year Henkel improves its products, the Moment brand has become popular not only in our country, but all over the world. The sealant of this brand has reliability, high quality and durability. And also such goods have a very reasonable cost.

But on the recommendation of experts, you should not save and neglect your health, and it is better to choose a neutral type of Moment sealants, which include alcohol instead of acetic acid. Such a composition, of course, is more expensive, but it is better not to skimp on safety.

For information on how to seal the seam between the bathroom and the wall with silicone sealant, see the next video.