Wall preparation: measurements, paint consumption

It is easy to calculate the area of walls without window and door openings: multiply the length of the wall by its height. The area of the wall where the door stands is minus (the area of the wall minus the area of the door). The area of the window is also minus.

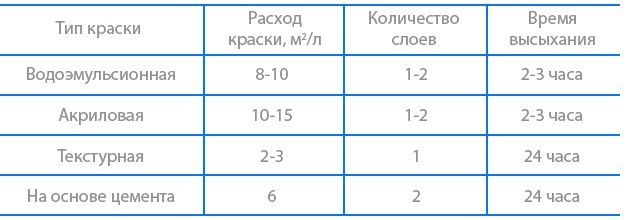

Consumption of paints per 1m2:

- Oil - about 150 g per 1m2.

- On a water-based basis - up to 300 per 1m2 (at least 2 coats are required).

- Acrylic - 150 g per 1m2. Often requires the addition of film-forming substances (drying oil).

There are special water-based formulations that promise that 1 liter of paint is enough for 18 m2, while only one layer is required. But do not trust such bold assurances.

After you take measurements, decide on the color and amount of paint - take a little more than you calculated (by about 10%). Despite the specified characteristics, paint may be spent more than planned - there may be microcracks on the walls.

Types of paints for outdoor use

PVA dispersion paints

PVA dispersion paints

Before new types of paint appeared, water-based paints were widely used, the basis of which was polyvinyl acetate, a certain marking indicated this.

The PVA base is capable of creating a matte, opaque film that is not afraid of moisture, but over time the base acquires a specific yellowish tint. Paints with such a base are used in dry rooms that are not exposed to moisture. There are PVA-based mixtures that have protective properties against moisture, but acrylic dispersions are much more reliable than such compositions. Due to their narrow field of application and ease of manufacture, PVA-based paints have a low cost.

Today the Russian market offers a large selection of materials with a PVA-dispersion base, they are economical. However, buyers do not always have sufficient knowledge about such paints and their area of application.

Paints based on styrene-butadiene dispersions

The paints of this group have a low cost price due to the use of cheap film-forming substances. As a binder in paints, styrene-butadiene binder is used, exactly the same is used in paints with a PVA base.

Therefore, the use of such materials is limited, they are used only indoors, which does not have bright lighting. There are paints for universal work, they can be used both indoors and outdoors.

Acrylic dispersion paints

Water-dispersion paints based on acrylic substances are the most expensive of the other water-dispersion paints used in construction. But materials based on acrylic dispersions have certain properties due to which they significantly stand out from other compositions. Thanks to the acrylic binder, paints have strength, they have protective properties against UV radiation.

Water-dispersion paints based on acrylic substances are the most expensive of the other water-dispersion paints used in construction. But materials based on acrylic dispersions have certain properties due to which they significantly stand out from other compositions. Thanks to the acrylic binder, paints have strength, they have protective properties against UV radiation.

Such bases are used in compositions:

- for processing wooden surfaces;

- for facade work;

- for other special materials.

Russian-made paints on an acrylic base are marked with a special marking - "VD-AK". They are characterized by a porous, vapor-permeable coating that is highly resistant to light and atmospheric influences. Such materials cover textured surfaces well, adding additional rigidity to them. Acrylic paints are universal; they are in great demand in Europe and Russia.

Acrylic copolymer based paints

Such paints are very economical, they are in great consumer demand, due to this they are very common in the market of paints and varnishes. In the manufacture of such compositions, polyvinyl acrylate, styrene-poly-acrylate, polyacrylosiloxane and other substances that form a film are used. Paints based on such bases are cheaper, so they are used more often than others. They have the same markings as acrylic paints.

Such paints are very economical, they are in great consumer demand, due to this they are very common in the market of paints and varnishes. In the manufacture of such compositions, polyvinyl acrylate, styrene-poly-acrylate, polyacrylosiloxane and other substances that form a film are used. Paints based on such bases are cheaper, so they are used more often than others. They have the same markings as acrylic paints.

The air permeability of these paints against other water-based paints is lower.

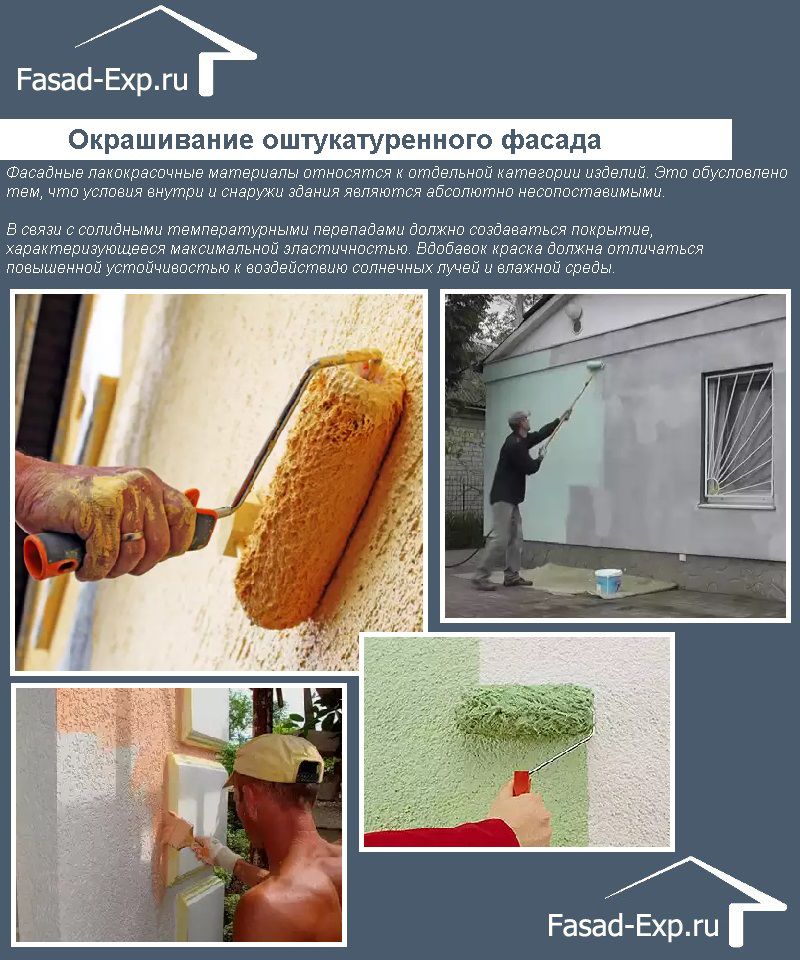

External surface treatment has certain requirements for the processing of paint materials. Paints are used not only for decoration, but also for protection from external influences

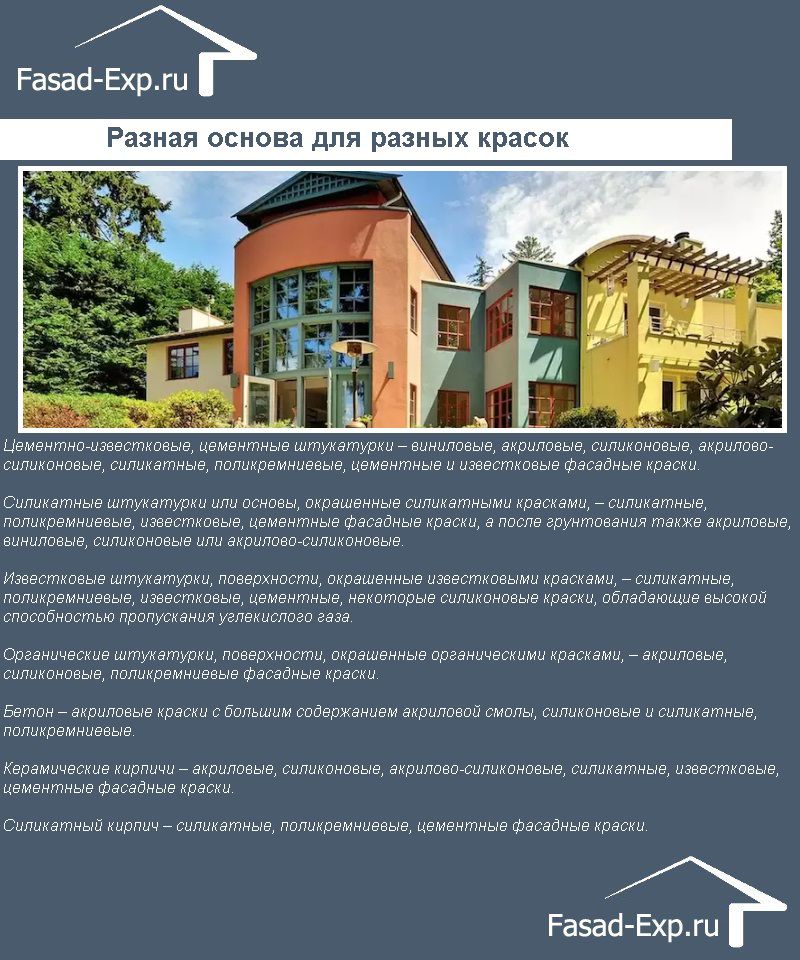

When choosing paints and varnishes, you should pay attention to the surface to be treated

According to the materials used in construction, the facades are divided into:

- brick;

- concrete;

- gypsum;

- metal;

- wooden;

- other.

It is necessary to correctly choose the paint and apply it according to the instructions given by the manufacturer. Then the paint will extend its life, providing protective properties. Thanks to this, the cost of repairs will be reduced.

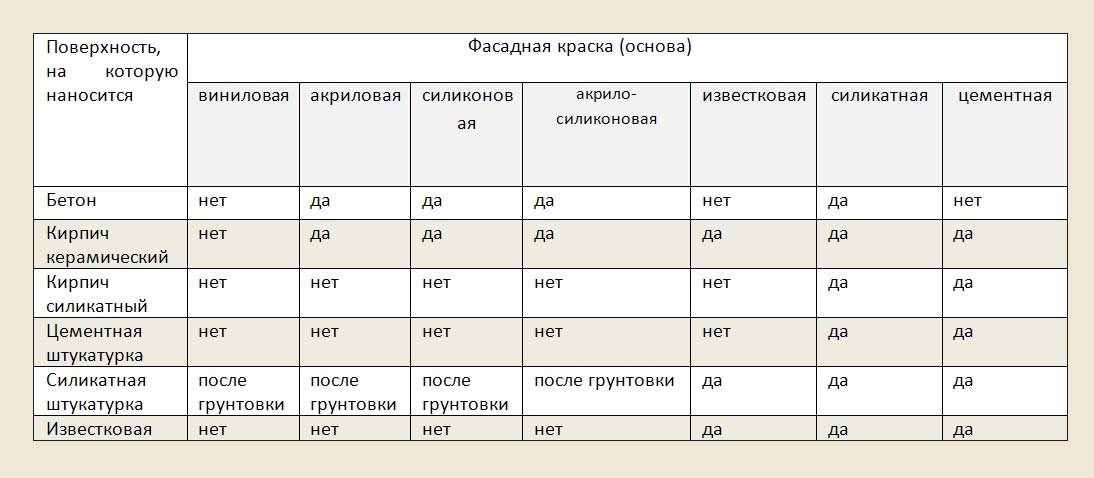

Table. Applying facade paints to the wall surface material.

| Wall material | Facade paint base | |||||||

|---|---|---|---|---|---|---|---|---|

| Vinyl | Acrylic | Silicone | Acrylic-silicone | Limestone | Silicate | Polysilicate | Cement | |

| Concrete | No | Yes | Yes | Yes | No | Yes | Yes | No |

| Ceramic brick | No | Yes | Yes | Yes | Yes | Yes | No | Yes |

| Silicate brick | No | No | No | No | No | Yes | Yes | Yes |

| Cement and cement-lime plaster | No | No | No | No | No | Yes | Yes | Yes |

| Silicate plaster (based on liquid glass) | yes (only after priming the wall) | Yes | Yes | Yes | Yes | |||

| Lime plasters and paints | No | No | No | No | Yes | Yes | Yes | Yes |

| Organic plasters and paints (on artificial resins) | No | Yes | Yes | Yes | No | No | Yes | No |

Views

The facing coating is different. The usual oil paints are a thing of the past - the price is too high for poor quality. They include drying oil, fillers and color pigments. The toxicity of this kind also makes them a huge disadvantage.

Oil products do not have the quality of protection against weather conditions and require repeated application. In addition, their composition is the most flammable.

The advantage of the oil option is the density of the product, into which dust and grains of soot from the roads will definitely not eat. It is applied very simply, does not require additional skills. To choose this type of coverage, you need to know the designations on the banks. The letters indicate the main raw material, for example, PE is a polyester resin. The first number indicates the area of application:

- 1 - this is for external work;

- 2 is for interior decoration.

There may be a second number, it already shows the type of binder:

- 1 is a natural drying oil;

- 2 is oxol.

To replace them, frost-resistant alkyd-based mixtures appeared, but even in winter they dry for a very long time. Alkyd resins in their composition must be diluted with linseed oil, kerosene or turpentine, which is also a minus in terms of toxicity. However, it is this feature that really protects against bugs and moisture. A thick film forms on the drying surface, which protects against external factors.

You need to carefully approach the issue of choosing an alkyd paint. Its high price is due to the natural ingredients in the composition. Each item must be certified and validated. Modifications with chemical solutions can cause accidents, which is why alkyd paint is usually not used at home.

Water-based products are durable and harmless, which dries very quickly. The composition is 100% non-flammable. The coating will not fade over the years, and to restore brightness, you just need to wipe the walls with detergents.Water-based facade paint has a high level of protection against weather conditions, does not contain a single toxic element for human health, and is also characterized by ease of use without requiring additional skills.

The basis of water-dispersion paints is a physical process. Mineral paint is a variety of them. It is based on lime or white cement. It is more suitable for interior work.

Frost-resistant and not so capricious option - these are acrylic materials. They are suitable for any job. Wear is not a hindrance for such paint. She perfectly tolerates heat and dampness, lasts more than 7 years.

Synthetic latex can also be the base of the product. The material is very flexible, which helps to hide cracks and unevenness, for example, due to poor priming experience.

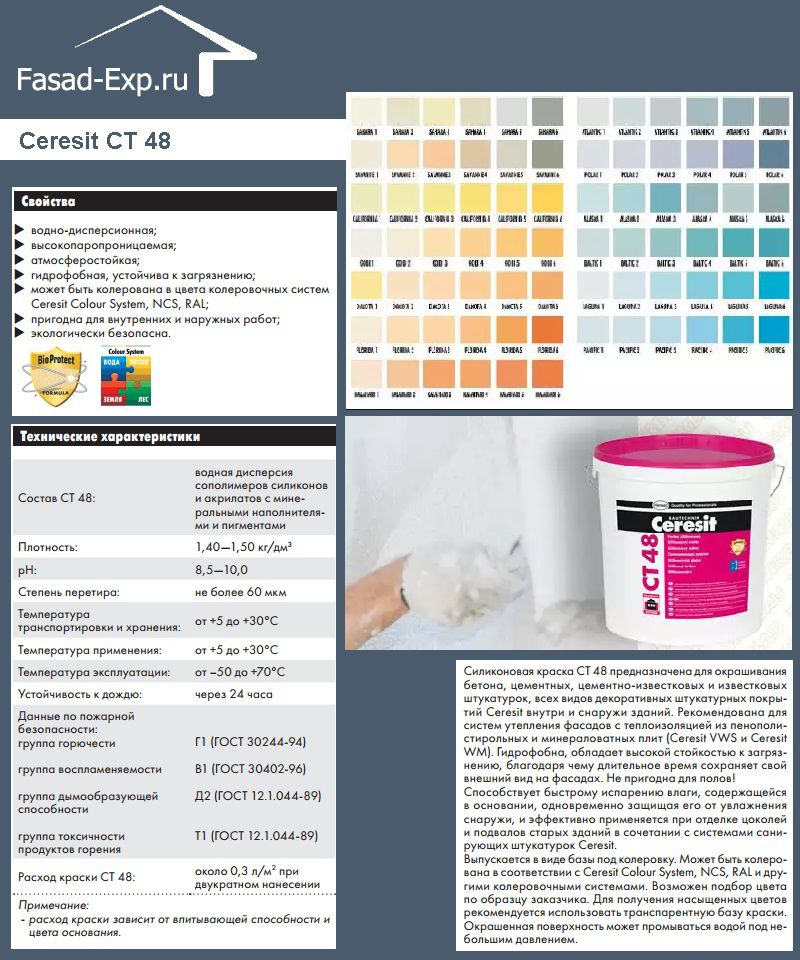

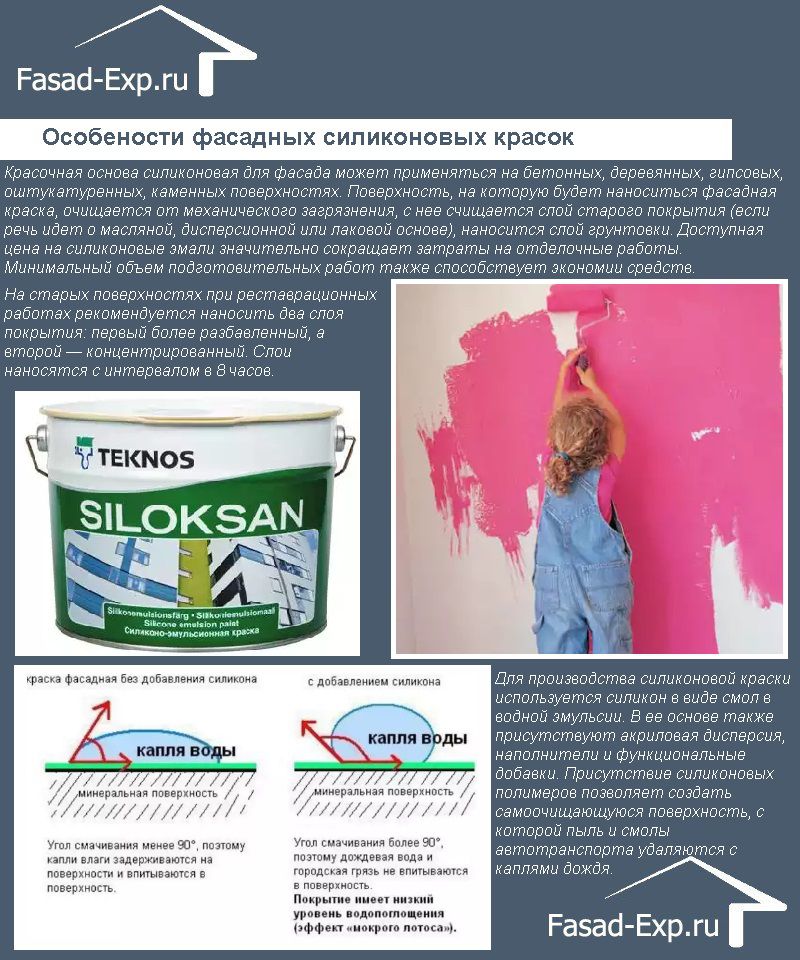

Silicone treatment is suitable for homes located in humid continental regions. The walls will not fade or fade, the color will remain bright and even, and the coatings cracked from rain can be filled with the remaining paint, because the structure of the composition does not leave visible traces of reapplication.

No. 8. Facade paint manufacturers

The quality of the paint and the compliance of its real properties with the declared ones largely depends on the name of the manufacturer. On store shelves, you can find products of dozens of companies, both foreign and domestic. Some of the largest and most proven manufacturers are:

- Tikkurila is a large Finnish manufacturer that needs little introduction. The assortment includes paints intended for painting wooden and stone facades, metal surfaces, concrete plinths. Silicone, silicate, lime and acrylic compounds are presented, the quality is exemplary;

- Dulux is one of the world's largest paint and varnish companies. Plants are located in 26 countries of the world. For outdoor work, paints with a matte, glossy and textured surface are presented. All formulations have antiseptic properties, they are guaranteed for 15 years;

- Dufa is a large German company operating since 1955. Produces paints for all occasions, for all surfaces and conditions of use. For facades, water-dispersion compositions are produced, there are especially strong and especially elastic compositions;

- Marshall is a Turkish company, which today is part of the world's largest concern AkzoNobel. The products are in great demand on the domestic market, there is a development of a network of points of sale. For the facade, only acrylic paint is produced, which can be tinted in any shade;

- Caparol offers one of the largest selection of façade paints. The assortment includes paints on a mineral and dispersion basis, paints intended for concrete, cement and lime plasters;

- Eurolux is a domestic manufacturer, whose products are much cheaper than their foreign counterparts, but at the same time they are not particularly inferior in quality to them. There is acrylic and latex paint for the facades;

- Optimist is another domestic manufacturer offering a decent range of facade paints, incl. silicone, acrylic and latex. The quality is not bad, the price is affordable;

- OLIMP paints are produced by Descartes. The products fully meet all international requirements and can safely compete with foreign counterparts. For the facade, matte acrylic paint is produced, which can be tinted in any color.

It is better not to save on facade paint - not only the appearance of the house depends on it, but also in many respects its durability and strength.

Facade paint for outdoor use - how to choose a type

There are quite a few varieties of paint and varnish compositions claiming to be the best facade paint for outdoor work, and when you first look at their list you can get a little confused.But upon closer examination, it turns out that choosing what paint to paint the facade of the house with should be based on the wall material and the list will be significantly reduced. In outdoor painting, the following types of paint mixtures are most often used:

- Oil;

- Water-based;

- Enamel;

- Silicate;

- Calcareous.

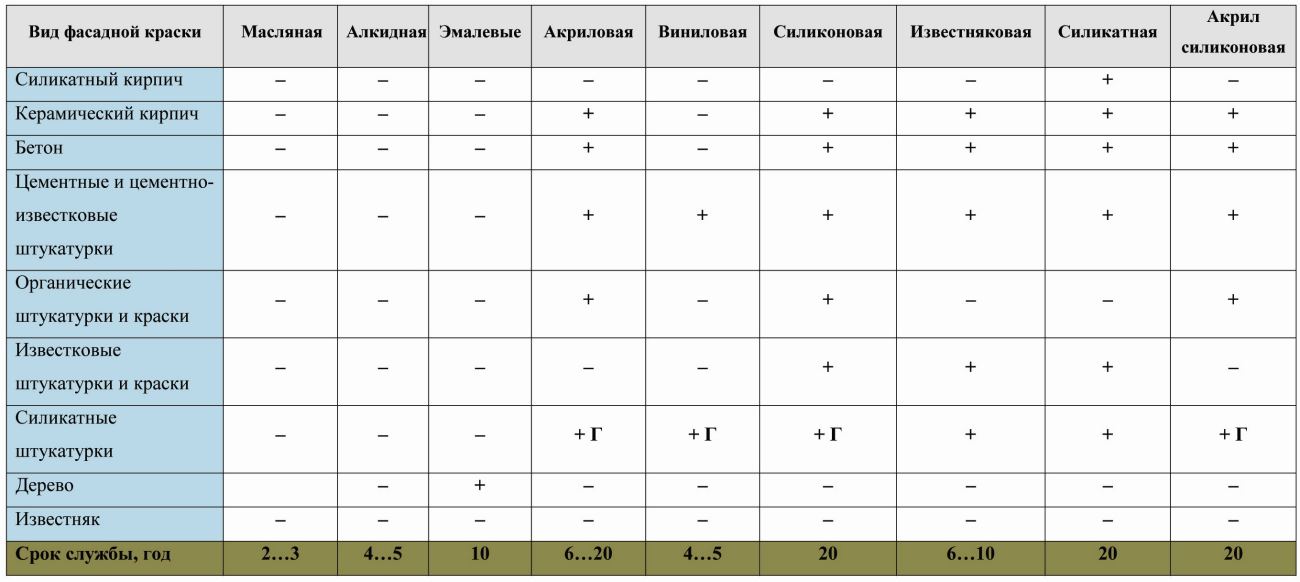

All types of facade paints have their own strengths and weaknesses, but first of all, it is necessary to proceed from compatibility with the base. The choice simplifies the choice of a clear table of types of paint for the facade, which reflects information about their field of application and service life.

Facade paint - types, table:

It is worth dwelling on the characteristics of each type in more detail so that the consumer can independently assess the pros and cons and make a reasoned decision.

Silicate paints are based on liquid glass, with the addition of mineral pigments and organic hardeners. The chemical composition allows them to be used for painting silicate and ceramic bricks, concrete, cement, lime and silicate plasters, gas blocks, foam concrete.

The advantages of silicate mixtures include:

- Weatherproof, providing immunity to UV radiation and precipitation;

- High values of vapor permeability, guaranteeing the removal of moisture from the inside of the building;

- Good adhesion to inorganic substrates, making it possible to use it on a large number of materials;

- Relatively low cost;

- Durability providing up to 20 years of service;

- Refractoriness after solidification.

However, a silicate coating also has a number of disadvantages. These include low adhesion to organic surfaces, poor color gamut and low elasticity. In addition, high vapor permeability, which protects walls from moisture, limits its use for unheated buildings.

Perhaps the best front wood paint is oil paint, consisting of natural or synthetic drying oils and pigment particles. The waterproof film it creates on the surface protects the wood structure from water and ultraviolet radiation, and its excellent biological stability prevents the development of mold and decay processes. A pleasant addition is the affordable cost of oil formulations.

Despite the fact that the oil variety is the best paint for a wooden facade, it also has weak points. The disadvantages of this type of paint and varnish solutions include insufficient vapor permeability, slow drying and insufficient durability due to cracking under good lighting conditions. It is impossible not to mention also the unsuitability of oil paints for alkaline surfaces, which are destroyed under their influence.

Speaking about which paint is the best for the facade of a wooden house, one cannot fail to mention the stain. Strictly speaking, these solutions do not belong to paints, but to impregnations, but their property to accentuate the natural pattern of wood is worthy of decorating the appearance of any home.

Enamel mixtures are widely used for wood and metal elements, since, like oil, they are incompatible with alkaline bases. After drying, a dense, strong, elastic film is formed with a durability of up to 10 years. The surface becomes scratch-resistant and has a glossy sheen. But still, enamel is not the best paint for the facade of a wooden house.

Glossy surfaces focus on the slightest irregularities, while dullness, on the contrary, somewhat conceals defects. That is why you rarely see gloss on facades.

How to make a calculation?

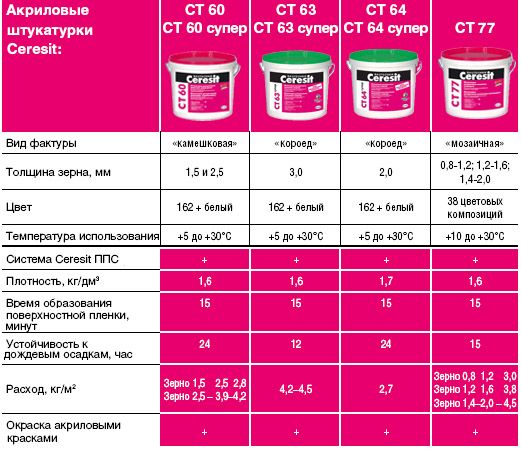

Acrylic-based water-dispersion mixtures are widely used for interior and exterior decoration. Such paints give the surface a matte sheen, and you can make the necessary tone using acrylic paste. Due to this, such compositions have a rather large color gamut, do not fade or fade in the sun.

Aerosol acrylic mixtures should be applied to surfaces previously used with primer, varnish and paint from the same manufacturer. Works can be carried out at temperatures up to + 50 °.

These indicators are influenced by factors such as surface texture, roughness and absorbency.

How much material is needed is also influenced by the method of application. When using a spray gun, paint consumption per m2 will be less than when painting with a roller. But when using a brush, you have to use 15% more material than indicated on the package.

When applying the coloring product to cement or plaster, the surface to be treated is additionally primed. It is worth remembering that different types of acrylic solutions must be used for walls and ceilings. This is due to the fact that the dye on the walls is subjected to much more stress than on the ceiling.

Wallpaper paint consumption

For uniform and economical coloring of a textured surface, it is better to opt for a roller with a long pile, 10-25 mm.

Consumption of acrylic composition for facade work

Based on the peculiarities of the texture of the facade, paint consumption per 1 sq. can be 180-200 g per m2 of wall. When using decorative plaster, this figure rises to 220-250 g

Consumption of textured acrylic-based paints

When carrying out repair work using acrylic enamels, the paint consumption per 1 m2 may slightly exceed the usual rate. The labels usually indicate a consumption of 1-1.2 kg per m2. However, in order to obtain a high-quality surface, the material will be needed with a margin, approximately 5% more than usual. This difference compensates for the unusual texture.

The second coat should be applied no earlier than 4 hours later. In order to reduce the consumption of acrylic paint per 1 m2, masters advise to work at a temperature regime of + 20 ° and normal air humidity.

In fact, determine how much paint is used per square meter. m, quite easy