Advice

Let's consider how to choose a high-quality sealant that will allow you to achieve the necessary goals and complete the tasks. To begin with, even before going to a specialized store, you should clearly understand in what conditions and where the product in question will be used. If we are talking about a bathroom, then you should definitely buy a moisture-resistant and water-repellent composition. If we are talking about a field made of wood, then it should be as elastic as possible, and it should not contain any solvents or substances of a similar type.

Also, before purchasing a sealant for home use, it is better to pay attention to a few points.

- Where this composition can be used - for external or exclusively for internal work, or in both options at once.

- In what kind of work it can be used - window, plumbing, roofing or some others.

- For what categories of surfaces is it intended.

- The elasticity characteristics that it has.

- Makeup color. Can it be dyed, or, on the contrary, it cannot be dyed, so that its elasticity characteristics do not decrease.

- What type of sealant is there: household or professional. The latter can only be intended for a person engaged in the construction industry and clearly understands how this particular composition can be used.

- Working temperatures of the composition. That is, can the solution be used in the climatic conditions of the region where you are going to use it.

Even following these minimal tips will give you the opportunity to find a quality and interesting solution for your home.

For information on how to work with anaerobic sealant adhesives, see the next video.

Basic requirements for compositions

To choose a really high-quality sealant, it is necessary to assess its compliance with the most important criteria:

- Suitability for a particular material. Some sealants are designed for plastics, others are suitable for metal substrates. There are also universal compounds that are suitable for any plumbing task. The information the user needs is always on the packaging.

- Resistance to adverse effects. A good sealant must withstand the effects of household chemicals, alkalis, ultraviolet radiation, high and low temperatures.

- Long service life. The tool must serve for at least 5 years when it comes to sealing pipes, and up to 3-5 years when sealing the seams between the wall and the bathroom, and other plumbing.

- Elasticity. The sealant should not crack from vibration, temperature extremes, resulting in the expansion and contraction of materials. With a poor elasticity index, the seam will quickly deteriorate.

- Polymerization time. If the repair in the bathroom is urgent, you need to choose the fastest-drying compounds.

Views

There is a wide variety of sealants. Each of them has its own special and unique properties. We will try to tell you about all types of sealants that are available today.

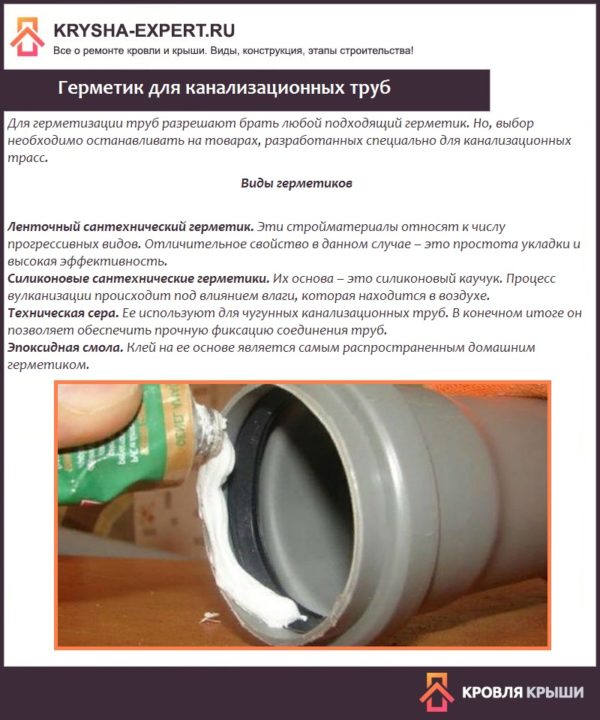

The first category to be mentioned is the sealing type tapes. They are usually either foil-clad or conventional and are intended to seal the joints of various water and sewer pipes and pipelines. They are created on the basis of polymeric substances. The term of use of such an option can be up to 40 years.

Another interesting option is polymer sealants. They are used to process sewerage joints and water supply systems.They are a great solution because they are versatile and can work with just about anything. Such a material is made on the basis of rubber, which allows it to have excellent elasticity and good adhesion properties. There will be silicone sealant from the same series. The silicone solution is by far the most reliable.

It should be said that they can be:

- neutral;

- acidic.

The first category does not have acids in its composition, which prevents it from destroying pipes. This greatly expands the possibilities of its use. At the same time, such a sealant is more expensive. And the acidic options are of excellent quality at a fairly affordable price. However, they are not suitable for all surfaces, and with some they can enter into various chemical reactions.

The third category of sealants is industrial sulfur. It is created during the processing of various petroleum products and is sold in the form of lumps or powder. This option will be an excellent solution for joint sealing on cast iron pipes. Low cost will be an additional advantage. Sulfur is a tough yet brittle pipe sealant that must be used correctly.

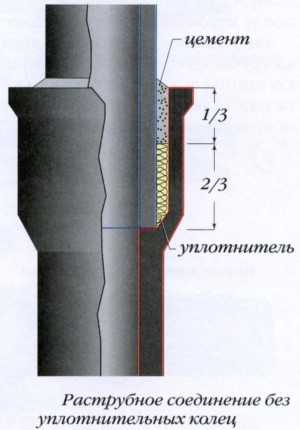

The next option is Portland cement. This option is made from calcium silicates, clinker and gypsum. To use it, you must dilute it with water. When you get the paste, you can start using it. This option perfectly seals pipe joints and can be an excellent solution if you need to seal other joints as well.

The next type is epoxy, which is a liquid all-purpose adhesive. To obtain good sealing properties, it is mixed with a hardener. It is very convenient to use such a resin if the manufacturer's recommendations are strictly and accurately followed.

And also often bitumen mastics have been used as a sanitary sealant in recent years. Especially interesting will be mastics based on bitumen and rubber, as well as bitumen and polymer substances. Such a waterproof option will be an excellent solution when working in an apartment or bathroom. Speaking specifically about pipes, this moisture-resistant option will be an excellent solution for polypropylene pipes and PVC-based pipes.

Another type that I would like to mention is hemp, as well as jute ropes. They are excellent for sealing joints on pipes made of cast iron or ceramic. Such materials are readily available and very easy to use. At the same time, they are inferior in characteristics to modern sealants.

Selection Tips

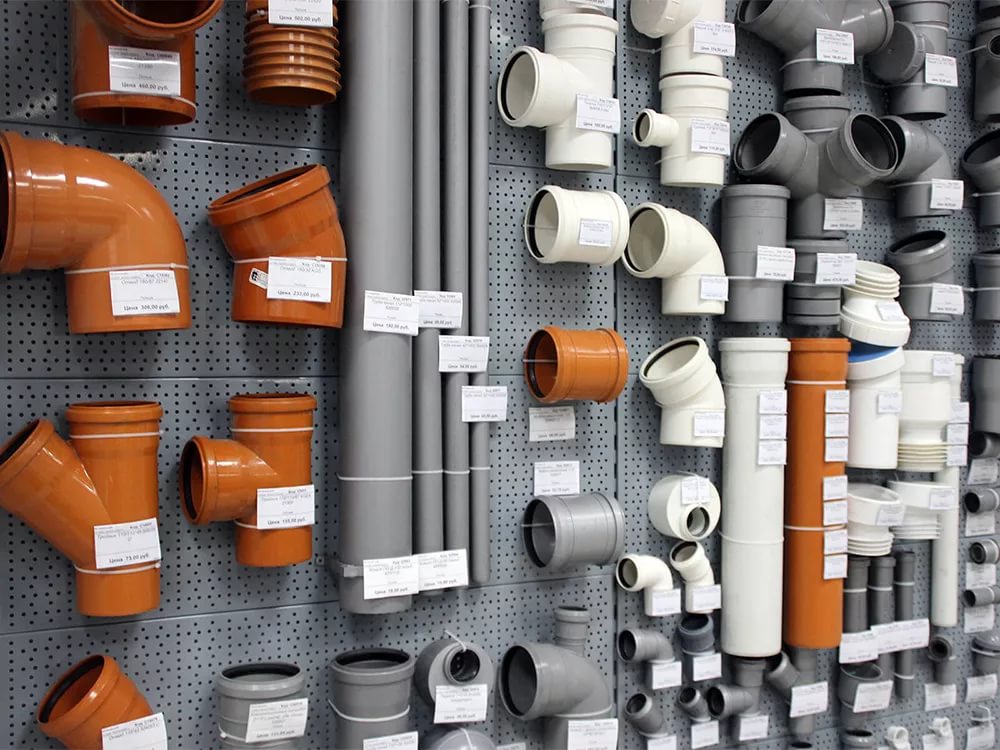

It is quite difficult to independently calculate a suitable diameter for an external sewage system in certain conditions, but there are general recommendations that will help solve the problem.

- A 5-centimeter diameter is quite enough for a shower, drainage from a sink and similar elements.

- From the toilet, drains are discharged into 11-centimeter structures.

- For arranging a full-fledged bathroom, on the territory of apartments and private houses, the minimum size is also 11 cm.If the building is multi-storey, then the craftsmen often choose vertical systems with a diameter of up to 15 cm.If they are made in accordance with GOST 51613 2000.

- 20 centimeters should be equal to the cross-section of the pipeline, if we are talking about a highway in a horizontal plane, which collects and drains waste from the whole house.

- There should not be a branch smaller than the riser, along which the drains go from the plumbing fixtures to the pipe vertically.

Video

PVC plumbing pipes with pressure

They are relevant for systems in which pumps are responsible for the forced circulation of liquid. This creates pressure with an artificial origin, then the flow becomes continuous.

The installation of pumps will be especially relevant where there are many apartments, premises with a large area.

The wall of a pipe with a size of 50 mm increases in thickness, otherwise they will not be able to withstand the increased load. The use of multilayer products is allowed. And here the characteristics are regulated by GOST 51613 2000.

Non-pressure type of PVC pipes

They are most often used in modern sewer systems. Their design is standard. They are not recommended for use in artificially pressurized systems.

It is possible to install pressure pipes along the entire length of the external drain, but this solution is too expensive. Similar non-pressurized materials are 25 percent cheaper than pressurized ones.

Watch the video

About corrugated varieties

They have the most unusual appearance. The walls look like an accordion. That allows installation even in places that are difficult to access.

The structure has an inner and outer layer. For the manufacture of the inner, a smoother material is used so that blockages do not appear inside. The outer layer is standard PVC.

How to connect plastic pipes with cast iron?

An ordinary rubber adapter is enough if you need to connect a system that has a socket. Plastic outer adapters are needed where there is no socket.

When using rubber cuffs, the replacement is as follows.

- We clean the socket with a size of 250 mm from plaque and dirt, if they appear on the surface.

- Apply a layer of sealant to the outer surface of the socket. Then the part is inserted.

- A plastic pipe for the sewer system is connected to the collar.

Plastic connectors require a slightly different procedure.

- We level the edge of the pipeline by 250 mm with a grinder, if part of it burst during operation.

- We put on the structure of 250 mm rubber cuffs. Its surface is pre-coated with a compound for high-quality sealing.

- A plastic adapter is put on top.

Video

What other adapters are there for plastic products?

The range of plastic external adapters on the modern market is quite wide. They are less reliable than metal ones, but they are more affordable. And their installation can be easily done by hand.

Adapters are available in polyvinyl chloride and polyethylene for 250 mm, which are mounted in systems with rubber cuffs.

A firm fixation is created due to the elastic ring inside; no additional installation tools are required.

Not able to withstand high pressure and PVC fittings for glue mounting. Although they are more reliable than the previous version.

Video

Polypropylene adapters are available for 250 mm, for the installation of which welding is used. Form one-piece connections. For work, you must use special soldering irons complete with nozzles. They are made in the same size as the diameter of the pipeline.

Finally, some manufacturers produce 250 mm structures in which plastic elements are inserts, and the product itself is metal or made of composite.

These are also quite popular plumbing pipes and PVC adapters for sewage.

Benefits of using the tool

If you seal water pipe connections even with pressurized water, for example to eliminate leaks, then it is worth using a silicone sealant.

The sealant has a long service life

It has advantages in the form of:

- Resistant to ultraviolet rays;

- Resistance to various natural conditions;

- Excellent adhesion to various plumbing installations;

- Resistant to temperatures from -50 to +200 ᵒС;

- Possibilities of application to cold and hot surfaces.

The composition of the material contains a fungicide, due to which it becomes water resistant, which means that it is a reliable obstacle to leakage and the formation of mold.Waterproof gel sealant, which eliminates leaks on polypropylene pipes, provided that it is of high quality, must have good adhesion to various materials, a smooth and shiny surface after drying, high strength even at temperatures from -50 to +150 ᵒС, resistance to aggressive a chemical element that can get on the seams when washing the bathroom, elasticity, which is necessary to fix the movable element.

Thread lubrication is carried out on both hot and cold pipes, for the manufacture of which polypropylene material was used. The main thing is that this silicone glue is resistant to such temperatures.

Application and performance characteristics

Most often, such a sealant is used when installing plumbing: it helps to seal joints that can get water, as a result of which mold will settle there. The product is perfect for sealing joints between the wall and the bathroom, shower, sink, toilet bowl, countertop. High-quality sealants are used when laying or replacing elements of water supply and sewerage systems. When assembling pipes, they will eliminate leakage and increase the service life of the unit.

Since most sanitary sealants are antiseptic, they are suitable for installing window systems inside and outside buildings, helping to prevent mold and mildew. Also, any of the sealants can be used for other purposes:

- roofing works;

- strengthening greenhouses;

- sealing joints in masonry;

- installation of vinyl cladding;

- mounting mirrors.

A good sealant has the following qualities:

- a high level of elasticity, the ability to apply to deformable bases, moving elements and parts of structures;

- resistance to water, steam, condensate, chemicals and UV radiation;

- excellent adhesion to ceramics, concrete, tiles, stone, glass;

- tolerance of temperature changes;

- versatility and low consumption.

What problems does plumbing sealant solve?

Experienced plumbers recommend that you take sealing issues as seriously as possible. The risk of leakage always remains, and only the use of special compounds helps to reduce this danger. If there are holes between the wall and the bathroom, mold is likely to appear in the room, and a leak in the water supply system can even threaten with serious troubles. The most problematic areas are recognized where it is required to insert fittings or create pipe branches: there the use of sealant is especially necessary.

The use of plumbing sealant when connecting water pipes

A sealant for water pipes and sanitary ware solves the following tasks:

- preventing the appearance of leaks, the cause of which is the presence of cracks, cracks or too strong a pressure of water;

- protection against temperature extremes arising from the regular supply of hot water;

- keeping important parts and assemblies intact, extending their service life;

- enhancement of the effect of the use of gaskets.

Composition of sealants

Silicone sealant is made on the basis of silicon compounds and various polymers, as well as additives:

- fungicides and antiseptics to provide antifungal properties;

- organic extenders to reduce viscosity and better flow into small cracks, holes;

- fillers (quartz and glass dust) to enhance adhesion;

- pigments to give a certain shade.

Other sealants may include acrylic, polyurethane, organic solvents, and other components that provide a reliable bond and seal.

Forms of issue

Many sealants are sold in plastic cartridges for a gun with a volume of 290-360 ml. Also on sale there are products in tubes of 50-100 ml - in ordinary ones or equipped with a special plunger like a syringe.For large-scale plumbing work, it makes sense to purchase soft packs of sealant of 600 ml or more, for which special pistols are used to squeeze out.

Features of choice

If you are going to purchase a means for sealing equipment in a bathroom or toilet, you should take into account some of the nuances.

- Silicone sealant adhesives are suitable for metal products: aluminum, copper, hard alloys of mercury. But they can glue any combination of materials. At the same time, there is no need for preliminary preparation of surfaces due to good adhesion.

- Acid sealants are more suitable for the treatment of water supply pipes, since they are not subject to biocorrosion. It is better not to use them for non-ferrous metals due to their destructive effect. In addition, acidic products contain biocides, so such formulations should not come into contact with food storage areas.

- Neutral silicone mixes are needed when working with plastic parts of equipment, but they are difficult to paint. That is why you should immediately choose a certain color in order to mask the joints.

- To seal the plumbing structures, a white or transparent waterproof compound is usually used, which ensures a reliable connection of plumbing fixtures, shower cabin panels, gaps between the wall and the bathroom, and fixing the toilet bowl. It also helps to avoid stains and mildew.

- It is better to purchase sealants that have additional characteristics, for example, heat resistance, fire resistance and other qualities.

It is important to pay attention to such issue as drying time. This and other information, as a rule, is contained in the instructions or indicated on the packaging. The sealant must be selected for the intended purpose and suitable for the operating conditions

The sealant must be selected for the intended purpose and suitable for the operating conditions.

It is always necessary to check the expiration date of the product, as well as the integrity of the packaging material, as this can affect the quality of the sealant. In addition, it is wiser to purchase such a product from a trusted manufacturer.

In order for the plumbing equipment to serve for a long time, it is necessary to effectively seal the plumbing fixtures. To do this, you need to choose a suitable high-quality product and apply it correctly. This will be the key to success.

For the intricacies of applying silicone sealant for sealing joints in the bathroom, see below.

In what forms is the sealant produced, types

Depending on the material of the water supply system, different insulating pipe sealants are used:

Linen fibers - serve to seal the joints of the knees of metal parts. The tow is disassembled into fibers, while the layer can be folded of any thickness. If water seeps out at the attachment site, the flax will absorb the liquid and swell, blocking the flow. But the water will seep through the fibers and leak.

Flax is not used in pipelines with high water pressure. It can be used in combination with liquid sealants for better insulation.

Since linen contains natural fibers, it is susceptible to rotting and mold formation if it gets in contact with water. To slow down this process, the tow is impregnated with varnish.

Thread for plumbing work. It is a thin elastic tape impregnated with a solution that does not shrink and does not dry out. It is evenly wound on threaded pipe joints. The use of plumbing thread allows you to tighten the thread not completely, while the seal will remain.

The thread for plumbing is not destroyed by water, does not rot, protects the surface from corrosion. The disadvantages of the seal are the high cost and processing of holes with a diameter of no more than 5–7 cm. If the winding is uneven, there may be gaps through which water can leak.

FUM (fluoroplastic) sealant.It is a smooth elastic strip that is wrapped around threads or elbows. Fluoroplastic sealant for water supply pipes is not subject to decay, shrinkage. Withstands high pressure, temperatures up to + 280˚С, protects against corrosion.

But FUM pipe compactor may not withstand prolonged vibration. If you disassemble the joints with fluoroplastic, then with further installation it must be reapplied.

Liquid formulations are produced in cylinders or soft packs for filling into a pistol. They are used for large pipe diameters. Or in bottles for minor repairs and installation of small connections. Depending on the composition, insulating solutions are:

Acidic sealants contain an acid as a solvent. They are cheaper than neutral ones, they form an elastic waterproof seam.

Having an acidic environment, they prevent the development of mold and decay. They are not destroyed by UV rays, they can withstand pressure and temperature drops from -40 to + 120˚С.

The disadvantages of acidic sealant include the fact that they can damage the amalgam coating and non-ferrous metals. Also, acidic insulating compounds are not used in areas in contact with food.

The neutral ones are made on the basis of synthetic rubber. It is a viscous dense mass that polymerizes on contact with air. Neutral sanitary glue forms an impermeable elastic seam that retains its qualities under deformation and vibration loads.

Such compounds do not destroy plastic pipes and protect metal pipes from corrosion. They are resistant to UV rays, are not afraid of solvents, and have an operating temperature range from -40 to + 280˚С.

Sanitary silicone sealants are transparent viscous substances. They create an elastic connection that does not collapse, does not crack under vibration or high water pressure. They have high adhesion to metal, plastic and alloys.

Resistant to the action of reagents, solvents.

Anaerobic solutions polymerize in the absence of oxygen. If some of the sealant remains on the outside, it can be easily removed, since the sealant remains in the air in a liquid state.

Anaerobic composition allows you to connect plastic and metal parts. Not afraid of chemicals, high water pressure.

What is a pipe sealant

Pipe sealant

Various insulating materials are used to seal threaded connections on pipelines.

Liquid silicone sealant

Plumbing silicone sealant for sealing pipe joints is a synthetic adhesive that, after drying, forms a plastic joint. It is best used in conjunction with a fiber gasket, such a connection can withstand high pressure in the pipeline.

Anaerobic sealant

Used to seal metal fittings. It is applied inside the threaded joint where there is no air. It has high thermal and chemical resistance, withstands pressure up to 16 atm. Its adhesion to metal forms a strong bond. It does not freeze in the air, the excess will be removed with a rag.

FUM tape

Smooth synthetic tape for sealing pipes. Stretches when winding and tightly covers the thread, convenient to use. Protects threads from corrosion.

Dry flax

Natural organic matter. One of the first materials used in plumbing. Hygroscopic, absorbs moisture, decays or dries up and crumbles into fibers. Previously, flax was used with paint. Now they use pastes that protect it from moisture and drying out.

Plumbing thread

A thin synthetic thread is wound in each thread, while stretching and forming a tight connection. Experienced plumbers use unilok thread, a neat and strong connection is obtained. The disadvantage of this sealant is the high price.

Sewer pipe sealants

Sealant for sewer pipes represented by the following types:

- sealing tapes;

- polymer compositions;

- ropes made of natural materials - jute or hemp;

- epoxy resin;

- Portland cement;

- rubber cuffs.

A good sealant for polypropylene sewer pipes is a special tape. This is an adhesive tape made of foil, which, when wound on pipes, sticks to them and serves as a good protection against water leaks. It can be of summer and winter design, which is indicated in the marking. The summer version is used for sewerage inside the apartment. For the external piping, a winter version is required.

The sealant for PVC sewer pipes can be polyurethane glue. With its help, separate parts of the pipeline are connected. We get a tight one-piece joint. It is selected taking into account the operation and chemical composition.

Liquid sealants

Available in suspension form. Not used on their own, only in conjunction with fiber materials. It will simply be forced out of the joint, especially in high pressure pipelines. They are used as a lubricant for connections of water supply elements

Anaerobic sealant is an exception.

Benefits of an anaerobic sealant

- Curing occurs as a result of polymerization. Excess is well removed, since it does not harden in air.

- Good adhesion for joining plastic and metal pipes

- The ability to use not only for sealing a water supply system, but also pipelines with aggressive agents due to the inertness of the sealant.

- Successful application for sealing a pressure pipeline.

- Automation of the sealing process is possible.

disadvantages

Disassembling threaded connections sealed with anaerobic sealant requires a special tool or preheating the connection.

Features of the use of anaerobic sealant

When performing work below the required one, for high-quality sealing, preliminary heating of the elements is necessary. The sealant should be applied as evenly as possible, spreading it over the entire surface of the thread. It is allowed to apply sealant to both external and internal threads. Before carrying out sealing work, the screw connections must be cleaned and degreased.

Plumbing sealant and sealants

Assembly adhesive is widely used in construction during assembly, installation and repair work. The main advantage is the ability to bond materials of different structure, for example, concrete and plastic, wood and metal, etc.

Many manufacturers add various additives to their products that enhance certain properties. This can be especially strong fixation, frost resistance, fast solidification, transparency, etc. Thus, each user will be able to choose the mounting adhesive that best suits his needs.

Gaskets for adapters and plugs are consumable items used when installing central heating batteries. They serve to seal connections, protect the system from leaks. They are rings of different diameters made of elastic material. Paronite gaskets made of asbestos-rubber mass. They are cheap and durable. In case of failure, they are easily replaced with new ones. Material for silicone gaskets it serves as a medical silicone. Unlike paronite products, such gaskets retain their properties when exposed to chemicals and high temperatures, and do not lose elasticity over time. They are installed in a special groove in the radiator, so the connection looks very aesthetically pleasing and neat.

Polyurethane foam is a widespread sealant. This liquid mixture of chemicals, on contact with air, expands and solidifies into rigid polyurethane foam.Able to fill gaps, joints, seams and other hard-to-reach holes. It is used for the installation of windows, doors, heat and sound insulation and other construction work. Supplied in cylinders up to 1 liter. Distinguish the following types of polyurethane foam.

One-component is a standard sealant that expands under pressure from the container it is supplied in. Two-component polyurethane foam has a complex composition, and some components must be prepared in advance. The balloon is inserted into a construction gun.

By area of use

Household foam is intended for simple and small construction work, it can expand up to 40 liters in volume. Usually one-component. Professional foam is used in large construction and renovation, expands to 80 liters.

Summer foam can withstand temperatures from +5 to +35 ºС, winter foam - from -25 ºС, all-season - from -10 to +30 ºС.

An important characteristic of all formulations is fire resistance. On the packages you can find the markings: B1 - resistance to open fire, B2 - the ability to self-extinguish, B3 - heat and moisture resistance. This foam is water resistant and therefore suitable for use in the bathroom and pool.

Sealant guns are the most convenient and economical way to apply it.

The tube with the sealant is placed in the device, under the pressure of the piston, the contents are fed through the tip to the work area. The piston can be set in motion by tightening the screw or by pulling the trigger.

Frame models are designed for sealants in a cartridge, and sealant is placed in cylindrical ones without packaging, the role of a tube is played by the body of a gun.

The gun for polyurethane foam is used in the course of repair, construction, insulation and sealing.

The device provides the most accurate application and economical material consumption. It is very easy to use: the can is placed in the barrel, when the trigger is pressed, foam is released through the tip.

The pistol can be used with one hand, while the other can be used for auxiliary work.

How to choose a sewer pipe sealant

It is necessary to build on the type and structure of the engineering communications themselves. Polymer sealants are perfect for processing joints in an apartment, office, cottage, since they:

- are inexpensive;

- available to a wide range of consumers;

- presented in a rich assortment;

- easy to use;

- do not require special training.

For a large amount of work, it is recommended to combine materials with each other. Optional: sealing tape + mastic / epoxy / sealant.

An important factor is the material for the manufacture of pipes. You need to make sure that the selected agent has good adhesion to metal, cast iron, polypropylene and PVC products, since the quality of the seam and its durability depend on this.

In some cases, other means of sealing the drains of drain lines are also suitable:

- rope soaked in resin - for cast iron / ceramic drains;

- technical sulfur - for sealing small joints;

- sealing collars - made of rubber and suitable for various types of pipelines.

How to apply

To make the sealing seam even, masking tape is glued to the walls and sides of the bathroom.

To seal seams, cracks and joints in the bathroom, products are used in the form of a convenient applicator, or they additionally purchase a mechanical construction gun.

For application you will need:

- personal protective equipment (goggles or mask, gloves)

- clean cloth or rags

- acetone (it is possible to use technical alcohol)

- masking tape

- leveling spatula

Plumbing sealant application

The process is as follows:

- Wipe the surface dry and degrease with acetone

- Along the future seam along its entire length, masking tape is glued so that the substance lies flat and does not stain the surface

- Put on protective equipment, provide fresh air access to the room (when using toxic substances)

- The sealant tube is cut at an acute angle, the applicator is put on for even application

- The product is squeezed into a crevice or gap, gripping both mating surfaces

- The pressure on the tube should be constant, and the line of application should remain continuous

- The finished seam is leveled with a spatula

- The composition should harden (stop sticking to your hands), and then dry completely

Replacing the old seam follows the same scheme with the only difference that the previous composition must be carefully removed from the surface (mechanically or using a chemical solvent).

Laminate on a wooden floor with your own hands: a complete description of the process. Laying schemes, what materials should be used (Photo & Video) + Reviews