MS polymer sealants

A newly emerged type of sealant that is rapidly gaining popularity due to its excellent properties. They combine the qualities of silicones and polyurethanes, reliably protecting against leakage, forming elastic and reliable connections.

VS polymers - excellent qualities for bathrooms and other wet areas

Properties and scope

The main advantage of sealants based on MS polymers is that in addition to the properties of the sealant, they still have a high adhesive ability, therefore, their polymers are also called adhesive sealant. They have the following properties:

- Excellent adhesion to all building materials without the need for primers.

- Solvent free, safe and virtually odorless.

- They dry quickly and harden even at sub-zero temperatures (only slower).

- When dry they do not harden, they remain elastic (elasticity range 25%).

- After drying, you can paint.

- They do not crack or change color under the influence of the sun.

- Waterproof, can be used in fresh and salt water.

-

When applied, they do not spread, a neat seam is easily formed on vertical and horizontal, inclined surfaces.

Excellent properties. There are also disadvantages. The first is a high price, but it is justified, since the seam does not crack and does not leak for a long time. The second - after a while, the surface of the white sealant may turn yellow. This does not affect the quality of the seam, but it looks ugly. You can remove yellowness by wiping the seam with refined gasoline. The third minus - after hardening, the composition is removed only mechanically. No solvents act on it.

Manufacturers and prices

Almost every major manufacturer has MS sealants, and they also have various additives that give special characteristics, so that you can choose exactly according to the situation and for a specific type of work.

| Name | Colour | Special properties | Skin formation | Release form | Price |

|---|---|---|---|---|---|

| Bisin MS Polymer (adhesive sealant) | white / transparent | Glass, mirrors, plastics, bricks, natural stone, concrete, wood, iron and many other metals. | 15 min at + 20 ° C | Tube for pistol (280 ml) | 490-600 rub |

| BOSTIK MS 2750 | White black | Metal, wood, glass, expanded polystyrene, etc. | 30 min at + 20 ° C | Tube for pistol (280 ml) | 400-450 rub |

| BOSTIK SuperFix | White gray | Suitable for underwater, swimming pools and rooms with high humidity | about 15 minutes | Tube for pistol (280 ml) | 400-550 rub |

| TECFIX MS 441 | transparent | Resistant to seawater, chlorine, mold and fungi | 10 min at + 23 ° C | Aluminum film sleeve (400 ml) | 670-980 rub |

| 1000 USOS | white, transparent, gray, blue, green, tiles, black, brown | For bathrooms and kitchens with anti-mold action | 15 min at + 20 ° C | Tube for pistol (280 ml) | 340 rbl |

| SOUDALSEAL High Tack | White black | For sanitary rooms and kitchens - resists the formation of fungus |

10 min at + 20 ° C | Tube for pistol (280 ml) | 400 rbl |

| SOUDASEAL 240 FC | White, black, gray, brown | For sanitary rooms and kitchens, fast curing | 10 min at + 20 ° C | Tube for pistol (280 ml) | 370 rbl |

| SOUDASEAL FIX ALL High Tack | White black | For sanitary facilities, super strong initial hold | 10 min at + 20 ° C | Tube for pistol (280 ml) | 460 rbl |

Despite the fact that this type of sealant has appeared recently, the range is solid, since the combination of high adhesive ability and sealant properties is very convenient and the product is in demand.

The main advantage of MC sealants is elasticity after drying, tolerance of prolonged direct contact with water, and resistance to the growth of fungi and bacteria. Therefore, this type of sealant is used to seal the junction of a bathroom or shower stall with a wall. In the case of a shower cabin, it is also good because it does not slip when applied vertically.

Another positive point - most of the compositions have a pasty consistency, which lies flat, does not bubble. After application to the initial curing (skin formation), the applied sealant can be easily leveled to the desired shape.

Acrylic

These are the cheapest sealing compounds, which at the same time have good technical characteristics:

- Does not contain hazardous and toxic components.

- Chemically neutral.

- Good adhesion to most surfaces (concrete, brick, plastic, glass, metal, wood and its derivatives MDF, chipboard, plywood).

- Temperature range from -20 ° C to + 80 ° C (available with a wider and narrower range).

- Withstands long-term vibration with a small amplitude (used in mechanics and mechanical engineering when installing devices).

- After polymerization, the seam is inelastic, fracture begins at a stretch of 10-12%.

- Fast drying.

-

The dried surface can be painted or varnished.

In general, good qualities, especially when you consider the low cost, as well as harmlessness. You can work with acrylic sealants without protective equipment, and the short time required for curing speeds up the work. Their disadvantage is shrinkage during drying. Because of this, when in contact with water, the seam begins to leak, so such a bathroom sealant is best used in places where water does not flow. Also, prior to application, for better adhesion, a surface primer (under acrylic) is required. In this case, you are more likely to get a leak-proof seam.

Application area

The main disadvantage of acrylic sealants is the stiffness of the resulting joint. Even with small extensions, it bursts. That is, it is not worth using it to protect the junction of a steel or acrylic bathtub (shower tray) with a wall. Under load, they change their size and so that the seam does not collapse, it must be elastic.

Perfect for filling voids and cracks in various building materials (brick, concrete, etc.), joining fixed or inactive joints (gaps between the jamb and a brick or concrete wall, sealing knocks in pipes, etc.). These compounds are used to treat the unprotected edges of furniture that is installed in the bathroom, suitable for filling the junction of the sink with the wall.

Acrylic sealants are good for filling cracks

Another unpleasant moment: in a humid environment, fungi and bacteria grow well on the surface of an ordinary acrylic sealant. This disadvantage is eliminated by the presence of antiseptic additives, but it is better not to use acrylic sealants for areas constantly in contact with water.

And one more thing: in the bathroom, acrylic quickly changes color - it begins to turn yellow. Therefore, you should not use white. Better colored (there are some) or transparent. The color changes are not so visible on them.

When choosing, it is worth remembering that acrylic sealants may or may not be waterproof. Acrylic bathroom sealant must be water resistant. Even in those areas where water cannot directly contact with it, but due to high humidity it can absorb moisture from the air.

Acrylic sealant brands

There are quite a few good brands. Only for the bathroom, it is imperative to look so that the composition is moisture resistant.

- Bison Acrylic. There are several different formulations: Super fast, drying in 15-30 minutes, Universal - can be used to seal wood.

- Bosny ACRYLIC SEALANT;

- Boxer;

- Dap Alex Plus. It is an acrylic latex compound with greater elasticity and additives against fungi.

- KIM TEC Silacryl 121. Polyacrylate moisture resistant and elastic sealant. Can be used in areas of prolonged contact with water.

- Penosil. For filling joints and cracks that are not in direct contact with water.

There are many other brands and manufacturers. Many acrylic sealants have special additives that change their properties. If you are satisfied with their harmlessness, you can find a composition even for direct contact with water.

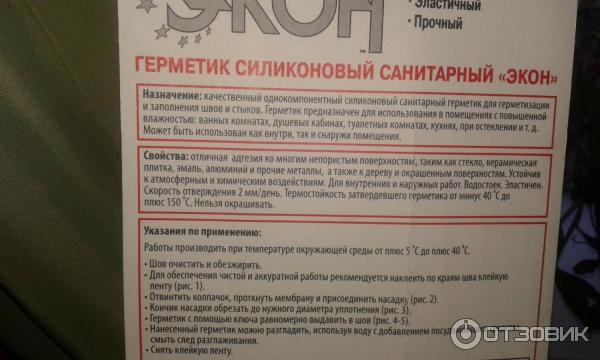

Purpose, composition and properties

Sanitary sealant is universal, but due to its high cost, neutral is more often acquired.

Sanitary options are widely applicable for a variety of purposes:

- for plumbing works;

- when laying pipes;

- for processing joints and seams;

- for filling gaps;

- when installing kitchen equipment;

- for processing window frames;

- for grouting tiles;

- for insulation during electrical installation and repair work.

Sanitary sealants contain special additives that protect against mold and other organic deposits, such as those of a bacterial nature. They increase the cost of the material, but they are simply necessary in places with high humidity. Also, silicone products are quite resistant to chemical attack.

Due to these additives, sanitary sealants cannot be used in work involving food, drinking water and animals. This is the main difference from the universal remedy.

Sanitary silicone sealant has the following composition:

- silicone rubber - constitutes the bulk;

- hydrophobic filler;

- plasticizers for elasticity;

- a thixotropic agent that makes the material less viscous;

- fungicide that provides protection against fungus;

- primers that enhance adhesion;

- coloring pigment;

- catalyst.

Thanks to the additives, silicone sealants are resistant to ultraviolet radiation, withstand frosts down to -30 ° C, have high elasticity, and are not afraid of temperature extremes and atmospheric precipitation. Therefore, they are perfect for outdoor renovations, glazing of facades of buildings and greenhouses.

For home use, it is better to purchase sanitary sealants in small tubes. After opening the package, the tightness conditions are violated, and the remaining unused silicone will dry out over time or deteriorate its quality characteristics. If necessary, it is better to buy fresh. With large-scale repair work, for example, replacing pipes and plumbing in the bathroom, you can buy a larger tube, this will be more economical. For convenience, you will have to purchase a special pistol, which is characterized by reusable use, but cheap models quickly fail.

Manufacturers

The German corporation Henkel occupies a leading position in the rating of manufacturers of sanitary sealants. Her trademarks "Ceresit" and "Moment Herment" receive very good consumer reviews.

The rest of the well-known brands are distributed almost equally in terms of popularity.

The Ceresit brand of Henkel Bautechnik, a subsidiary of Henkel Corporation, is highly valued by consumers. Ceresit cs 15 sealant adheres perfectly to porcelain, ceramic, glass, enamel edges. Any surface, porous and smooth, is subject to it. It has high elasticity, water resistance, heat resistance, does not fade, the sun's rays do not affect it.

Acidic and neutral sealants

Silicon seal remover (HG). Includes a brush for application and a spatula for removal (1 pack. 100 ml - 655 rubles). Photo: HG

In addition to silicone rubber, the sanitary sealant contains substances that provide strength and thixotropic qualities (thanks to the latter, the sealant does not drain from vertical surfaces), fillers, vulcanizing components, adhesion enhancers for reliable constant contact with the surface, fungicides (these additives practically exclude the growth of fungi and mold on the seam surface), plasticizers and dyes.

Sili-Kill silicone remover (Den Braven) (1 pack of 100 ml - 314 rubles). Photo: Den Braven

After the mass leaves the tube, the vulcanization reaction begins. It occurs with the participation of moisture in the air. Depending on the type of compounds formed during this, silicone sealants are divided into two large groups: acidic and neutral.In the former, acetic acid is released during curing, which can be understood by the characteristic odor, in the latter, harmless alcohols and water.

Each type of sealant has its own advantages and disadvantages. Acidic ones have better adhesion and are cheaper. However, they cannot be used with materials that react with acetic acid and begin to degrade. These include metals that are not resistant to corrosion, mirrors with a thin layer of amalgam, natural stones (including marble, limestone), concrete. As a result, metals prematurely corrode, mirrors darken and become stained, at the contact points of acid sealant and cement concrete, which has an alkaline nature, a layer of powdered salt appears, which prevents adhesion.

Surfaces that are poorly compatible with acidic sealants work well with neutral silicone sealants. Their distinctive feature is chemical inertness and, alas, a higher cost. It is these compounds that are used to seal PVC and acrylic surfaces, including acrylic bathtubs.

Acidic Silicone Sealants

| Name, brand |

Silicone Sanitary Tytan Professional |

Kitchens, bathrooms |

Ceresit CS 15 |

Premium Sanitary Silicone |

Sanitary silicone S25 |

Isosil s205 |

|

Manufacturer |

Selena |

Soudal |

Henkel |

Penosil |

Pufas |

Iso Chemicals |

|

Skin-forming time, at 23 ° C and 50% rel. humidity, min |

5–40 |

7 |

10–35 |

10–25 |

10 | 25 |

|

Cure rate in depth at 23 ° C and 50% rel. humidity, mm / day |

2 | 2 | 2 | — | 3 |

1–2 |

|

Heat resistance, ° C |

–40…+100 |

–60…+180 |

–40…+150 |

–40…+100 |

–25…+120 |

–40…+150 |

|

Expiration date, months |

18 | 12 | 18 | 18 | 24 | 24 |

|

Packaging, ml |

310 | 300 |

280 |

310 | 310 | 280 |

|

price, rub. |

232 |

239 |

180 | 202 |

256 |

220 |

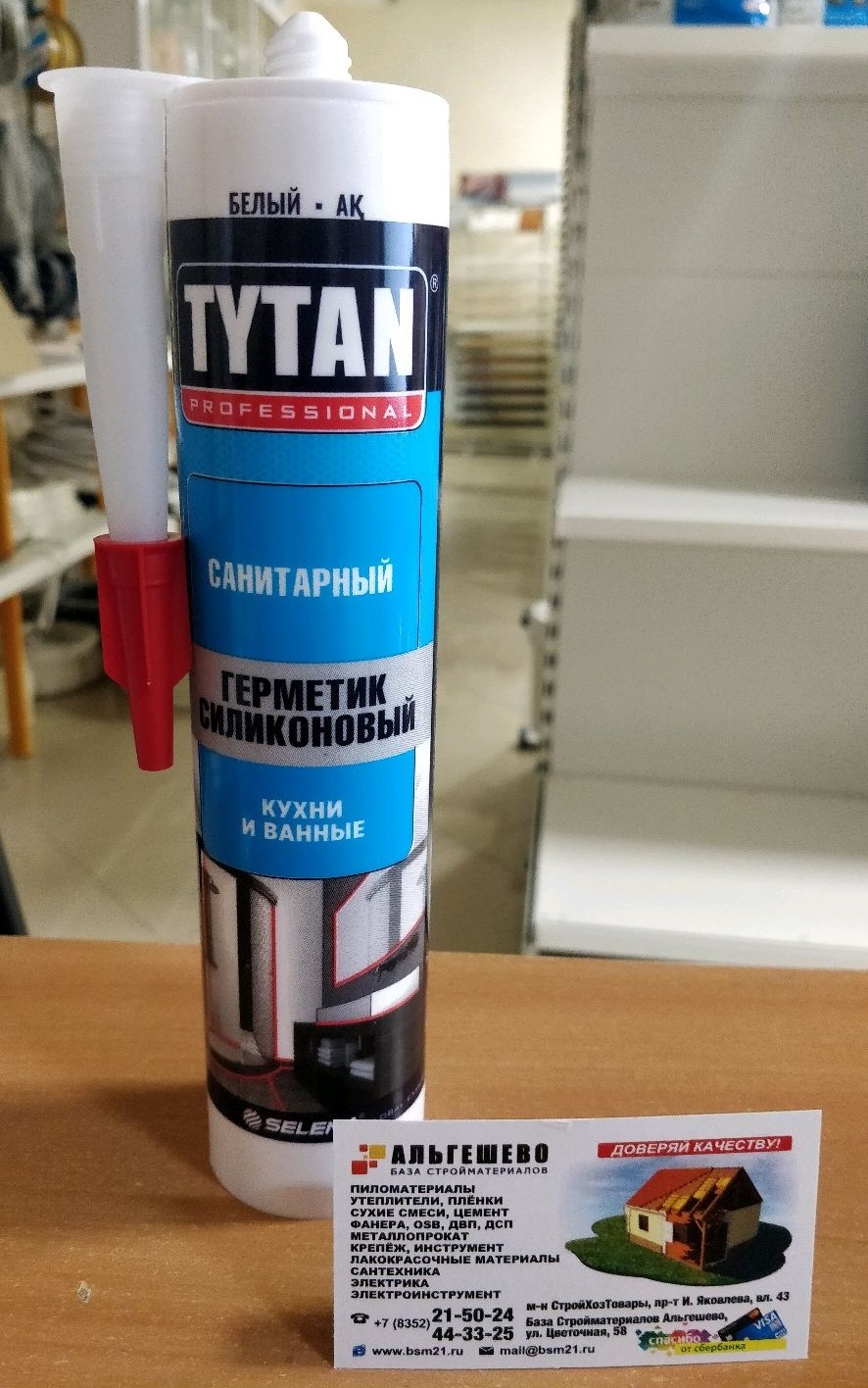

Silicone

Quite a popular type of sealing compounds. In composition, they can be acidic and neutral. Acidic ones are easier to manufacture, they are cheaper, but it is difficult to work with them indoors - they have a strong smell before they harden. The second negative point of acidic ones is that when applied to a metal, it quickly oxidizes. Therefore, it is not worth using it to seal steel and cast iron baths. Neutral silicone sealants do not react with materials, therefore their field of application is wider. But the production technology is more complicated and they cost more.

Bathroom silicone sealant is a good solution

Both acidic and neutral silicone sealants may or may not be waterproof. Only waterproof baths are suitable. They also come in one-component and two-component. For private use, one-component is mainly used, since they do not need to be mixed before use.

Properties and scope

Properties and applications of silicone sealants:

- They have good adhesive properties. They can be used to seal the joints of stone and plastic window sills, when installing sinks and other appliances in the countertop.

-

It is used for sealing glass joints, non-porous building materials (metal, plastic, glass, wood, ceramics), adjoining drywall to the ceiling, drain pipes.

- They are characterized by increased tolerance to high temperatures, and can be used to seal joints around chimneys.

- Resistant to water, can be used to seal the junction of bathrooms and showers, sinks and other plumbing fixtures.

The main advantage of silicone sealants is that after polymerization, the seam remains sufficiently elastic. It does not crack and can be used to seal the junction of an acrylic or steel bathtub with a wall. The disadvantage is the susceptibility to the appearance and reproduction of the fungus. It is solved by adding antiseptic additives. To prevent the development of mold and mildew, it is best to use a silicone sealant for the aquarium or special plumbing. Both of these types have antibacterial properties.

Brands and prices

Silicone bath sealant is popular today and there is a pretty decent assortment in any store.

| Name | Colour | Special properties | Surface film formation | Release form and volume | Price |

|---|---|---|---|---|---|

| BAU MASTER UNIVERSAL | White | acid | 15-25 minutes | Tube for pistol (290 ml) | 105 rbl |

| Bison Silicone Versatile | white, colorless | acidic, resistant even to seawater | 15 minutes | Tube for pistol (290 ml) | 205 rbl |

| KIM TEC Silicon 101E | white, transparent, black, gray | acidic, contains antibacterial additives | 25 minutes | Tube for pistol (310 ml) | 130-160 rub |

| Somafix universal silicone | white, colorless, black, brown, metallic | acid | 25 minutes | Tube for pistol (310 ml) | 110-130 rub |

| Somafix construction | white, colorless | neutral, does not turn yellow | 25 minutes | Tube for pistol (310 ml) | 180 rbl |

| Soudal Silicone U universal | white, colorless, brown, black, | neutral | 7 minutes | Tube for pistol (300 ml) | 175 rbl |

| WORKMAN Silicone Universal | colorless | acid | 15 minutes | Tube for pistol (300 ml) | 250 rbl |

| RAVAK Professional | neutral, anti-fungal | 25 minutes | Tube for pistol (310 ml) | 635 rbl | |

| Ottoseal s100 sanitary | 16 colors | acid | 25 minutes | Tube for pistol (310 ml) | 530 rbl |

| Lugato Wie Gummi Bad-Silicon | 16 colors | neutral with bactericidal additives | 15 minutes | Tube for pistol (310 ml) | 650 rbl |

| Tytan silicone sanitary, UPG, Euro-Line | colorless, white | acidic with bactericidal additives | 15-25 minutes | Tube for pistol (310 ml) | 150-250 rub |

| Ceresit CS | colorless, white | acidic / neutral | 15-35 minutes | Tube for pistol (310 ml) | 150-190 rub |

As you can see, there is a very wide variation in prices. Expensive sealants (Ravak, Ottoseal. Lugato) - made in Germany, Denmark, Czech Republic. According to reviews, they are of excellent quality - they have been used for several years without changes, the fungus does not multiply on them. They are presented in the widest range of colors.

Inexpensive Ceresit, Tytan, Soudal serve well. These manufacturers have a wide range of both acidic and neutral silicone sealants. There are also other types (acrylic, polyurethane). There are also good reviews on them for use as a sealant for a bathroom - a joint with a wall.

Peculiarities

In everyday life, sealants are used to adhere various surfaces, for example, ceramics, plastic, wood, glass and tiles, it can be used for grouting. Silicone sealants have excellent adhesion and water resistance. The material is flexible, easy to use and durable.

Sealants are multicomponent, when silicone hardens under the influence of a certain substance, and one-component, hardens with water by the action of air or moisture.

The latter are divided into several subspecies.

- Neutrals are all-rounders that are used almost universally.

- Acidic - reliable, flexible, the most inexpensive in the line. They have a pronounced vinegar smell due to the acid they contain. They are aggressive to some materials, therefore they have a narrow application, often these are metals that are not subject to the negative effect of acid, ceramics, glass.

- Sanitary - contain special fungicidal additives, therefore it is used in rooms with high humidity and in plumbing. This subspecies is the most expensive.

In order for the sanitary sealant to fulfill its task and please with the result, it is important to pay attention to the following points when buying:

- shelf life - the "old" sealant may peel off or not at all fasten the structural parts;

- plasticity - the parameter shows at what air temperature you can work with it, what is its elasticity, this is important when working outdoors at low temperatures;

- the quality of adhesion of a certain brand;

- shrinkage - shows how much the sealant will shrink when exposed to air and moisture. Normally, the silicone sealant should shrink no more than 2%.

Recommendations for use

In order for the sanitary sealant to adhere well and not flake off over time, it must be applied correctly, following the instructions on the package. It can be tested before use. To do this, you need to apply a little silicone to a piece of plastic and allow it to completely cure. If the seam comes off completely with ease, then the sealant is either expired or of poor quality. If it comes off with difficulty or in pieces, then you can safely use it.

There are several steps to follow to apply the sealant.

- It is necessary to remove the old sealant layer, if any, to clean it if necessary.The surface must be dry and clean for the best adhesion. Degrease. The instructions for use on some cartridges, on the contrary, advise slightly moistening.

- To make the seam even and neat, glue masking tape on the sides.

- Insert the cartridge into the gun, cutting off the tip at a 45 degree angle. The thickness of the sealant extruded depends on how far the tip is cut from the edge.

- Apply sealant. To keep the seam of the same thickness, press the gun trigger with equal force. You can smooth and smooth the seam with a rubber spatula, a damp cloth or a soapy finger. If a film has formed, you can no longer touch it.

- After laying the seam, immediately tear off the tape. You can remove excess or the consequences of inaccurate application by rubbing with the rough side of a sponge, a rag or a rubber spatula. The sealant must be wiped off immediately, after hardening it will be very difficult to do this.

The first film appears within 10-30 minutes. The full cure time depends on the type of sanitary sealant. Acid versions harden in 4–8 hours, neutral ones - about a day. The hardening time is influenced by the amount of additives and dyes, the more there are, the longer it hardens, the thickness of the joint, the temperature and the humidity of the air. On average, the sealant hardens completely in a day, with external work - up to one week.

If drying time matters, then the process can be artificially accelerated:

- improve ventilation;

- increase the air temperature, the sealant will dry 1.5-2 times faster;

- sprinkle the frozen film with water from a spray bottle.

For information on how to properly use silicone sealant, see the next video.

Deleting

There are two ways to remove sanitary silicone sealant from various surfaces: mechanically or using special cleaning agents.

The first method can be used if you need to remove fresh, not yet cured silicone sealant. You can simply pick it up with a knife blade, and then collect it with your hands. A sharp knife can also be used to scrape off a thick layer of old, long-set sanitary sealant.

If the layer of silicone sealant is thin enough and does not lend itself to mechanical stress, solvents and silicone removers will come to the rescue. Both ordinary acetone or white spirit are suitable, as well as specialized products that can soften silicone without damaging the surface. These include, for example, Silicone Remover, Sili-Kill and Permaloid.

Additional Information: Sanitary silicone sealant moment instructions for use

The next step is to partially solidify, which should be expected after 3 hours. If the layer is thin, then the sealant can completely harden after this time. Curing is achieved at room temperature within 24 hours.

If the seam turned out to be deep enough, and its width is large, then the process in this case is delayed for a longer amount of time. After final drying within a week, the strength of the joint increases, for this reason the surface should be left for a longer time.

Secondly, the sealant should be selected with an eye to the material with which it will come in contact. For example, if the sealant will be used on non-acid-resistant materials such as glass, non-ferrous metals or natural stone, you must purchase an acid-free sealant. Aggressive sealants containing acids have a strong vinegar odor.

- expiration date - the “old” sealant may peel off or not at all fasten the structural parts;

- plasticity - the parameter shows at what air temperature you can work with it, what is its elasticity, this is important when working outdoors at low temperatures;

- the quality of adhesion of a certain brand;

- shrinkage - shows how much the sealant will shrink when exposed to air and moisture.Normally, the silicone sealant should shrink no more than 2%.

The peculiarities include the fact that the manufacture of products is based on maximum environmental protection in strict accordance with all indicators of high quality. There are more than 200 types in the names of goods, but the main part is occupied by the sealant. Also popular are products such as polyurethane foam and self-adhesive tape.

Before purchasing, consumers ask themselves the question of whether how long does silicone dry sanitary sealant "Moment" brand. In the case of this composition, you can follow the recommendations from the manufacturer. A film will form within 15 minutes if the ambient relative humidity is 50%.

Whereas the ambient temperature should be 23 ° C. This composition will harden in a day if its thickness is 2 mm. Sealant moment silicone universal white reviews?

This curing rate is to be expected under the mentioned conditions.

“Moment of Silicotech” makes the joint surface smooth and even. If necessary, immediately after application, the product can be adjusted and smoothed with wet hands - it is easily washed off from the hands and tools that were used in the work. In the process, make sure that the "Moment" does not go beyond the seam.

If this does happen, then remove the excess sealant with a damp cloth.

The bathroom differs in many ways from all other rooms in the house. A special microclimate is maintained here, the main features of which are high air humidity and temperature drops. Therefore, for the renovation of the bathroom, special finishing and building materials are used, intended for use in rooms with high levels of humidity and with changing temperature conditions.

Peculiarities

The sanitary sealant is based on a silicone polymer.

Its main components are:

- pigments;

- silicone rubber;

- filler;

- a vulcanizing agent that makes it similar to a rubber mass;

- various plasticizers that give elasticity;

- fungicidal additives that have an antifungal effect;

- catalysts and strength enhancers.

A sealant is necessary to ensure the watertightness of the surface, which is ensured by filling its joints, cracks and seams. Silicone sanitary version differs from acrylic, bitumen and polyurethane in that the biocidal components added to it protect the surface from mold and mildew. Sanitary sealant is environmentally friendly, aesthetic and versatile, so its use is widespread.

The main properties of a universal sanitary product are water, thermal and frost resistance, resistance to ultraviolet radiation, pathogens, aggressive cleaning agents, elasticity and durability. Sanitary sealant contains organosilicon compounds that increase the sealing of joints. Silicone contributes to strength and at the same time good elasticity. Sanitary silicone sealant has excellent surface adhesion.

Such a sealant is able to withstand any fluctuations in heat and cold, an unexpected drop in air temperature. It does not absorb moisture and is recommended for use in places with high humidity: baths, laundries, swimming pools, bathrooms and showers.

Selection Tips

- When buying a sanitary silicone sealant, carefully study its composition: about 90% should be silicone rubber and filler (and both should be approximately equal). The remaining 10% are fungicidal additives, plasticizers, catalysts, etc.

- For the production of high-quality silicone sealant, more expensive materials are used and, as a result, a higher price is assigned for it. Therefore, buy a sanitary sealant no less than 150 rubles for a standard package.

- If the packaging of the sanitary sealant is labeled “A,” it means that it is an acidic sealant. These sealants have a pungent vinegar odor. Silicone sealant universal transparent moment characteristics? When working with them, the skin of the hands and the respiratory tract should be protected. In addition, acidic sealants may not be used on all types of materials.

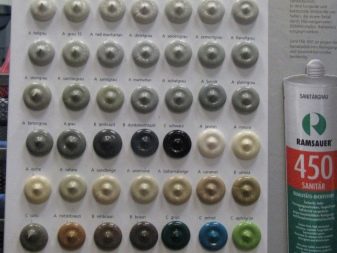

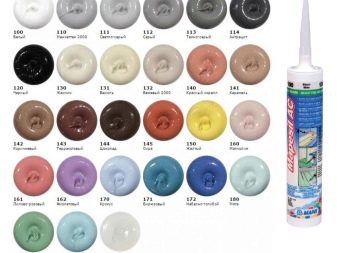

Colors

Sealants containing silicone are not advised to paint after they have hardened, because the paint will peel off. For this reason, colored products are produced: brown, gray, black. Neutral colors are in great demand: white, colorless (transparent).

For the treatment of cracks in bathrooms, grouting gaps in the bathroom and in the kitchen, the white color of the sanitary composition is used. When building pools, white is also preferred. The use of a transparent medium is reasonable, since it is almost impossible to discern the substance. They are used to seal the gaps of flooded floors, wooden structures and glass edges. Gluing tiles to concrete is also done with a transparent sealant.

The transparent color is useful when grouting joints in terrariums, aquariums, as well as any smooth surfaces. It is recognized as completely harmless to the inhabitants of the aquarium. In addition, fresh and salt water has no effect on the silicone sealant.