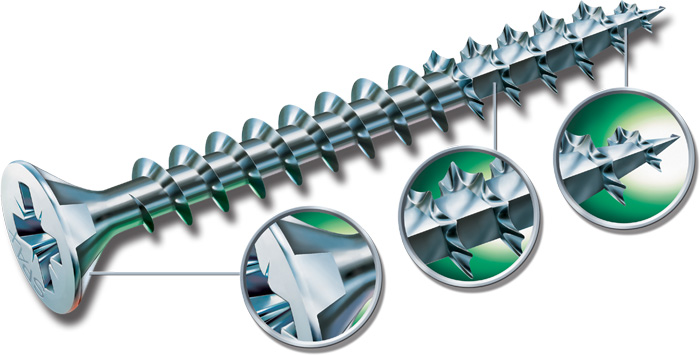

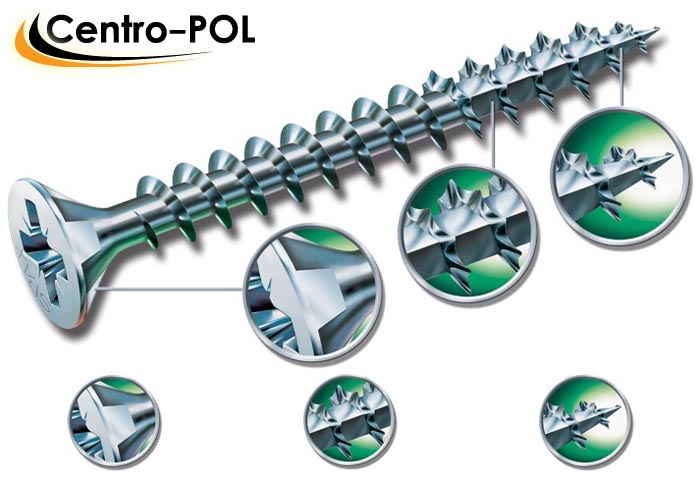

Features of Spax self-tapping screws

Spax fasteners are manufactured from carbon steel or stainless steel (A2)

Spax fasteners are manufactured from carbon steel or stainless steel (A2)

Spax hardware was specially designed for fixing various solid wood products: block house, parquet, solid, parquet and decking, furniture and other products. Thanks to the special configuration of the self-tapping screw, the installation and assembly of wood elements is accelerated and simplified, you do not have to worry about cracking and deformation of the array, because this will not happen with such fasteners.

Spax fasteners are manufactured from carbon steel or stainless steel (A2). A zinc anti-corrosion coating acts as a protective layer. The assortment of this brand also includes moisture-resistant self-tapping screws with a brass coating. Such hardware is ideal for fixing solid wood decking.

Self-tapping screw Spax with oxidized coating

Self-tapping screw Spax with oxidized coating

So that in the process of screwing in the self-tapping screw, the cap can be well drowned in the material, the manufacturer makes it with a slight tilt relative to the axis of the element. To prevent spontaneous twisting during natural deformation of the coating, the self-tapping screw is equipped with a wavy profile. Thanks to this, the holding force of the hardware of this brand is much higher than that of other fasteners.

The product consists of several parts:

- A special quadrangular tip allows you to attach boards without pre-drilling a hole. With these self-tapping screws, even very thin floorboards will be insured against cracking.

- To ensure smooth and easy screwing, wavy turns follow the tip. The longer the hardware, the more such turns.

- This is followed by a thin, smooth galvanized steel part (A2). It is completely hidden in the body of the board.

- A special head inclined to the axis of the product provides a secret fixation. Thanks to the clumsy edging, the self-tapping screw is insured against spontaneous unscrewing during the operation of the floor covering.

Advantages of Spax fasteners

The slanted hat is completely recessed into the body of the board

The slanted hat is completely recessed into the body of the board

- The special four-sided design of the tip allows you to gently remove wood fibers without cracking the product. This tip shape makes screwing easier and faster.

- Thanks to the wavy profile of the screw part, smooth screwing in is ensured. At the same time, you will need to make less physical effort for this.

- The bit with a cutter allows you to attach boards without pre-drilling holes.

- The tilted hat is completely recessed into the body of the board.

- The perforation on the back of the cap has a locking effect. As a result, the screw will not unscrew over time.

How to choose Spax screws

The main problem of choice is the correct selection of the length of the fastener. The choice of the length of the hardware for fixing the terrace board is made, focusing on the following rules:

- If the installation of the decking will be carried out using special clips, then the length of the self-tapping screws screwed through the clip into the side of the board should be 2.5 times greater than the thickness of the flooring.

- To fasten the clip to the lags, self-tapping screws with a length of one and a half times more than the thickness of the terrace board are suitable.

- If the fastening will be carried out through the front surface of the terrace floorboard, then the length of the hardware should be three times the height of the flooring.

The choice of self-tapping screws Spax

Diagram of the device of steel self-tapping screws Spax

Diagram of the device of steel self-tapping screws Spax

Self-tapping screws of this brand are available in different lengths. To correctly select the length of the Spax fastener for a solid board, follow the following rules:

- The length of the fastening element should be 2-2.5 times greater than the thickness of the board when fastening solid wood products to the thorn.

- When fixing in the groove, the length of the self-tapping screw should be 1.5-1.9 times the thickness of the massive floor covering. This method of fixing is used only when installing the outer boards.

- The length of the self-tapping screw, which is 2.5-3 times the thickness of the floor product to be laid, is needed when fixing through the entire thickness of the board to the base. This fixing method is used only when laying the first and last floor element in the places where the skirting board will be installed. Also, fastening through the entire thickness is used when laying a plywood base on logs.

General advice for choosing fasteners

The self-tapping screw is selected based on the thickness of the floorboards to be laid

The self-tapping screw is selected based on the thickness of the floorboards to be laid

There are general rules that should be followed when choosing fasteners for flooring. By following them, you are guaranteed to acquire reliable and durable self-tapping screws. So, when choosing a mount for installing a terrace flooring, follow these simple rules:

Pay attention to the dimensions of the element. The self-tapping screw is selected based on the thickness of the floorboards to be laid

The thicker the board, the deeper the fasteners should go into the base frame. The diameter is selected depending on the place where the screw is screwed in. If the fastening is made in a thin spike, then the diameter should be small, in order to screw the fastener through the entire thickness of the board, you will need to buy a larger diameter self-tapping screw.

Slot and thread characteristics. By these indicators, it is easy to distinguish high-quality fasteners from low-grade products. Reliable manufacturers, for example, Spax, have self-tapping screws with uniform threads with threads of the same thickness and angle of inclination. The smooth slot will ensure a good fit of the screwdriver and quick screwing in.

Self-tapping coating can be of different types:

uncoated is the worst option, so it is not recommended to use it;

with an oxidized protective layer - such screws can be distinguished by their gray or blackish color. These are good fasteners with increased durability;

galvanized - these products have a silver or gold surface. They are marked with the designation A2. This mount is considered the most durable and reliable. However, the cost of these hardware is rather big.

- A kind of hat. For editing, this parameter is of great importance. Depending on the purpose of the self-tapping screw, the caps come in different configurations. Products with wide heads are suitable for fixing sheet material. For wood, you need to buy elements with a standard head. However, to make a flush mount, you need hardware with a 60 ° beveled head.

How to choose?

Before purchasing such items, you should pay special attention to some selection criteria. Be sure to look at the head variety

It can be hidden - in such options, the head, after installation, is completely buried in the material, it will not protrude above the boards. There is also a semi-countersunk head, it has a smooth transition from the central rod to the thread. Such models, after fixing, completely sink in both from the outside and from the inside.

Specimens with a semicircular head have a fairly large pressing surface of the material. This allows the part to be fixed to the surface as firmly and reliably as possible. Semicircular heads with a press washer will be the best option for joining sheet materials. They are distinguished by a slightly increased surface and reduced height.

Truncated cone screws are used for metal structures or drywall. As a rule, such models are coated with a special phosphate protective agent. The hexagonal heads of the self-tapping screws can be fixed only with powerful electric devices with attachments. Cylindrical products can only be screwed into a slightly drilled recess. Be sure to look at the thread type before buying.It can be rare, such models are used for softer materials. Most often, these screws are used for wood, asbestos, plastic. The middle thread is considered a universal option, which is taken to fix concrete surfaces, in this case the elements are hammered into the dowels.

Self-tapping self-tapping models with frequent threads can also be used to fasten metal thin sheets, while dowels are not needed. Samples with an asymmetric thread are best used when assembling furniture. However, it will be necessary to pre-drill the hole.

The following video talks about Spax self-tapping screws.

Requirements for fasteners for decking

Self-tapping device for decking

Self-tapping device for decking

Terrace flooring differs significantly from indoor flooring. Such a flooring is constantly affected by unfavorable weather factors - rains, temperature fluctuations, humidity and sunlight. In this regard, increased requirements are imposed on fasteners for terrace coverings.

Usually, two types of fasteners are used to fix the deck board, depending on whether brackets will be used or the installation will be carried out by screwing through the front surface. The selection of self-tapping screws for decking is done according to the following parameters:

- Galvanized (A2) hardware with silver or gold plating is usually used. For reliable and durable fixation, their diameter must be at least 4 mm.

- The length of the mount depends on its purpose. You can use elements from 4 to 6 cm in length. Some of them are used for attaching clips, while others are suitable for corner caps.

- The drill bit makes it easier to screw the fastener into the board. This is the tip that Spax screws have, for which they are very appreciated.