Dimensions (edit)

As for the dimensions, according to the requirements of GOST, the diameter of the hexagon cannot be less than 8 mm. If this indicator does not match, then we are definitely talking about some other type of fastener. The size chart also mentions the following basic parameters for a hexagon:

- 6x50;

- 6x60;

- 6x100;

- 8x80;

- 8x100;

- 10x60;

- 10x100;

- 12x70.

For each type of hex, a specific type of key is used, and each of them has its own field of application, where they will work most effectively. Choosing a hexagon in terms of size and performance, as well as design features, the risk of making a mistake becomes much less.

Where are they used?

As mentioned above, the design features of the countersunk head self-tapping screw contributed to the widespread use of the product in the process of fastening various elements:

- wooden;

- plastic;

- steel sheets (metal products).

Most often, this fastener is used when working with wood. In the process of carrying out facade and roofing works, the potay self-tapping screw is an indispensable element. Its use makes it possible to reliably fix the structure assembly and maintain its aesthetic, reliable appearance, a smooth and even surface.

The video below briefly talks about the application and the difference between a self-tapping screw and a screw.

Species overview

Self-tapping screws with a pointed tip can be classified according to different criteria. So, depending on the type of head, they are divided into the following models.

Hex head products

Such devices are outwardly similar to ordinary bolts. But they are distinguished by a rare screw thread and a slightly sharpened tip. These samples, as a rule, are taken for fastening large massive wooden structures.

Fasteners with press washer

These fasteners differ in the increased area of the contact area of the head area. The press washer allows you to press wooden or metal boards as tightly as possible (but their thickness should not exceed 10 millimeters).

Countersunk Locks

Most often they are used for fastening wooden sheets, but they can be used for metal as well. These types are considered universal options, they have an average thread pitch, their heads are distinguished by a special reinforced emphasis, but when fixing them in the material, you should not apply a lot of physical effort.

Hemispherical head retainers

Similar options for fasteners can also be attributed to the universal group. They have a very pointed tip. Models are considered the most suitable option for attaching a metal frame to a wooden crate. They can also be taken to attach profiles to each other.

Round head self-tapping screws

These types of fasteners can be used to attach metal profiles, mainly those made of aluminum or soft alloys with aluminum. There is a small cross-shaped slot on the head, such an element makes it possible to use self-tapping screws for powerful screwdrivers. The central rod of the product has a tight single-start thread.

Also, self-tapping screws with a sharp tip can be classified depending on what material they can be used for.

By wood

Fasteners for wood, lining have rare threads in the form of thin screws. Wooden products are considered softer and more pliable to processing, so they do not require too sharp self-tapping screws. Fasteners can be inserted into surfaces without preliminary drilling, but self-tapping screws with a drill can significantly speed up this process and make it simpler.

Furniture screws

Such options allow you to fasten chipboard and MDF boards, from which furniture structures are mainly made. The fixing elements have a traditional length of 50 millimeters. Their hat is hexagonal.

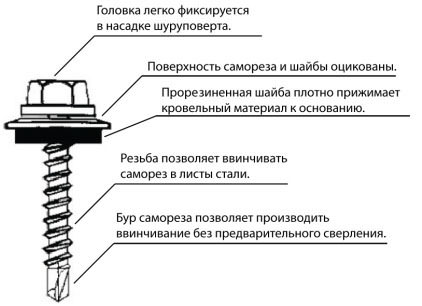

Roofing types

Such self-tapping screws with a drill have a hexagon head and a special rubber washer-gasket. The last element plays an important role, since it is thanks to it that sufficient insulation from a large amount of moisture is ensured, and it also acts as a shock-absorbing seal for the joints.

Vandal-proof varieties

These special tipped self-tapping screws have a cap with special grooves. They can have a star-shaped, multifaceted shape.

Self-tapping screws with drills also differ from each other in the type of thread.

- Coarse thread. As a rule, it runs along the entire length of the metal rod and has a rare pitch. The model will be suitable for working with soft materials, including different types of wood, plaster and plastic.

- Average. This thread is found in universal types of self-tapping screws. Almost all materials can be recorded with such models.

- Frequent double-start threads. This type is suitable for working with thin metal sheets. There is a thin, sharp tip at the end of the rod.

- Asymmetric thread. It is often used in production, in domestic conditions it can be taken for the assembly of furniture structures.

- Variable serrated thread. This type is used in cases when you need to attach products to a brick or concrete surface without using dowels.

Vandal-proof views

Such screws may externally be similar to other options, but upon closer inspection, the difference is obvious.

It consists of special types of grooves on the caps; these can be multifaceted, star-shaped or paired notches. They cannot be unscrewed with an ordinary tool, which explains the name of the fastener.

Within the framework of this article, the most common types of self-tapping screws are described. There are many types, including a narrow focus, so it is advisable to try to select exactly those fasteners that are designed to connect specific materials. It is not worth saving and using available fasteners, since a poor connection of surfaces is possible, which will lead to a violation of the strength of the connection.

Species overview

Self-tapping fasteners are of different types, thanks to which you can always find the right option for a particular job. Black and colored products can look different and have different purposes:

- decorative;

- roofing;

- for drywall;

- for metal profiles of different thicknesses.

The thread of these products can also be different.

- Coarse is a high thread that has a wide pitch. Such parts are often held together by soft and loose materials.

- Shallow - low with a narrow step. Such products connect a dense and hard surface.

- Double-threaded, which has both high and low turns, which alternate with each other. This fastener is considered the best option for fastening materials of different characteristics.

Often on sale there are reinforced hardware for a hexagon and a screwdriver. You can find out about the characteristics and purpose of the bolt thanks to the marking.

By head type

Usually self-tapping screws for metal have semicircular and cylindrical heads, there are also options with a hexagonal or spherical head. Metal products with hex heads are currently considered the most common, since they do not require a lot of time and effort during operation. Also, the master can purchase products with rounded, countersunk, trapezoidal heads, as well as press washers and EPDM gaskets.

The slot for hardware fixing metal surfaces can be of the following types:

- anti-vandal;

- Torx;

- Ph;

- Pz.

By tip type

According to this criterion, self-tapping screws are pointed and with a drill.The former are characterized by the presence of a pointed tip and a rolled thread. It can be used when working with metal, the thickness of which does not exceed 0.9 mm.

The second version of the fastener has a pointed drill with two feathers at the end. With the help of this product, metal is fixed, which is more than 2 mm thick. Hardware with a drill is used for mounting the internal and external parts of the product. Their reliability is ensured by a zinc coating and a painted head.

By type of coverage

The coating of self-tapping screws for metal can be different.

Phosphated. In this case, the fixing bolt is colored black. Such hardware is made from carbon steel, after which it is treated with phosphates. Often, such a product is used in a room where there is high humidity.

They can only be used during interior work and under normal indoor humidity conditions.

Standard

The quality of hardware is regulated by GOSTs, the main of which is 1145-80. According to this standard, metal products can have a countersunk head and a different type of slot. If the product is manufactured strictly in accordance with GOST, then it can be used in industry, production and construction. Such screws are made from carbon steel, stainless steel.

Products that are manufactured according to DIN 7981 and DIN 7982 are capable of holding thin sheets of metal together. However, it is recommended to re-drill the surface before carrying out the procedure. Products with shape C have a sharp tip, and those with shape F have a blunt tip.

Self-tapping screws DIN 7982 are made of steel, they differ little from products that are made in accordance with GOST 10621-80 and ISO 7049. They have found their application in the machine-building and instrument-making industries.

Specifications: dimensions, weight and more

Mainly made of carbon steel and galvanized. Thanks to the anti-corrosion coating, they serve for a rather long time - about 50 years. In addition to them, stainless steel hardware is presented on the market, however, they are much more expensive. As a rule, they are used in especially critical areas for which it is necessary to provide increased strength.

These products are also distinguished by the shape of the cap. She may have:

- standard view, that is, equipped with a screwdriver, or;

- with edges, for which special bits for roofing screws are used.

See how they might look in the photo.

Further, depending on the type of roofing material, the caps can "sink" in the coating or, as in the case of the option with a press washer, press it, which will completely protect the hole from water penetration. The hat of the latter has the form of a hemisphere.

Hardware can be supplied with a metal, usually aluminum, washer with a rubber gasket. A sealing gasket made of a special self-vulcanizing material EPDM with a thickness of 2.8 mm is considered more effective and durable.

Among the wide variety of market offers, you can always pick up fasteners that have a length that exactly matches the wavelength of the roofing sheet.

Peculiarities

Self-tapping screws are one of the most commonly used types of fasteners. The main reason for this popularity is the presence of a countersunk head on the product. Its shape is so perfect that the working surface after mounting the self-tapping screw remains flat, without any bulges.

Such fasteners have a number of other features, namely:

- strength;

- reliability;

- wear resistance;

- corrosion resistance;

- long service life;

- wide selection and assortment.

All self-tapping screws differ in size and purpose. There are fasteners designed for fastening wooden or plastic structural elements, there is also a separate type for working with metal.

The design of a self-tapping screw is practically no different from a conventional screw. It consists of:

- a rod, along the entire length of which the thread is located (sometimes the thread is applied only to a part of the product);

- slotted heads (the type of head is different);

- tip of a sharp or blunt type.

It can be stainless carbon steel or non-ferrous metal such as brass. After manufacturing, the fasteners can be treated with a special coating that increases its anti-corrosion properties. Most often it is zinc or other phosphate substances.

The production process, control of the materials and raw materials used are clearly spelled out and provided in the regulatory documents GOST 1145-80, GOST 1144-80 and GOST 1146-80. Also, these regulations control the passage of all necessary laboratory tests and the issuance of quality certificates.

The product is characterized by the following parameters:

- screw diameter, mm;

- screw length, mm;

- slot size;

- type of thread;

- appointment.

Specifications

Considering the roofing screws (they are hardware or fasteners), as they say in the section, we can say that they consist of three parts with different functional purposes. It:

-

Drill, or drill on the edge of a self-tapping screw

facilitating self-drilling. -

Body with threads for screwing in and deepening fasteners

in a crate made of wood or metal. -

Hat, or head, used for screwing in a self-tapping screw

and further fixing the roofing material.

Due to the specificity of the application, roofing screws are made from strong grades of hydrocarbon steel.

Subsequent zinc coating ensures their protection against corrosion damage. In addition to galvanized ones, on sale you can find copies made of "stainless steel", but their cost is much higher.

As for the shape of the hats, in addition to the standard round shape, for a Phillips screwdriver, self-tapping screws with a figured hex head are produced. It is more convenient to work with such fasteners and therefore it is most popular when installing roofs.

When talking about dimensions, we mean the ratio of the diameter to the length of the product. As for roofing screws, the existing range of sizes is wide enough and provides reliable fastening of roofing materials with different profile configurations. Of course, the size also affects the weight of the product.

But the most distinctive feature of this type of fastener is its complete set with a special washer.

The washer is a combined metal and rubber structure under the influence of high temperatures. Having a round shape, it is designed to press the material more tightly to the lathing while simultaneously sealing the hole under the screw head.

The table below shows some comparative characteristics of the most common fastener samples:

|

The size |

Outside diameter mm. |

Drill diameter |

Drill length mm. |

Washer diameter mm. |

Rubber thickness mm |

Washer thickness mm. |

Approx. weight per 1000 pieces kg |

| 4.8x19 | 4,62 – 4,8 | 3,9 | 5,5 — 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 3,10 |

| 4.8x25 | 4,62 – 4,8 | 3,9 | 5,5 — 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 3,70 |

| 4.8x32 | 4,62 – 4,8 | 3,9 | 5,5 — 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 4,20 |

| 4.8x38 | 4,62 – 4,8 | 3,9 | 5,5 — 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 4,80 |

| 4.8x50 | 4,62 – 4,8 | 3,9 | 5,5 — 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 5,80 |

| 5.5x25 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 — 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 6,33 |

| 5.5x32 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 — 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 7,55 |

| 5.5x38 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 — 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 7,84 |

| 5.5x50 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 — 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 8,40 |

| 6,3x25 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 9,45 |

| 6,3x32 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 9,50 |

| 6,3x38 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 10,45 |

Well, and the last, maybe directly and not related to technical characteristics. To ensure an aesthetic match with the roofing material, manufacturers paint the top and fastener washers in different colors.

Painting, produced by powder paint mixtures with further firing in muffle furnaces, should retain this most aesthetic appearance for as long as possible. And if the paint lags already at the installation stage, this is a sign of poor-quality fastening material.

Peculiarities

If we consider a self-tapping screw for a hexagon, then outwardly it looks more like a bolt with several external signs.

- Screw threads are infrequent.

- The sharp end is not too sharpened and hardly stands out.

Its scope of application is quite wide due to how original its design is.If a hex head screw is used simultaneously with a dowel, then, for fastening large parts to a tree, you can use this self-tapping screw to fasten the necessary parts even to concrete. The only caveat is that the dowel in diameter should be exactly twice as large as the head for reliable fastening.

For work, you will need keys of 10, 13 or 17 mm, depending on the type of bolt that the master plans to use. Also, such fasteners are sometimes called "wood grouse", because it tightly secures almost any object to the surface with the right approach. When the socket head bolt is used to organize the roof, its design also has a number of features.

- A hard and sharp tip, similar in shape to a drill.

- Hex head bolt.

- Rubber washer.

The latter serves as a kind of insulator that reliably protects the bolt from moisture ingress. Accordingly, in this case, there is less risk of rust and moisture. In addition, the washer makes the connection to the screw much tighter than under normal conditions. In terms of their diameter, such fasteners can be from 8 to 10 mm inclusive. And the length can be up to 100 mm, so you can pick up a screw for literally any roofing material, with any level of load, depending on the need and need.

Anti-vandal self-tapping screws that cannot be turned out without the use of special tools are also popular among hexagonal or multi-sided screws.

Their very design outwardly already attracts a lot of attention, and the rigid fastening eliminates the risk of any kind of structural damage, which is very useful in public facilities, especially if you pay attention to the name of the screws

Self-tapping screws with a press washer in the design can also have six faces, but in this case there is one important nuance. The area of their cap is much larger, which is suitable for attaching metal sheets. Most often they do not have any characteristic color; outwardly, they resemble ordinary silver bolts.

Another option, when it comes to the design features of specialized screws, is self-tapping screws for the production of furniture. They are distinguished by a blunt tip and are tightened with a special hex wrench. Their diameter is generally the same for the entire length, but towards the head the bolt itself becomes a little thicker.

Dimensions (edit)

Before buying self-tapping screws with a tip, you should pay special attention to their size, because the quality of future work largely depends on these characteristics. In addition, when choosing, you need to correctly correlate these parameters with the dimensions of the material being processed, with the type of surfaces (wood, metal, drywall)

On the Internet, you can see tables that indicate the standard sizes of various screws. So, their length most often varies from 13 to 51 mm. The head diameter can be approximately 7 mm. The diameter of the press washer reaches 10-13 mm. ButBut in essence, models with non-standard sizes. So, the length of models intended for roofing can reach 150-170 millimeters.