Photo of wood grouse screws on wood

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- Expansion dowel

- What are wood screws

- How to choose a wall mount for your TV

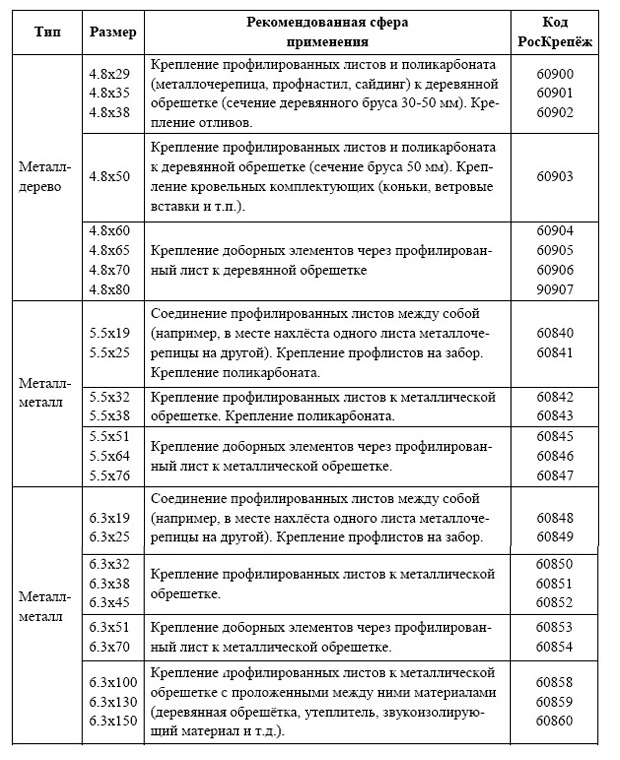

Roofing screws

These self-tapping screws are designed for fastening roofing materials - profiled sheets, metal tiles. Thanks to the rubber

washer EPDM, the roof surface retains its waterproofing properties after screwing in the fastener.

These hardware are of two types: for fastening to a wooden crate or a metal base.

Self-tapping screws designed for fastening the roof to metal have a smaller thread pitch and a greater thickness. Maximum

the thickness of the metal base is characterized by maximum drilling capacity in the table below.

| The size | L is long, mm | D outer diameter, mm | Dp drill diameter, mm | Max. way. drilling, mm | Dw washer diameter, mm | S size under the key, mm |

|---|---|---|---|---|---|---|

| For fixing to a wooden base | ||||||

| 4,8×29 | 27,75 — 30,75 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×38 | 36,75 — 39,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×50 | 48,75 — 51,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×60 | 58,75 — 61,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×70 | 68,50 — 71,50 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×80 | 78,50 — 81,50 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| For attachment to metal base | ||||||

| 5,5×19 | 18,00 — 20,00 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×25 | 24,00 — 26,00 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×32 | 30,75 — 33,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×38 | 36,75 — 39,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×51 | 49,75 — 52,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×64 | 62,75 — 65,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×76 | 74,50 — 77,50 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 6,3×19 | 18,00 — 20,00 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×25 | 24,00 — 26,00 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×32 | 30,75 — 33,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×38 | 36,75 — 39,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×50 | 48,75 — 51,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×60 | 58,75 — 61,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×80 | 78,50 — 81,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×100 | 98,50 — 101,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×130 | 128,50 — 131,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×150 | 148,50 — 151,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×175 | 173,50 — 176,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

For the sake of fairness, it is worth noting that for twisting into metal, thicker than 1 mm., You need to purchase

high-quality fasteners. If you use self-tapping screws from an unnamed manufacturer, then there will be a high probability

breaking off heads when screwing into thick metal.

All roofing screws, in addition to the hex head, are sometimes produced with an additional slot. That's why

they can be twisted with a cross bit, about the bit number is not information. However, the most convenient installation will still be

using a hex head for a drill driver.

How to choose?

Of course, the most important thing is to decide on the purpose of using a self-tapping screw: why and where the hardware will be used, whether it will be affected by natural conditions (rain, snow). In addition, it is worth checking the quality of the screws you need.

- Hardware must be identical in color - this is direct proof that they are processed equally well and will serve exactly the same.

- There should be no difference in size either - visually, everything is the same length and thickness. The same applies to the thread pitch: the threads are clear and with the same cutting interval.

- If there are special drills at the end, there should be no burrs. The edge must be sharp, not broken off, otherwise such a part will automatically become unusable.

- The notch in the form of which the slot is made must be clear, deep and symmetrical.

- High quality self-tapping screws, as a rule, are marked with a special marking on the packaging - this is a capital Latin letter. Fasteners with such markings are produced at large factories and undergo additional testing and certification. By choosing high-quality products, you will not have to worry that the fasteners will break off at the most inopportune time.

Self-tapping screw with a hex head ("hex self-tapping screw")

It looks like an ordinary bolt, but differs in the following features:

- infrequent screw thread;

- slightly pointed end.

The main application is fixing massive parts and large objects. "Hexagonal self-tapping screw" can be screwed into wood, and if you use a dowel, then into concrete.

Attention! The dowels for hexagonal screws must be two sizes larger than the self-tapping screw!

All work with such fasteners is carried out with keys of 17, 13 and 10 mm. It is clear that the head of the long and thickened screw will be 17.0 mm in size, and at the shortest 10.0 mm.

The choice of the length of the screws

There are several rules for choosing the length of a self-tapping screw that apply in different situations. When joining / joining two not very massive parts, the following selection rules work:

-

So that you do not connect, the sharp end of the self-tapping screw should not stick out from the other side of the parts to be connected. That is, in any case, it should be shorter than the parts to be joined. Moreover, it is believed that the maximum strength will be if at least 5-6 mm remains to the edge of the lower part. So count it.

The length of the self-tapping screw is selected depending on the parts to be fastened

- On the other hand, the minimum self-tapping screw should fit into the bottom part by at least 1/3 of the thickness of the part to be attached. That is, if you fasten, say, a beam of 100 * 100 mm, then the minimum length of the self-tapping screw should be 1/3 longer. For this timber, the minimum screw length is 100 + 100/3 = 133 mm. Take the nearest larger. If you fasten a board 28 mm thick, then the minimum screw length is 28 + 28/3 = 37 mm (usually 42 mm is chosen).

If a thin piece is attached to a massive base, another rule works. Then the length of the fastener should be 2-2.5 times longer than the attached part. So it is necessary to select the length of the self-tapping screw if you attach something to a wall, say, or to a concrete floor. In this case, in order to fix the same 28 mm board to the wall, the length of the fastener is 56-70 mm. This is the difference.

Self-tapping screw sizes: the most applicable options

How to choose the length of the self-tapping screws, it seems, should be clear. Now about what they are in general. The situation here is confusing. Neither screws nor self-tapping screws have a common standard. There are several standards of "worn out" years of release, in which the sizes of some types of self-tapping screws are prescribed.

- GOST 1145-80. Countersunk self-tapping screws.

- GOST 1144-80. Round head screws.

- GOST 1146-80. Half-countersunk head screws.

The situation today is that each manufacturer produces its own "line". They are oriented, of course, on demand. Well, the parameters of the heads are usually made in accordance with one or another GOST. This will somehow stabilize the situation. Sometimes the assortment - diameters and lengths are also made according to the standard. In this case, in the description of self-tapping screws, the diameters in which they are generally produced are indicated, and then there is a postscript: it corresponds to such and such a GOST. This means that the heads comply with the specified standard, as well as that the assortment corresponds.

How, then, are self-tapping screws chosen in terms of length and diameter? Calculate / determine the length that is needed, determined with the type of head. Then they look at the diameters and make the final choice. Let's say right away that the principle “thicker is better” does not work for wood. This can be applied to metal. For wood, thinner ones are better, but with good carvings and made of good metal. This is ideal.

If the manufacturer has his own parameters of self-tapping screws, they are indicated in the description

But this is not enough.The store usually offers up to a dozen options of the same size, but from different manufacturers. And if it is more or less easy to decide on the metal and the type of processing, then it is difficult to choose which brand to take. There are, of course, proven ones, but they are expensive. Although, if we take the cheap ones, 30-50% can go to marriage. What kind of marriage? Then bend, then the hats fly off. It is not always, but often. If you are "lucky" to run into such fasteners, it turns out that buying "expensive" ones would not be more expensive. Well, or not much more.

Now compare the two tables. They are compiled according to different GOSTs. As you can see, the diameters and lengths are the same. This makes life easier. If, in the production of fasteners, the standard was adhered to in terms of the diameter / length ratio, then everything is simple. If not, then the manufacturer in the description of the screws attaches a table with dimensions (as in the picture above).

Recommendations for choosing high-quality fasteners ↑

in the photo self-tapping screws with a drill

in the photo self-tapping screws with a drill

Manufacturers who value their reputation strictly test their products according to various parameters, subjecting them to various loads. When tilting the hardware:

- at 5 °, it must maintain resistance to 20 thousand vibrations;

- 10 ° - respectively to 2 thousand;

- 15 ° - to 100 vibrations.

Quality products pass these tests without any change in steel quality.

Branded products are necessarily marked with several Latin letters, which should indicate its factory origin and compliance with the requirements of GOST.

As already noted, roof fasteners are equipped with rubber washers, which seal the areas of contact between the caps and the coating and prevent water from getting under the cap. In other words, the rubber gasket prevents corrosion on the roof.

On high-quality self-tapping screws, the rubber gasket and the washer itself should, as it were, merge together, otherwise the service life of the gasket will be limited to at most two years, after which it will collapse.

On a note

You can quite easily distinguish a factory product from a fake using ordinary pliers. Clamp the washer with them: if this damages the rubber gasket or peels off the paint, then you are dealing with material of dubious quality.

Therefore, do not seek to acquire too cheap parts - the risk of running into a fake is too great. It is much more reliable to buy branded from trusted suppliers.

Length plays a significant role in its selection. At the same time, they are repelled by several parameters, for example, from the type of material for the coating or the features of the rafter system. The main recommendations can be found in the following table:

GOST for self-tapping screws for metal 11650-80

Drills for metal GOST 10903-77

2020 .

Dimensions and weight

In principle, when choosing the right size of a self-tapping screw, you can always take a sample with you, but if this is not possible, then you should understand a little about the existing samples.

The parameters of the self-tapping screw are determined by the length and diameter:

- there is a standard range of fastener lengths: 10, 15, 20, 25, 30, 35, 38, 40, 45, 48, 50, 55, 60, 63, 70, 75, 80, 100, 120, 150 mm;

- the most commonly used self-tapping screws are universal, their standard parameters in diameter are 1.6, 2.0, 2.5, 3.0, 3.5, 4.0, 5.0, 6.0, 8.0, 10 , 0 mm.

These are standard sizes, but there are exceptions. The longest self-tapping screws reach 200-250 mm in length, they are designed to connect thick layers of wood. The smallest sometimes do not reach one centimeter.

Experienced craftsmen first determine the thickness of the self-tapping screw, depending on its further use, they choose thinner or thicker ones. The next criterion is the length, someone will need a short one, and someone will not be able to do without a long self-tapping screw. Then refer to the diameter of the product. All self-tapping markings are very easy to read, and even the most inexperienced person will be able to decipher it. If the size of the package is 6x40 or 5x25, then the first value always indicates the diameter of the product, and the second - its length. Knowing this, it will not be difficult to choose the necessary fasteners yourself.

As a rule, manufacturers attach tables with the dimensions of their products, in them you can see how long the self-tapping screw can be and with what diameter of the cap.

By weight, the screws also differ. The mass of one hardware is with the parameters:

- 3.5 x 16 - 1.08 g;

- 3.5 x 19 - 1.13 g;

- 3.8 x 64 - 3.75 g;

- 3.8 x 70 - 4.73 g;

- 4.2 x 70 - 4.22 g;

- 4.2 x 76 - 4.79 g;

- 4.8 x 89 - 7.63 g;

- 4.8 x 95 - 8.58 g.

How to choose?

When choosing self-tapping screws for wood, do not dwell on metal or universal fasteners. Narrow-profile hardware will hold together a wooden structure better, and universal ones are optimal for joining metal and wooden surfaces. First you need to choose the type of screw head, the main point here is the connection to be made. Further, the type of slot. The most popular head recess types are TORX. They take the best torque from the tool.

Thread type - all over the screw rod or not. To connect two wooden parts, hardware with an incomplete thread is suitable. The length should correspond to the size of the element to be screwed on. There is a zone without threads under the head, and thanks to it, there is a tight fit of the materials to one another. To facilitate screwing into dense wood, it is recommended to take fasteners that have a mill or mill. Only hardware with incomplete screw threads is equipped with it. It consists of several grooves located at the beginning of the thread. They help to "soften" the wood surface.

It is imperative to pay attention to the size of the diameter and length of the screw rod in order to prevent cracking of the wood during operation. An important point is where the thread originates from, it should be from the very end

A loop located far away indicates that the end is not pointed and blunt. Working with such fasteners will bring a lot of problems.

The choice of color also depends on the material with which to work. For wood, yellow self-tapping screws are best, but they have a higher price. Black fasteners have a number of disadvantages: they are susceptible to corrosion, and stains can occur on the wooden surface. This is not so critical for metals, because the bond can be painted over. Also, black hardware is quite fragile - if you twist them, the hat may break off. An example would be flooring. Boards tend to dry out and bend, because of this, the load on the self-tapping screw increases, the head breaks off. Therefore, the wooden floor starts to creak.

For information on how to choose the right self-tapping screw for wood, see the next video.

Size charts

Below are the dimensions of the most common self-tapping screws.

Sizes of black wood screws

|

Nominal diameter, |

Unit rev. |

3,5 |

3,8 |

4,2 |

4,8 |

|

Head diameter, A |

mm |

7,9-8,5 |

8,5-9,1 |

||

|

Head height, F |

mm |

4,5-7,0 |

|||

|

Outer thread diameter, D1 |

mm |

3,5-3,9 |

3,8-4,2 |

4,2-4,6 |

4,9-5,4 |

|

Internal thread diameter, D2 |

mm |

2,1-2,4 |

2,2-2,5 |

2,6-2,9 |

3,1-3,4 |

|

Thread pitch, P |

mm |

2,7-2,8 |

2,8-2,9 |

3,1-3,2 |

|

|

Slot depth, Q |

mm |

2,4-2,9 |

2,5-3,2 |

||

|

Slot width, M |

mm |

4,5-5,1 |

|||

|

Slot |

mm |

Philips No. 2 |

|||

|

Head radius, R |

mm |

4,5-5,0 |

|||

|

Minimum torque |

N * m |

2,0 |

2,8 |

4,5 |

6,5 |

The length of the hardware is standardized and can be: 16; 19; 25; 35; 41; 45; 51; 55; 64; 70; 76; 89; 95; 102; 127; 152 mm.

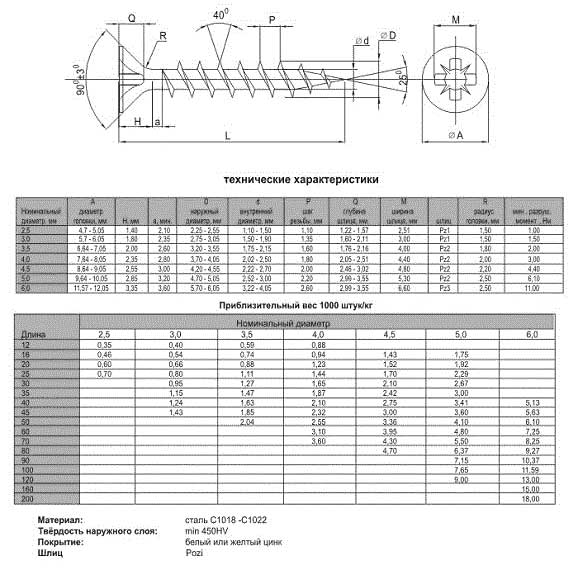

Sizes of yellow wood screws

|

Nominal diameter, |

Unit rev. |

2,5 |

3,0 |

3,5 |

4 |

4,5 |

5 |

6 |

|

Head diameter, A |

mm |

4,7-8,1 |

5,7-6,1 |

6,6-7,1 |

7,6-8,1 |

8,6-9,1 |

9,6-10,1 |

11,6-12,1 |

|

Head height, H |

1,4 |

1,8 |

2,0 |

2,35 |

2,55 |

2,85 |

3,35 |

|

|

Outer thread diameter, D |

2,3-2,5 |

2,8-3,1 |

3,2-3,6 |

3,7-4,1 |

4,2-4,6 |

4,7-5,1 |

5,7-6,1 |

|

|

Internal thread diameter, d |

1,1-1,5 |

1,5-1,9 |

1,8-2,2 |

2,0-2,5 |

2,2-2,7 |

2,5-3,0 |

3,2-4,1 |

|

|

Thread pitch, P |

1,0 |

1,35 |

1,6 |

1,8 |

3,0 |

3,2 |

3,6 |

|

|

Slot depth, Q |

1,2-1,6 |

1,6-2,1 |

1,8-2,2 |

2,0-2,5 |

2,5-3,0 |

3,0-3,6 |

||

|

Slot width, M |

2,5 |

2,5 |

3,0 |

3,5 |

4,8 |

5,3 |

6,3 |

|

|

Slot |

||||||||

|

Head radius, R |

Pz1 |

Pz2 |

||||||

|

Minimum torque |

N * m |

1.0 |

1.5 |

2.0 |

3.0 |

4.4 |

6.1 |

11 |

Length of yellow self-tapping screws

|

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

|

2.5 |

10 |

3.5 |

12 |

4.0 |

35 |

4.5 |

60 |

5.0 |

100 |

6.0 |

140 |

|

13 |

16 |

40 |

70 |

120 |

160 |

||||||

|

16 |

20 |

45 |

80 |

6.0 |

40 |

180 |

|||||

|

20 |

25 |

50 |

5.0 |

20 |

45 |

200 |

|||||

|

25 |

30 |

60 |

25 |

50 |

|||||||

|

3.0 |

10 |

35 |

70 |

30 |

60 |

||||||

|

12 |

40 |

4.5 |

16 |

35 |

70 |

||||||

|

16 |

45 |

20 |

40 |

80 |

|||||||

|

20 |

50 |

25 |

45 |

90 |

|||||||

|

25 |

4.0 |

12 |

30 |

50 |

100 |

||||||

|

30 |

16 |

35 |

60 |

110 |

|||||||

|

35 |

20 |

40 |

70 |

120 |

|||||||

|

40 |

25 |

45 |

80 |

130 |

|||||||

|

45 |

30 |

50 |

90 |

Dimensions of self-tapping screws with a press washer

|

Designation |

L, mm |

Q, mm |

D, mm |

P, mm |

d, mm |

U, mm |

H mm |

A, mm |

B, mm |

|

4.2x13 |

12,5-13,5 |

1,9-2,35 |

4,15-4,28 |

1,6-1,75 |

2,68 |

1,0-1,2 |

2,1-2,45 |

10,6-10,8 |

7,0-7,15 |

|

4.2x14 |

13,5-14,5 |

||||||||

|

4,2x16 |

15,5-16,5 |

||||||||

|

4,2x19 |

18,5-19,5 |

||||||||

|

4.2x25 |

24,0-26,0 |

||||||||

|

4,2x32 |

31,0-33,0 |

||||||||

|

4.2x41 |

40,0-42,0 |

||||||||

|

4,2x51 |

50,0-52,0 |

||||||||

|

4,2x76 |

75,0-77,0 |

Dimensions of self-tapping screws with a hex head

|

Outer thread diameter, d, mm |

5 |

6 |

8 |

10 |

12 |

16 |

20 |

|

|

Internal thread diameter, d2, mm |

4,2 |

5,6 |

7 |

9 |

12 |

15 |

||

|

Thread pitch, P, mm |

2,2 |

2,6 |

3,6 |

4,5 |

5,0 |

6,0 |

7,0 |

|

|

Head height, k, mm |

3,5 |

4,0 |

5,5 |

7,0 |

8,0 |

10,0 |

13,0 |

|

|

Floor key size, S, mm |

8 |

10 |

14 |

17 |

19 |

24 |

30 |

|

|

Bar length, L, mm |

min |

20 |

20 |

25 |

30 |

40 |

60 |

80 |

|

max |

60 |

140 |

200 |

300 |

380 |

300 |

200 |

Sizes of roofing screws

|

Designation |

L, length, mm |

P, thread pitch, mm |

C, flange thickness, mm |

Df, flange diameter, mm |

e, for references, mm |

K, head height, mm |

S, turnkey size, mm |

|

4.8x19 |

18-20 |

1,6 |

0,9 |

9,8-10,5 |

8.71 min |

3,8-4,3 |

7,78-8, |

|

4.8x25 |

24-26 |

||||||

|

4.8x32 |

31-33 |

||||||

|

4.8x38 |

37-39 |

||||||

|

4.8x50 |

49-51 |

||||||

|

5.5x25 |

24-26 |

1,8 |

1,0 |

10-11 |

5,25-5,4 |

||

|

5.5x32 |

31-33 |

||||||

|

5.5x38 |

37-39 |

||||||

|

5.5x50 |

49-51 |

||||||

|

6,3x25 |

24-26 |

11 min |

9,8-10 |

||||

|

6,3x32 |

31-33 |

||||||

|

6,3x38 |

37-39 |

||||||

|

Designation |

D, Thread diameter, mm |

Dp, Drill diameter, mm |

T, Drill length, mm |

Dw, Washer diameter, mm |

AG, Rubber thickness, mm |

A Washer thickness, mm |

Weight 1000 pcs, kg |

|

4.8x19 |

4,62-4,8 |

3,9 |

5,5-6,0 |

13,8-14,2 |

2,8-3,2 |

0,8-0,9 |

3,2 |

|

4.8x25 |

3,8 |

||||||

|

4.8x32 |

4,3 |

||||||

|

4.8x38 |

4,9 |

||||||

|

4.8x50 |

5,9 |

||||||

|

5.5x25 |

5,28-5,5 |

4,55-4,7 |

7,6-9,0 |

6,34 |

|||

|

5.5x32 |

7,56 |

||||||

|

5.5x38 |

7,85 |

||||||

|

5.5x50 |

9,46 |

||||||

|

6,3x25 |

6,03-6,3 |

5,4-5,55 |

8,0-9,6 |

15,9-16,3 |

8,5 |

||

|

6,3x32 |

13,8-14,2 |

9,6 |

|||||

|

6,3x38 |

10,4 |

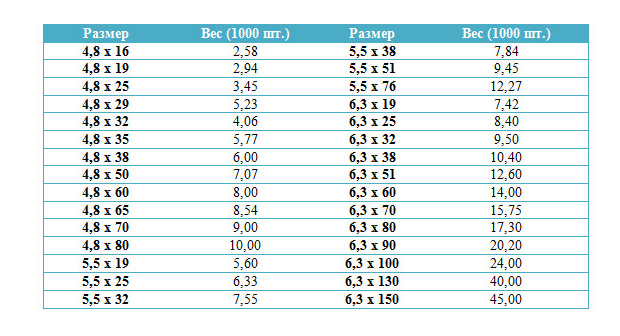

In the wholesale purchase of fasteners, in addition to their design features, the weight of the hardware is also important.

Varieties ↑

raznovidnosti-1

raznovidnosti-1

raznovidnosti-2

raznovidnosti-2

There are two types of fasteners - self-tapping screws for metal and wood. The first ones are larger in diameter than the second ones, and they hold worse in wood, therefore, they are practically not used as fasteners for wooden structures. Actually, as well as vice versa, self-tapping screws for wood are impossible or at least very difficult to screw into metal. They also differ in thread pitch: according to GOST, self-tapping screws for metal have more frequent threads.

Healthy

1000 pieces of 4.8 * 29 format products weigh about 5 kg. By the way, as a rule, when buying in a store, you will see not the price per piece, but for the same 1000. Nevertheless, we note: the price of one self-tapping screw with a polyester coating is about 3 rubles, and a dyed one with a polymer layer - from 8 rubles.

For metal with a drill: GOST, dimensions, features

dimensions, weight

dimensions, weight

In addition to the threads running through the body of these elements, they have a pair of vertical drilling blades at their end. When screwing in the hardware, they drill a pilot hole, that is, the installation is carried out directly into the metal base without preliminary drilling. These products prevent deformation of the metal coating and protect it from damage at the attachment points. The package also includes a metal washer and a press-fit weatherproof rubber gasket. The head of the hardware is hexagonal. They are mounted using a bit for a roofing screw.

Wood: dimensions

They are used when connecting any elements made of wood. The presence of a drill at the end of the part makes it as easy as possible to use it. If holes are pre-drilled on metal profiles, they can be used to attach metal profiles to wooden surfaces. Fastening is carried out using the through-mounting technology, using a special socket wrench for a hexagonal nozzle. The most in demand are self-tapping screws for a hexagon for wood with a length of 100 and a diameter of 8 mm. Note that in this case, their length ranges from 11 to 200 mm.

wood screws size table

wood screws size table

Important

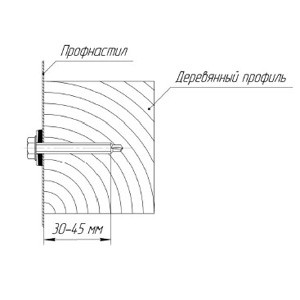

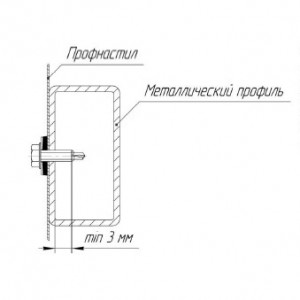

The type of self-tapping screw is chosen depending on the type of base to which the material for the roof is supposed to be attached: for a wooden base, fasteners with a sharp end are needed, for a metal base - a drill-shaped one.

Galvanized and painted

Usually, roofing screws for metal tiles, polycarbonate or other sheet materials with a polymer coating, as well as for slate, are colored. The sheets and fasteners to be fixed should match each other as much as possible in color, therefore, as a rule, they are selected by marking. The most commonly used RAL colors are:

- green - 6005;

- cherry - 3005;

- blue - 5005;

- white - 9003;

- brown - 8017.

The use of colored species not only improves the aesthetics of the roof. The paint becomes an additional barrier to corrosion.

On a note

These products differ from the previous types only in coloring. The weight and dimensions of one part are clearly regulated by GOST.

How are roofing screws

Roofing screws have huge differences from any other types of fasteners. In order to overcome the resistance of the roofing sheet, with which the self-tapping screw is attached, its rod always has a significant diameter.

The specially developed carbon steel of this fastener gives extra strength to the adhesion.

The roofing screw cap is manufactured in two main versions, hexagonal and semicircular. In the first case, the fasteners are equipped with a cross recess, and in the second - without any slots. Using a screwdriver or a special bit, the self-tapping screw of the first option is screwed in. The second, provides for the use of special hexagonal nozzles for working with a screwdriver.

An additional feature in roofing hardware is the presence of 2 washers on them. The first washer is made of specially formulated hard rubber. The main task of the washer is to ensure sealing at the installation site, which, due to the tight pressing of the metal sheet to the hole, is achieved. With the help of the second washer, the force from the head of the self-tapping screw is distributed to the rubber gasket.

In view of this, the possibility of atmospheric moisture penetration to the hole on the metal sheet completely disappears.