3.

Any screw or self-tapping screw has a certain volume, and when we screw a screw or self-tapping screw into wood, we thereby try to reduce the volume of wood by the volume of the screw. No miracle happens. Partially the volume of the wood is reduced by crushing the wood, i.e. due to inelastic deformations. Moreover, the dumber the screw or self-tapping screw (and self-tapping screws are also blunt), the greater the proportion of inelastic deformations that occur under the tip of the screw, which means that you need to press harder on the self-tapping screw or screw to make these deformations. Part of the volume is freed by splitting the wood along the fibers, while a gap appears between the fibers, and, scientifically speaking, a crack. The crack opening width depends not only on the factors listed in clause 2, but also on the geometric dimensions of the product and the point of application of the load. The greater the geometrical parameters of the product and the closer the screwing point of the self-tapping screw is to the center of gravity of the section, the smaller the crack opening width, and hence, again, more efforts must be made to tighten the self-tapping screw or screw in such a place. And the smaller the width and height of the product and the closer the place of screwing the self-tapping screw to the edge, the more likely it is that the product will not just crack, but also split, and then it will be very easy to tighten the self-tapping screw or screw, but there will be no benefit from such a self-tapping screw or screw. but only one continuous harm. The rest of the volume for the screw to be screwed in is freed due to elastic deformations. The distribution of internal stresses in the body of the wood during elastic deformations leads to the appearance of cracks. A similar situation is observed when screwing self-tapping screws into parts made of chipboard or OSB of small sizes, wood-chip or oriented strand boards have a lower strength than wood.

Types and sizes

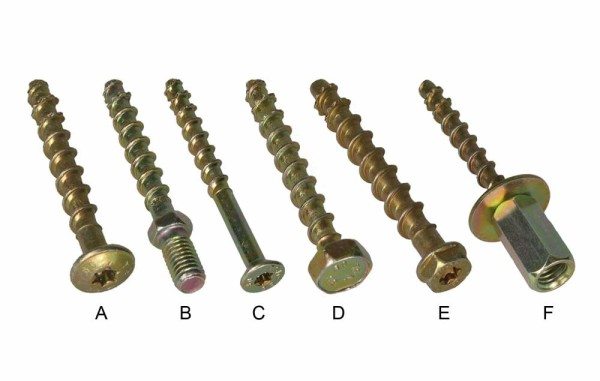

Depending on the type of head, all self-tapping screws can be divided into several independent groups.

Countersunk head varieties. Such models most often have a conical design with cross-type splines. To work with such a variety, you first need to prepare a seat. To do this, you need to make a small chamfer, which will allow you to place the butt so that it is in the plane of the material. Models with this head structure will not protrude from the concrete surface after installation. Today, there are versions with a reduced head. They have a smaller diameter, provide a more reliable fastening, but more effort should be applied when installing them.

Self-tapping screws can also be divided into separate categories depending on their protective coating. Many models are produced with a special oxidized coating. The latter is in the form of a thin oxide film, which gives the details a black color. Such options are capable of withstanding significant loads, but it should not be forgotten that they should not come into contact with moisture during operation.

There are also models coated with phosphated compounds. These varieties, like the previous version, will be colored black. They are also able to fix material of significant weight, while they have good resistance to the effects of water. The cost of such models will be higher compared to other types.

Galvanized self-tapping screws for concrete can be white or yellow, but they practically do not differ from each other in important properties. These models are most often used to install products that will be located in the open air, since these self-tapping screws are especially resistant to various atmospheric influences.

Self-tapping screws are also classified depending on the material from which they are made. The most common option is high strength and quality carbon steel. Such a foundation is considered to be quite solid. Most often it is used together with impurities. In addition, this metal is particularly durable.Fasteners made from this metal are relatively inexpensive.

Also, ordinary stainless steel can be used for the production of such self-tapping screws. This material will become the best options in the event that further contact of fasteners with moisture is possible. After all, models made of such material will not rust and will not lose their properties.

As a rule, self-tapping screws made of alloy stainless steel are not covered with additional protective coatings. Indeed, in the composition of such a metal there is nickel and chromium, which already provide excellent anti-corrosion properties of products.

There are also special types of decorative screws. They are most often made from wood, plastic or various non-ferrous metals. But such samples are extremely rarely taken for concrete surfaces, since they cannot withstand too much stress.

The sizes of self-tapping screws for concrete can be different. They are chosen depending on the thickness of the surface and on what diameter the holes should be made.

Tools can have different thread configurations.

- "Herringbone". This type is a slightly oblique thread, which is formed by small metal cones nested into each other. The herringbone model most often has a cross section of 8 millimeters.

- Universal. Such a thread on a self-tapping screw can be used with or without a dowel. As a rule, the tool is available in sizes up to 6 millimeters.

- With an inconsistent pitch of turns. These variable-pitch specimens provide the most reliable fastening of materials, while additionally performing notches. It is this type that is more often found on self-tapping screws without drilling. The standard value for the diameter of such devices is 7.5 millimeters.

The length of these devices can vary from 50 to 185 mm. The depth ranges from 2.3 to 2.8 mm. The height of the cap reaches values of 2.8-3.2 mm. The diameter of such self-tapping screws can be from 6.3 to 6.7 mm.

The thread pitch also plays an important role. For different models, it can reach a value of 2.5-2.8 mm

How can you replace a nail

Dowel instead of a nail

When it comes to concrete, the nail is not considered the best solution.

You can replace it with a dowel.

It is sold in hardware stores and is relatively inexpensive.

A wide selection of products is available for the buyer's choice: plastic, metal, nylon.

If you need to hang a picture or a shelf, when hammering it must be held at an angle from top to bottom.

Thus, the mount will become more reliable and will last for many years. In the event of an unforeseen impact on the walls from time to time or the peculiarities of the climate, the interior detail will not fall, it will be held securely.

Special dowel-nails will also be an ideal option. They are intended directly for driving into concrete. Concrete nails have thicker walls, so they will not break while working with them.

If it is allowed to replace the nail with a more suitable solution, it is worth paying special attention to this.

Nagel on a brick. Types of self-tapping fasteners and their parameters

The classification of self-tapping screws for working on concrete without preliminary drilling is carried out based on the material, special coating, the shape of the slot and head, and the type of thread notch. Anchor pins for concrete are made strictly in accordance with GOST 1147-80. For the production of self-tapping screws, domestic or imported steel wire is most often used. Carbon steel will be used of our grades 08kp, 10kp, 10, 10ps and foreign ones - S1010, S1022, S1018. After the product is machined from a blank, its surface is hardened for strength. The following are used as protective measures:

- Galvanized. A zinc layer is applied to the product by electroplating, which protects the screw from corrosion (the color is yellow or silver).

- Phosphating.The color is obtained black or gray due to the interaction of the steel product with phosphates.

- Oxidation. Obtaining a protective film on the fasteners is carried out using an oxidizing agent. As a result of a chemical reaction, the nail turns black.

Fasteners are used without special coating if they are made of alloyed stainless steel. The alloy has anti-corrosion properties. Self-tapping brass elements are durable and resistant to aggressive environments. Their disadvantage is their softness and tendency to deformation.

The head of the hardware can be countersunk, protruding, it can have a cylindrical shape, the form of a half-cone or a hexagon. The slots are made cruciform, hexagon wrench, in the form of a Torx sprocket, in the form of a barrel for a socket wrench. A straight slot is not used. He will not be able to transfer the necessary efforts to tightly screw the self-tapping screw into dense, heterogeneous flesh.

Self-tapping screws are made with different configurations:

- Universal. Here the fastener has a multifunctional purpose. It can be used with or without a dowel. The length does not exceed 220 mm, the diameter is no more than 6 mm.

- In the form of a herringbone. An oblique threaded section is obtained using cones nested one inside the other. The length of the self-tapping screw has been increased to 200 mm, the cross-section - up to 8 mm. The part is driven into the prepared hole without or using a dowel.

- With different frequency of turns. Such self-tapping screws hold more firmly in concrete and you can work with them without using a dowel. They are also called turbo screws. Such a non-standard thread cut is applied to the entire length of the dowel, which can take values from 52 mm to 212 mm, while the outer diameter is 7.5 mm.

General information

Although the modern construction market offers many options, self-tapping screws remain the most popular. They are peaked rod-shaped screws, the head of which has a cross notch. Such a fastener is highly durable, which allows it not to bend or collapse under the influence of heavy loads.

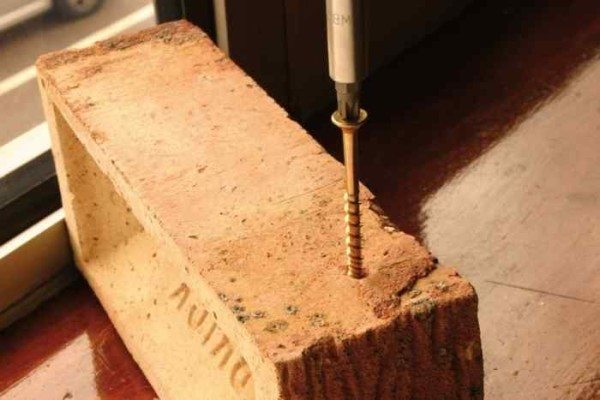

How to use a concrete screw when working with aerated concrete

Material

For the manufacture of self-tapping screws, various materials can be used, which are selected depending on the type and conditions of use.

The main ones are:

- carbon steel;

- stainless steel;

- brass.

The common feature of each of them is high strength, and their price does not differ much from each other.

The most common fasteners are made of carbon steel. Such self-tapping screws have an additional protective coating that protects them from oxidation and other types of influences.

Anchor screws for concrete

In order not to get confused in the types of coating for carbon steel, you must remember their color designation:

| Silver | In this case, the protective coating is a zinc layer. Such self-tapping screws can be used equally effectively for various jobs. |

| Yellow | Such fasteners are also processed with zinc, but they have a slight disadvantage in comparison with silver ones. It can only be used when working with concrete indoors. |

| Black | Another type of coating for carbon steel screws is oxidized. They are recommended for use during interior work in rooms with normal air humidity. |

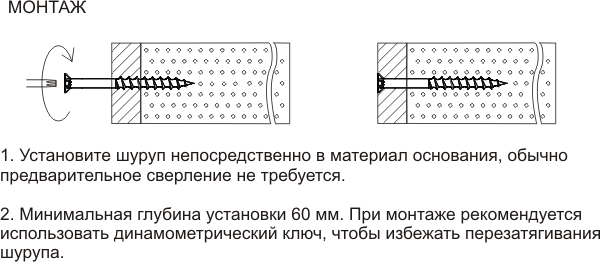

Before installing the self-tapping screw - make a hole for the dowel with a puncher

Views

Self-tapping screws can come complete with dowels, or simply screw into the surface without them with your own hands.

Due to the different characteristics of the elements, they can be divided into three main groups, each of which has different properties:

- Universal with medium thread pitch. The range of lengths of such fasteners is 12-220 mm, and the diameter is 3-6 mm.They can be used equally effectively with or without concrete dowels in bases made of bricks (concrete).

In the photo - a self-tapping screw with a herringbone type

- With herringbone thread. The range of lengths is similar to the first group, and the diameter can be in the range of 3-8 mm. These elements are fixed only using dowels. To create a hole for the dowel, use a drill with the same diameter as the dowel. The drilling depth should be 3-5 mm longer than the length of the latter, and the self-tapping screw should have the same length.

Installation of a self-tapping screw into concrete without drilling

- Dowels - variable type of thread with notches. Such elements differ in different lengths (in the range of 70-200 mm) and a constant diameter of 7.5 mm. It is used without a dowel. For its installation, it is necessary to drill a hole Ø 6 mm in the base and a length exceeding the length of the self-tapping screw by 10-15 mm.

Product selection

There are several types of self-tapping screws, which differ from each other in the type of fastening, material and structure. The choice of one or another name depends on the situation and external influences that have a direct impact on the fastener. Consider the most common types of screws and their scope.

Self-tapping screws with dowels

Self-tapping screw dowel for foam concrete with plastic cover

This is the most common type of fasteners in the construction market - they are produced in the form of self-tapping screws with two types of thread and plastic dowels. The presence of a dowel is explained by the fact that a hole drilled with a drill in concrete is not able to provide a tight fixation, without which the fixing will not be reliable. The plastic casing acts as a seal that smoothes this circumstance as much as possible.

If you are choosing self-tapping screws for aerated concrete, then fastening with a dowel is the most optimal option. Given the low density of the foamed material, self-tapping screws for aerated concrete without a sealant will not be able to provide the proper reliability factor.

The plastic casing increases the contact area of the self-tapping screw with the wall, which is especially important in the case of low-density concrete.

There are two types of self-tapping screws with a dowel, which differ from each other in the structure of the thread.

Herringbone carving

- "Herringbone". The herringbone profile is a non-communicating thread that is fixed in the hole according to the principle of driving nails into concrete. After fixing, such a self-tapping screw cannot be removed by unscrewing, which significantly complicates dismantling. However, they also do not need to be tightened - a few strong blows are enough, which in some cases can significantly simplify the installation process;

- Universal profile. This product looks like an ordinary self-tapping screw and is mounted accordingly. The screw is simply screwed into the dowel, and when dismantled, it is removed by unscrewing. This type of fastening is somewhat inferior in reliability to the previous name.

Dowel fixing scheme

The dimensions of self-tapping screws for concrete are from 3 to 6 mm in diameter and from 12 to 220 mm along the length of the product. Herringbone screws can be more massive in diameter, but are somewhat limited in length.

Installation of self-tapping screws with dowels is carried out in pre-drilled holes, which must correspond to the diameter of the plastic casing. The dowel should fit snugly into the hole and not dangle. After that, the fastener itself is driven into it.

Self-tapping screws without dowels

Screws without dowels

Before screwing the self-tapping screw into concrete without a dowel, it is necessary to drill a hole with a special drill with a diameter of 6 mm (the diameter of the pins is 7.5 mm). Only after that the screw is screwed into the hole by means of a screwdriver - the variable notch will expand the cavity, and the upper thread will fix the self-tapping screw.

Variable thread screw

This type of fastening refers to stationary solutions - before screwing the self-tapping screw into concrete, it is necessary to accurately determine its location, since after fixing it will no longer be possible to unscrew the fasteners.

Coating type

For the most part, self-tapping screws for concrete are made of carbon steel, which is covered with a protective layer to protect against corrosion. The exception is stainless steel screws, but their price is an order of magnitude higher than conventional counterparts.

There are several options for a protective coating, among which the following should be highlighted:

Galvanized. The zinc layer has a characteristic metallic silver luster - it is the most reliable anti-corrosion coating today. These products can be used both indoors and outdoors;

Zinc and oxide coatings

- Copper-plated. The yellow screws are copper or brass plated - their use is limited to interior work;

- Oxidized. Black self-tapping screws are exposed to blackening, as a result of which an oxide film forms on their surface, which prevents the formation of rust. They can only be used in conditions with normal humidity.

Turboscrews for concrete

Screws with variable threads (d 5 mm) are also often called self-tapping screws without drilling, pins or turbo screws for concrete. These products are made of ultra-resistant materials (carbon steel, high-strength stainless steel or brass) and are treated with protective yellow coatings (galvanized) to prevent corrosion.

The main distinguishing feature of the dowel is the variable serrated thread. It is thanks to her that the coefficient of adhesion to the concrete surface increases. A screwdriver is enough to screw in the dowel.

The length of the turbo screws is from 52-212 mm, the width of the cross-shaped head (there are also products with a star-shaped head, a barrel and a hexagon) is 11 mm, and the cross-section of the rod is 7 mm (does not change regardless of the length).

Healthy! The deeper the dowel is installed, the greater its bearing capacity becomes.

Most often, turbo screws are used when working with porous concrete and hollow blocks.

In addition to the type and color of hardware, you should also pay attention to some recommendations

Drilling a hole in concrete

If the drilling of a concrete wall is done with a perforator or a drill with an impact function, then the brazed drill should be discarded. The solder will simply fall off from the blows. It is better to use a hammer drill bit. It has longitudinal grooves on its surface. The working tool gets very hot during drilling. To avoid overheating and failure of the drill, it must be periodically moistened with water. The depth of the hole should be equal to the length of the screw.

You can do without a drill and a hammer drill at all, if you take an old drill of the required diameter. It must be attached to the wall and applied 2-3 blows with a hammer. After that, turn the drill in the hole and repeat all operations until the required depth is reached. All that remains is to remove debris from the hole. This is not easy to do. You can blow forcefully into the hole with your eyes closed.

Further, the self-tapping screw can be tightened by inserting a match into the hole for fastening strength. It is not recommended to tighten it with a screwdriver that has a high rotation speed. The screwdriver cannot be stopped in the right place. It will definitely turn over and loosen the fastening of the self-tapping screw. It is better to screw it in with an ordinary manual screwdriver. You can hang a mirror, shelf or painting on a screwed-in self-tapping screw.

This was the easiest way to get the job done. Let's consider a few other options.

Concrete is a very durable building material. It is not very easy to install fasteners on it for hanging cabinets or other objects. There are many jigs and tools available for this purpose. The most popular of them are self-tapping screws.With the right choice, there are no special problems in the installation of hinged structures. Self-tapping screws in stores are presented in huge quantities. They differ from each other in color, size, thread, material of manufacture. Most often they are equipped with plastic dowels (photo No. 1), which provide a tight fixation of the self-tapping screw in the wall (photo No. 2).

Herringbone self-tapping screws cannot be unscrewed back. But they should not be screwed in either. They are simply hammered in with strong hammer blows. The diameter of the self-tapping screws for concrete is 3-6 mm. Their lengths range between 12 and 220 mm. Fasteners with dowels must be selected correctly. The dowel should fit completely and tightly into the hole. There are fasteners with variable threads (photo # 3), which widens the hole and the upper part fixes the fasteners in the wall.

Most concrete fasteners are made of carbon steel. Steel is protected from corrosion in various ways. The following types of protective coatings are common:

- galvanized;

- oxidized;

- copper-plated.

Galvanized parts have a characteristic silvery sheen. This coating is by far the most durable. It is used both outdoors and indoors. The oxidized products are black (photo no. 4). They undergo a special blackening, as a result of which a protective film is formed on the surface. This oxide film prevents rust. Oxidized products are used in conditions of normal humidity. Copper-plated screws are plated with brass or copper. They are yellow and are used for interior work.

How to remove an anchor

It is usually not a screw or bolt that is inserted into the anchor, but a hairpin (the same bolt, only without a head) or a hook. A bolt is screwed into the frame anchors, at the lower end of which the expanding element is held by means of a thread.

In general, the anchor is pulled out with pliers:

- Remove the nut.

- Hit the pin with a hammer and push it into the hole.

- Grasp the sleeve with pliers and remove.

Frame anchor:

- Remove the bolt.

- Use pliers or pliers to remove the anchor sleeve.

- Insert the bolt into the vacant hole and turn clockwise to push the wedge onto the bolt.

- Take out both elements.

If the bolt is rusted

If you cannot remove the bolt because it has oxidized, you should try to reanimate it. For this, the parts are well moistened with a rust converter, kerosene or WD-40. Leave for the time indicated on the package, or longer (up to half a day). During this time, the oxides should go away. After cleaning the bolt, you need to try to remove the nut or unscrew the bolt.

If the bolt is broken or has a ripped slot

If you tighten a bolt, screw or screw too quickly or with the wrong screwdriver, it is easy to rip off the grooves. Less often, but it happens that the head breaks off at all or partially - in particular, in case of an unsuccessful attempt to pull out the frame anchor without removing the conical "anchor".

To unscrew a broken self-tapping screw or bolt, it is drilled out and a chopik is driven into it (extractor: a wedge-shaped screw with a left-hand thread), fixed in a drill, screwdriver or pliers. Then the whole structure is rotated counterclockwise.

If the sleeve is installed incorrectly

The most common problem with anchor dowels is that they cannot be hooked onto the edge with pliers or even narrow-nose pliers. To avoid this, it is sufficient to install the anchor correctly: leaving at least 2 mm above the wall level. This length is enough to pick up the sleeve, but it can be easily closed with plaster or any profile.

What to do if the sleeve cannot be hooked:

- Screw in the self-tapping screw between the sleeve and the stud and pull it out, grabbing the stud if possible.

- Remove or push the pin / bolt, drive a self-tapping screw or other tool between the wall and the sleeve, breaking and bending the edge of the anchor with an angle. Then pull on the resulting metal corner.

- Drill out the top layer of the wall around the dowel to free the edge of the sleeve.

In extreme cases, the anchor is cut with a circular saw and its parts are taken out separately.

As a rule, metal dowels and anchors are installed where their dismantling is not required, and the load will be significant. In some cases, it makes sense not to pull out the sleeve, but to hammer it deeper and close it with cement or other mortar or a plastic / wooden chock. In any case, there are no unsolvable problems: the dowel or anchor is almost always removed, it is worth putting in patience and effort.

Video: Types and purpose of dowels