Peculiarities

A variety of fasteners in shape, size, material and method of application allows unlimited use in various areas of the construction industry. The most common types of self-tapping screws:

- on wood;

- for metal;

- with a press washer;

- roofing;

- confirmation or furniture;

- wood grouses are construction.

In 2007, Global Rivet began manufacturing and supplying Harpoon self-tapping screws.

Multi-stage control over the quality of produced materials avoids rejects. There are several verification steps for this:

- visual quality assessment;

- checking for correct geometry;

- assessment of the quality of the protective coating;

- checking the strength of the product.

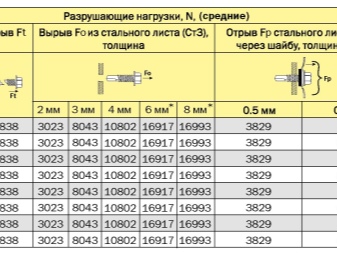

Tested:

- the quality of overcoming steel surfaces;

- twisting the head;

- fracture of the screw barrel;

- cuts, tears and tears from steel sheets;

- the strength of the packaging material.

Types and design features of self-tapping screws for profiled sheet

Although various types of self-tapping and self-drilling screws for corrugated board differ in many ways, the most reasonable is their classification by purpose. The hardware design largely depends on the base material:

- Self-tapping screws for metal sheeting allow you to securely fasten roofing and cladding elements to a profile, beams and other metal structures. The cylindrical rod of the products can have different lengths and ends with a drill tip that quickly forms a pilot hole for screwing in the hardware.

- Distinctive features of self-tapping screws for profiled sheets for concrete or wood are a tip in the form of a tip, a lower frequency and a variable thread profile... Thanks to this design, fasteners are firmly fixed in the material without destroying it, and are highly resistant to tearing.

The general design features of self-tapping screws for corrugated board include the hexagonal shape of the head and the assembly of the element with a sealing washer or press washer, which more evenly distributes pressure over the surface of the material and prevents damage to it.

The HARPOON trapezoidal sheet fastener is made of hardened carbon steel with a protective anti-corrosive coating.

You can buy high-quality self-tapping screws for corrugated board at the best price by contacting our consultants. The application can be submitted by phone 8-800-333-07-89, e-mail or directly on the website via the feedback form.

The specialists of HARPOON will provide you with all the necessary information about the type of fasteners you are interested in, inform the cost of self-tapping screws for the profiled sheet, and also help you choose products whose characteristics are most consistent with a specific project.

Areas of application and advantages of self-tapping screws for corrugated board

Self-tapping screws for profiled sheets, which can be ordered at a bargain price per piece on the HARPOON website, are used in various types of installation, construction and repair work. At the same time, most often galvanized self-tapping screws for corrugated board are used when installing fences, installing roofs and facing facade materials.

Fasteners created using such hardware have a number of important advantages, the most important of which are:

- High tensile strength, shearing, tearing, tearing and other hard mechanical loads;

- Excellent joint isolation from moisture penetration due to the ideal correspondence of the geometry of the formed channel and the fastening element located in it.

Usage

In the process of building houses or assembling any other structures from sandwich panels, several basic requirements are usually considered:

- stable and long-term fastening of structural elements to each other;

- during fastening, avoiding the application of defective violations of the surface of the panels;

- penetration of the fastening element to the proper depth.

The design of the product depends on the area in which it will be used.

The wall fasteners have a distinctive design feature: they are equipped with a hidden head and can be fixed with a hexagon.

Another distinction is the outer coating of the fasteners. A certificate of conformity has been developed for each product, which must contain all the data. External coatings are as follows:

- from tin, providing plasticity and reliable fixation;

- made of cadmium-chromium alloy with anti-corrosion properties;

- made of copper, which protects the screw itself well, but, unfortunately, does not imply secondary use;

- from nickel, the most resistant, little subject to wear and external atmospheric factors.

For the correct selection, you need to follow the selection conditions recommended by the manufacturer.

Thanks to the double thread, it becomes possible to fix it both in the skin itself and in the surface to which it is mounted.

For more than a decade of use, the products of the Global Rivet company, which produce Harpoon self-tapping screws, have received excellent recommendations in various fields of application.

- Construction. Construction of suspended facade systems for both conventional and high-rise building projects. Assembly of lightweight metal structures and lightweight building structures made of thin steel.

- Industrial products. Domestic auto industry, instrument-making institutes, nuclear industry, medical equipment and pieces of furniture, electrical engineering, household appliances, food industry, equipment for trade.

It is safe to say that the products manufactured by Harpoon have proven themselves in the market for similar products from the most advantageous side. The recommendations given by the manufacturer allow you to safely give preference in the choice of analogs.

For wood screws, see below.