How to choose the length of the screw

In order for the fastening of structural elements to be reliable and safe, it is necessary to choose the correct length of the fastener.

When choosing the length of the hardware for fastening wooden structural elements, most often they are guided by a simple rule: the self-tapping screw should go deeper into the base part by a third of the height of the attached element. In other words, if the height of the attached part is 30 mm, for reliable fastening, the self-tapping screw must enter the base by at least 10 mm. Simple calculations show that in this case, it is quite enough self-tapping screw 40 mm long... If the calculated length does not correspond to the standard length of the fastener, the next larger dimension should be used.

When attaching to a stationary base, such as a concrete wall, several factors must be considered:

- the length of the self-tapping screw should be 2 - 2.5 times the height of the attached part;

- in order for the self-tapping screw not to rest against the concrete base, it is necessary to take into account the depth of the mounting hole and the length of the plastic dowel;

- it is preferable to fasten massive structural elements to a stationary base using galvanized or yellow passivated hardware, since their bearing capacity is noticeably higher than that of phosphated or oxidized self-tapping screws;

- for screwing into a plastic dowel, it is preferable to use self-tapping screws with a large thread pitch.

Important! When connecting structural elements, self-tapping screws should not go through, this not only contributes to the appearance of cracks, but can also lead to serious injury

Diameters and lengths of self-tapping screws with a countersunk head GOST 1145-80 and a half-countersunk head GOST 1146-80

| Self-tapping screw diameter, mm | Screw length, mm | Self-tapping screw diameter, mm | Screw length, mm |

|---|---|---|---|

| 1,6 | 7, 10, 13 | 4,0 | 13, 16, (18), 20, (22), 25, 30, 35, 40, 45, 50, 60 |

| 2,0 | 7, 10, 13, 16 | 5,0 | 13, 16, (18), 20, (22), 25, 30, 35, 40, 45, 50, 60, 70 |

| 2,5 | 7, 10, 13, 16, (18), 20, (22), 25, | 6,0 | (18), 20, (22), 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 |

| 3,0 | 10, 13, 16, (18), 20, (22), 25, 30 | 8,0 | 50, 60, 70, 80, 90, 100 |

| 3,5 | 10, 13, 16, (18), 20, (22), 25, 30, 35, 40 | 10,0 | 80, 90, 100 |

How, then, are self-tapping screws chosen in terms of length and diameter? Calculate / determine the length that is needed, determined with the type of head. Then they look at the diameters and make the final choice. Let's say right away that the principle “thicker is better” does not work for wood. This can be applied to metal. For wood, thinner ones are better, but with good carvings and made of good metal. This is ideal.

If the manufacturer has his own parameters of self-tapping screws, they are indicated in the description

But this is not enough. The store usually offers up to a dozen options of the same size, but from different manufacturers. And if it is more or less easy to decide on the metal and the type of processing, then it is difficult to choose which brand to take. There are, of course, proven ones, but they are expensive. Although, if we take the cheap ones, 30-50% can go to marriage. What kind of marriage? Now they bend, then the hats fly off. It is not always, but often. If you are "lucky" to run into such fasteners, it turns out that buying "expensive" ones would not be more expensive. Well, or not much more.

What it is?

Self-tapping screws "bugs" got their name for a reason. We are talking about fasteners of the smallest size, the length of which does not exceed 10-15 millimeters. These screws are characterized by the presence of a flat, semi-cylindrical or slightly protruding cap, which allows you to reliably hide and fix the attachment point. Often a press washer is also present at the base of the fastener. There is a drill at the tip of the thread, which simplifies and speeds up the process of screwing into thin panels.

A special notch, located on the back of the head, prevents the self-tapping screw from turning out on its own. In most cases, "bugs" are made of oxidized metal. It is also possible to use a galvanized coating, which increases the material's resistance to environmental influences. It is customary to tighten small self-tapping screws with a screwdriver with a torque limiter.This tool allows you to protect the part from loss of the head, which will be extremely difficult to remove due to the size of the element.

They got their name "bugs" precisely because they are compact and have a miniature size. Squat due to the shortened thread, parts, like insects, "crawl through everywhere" - that is, they are suitable even for concealed installation. Flat fasteners with a thin, small leg and a large head are completely invisible, as a result of which they do not spoil the appearance of the furniture. In principle, like real bugs, they quickly "scatter on the floor" when they fall, it is very difficult to catch them: dropping a small self-tapping screw, it is much easier to immediately take a new one than to look for a dropped part for a long time.

The self-tapping screw "bug" may have a drill tip. This variety is created from low carbon steel with phosphate and zinc spraying. The diameter of the fastener is either 3.5 or 3.9 millimeters. The length of the part can reach either 9.5 or 11 millimeters.

The specific thread of self-tapping screws with a drill has a small pitch, which makes it possible to reliably and tightly join materials. The tip of the "bug" allows you to fix profiles without preliminary perforation of holes, as it is capable of drilling holes provided the metal thickness does not exceed 2 millimeters.

Another variation of the "bug" is a self-tapping screw with a sharp tip. Compared to fasteners equipped with a drill, this type contributes to a more reliable fixation of elements. However, sometimes their use requires preliminary marking. These self-tapping screws are also made from low carbon steel and are also treated with either phosphate or zinc. The dimensions of these fasteners correspond to the dimensions of the bugs with a drill.

Several notches located on the side of the thread on the head not only prevent self-unscrewing, but also contribute to a more rigid "docking". The sharp tip makes it possible to hold the self-tapping screw at the selected point, and then slightly pierce the sheet, after which direct twisting is carried out. Fine pitch threads easily cut the material without destroying it.

How to choose?

When choosing self-tapping screws for wood, do not dwell on metal or universal fasteners. Narrow-profile hardware will hold together a wooden structure better, and universal ones are optimal for joining metal and wooden surfaces. First you need to choose the type of screw head, the main point here is the connection to be made. Further, the type of slot. The most popular head recess types are TORX. They take the best torque from the tool.

Thread type - all over the screw rod or not. To connect two wooden parts, hardware with an incomplete thread is suitable. The length should correspond to the size of the element to be screwed on. There is a zone without threads under the head, and thanks to it, there is a tight fit of the materials to one another. To facilitate screwing into dense wood, it is recommended to take fasteners that have a mill or mill. Only hardware with incomplete screw threads is equipped with it. It consists of several grooves located at the beginning of the thread. They help to "soften" the wood surface.

It is imperative to pay attention to the size of the diameter and length of the screw rod in order to prevent cracking of the wood during operation. An important point is where the thread originates from, it should be from the very end

A loop located far away indicates that the end is not pointed and blunt. Working with such fasteners will bring a lot of problems.

The choice of color also depends on the material with which to work. For wood, yellow self-tapping screws are best, but they have a higher price. Black fasteners have a number of disadvantages: they are susceptible to corrosion, and stains can occur on the wooden surface. This is not so critical for metals, because the bond can be painted over.Also, black hardware is quite fragile - if you twist them, the hat may break off. An example would be flooring. Boards tend to dry out and bend, because of this, the load on the self-tapping screw increases, the head breaks off. Therefore, the wooden floor starts to creak.

For information on how to choose the right self-tapping screw for wood, see the next video.

Size charts

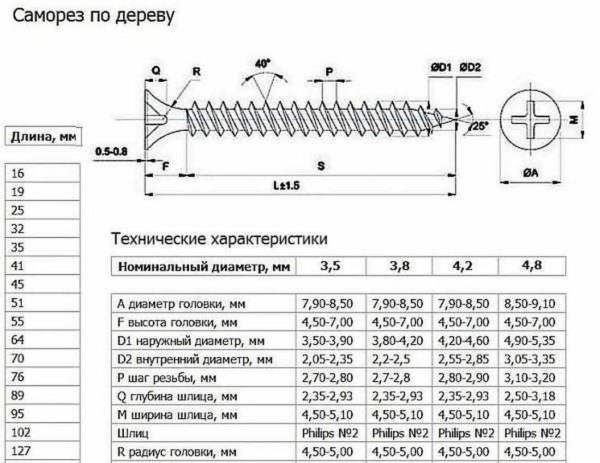

Below are the dimensions of the most common self-tapping screws.

Sizes of black wood screws

|

Nominal diameter, |

Unit rev. |

3,5 |

3,8 |

4,2 |

4,8 |

|

Head diameter, A |

mm |

7,9-8,5 |

8,5-9,1 |

||

|

Head height, F |

mm |

4,5-7,0 |

|||

|

Outer thread diameter, D1 |

mm |

3,5-3,9 |

3,8-4,2 |

4,2-4,6 |

4,9-5,4 |

|

Internal thread diameter, D2 |

mm |

2,1-2,4 |

2,2-2,5 |

2,6-2,9 |

3,1-3,4 |

|

Thread pitch, P |

mm |

2,7-2,8 |

2,8-2,9 |

3,1-3,2 |

|

|

Slot depth, Q |

mm |

2,4-2,9 |

2,5-3,2 |

||

|

Slot width, M |

mm |

4,5-5,1 |

|||

|

Slot |

mm |

Philips No. 2 |

|||

|

Head radius, R |

mm |

4,5-5,0 |

|||

|

Minimum torque |

N * m |

2,0 |

2,8 |

4,5 |

6,5 |

The length of the hardware is standardized and can be: 16; 19; 25; 35; 41; 45; 51; 55; 64; 70; 76; 89; 95; 102; 127; 152 mm.

Sizes of yellow wood screws

|

Nominal diameter, |

Unit rev. |

2,5 |

3,0 |

3,5 |

4 |

4,5 |

5 |

6 |

|

Head diameter, A |

mm |

4,7-8,1 |

5,7-6,1 |

6,6-7,1 |

7,6-8,1 |

8,6-9,1 |

9,6-10,1 |

11,6-12,1 |

|

Head height, H |

1,4 |

1,8 |

2,0 |

2,35 |

2,55 |

2,85 |

3,35 |

|

|

Outer thread diameter, D |

2,3-2,5 |

2,8-3,1 |

3,2-3,6 |

3,7-4,1 |

4,2-4,6 |

4,7-5,1 |

5,7-6,1 |

|

|

Internal thread diameter, d |

1,1-1,5 |

1,5-1,9 |

1,8-2,2 |

2,0-2,5 |

2,2-2,7 |

2,5-3,0 |

3,2-4,1 |

|

|

Thread pitch, P |

1,0 |

1,35 |

1,6 |

1,8 |

3,0 |

3,2 |

3,6 |

|

|

Slot depth, Q |

1,2-1,6 |

1,6-2,1 |

1,8-2,2 |

2,0-2,5 |

2,5-3,0 |

3,0-3,6 |

||

|

Slot width, M |

2,5 |

2,5 |

3,0 |

3,5 |

4,8 |

5,3 |

6,3 |

|

|

Slot |

||||||||

|

Head radius, R |

Pz1 |

Pz2 |

||||||

|

Minimum torque |

N * m |

1.0 |

1.5 |

2.0 |

3.0 |

4.4 |

6.1 |

11 |

Length of yellow self-tapping screws

|

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

Ø, mm |

L, mm |

|

2.5 |

10 |

3.5 |

12 |

4.0 |

35 |

4.5 |

60 |

5.0 |

100 |

6.0 |

140 |

|

13 |

16 |

40 |

70 |

120 |

160 |

||||||

|

16 |

20 |

45 |

80 |

6.0 |

40 |

180 |

|||||

|

20 |

25 |

50 |

5.0 |

20 |

45 |

200 |

|||||

|

25 |

30 |

60 |

25 |

50 |

|||||||

|

3.0 |

10 |

35 |

70 |

30 |

60 |

||||||

|

12 |

40 |

4.5 |

16 |

35 |

70 |

||||||

|

16 |

45 |

20 |

40 |

80 |

|||||||

|

20 |

50 |

25 |

45 |

90 |

|||||||

|

25 |

4.0 |

12 |

30 |

50 |

100 |

||||||

|

30 |

16 |

35 |

60 |

110 |

|||||||

|

35 |

20 |

40 |

70 |

120 |

|||||||

|

40 |

25 |

45 |

80 |

130 |

|||||||

|

45 |

30 |

50 |

90 |

Dimensions of self-tapping screws with a press washer

|

Designation |

L, mm |

Q, mm |

D, mm |

P, mm |

d, mm |

U, mm |

H mm |

A, mm |

B, mm |

|

4.2x13 |

12,5-13,5 |

1,9-2,35 |

4,15-4,28 |

1,6-1,75 |

2,68 |

1,0-1,2 |

2,1-2,45 |

10,6-10,8 |

7,0-7,15 |

|

4.2x14 |

13,5-14,5 |

||||||||

|

4,2x16 |

15,5-16,5 |

||||||||

|

4,2x19 |

18,5-19,5 |

||||||||

|

4.2x25 |

24,0-26,0 |

||||||||

|

4,2x32 |

31,0-33,0 |

||||||||

|

4.2x41 |

40,0-42,0 |

||||||||

|

4,2x51 |

50,0-52,0 |

||||||||

|

4,2x76 |

75,0-77,0 |

Dimensions of self-tapping screws with a hex head

|

Outer thread diameter, d, mm |

5 |

6 |

8 |

10 |

12 |

16 |

20 |

|

|

Internal thread diameter, d2, mm |

4,2 |

5,6 |

7 |

9 |

12 |

15 |

||

|

Thread pitch, P, mm |

2,2 |

2,6 |

3,6 |

4,5 |

5,0 |

6,0 |

7,0 |

|

|

Head height, k, mm |

3,5 |

4,0 |

5,5 |

7,0 |

8,0 |

10,0 |

13,0 |

|

|

Floor key size, S, mm |

8 |

10 |

14 |

17 |

19 |

24 |

30 |

|

|

Bar length, L, mm |

min |

20 |

20 |

25 |

30 |

40 |

60 |

80 |

|

max |

60 |

140 |

200 |

300 |

380 |

300 |

200 |

Sizes of roofing screws

|

Designation |

L, length, mm |

P, thread pitch, mm |

C, flange thickness, mm |

Df, flange diameter, mm |

e, for references, mm |

K, head height, mm |

S, turnkey size, mm |

|

4.8x19 |

18-20 |

1,6 |

0,9 |

9,8-10,5 |

8.71 min |

3,8-4,3 |

7,78-8, |

|

4.8x25 |

24-26 |

||||||

|

4.8x32 |

31-33 |

||||||

|

4.8x38 |

37-39 |

||||||

|

4.8x50 |

49-51 |

||||||

|

5.5x25 |

24-26 |

1,8 |

1,0 |

10-11 |

5,25-5,4 |

||

|

5.5x32 |

31-33 |

||||||

|

5.5x38 |

37-39 |

||||||

|

5.5x50 |

49-51 |

||||||

|

6,3x25 |

24-26 |

11 min |

9,8-10 |

||||

|

6,3x32 |

31-33 |

||||||

|

6,3x38 |

37-39 |

||||||

|

Designation |

D, Thread diameter, mm |

Dp, Drill diameter, mm |

T, Drill length, mm |

Dw, Washer diameter, mm |

AG, Rubber thickness, mm |

A Washer thickness, mm |

Weight 1000 pcs, kg |

|

4.8x19 |

4,62-4,8 |

3,9 |

5,5-6,0 |

13,8-14,2 |

2,8-3,2 |

0,8-0,9 |

3,2 |

|

4.8x25 |

3,8 |

||||||

|

4.8x32 |

4,3 |

||||||

|

4.8x38 |

4,9 |

||||||

|

4.8x50 |

5,9 |

||||||

|

5.5x25 |

5,28-5,5 |

4,55-4,7 |

7,6-9,0 |

6,34 |

|||

|

5.5x32 |

7,56 |

||||||

|

5.5x38 |

7,85 |

||||||

|

5.5x50 |

9,46 |

||||||

|

6,3x25 |

6,03-6,3 |

5,4-5,55 |

8,0-9,6 |

15,9-16,3 |

8,5 |

||

|

6,3x32 |

13,8-14,2 |

9,6 |

|||||

|

6,3x38 |

10,4 |

In the wholesale purchase of fasteners, in addition to their design features, the weight of the hardware is also important.

Coating

By themselves, the self-tapping screws "bugs" have increased durability, as they are made of an alloy of iron with carbon without impurities. Therefore, the coating applied to the fasteners is primarily responsible for the protective function. The extra layer helps prevent corrosion and, as a result, lengthens the service life.

The black color of the "bug" is due to the creation of a phosphate layer that improves the adhesion of the paintwork to the fasteners. Such self-tapping screws are perfect for painting and, painted with bituminous varnish, have enhanced protective characteristics. For example, they can be operated in high humidity conditions. However, it should be remembered that acids and alkalis destroy this phosphate film.

Self-tapping screws become white after galvanizing. In this case, with the help of zinc, only the upper layer of the hardware is oxidized, from 4 to 20 microns. Using zinc oxide, it is possible to prevent further oxidation of self-tapping screws, which occurs under the influence of oxygen. Galvanized self-tapping screws can be brown or have a yellow tint.