Classification

Self-tapping screws are classified into separate groups depending on different criteria - type of head and coating, type of tip, material.

By head type

Types of fasteners:

Self-tapping screws for metal with a press washer. Designed for joining metal sheets up to 1 cm thick. Thanks to the large head, the parts are securely fixed.

Hemispherical. Large fasteners that are designed to fix various metal workpieces.

Cruciform. They are considered the most reliable and versatile. For tightening, you can use standard Phillips bits for a screwdriver. They fit tightly into the material without breaking its structure.

Self-tapping screws with a straight slot. Such fasteners are more often used to connect wooden parts.

Hex head. Screwed into different materials. To tighten, you need a special wrench or screwdriver bit.

Countersunk head. To tighten the self-tapping screw, you must first drill a hole with a smaller diameter.

It is important that the cap fits snugly against the material, does not protrude outward.

Reduced countersunk bonnet. Small diameter head

It is easy to hide it in the material to be joined.

Self-tapping screws with a press washer (Photo: Instagram / anna_schelepneva)

By tip type

Depending on the type of tip, there are several types of fasteners:

- Self-tapping screws for metal with a drill. The tip of such fasteners is a drill consisting of two feathers. Suitable for fastening metal sheets up to 2 mm thick.

- Fasteners with a sharp tip. There is a thread on the rod for easy screwing. Suitable for fastening metal sheets up to 0.9 mm thick.

By type of coverage

Types of self-tapping screws:

- Phosphated - black hardware. Manufactured from carbon steel. They undergo additional processing with phosphates. Suitable for fastening parts in high humidity conditions.

- Oxidized - made of carbon steel, black. A protective film is applied to metal surfaces.

- Galvanized - carbon steel is used for manufacturing. The surfaces are coated with a zinc layer. They are used for the installation of metal parts outside, indoors.

- Galvanized yellow - products similar to standard galvanized fasteners, but different in appearance.

- Uncoated - suitable for indoor work at normal humidity levels.

Self-tapping screws of different types (Photo: Instagram / stroi_s_nami82)

By material

Material:

- Carbon steel is an alloy based on carbon and iron, which is not supplemented by foreign impurities. They are distinguished by a high strength indicator.

- Brass is an alloy based on copper and zinc. To change the technical characteristics, manganese, lead, nickel, tin, iron can be added. Brass fasteners stand out for their high wear resistance and reliability. The material is immune to prolonged exposure to moisture, temperature changes.

- Stainless steel is a material that contains about 10.5% chromium. The stainless steel has an increased strength index. The material is resistant to rust formation.

Recommendations for choosing high-quality fasteners ↑

in the photo self-tapping screws with a drill

Manufacturers who value their reputation strictly test their products according to various parameters, subjecting them to various loads. When tilting the hardware:

- at 5 °, it must maintain resistance to 20 thousand vibrations;

- 10 ° - respectively to 2 thousand;

- 15 ° - to 100 vibrations.

Quality products pass these tests without any change in steel quality.

Branded products are necessarily marked with several Latin letters, which should indicate its factory origin and compliance with the requirements of GOST.

As already noted, roof fasteners are equipped with rubber washers, which seal the areas of contact between the caps and the coating and prevent water from getting under the cap. In other words, the rubber gasket prevents corrosion on the roof.

On high-quality self-tapping screws, the rubber gasket and the washer itself should, as it were, merge together, otherwise the service life of the gasket will be limited to at most two years, after which it will collapse.

On a note

You can quite easily distinguish a factory product from a fake using ordinary pliers. Clamp the washer with them: if this damages the rubber gasket or peels off the paint, then you are dealing with material of dubious quality.

Therefore, do not seek to acquire too cheap parts - the risk of running into a fake is too great. It is much more reliable to buy branded from trusted suppliers.

Length plays a significant role in its selection. At the same time, they are repelled by several parameters, for example, from the type of material for the coating or the features of the rafter system. The main recommendations can be found in the following table:

GOST for self-tapping screws for metal 11650-80

Drills for metal GOST 10903-77

2020 .

Specifications: dimensions, weight and more ↑

Mainly made of carbon steel and galvanized. Thanks to the anti-corrosion coating, they serve for a rather long time - about 50 years. In addition to them, stainless steel hardware is presented on the market, however, they are much more expensive. As a rule, they are used in particularly critical areas for which it is necessary to provide increased strength.

These products are also distinguished by the shape of the cap. She may have:

- standard view, that is, equipped with a screwdriver, or;

- with edges, for which special bits for roofing screws are used.

See how they might look in the photo.

samorezi-1

samorezi-1

samorezi-2

samorezi-2

samorezi-3

samorezi-3

samorezi-4

samorezi-4

Further, depending on the type of roofing material, the caps can "sink" in the coating or, as in the case of the option with a press washer, press it, which will completely protect the hole from water penetration. The latter's hat looks like a hemisphere.

Hardware can be supplied with a metal, usually aluminum, washer with a rubber gasket. A sealing gasket made of a special self-vulcanizing material EPDM with a thickness of 2.8 mm is considered to be more effective and durable.

Among the wide variety of market offers, you can always choose fasteners that have a length that exactly matches the wavelength of the roofing sheet.

Main types

Self-tapping screw for wood

This type of part is characterized by a rare thread pitch, which is due to the low density and hardness of the wood. Based on the color of the material with which you have to work, you can choose a black, white or gold fixture with a large distance between the turns. Most often, builders use black self-tapping screws, but from time to time they have to select a tool to match, for example, while screwing a yellow furniture hinge.

The length of a self-tapping screw for wood varies from 11 mm (because of their small size, they are popularly called seeds) to 200 mm. They select it depending on the size of the part, adjusting the density of the connection of materials. So, when working with two bars of 50 mm each, it is recommended to use a self-tapping screw with a length of at least 80 mm.

Depending on the density of the wood, the size of the hole for the self-tapping screw is selected. Most often, for a part with a diameter of 4.5 mm, a hole of 3 mm or 3.5 mm is required, for 5 mm - 3.5 mm or 4 mm, for 6 mm - 4.5 mm. With this ratio of parameters, the wood material does not crack.There is no drill for wood with a pitch of 0.5 mm, so workers use a standard drill for metal, but in no case should the hole be made too large, otherwise the low density grip will be ineffective. Based on the diameter of the screw, a screwdriver is also selected. When working with yellow parts, use a bit PZ No. 1, PZ No. 2 or PZ No. 3, and with black parts, use a bit or a screwdriver with a PH No. 2 connector.

Self-tapping screw for metal

characterized by frequent pitch and small thread spacing

Sharp galvanized self-tapping screw with press washer

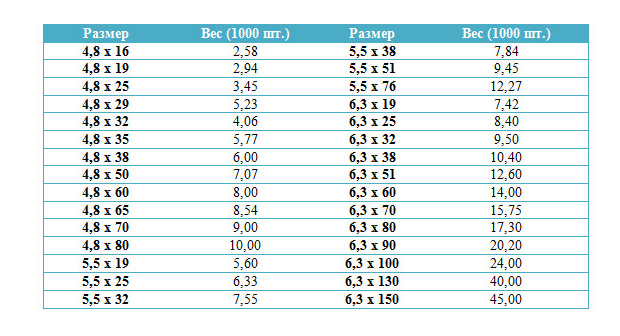

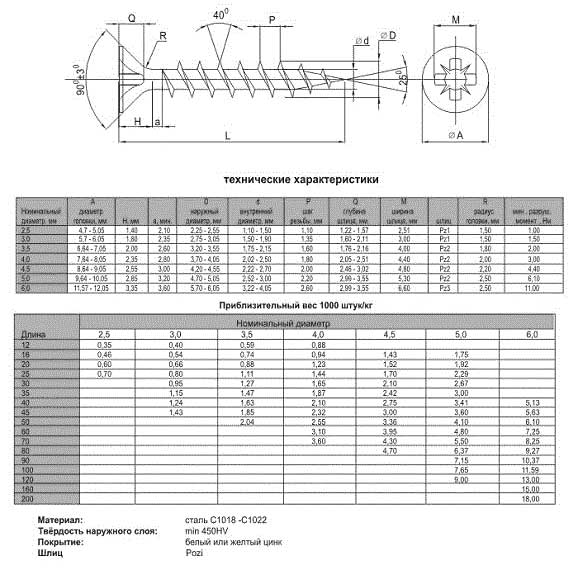

The size and weight in kg (1000 pieces) are respectively presented in the form of a table.

| 4.2x13 | 1,48 |

| 4.2x14 | 1,53 |

| 4,2x16 | 1,61 |

| 4,2x19 | 1,88 |

| 4.2x25 | 2,21 |

| 4,2x32 | 2,63 |

| 4.2x41 | 3,26 |

| 4,2x51 | 4,29 |

| 4,2x76 | 5,14 |

Self-tapping screw with a press washer with a drill

a special drill is attached to the tip of the part with a drill and a press washer

The size and weight in kg (1000 pieces) are respectively presented in the form of a table.

| 4.2x13 | 1,48 |

| 4.2x14 | 1,53 |

| 4,2x16 | 1,61 |

| 4,2x19 | 1,88 |

| 4.2x25 | 2,21 |

| 4,2x32 | 2,63 |

| 4.2x41 | 3,26 |

| 4,2x51 | 4,29 |

| 4,2x76 | 5,14 |

Other types

Roofing screw

use a bit with an internal hex

Confirmat (furniture tool)

Capercaillie (hex head screw)

The part is most often used when working with heavy wood structures, when special tool strength is required. The hole for drilling must correspond to the following ratio: for a 6 mm screw, a hole of 4.5 mm is required, for 8 mm - 6 mm, for 1 cm - 8 mm. A wrench is used to tighten the device, the hex head should be 1 cm, 1.3 cm or 1.7 cm in diameter based on the thickness of the screw.

If a tool with a dowel is used, the diameter of the latter should be approximately twice the size of the self-tapping screw. In this case, the hole on the working surface must match the diameter of the dowel.

Selection recommendations

When choosing self-tapping screws with a press washer, it is very important to pay attention to some parameters that are of the greatest importance in their subsequent use. Among the useful recommendations are the following

The white or silver color of the hardware indicates that they have an anti-corrosion zinc coating. The service life of such screws is as long as possible, calculated in decades.

But if work on metal is coming, you should definitely pay attention to its thickness - the sharp tip will roll over at a thickness of more than 1 mm, here it is better to immediately take the option with a drill.

A painted self-tapping screw with a press washer is the best choice for installing roofing or fence coverings. You can choose an option for any colors and shades

In terms of corrosion resistance, this option is superior to conventional black products, but inferior to galvanized ones.

Phosphated hardware has a color from dark brown to gray, depending on the characteristics of their processing, they have a different degree of protection from the influence of the external environment. For example, oiled ones receive increased protection against moisture, they are better stored. Phosphated products lend themselves well to painting, but are used mainly for work inside buildings and structures.

The type of thread matters. For self-tapping screws with a press washer for metal work, the cutting step is small. For woodwork, chipboard and hardboard, other options are used. Their threads are wide, avoiding breaks and twisting. For hardwoods, hardware is used with cutting in the form of waves or dashed lines - to increase the effort when screwing into the material.

Considering all these factors, it is possible to choose suitable self-tapping screws with a press washer for performing work on wood and metal, fastening fences from a profiled sheet, creating roofing coverings.

You will learn how to choose the right screws with a press washer and not purchase a low-quality product in the next video.

Selection principles

There are several factors to consider when choosing fasteners:

- The number and dimensions of fasteners. The longer the screws are, the more they weigh. This is not noticeable when connecting small parts, but if there are many fasteners, the weight of the finished product will increase.

- It makes no sense to use the longest self-tapping screws. It is enough for the fastener to pierce through the metal sheet.

- The type of coating for fasteners must be selected depending on the application.

- To securely fix the profiled sheets, you need to choose self-tapping screws with a special gasket. It should be fixed under the hardware head. The hat itself should be marked. A high-quality gasket is made of EPDM, a low-quality one is made of rubber.

- It is better to choose fasteners with a galvanized coating. It is a reliable protection against rust formation.

- You can find fasteners in different colors on sale. The shade is selected depending on the color of the profiled sheets.

Hardware store (Photo: Instagram / kubmaster1)

Applications

According to their purpose, self-tapping screws with a press washer are quite diverse. Products with a pointed tip are used to attach soft or fragile materials to a wooden base. They are suitable for polycarbonate, hardboard, plastic sheathing.

Painted roofing screws are used in combination with polymer-coated profiled sheet, their classic galvanized counterparts are combined with all soft materials, sheet metal with a smooth surface. It is necessary to screw in self-tapping screws with a drill bit with a special tool.

The main areas of their application:

- installation of metal lathing;

- hanging structures on a sandwich panel;

- installation and assembly of ventilation systems;

- fastening the slopes of doors and windows;

- formation of barriers around the site.

Self-tapping screws with a pointed tip have an even wider range of uses. They are suitable for most types of interior work, do not spoil even fragile and soft coatings, decorative elements in interior decoration.

Varieties ↑

raznovidnosti-1

raznovidnosti-1

raznovidnosti-2

raznovidnosti-2

There are two types of fasteners - self-tapping screws for metal and wood. The first ones are larger in diameter than the second ones, and they hold worse in wood, therefore they are practically not used as fasteners for wooden structures. Actually, as well as vice versa, self-tapping screws for wood are impossible or at least very difficult to screw into metal. They also differ in thread pitch: according to GOST, self-tapping screws for metal have more frequent threads.

Healthy

1000 pieces of 4.8 * 29 format products weigh about 5 kg. By the way, as a rule, when buying in a store, you will see not the price per piece, but for the same 1000. Nevertheless, we note: the price of one self-tapping screw with a polyester coating is about 3 rubles, and a dyed one with a polymer layer - from 8 rubles.

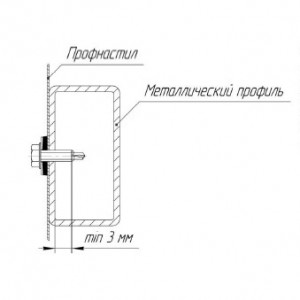

For metal with a drill: GOST, dimensions, features

dimensions, weight

dimensions, weight

In addition to the threads running through the body of these elements, they have a pair of vertical drilling blades at their end. When screwing in the hardware, they drill a pilot hole, that is, the installation is carried out directly into the metal base without preliminary drilling. These products prevent deformation of the metal coating and protect it from damage at the attachment points. The package also includes a metal washer and a press-fit weatherproof rubber gasket. The head of the hardware is hexagonal. They are mounted using a bit for a roofing screw.

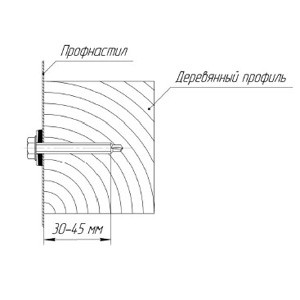

Wood: dimensions

They are used when connecting any elements made of wood. The presence of a drill at the end of the part makes it as easy as possible to use it. If holes are pre-drilled on metal profiles with a drill, they can be used to attach metal profiles to wooden surfaces. Fastening is carried out using the through-mounting technology, using a special socket wrench for a hexagonal nozzle. The most in demand are self-tapping screws for a hexagon for wood with a length of 100 and a diameter of 8 mm. Note that in this case, their length ranges from 11 to 200 mm.

wood screws size table

wood screws size table

Important

The type of self-tapping screw is chosen depending on the type of base to which the material for the roof is supposed to be attached: for a wooden base, fasteners with a sharp end are needed, for a metal base - a drill-shaped one.

Galvanized and painted

Usually, roofing screws for metal tiles, polycarbonate or other sheet materials with a polymer coating, as well as for slate, are colored. The sheets and fasteners to be fixed should match each other as much as possible in color, therefore, as a rule, they are selected by marking. The most commonly used RAL colors are:

- green - 6005;

- cherry - 3005;

- blue - 5005;

- white - 9003;

- brown - 8017.

The use of colored species not only enhances the aesthetics of the roof. The paint becomes an additional barrier to corrosion.

On a note

These products differ from the previous types only in coloring. The weight and dimensions of one part are clearly regulated by GOST.