The choice of the length of the screws

There are several rules for choosing the length of a self-tapping screw that apply in different situations. When joining / joining two not very massive parts, the following selection rules work:

-

So that you do not connect, the sharp end of the self-tapping screw should not stick out from the other side of the parts to be connected. That is, in any case, it should be shorter than the parts to be joined. Moreover, it is believed that the maximum strength will be if at least 5-6 mm remains to the edge of the lower part. So count it.

- On the other hand, the minimum self-tapping screw should fit into the bottom part by at least 1/3 of the thickness of the part to be attached. That is, if you fasten, say, a beam of 100 * 100 mm, then the minimum length of the self-tapping screw should be 1/3 longer. For this timber, the minimum screw length is 100 + 100/3 = 133 mm. Take the nearest larger. If you fasten a board 28 mm thick, then the minimum screw length is 28 + 28/3 = 37 mm (usually 42 mm is chosen).

If a thin piece is attached to a massive base, another rule works. Then the length of the fastener should be 2-2.5 times longer than the attached part. So it is necessary to select the length of the self-tapping screw if you attach something to a wall, say, or to a concrete floor. In this case, in order to fix the same 28 mm board to the wall, the length of the fastener is 56-70 mm. This is the difference.

Self-tapping screw sizes: the most applicable options

How to choose the length of the self-tapping screws, it seems, should be clear. Now about what they are in general. The situation here is confusing. Neither screws nor self-tapping screws have a common standard. There are several standards of "worn out" years of release, in which the sizes of some types of self-tapping screws are prescribed.

- GOST 1145-80. Countersunk self-tapping screws.

- GOST 1144-80. Pan head screws.

- GOST 1146-80. Half-countersunk head screws.

The situation today is that each manufacturer produces its own "line". They are oriented, of course, on demand. Well, the parameters of the heads are usually made in accordance with one or another GOST. This will somehow stabilize the situation. Sometimes the assortment - diameters and lengths are also made according to the standard. In this case, in the description of self-tapping screws, the diameters in which they are generally produced are indicated, and then there is a postscript: it corresponds to such and such a GOST. This means that the heads comply with the specified standard, as well as that the assortment corresponds.

Where are they used?

As mentioned above, the design features of the countersunk head self-tapping screw contributed to the widespread use of the product in the process of fastening various elements:

- wooden;

- plastic;

- steel sheets (metal products).

Most often, this fastener is used when working with wood. In the process of carrying out facade and roofing works, the potay self-tapping screw is an indispensable element. Its use makes it possible to securely fix the structure assembly and maintain its aesthetic, reliable appearance, smooth and even surface.

The video below briefly talks about the application and the difference between a self-tapping screw and a screw.

What is a screw, screw, self-tapping screw, bolt, washer and nut, what does it look like, what is it for?

Washer is a fastener that is auxiliary and is placed under the nut head. The main purpose of such a product is to increase the pressure area, as well as prevent the destruction of other fasteners. In addition, the washer prevents the fastener from loosening and makes it more resistant to all kinds of mechanical stress.

Washer

Screw - a fastener, which is a type of screw, differs from it in that it has a thick rod, an external thread, and a pointed tip. This makes it easier and easier to enter a hard surface. Namely, in wood or concrete. Most often, special holes are made for the screws, which are filled with a relatively soft material. This is usually a tree.

Screw

A screw is also a fastener, a type of which is a self-tapping screw or screw.The main feature of the fastener is that it is a male threaded rod with a large enough head for screwing in. Most often, special holes are made on the head so that the screws can be tightened with a screwdriver. Or they make special notches to screw in products using a special wrench.

Screw

A bolt is a fastener that is a cylinder with a sufficiently tall hex head. Most often it works together with a nut in pairs, and is used to connect some parts.

Bolt

Nut - a fastener, inside which there is a thread, is used in a set with a screw or bolt. Usually the nuts are made in a hexagonal shape so that they can be fastened with a wrench.

screw

Peculiarities

Self-tapping screws are one of the most commonly used types of fasteners. The main reason for this popularity is the presence of a countersunk head on the product. Its shape is so perfect that the working surface after mounting the self-tapping screw remains flat, without any bulges.

Such fasteners have a number of other features, namely:

- strength;

- reliability;

- wear resistance;

- corrosion resistance;

- long service life;

- wide selection and assortment.

All self-tapping screws differ in size and purpose. There are fasteners designed for fastening wooden or plastic structural elements, there is also a separate type for working with metal.

The design of a self-tapping screw is practically no different from a conventional screw. It consists of:

- a rod, along the entire length of which the thread is located (sometimes the thread is applied only to a part of the product);

- slotted heads (the type of head is different);

- tip of a sharp or blunt type.

It can be stainless carbon steel or non-ferrous metal such as brass. After manufacturing, the fasteners can be treated with a special coating that increases its anti-corrosion properties. Most often these are zinc or other phosphate substances.

The production process, control of the materials and raw materials used are clearly spelled out and provided in the regulatory documents GOST 1145-80, GOST 1144-80 and GOST 1146-80. Also, these regulations control the passage of all necessary laboratory tests and the issuance of quality certificates.

The product is characterized by the following parameters:

- screw diameter, mm;

- screw length, mm;

- slot size;

- type of thread;

- appointment.

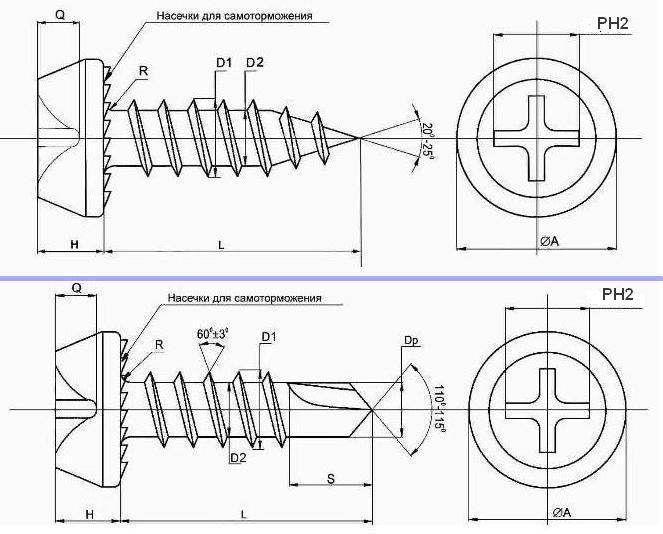

Self-tapping screws for fastening profiles "seeds"

These products are better known under the popular name "seeds" because of their external similarity with sunflower seeds.

There are both black, phosphate coated and galvanized. Due to the very sharp tip and small

sizes are ideal for fastening profiles up to 0.9 mm thick.

These self-tapping screws are much more effective when installing profiles for GKL on

compared with the "bugs" (which were mentioned above). Sharp tip allows you not to crawl along the profile and accurately

tighten the fasteners to the intended place.

These hardware are found in the version with a drill - for screwing into metal up to 2mm thick. All self-tapping screws have

slots for bit PH2.

| The size | L length, mm | Head diameter, mm | H head height, mm | D1 outer diameter, mm | D2 inner diameter, mm | Weight 1000 pcs, kg |

|---|---|---|---|---|---|---|

| Sharp tip 3.5 × 11 | 10,45-11,55 | 7,39-8,00 | 2,45-2,92 | 3,42-3,58 | 2,76-2,92 | 1,13 |

| Drill 3.8 × 11 | 10,20-11,80 | 7,60-8,00 | 2,70-3,00 | 3,75-3,95 | 2,76-2,92 | 1,13 |

The choice of the length of the screws

There are several rules for choosing the length of a self-tapping screw that apply in different situations. When joining / joining two not very massive parts, the following selection rules work:

-

So that you do not connect, the sharp end of the self-tapping screw should not stick out from the other side of the parts to be connected. That is, in any case, it should be shorter than the parts to be joined. Moreover, it is believed that the maximum strength will be if at least 5-6 mm remains to the edge of the lower part. So count it.

The length of the self-tapping screw is selected depending on the parts to be fastened

- On the other hand, the minimum self-tapping screw should fit into the lower part by at least 1/3 of the thickness of the part to be attached. That is, if you fasten, say, a beam of 100 * 100 mm, then the minimum length of the self-tapping screw should be 1/3 longer. For this timber, the minimum screw length is 100 + 100/3 = 133 mm. Take the nearest larger. If you fasten a board 28 mm thick, then the minimum length of the self-tapping screw is 28 + 28/3 = 37 mm (usually 42 mm is chosen).

If a thin piece is attached to a massive base, another rule works. Then the length of the fastener should be 2-2.5 times longer than the attached part. So it is necessary to select the length of the self-tapping screw if you attach something to a wall, say, or to a concrete floor. In this case, in order to fix the same 28 mm board to the wall, the length of the fastener is 56-70 mm. This is the difference.

Self-tapping screw sizes: the most applicable options

How to choose the length of the self-tapping screws, it seems, should be clear. Now about what they are in general. The situation here is confusing. Neither screws nor self-tapping screws have a common standard. There are several standards of "worn out" years of release, in which the sizes of some types of self-tapping screws are prescribed.

- GOST 1145-80. Countersunk self-tapping screws.

- GOST 1144-80. Pan head screws.

- GOST 1146-80. Half-countersunk head screws.

The situation today is that each manufacturer produces its own "line". They are oriented, of course, on demand. Well, the parameters of the heads are usually made in accordance with one or another GOST. This will somehow stabilize the situation. Sometimes the assortment - diameters and lengths are also made according to the standard. In this case, in the description of self-tapping screws, the diameters in which they are generally produced are indicated, and then there is a postscript: it corresponds to such and such a GOST. This means that the heads comply with the specified standard, as well as that the assortment corresponds.

How, then, are self-tapping screws chosen in terms of length and diameter? Calculate / determine the length that is needed, are determined with the type of head. Then they look at the diameters and make the final choice. Let's say right away that the principle “thicker is better” does not work for wood. This can be applied to metal. For wood, thinner ones are better, but with good carvings and made of good metal. This is ideal.

If the manufacturer has his own parameters of self-tapping screws, they are indicated in the description

But this is not enough. The store usually offers up to a dozen options of the same size, but from different manufacturers. And if it is more or less easy to decide on the metal and the type of processing, then it is difficult to choose which brand to take. There are, of course, proven ones, but they are expensive. Although, if we take the cheap ones, 30-50% can go to marriage. What kind of marriage? Now they bend, then the hats fly off. It is not always, but often. If you are "lucky" to run into such fasteners, it turns out that buying "expensive" ones would not be more expensive. Well, or not much more.

Now compare the two tables. They are compiled according to different GOSTs. As you can see, the diameters and lengths are the same. This makes life easier. If, in the production of fasteners, the standard was adhered to in terms of the diameter / length ratio, then everything is simple. If not, then the manufacturer in the description of the screws attaches a table with dimensions (as in the picture above).

Selection principles

There are several factors to consider when choosing fasteners:

- The number and dimensions of fasteners. The longer the screws are, the more they weigh. This is not noticeable when connecting small parts, but if there are many fasteners, the weight of the finished product will increase.

- It makes no sense to use the longest self-tapping screws. It is enough for the fastener to pierce through the metal sheet.

- The type of coating for fasteners must be selected depending on the application.

- To securely fix the profiled sheets, you need to choose self-tapping screws with a special gasket. It should be fixed under the hardware head. The hat itself should be marked. A high-quality gasket is made of EPDM, a low-quality one is made of rubber.

- It is better to choose fasteners with a galvanized coating. It is a reliable protection against rust formation.

- You can find fasteners in different colors on sale. The shade is selected depending on the color of the profiled sheets.

Hardware store (Photo: Instagram / kubmaster1)

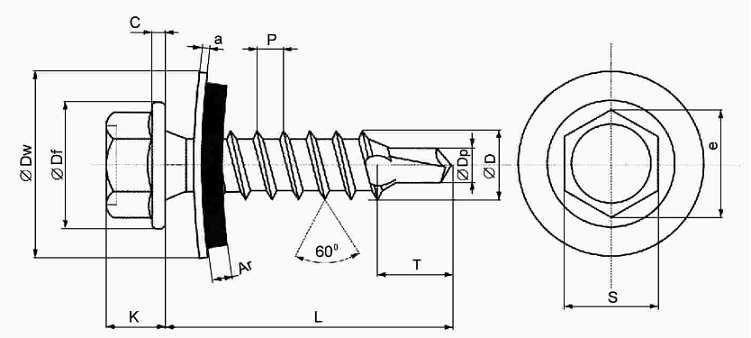

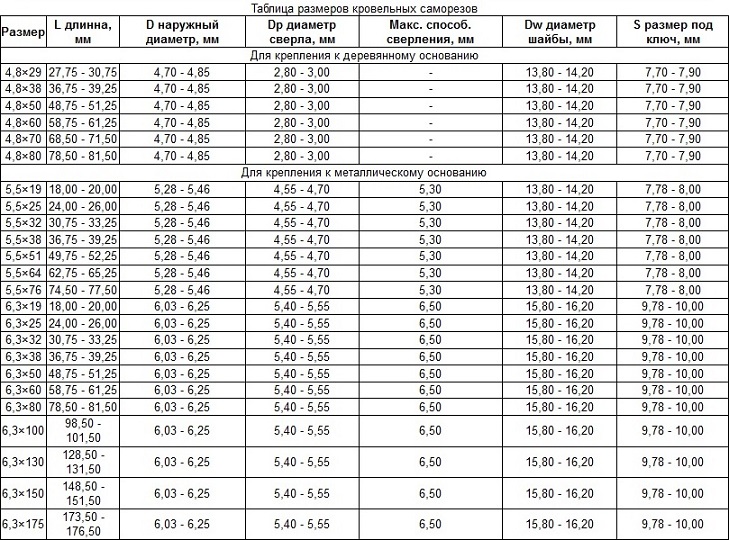

Roofing screws

These self-tapping screws are designed for fastening roofing materials - profiled sheets, metal tiles. Thanks to the rubber

washer EPDM, the surface of the roof retains its waterproofing properties after screwing in the fastener.

These hardware are of two types: for fastening to a wooden crate or a metal base.

Self-tapping screws designed for fastening the roof to metal have a smaller thread pitch and a greater thickness. Maximum

the thickness of the metal base is characterized by maximum drilling capacity in the table below.

| The size | L is long, mm | D outer diameter, mm | Dp drill diameter, mm | Max. way. drilling, mm | Dw washer diameter, mm | S size under the key, mm |

|---|---|---|---|---|---|---|

| For fixing to a wooden base | ||||||

| 4,8×29 | 27,75 — 30,75 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×38 | 36,75 — 39,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×50 | 48,75 — 51,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×60 | 58,75 — 61,25 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×70 | 68,50 — 71,50 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| 4,8×80 | 78,50 — 81,50 | 4,70 — 4,85 | 2,80 — 3,00 | — | 13,80 — 14,20 | 7,70 — 7,90 |

| For attachment to metal base | ||||||

| 5,5×19 | 18,00 — 20,00 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×25 | 24,00 — 26,00 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×32 | 30,75 — 33,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×38 | 36,75 — 39,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×51 | 49,75 — 52,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×64 | 62,75 — 65,25 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 5,5×76 | 74,50 — 77,50 | 5,28 — 5,46 | 4,55 — 4,70 | 5,30 | 13,80 — 14,20 | 7,78 — 8,00 |

| 6,3×19 | 18,00 — 20,00 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×25 | 24,00 — 26,00 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×32 | 30,75 — 33,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×38 | 36,75 — 39,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×50 | 48,75 — 51,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×60 | 58,75 — 61,25 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×80 | 78,50 — 81,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×100 | 98,50 — 101,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×130 | 128,50 — 131,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×150 | 148,50 — 151,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

| 6,3×175 | 173,50 — 176,50 | 6,03 — 6,25 | 5,40 — 5,55 | 6,50 | 15,80 — 16,20 | 9,78 — 10,00 |

For the sake of fairness, it should be noted that for twisting into metal, thicker than 1 mm., You need to purchase

high-quality fasteners. If you use self-tapping screws from an unnamed manufacturer, then there will be a high probability

breaking off heads when screwing into thick metal.

All roofing screws, in addition to the hex head, are sometimes produced with an additional slot. That's why

they can be twisted with a cross bit, about the bit number is not information. However, the most convenient installation will still be

using a hex head for a drill driver.

Length and diameter of roofing screws of different types

| Type of roofing screw | Roofing screw diameter, mm | Length of the roofing screw, mm |

|---|---|---|

| Pointed | 4.8 and 5.5 | 25, 38, 50, 65, 80 . |

| With short screw | 5.5 and 6.3 | 19, 25, 32, 38, 51, 64, 76, 102, 127 mm For 6.3 mm there are also 70, 80, 90, 102, 130, 150 and 170 mm |

| With long screw | 5.5 and 6.3 | 25, 32, 38, 51 mm |

Roofing screws are made of galvanized steel. And it is better if the galvanizing is galvanized. This coating is more durable. Sometimes paint is also applied over the galvanized steel. Color - to match the coated. Washers are made either also galvanized or made of aluminum alloy. The washer was said to have a rubber or silicone seal. Rubber is better than EPDM, it does not lose elasticity for a long time in the open air. The running dimensions of the roofing screws are shown in the table.

How to choose wood screws

It is not worth using self-tapping screws for metal or universal screws for fixing wood. Universal ones are good when you need to twist wood and metal. And when twisting two pieces of wood, they work worse. In the sense that specialized fasteners will hold the wood better. That is, we consider only wood screws. Believe me, there will be plenty to choose from.

Wood screws are better than yellow (yes, expensive) or white (a little cheaper)

As already said, wood screws have a rarer thread with a higher profile (the grooves between the turns are deeper). They are used not only for wood, but also for all types of sheet materials: gypsum fiber board, plywood, OSB (OSB), fiberboard and chipboard. Now about which ones work better.

Thread and other "bells and whistles"

First you need to choose the type of hat. Secret or with a press washer, cylindrical, hemispherical - select based on what kind of connection you need to make. It is also recommended to choose a spline of the TORX type, since it best transfers the torque from the power tool. Further in order.

- It is necessary to determine whether the thread should be applied to the entire rod or not. If you need to fasten two pieces of wood and pull them tightly together, take a self-tapping screw with an incomplete thread. This means that there must be an unthreaded area under the head. The length is equal to the thickness of the attached part or slightly more.Due to this zone, one part is "attracted" to another.

How to choose self-tapping screws for wood: a few chips for quick and high-quality work - To make it easier to screw into hard rock or sheet material, there are wood screws with a router or mill. The cutter is available only on self-tapping screws with an incomplete thread. It looks like a few screw-type notches, which are applied before the start of the thread. The notches soften the wood, after which the self-tapping screw "goes" better.

- In general, wood screws have a thinner point and thus prevent wood cracking. But there are also special "lotions" against cracking. It can be:

- grooves;

- cutting edges in the form of notches on the screw body;

- notches on several lower threads.

Are these bells and whistles necessary or is it wasted money? Incomplete threads are nothing new. One detail "sits" on top of another much more densely. And try the rest. Only from your own experience you will understand whether it works or not, and what exactly suits you best.

And practical advice on choosing wood screws

It is important that the thread runs straight from the tip itself. If the first turn is too far or the tip is blunt, do not take

There will be continuous torment, not work.

Classification

Self-tapping screws are classified into separate groups depending on different criteria - type of head and coating, type of tip, material.

By head type

Types of fasteners:

Self-tapping screws for metal with a press washer. Designed for joining metal sheets up to 1 cm thick. Thanks to the large head, the parts are securely fixed.

Hemispherical. Large fasteners that are designed to fix various metal workpieces.

Cruciform. They are considered the most reliable and versatile. For tightening, you can use standard Phillips bits for a screwdriver. They fit tightly into the material without breaking its structure.

Self-tapping screws with a straight slot. Such fasteners are more often used to connect wooden parts.

Hex head. Screwed into different materials. To tighten, you need a special wrench or screwdriver bit.

Countersunk head. To tighten the self-tapping screw, you must first drill a hole with a smaller diameter.

It is important that the cap fits snugly against the material, does not protrude outward.

Reduced countersunk bonnet. Small diameter head

It is easy to hide it in the material to be joined.

Self-tapping screws with a press washer (Photo: Instagram / anna_schelepneva)

By tip type

Depending on the type of tip, there are several types of fasteners:

- Self-tapping screws for metal with a drill. The tip of such fasteners is a drill consisting of two feathers. Suitable for fastening metal sheets up to 2 mm thick.

- Fasteners with a sharp tip. There is a thread on the rod for easy screwing. Suitable for fastening metal sheets up to 0.9 mm thick.

By type of coverage

Types of self-tapping screws:

- Phosphated - black hardware. Manufactured from carbon steel. They undergo additional processing with phosphates. Suitable for fastening parts in high humidity conditions.

- Oxidized - made of carbon steel, black. A protective film is applied to metal surfaces.

- Galvanized - carbon steel is used for manufacturing. The surfaces are coated with a zinc layer. They are used for the installation of metal parts outside, indoors.

- Galvanized yellow - products similar to standard galvanized fasteners, but different in appearance.

- Uncoated - suitable for indoor work at normal humidity levels.

Self-tapping screws of different types (Photo: Instagram / stroi_s_nami82)

By material

Material:

- Carbon steel is an alloy based on carbon and iron, which is not supplemented by foreign impurities. They are distinguished by a high strength indicator.

- Brass is an alloy based on copper and zinc.To change the technical characteristics, manganese, lead, nickel, tin, iron can be added. Brass fasteners stand out for their high wear resistance and reliability. The material is immune to prolonged exposure to moisture, temperature changes.

- Stainless steel is a material that contains about 10.5% chromium. The stainless steel has an increased strength index. The material is resistant to rust formation.