Scope of application

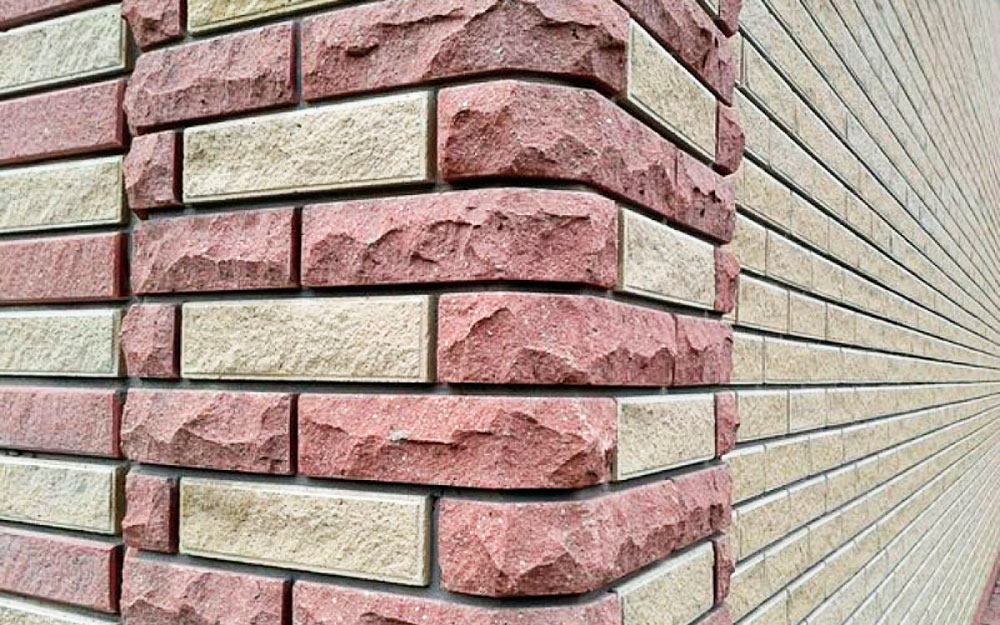

Torn bricks are used for both external and internal cladding. With a wide variety of types, it is difficult to imagine wherever he found his application. Let's try to summarize the already compiled idea of its comprehensive use:

- most often, torn bricks are used in facing facades to give a building a beautiful expressive look;

- the walls of houses do not have to be completely assembled with a stone; they can be partially decorated, creating a figured frame for the basement or foundation;

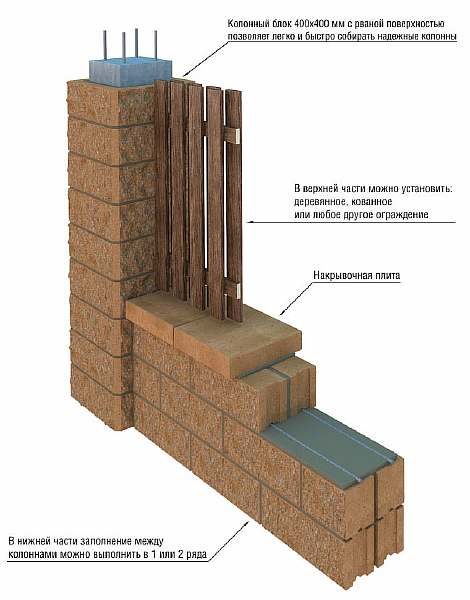

- the industry produces certain types of bricks for decorating pillars, porches, arches;

- door and window openings decorated with torn stone look perfect;

- brick is used in landscape design to decorate benches, flower beds, gazebos, patios, barbecue areas;

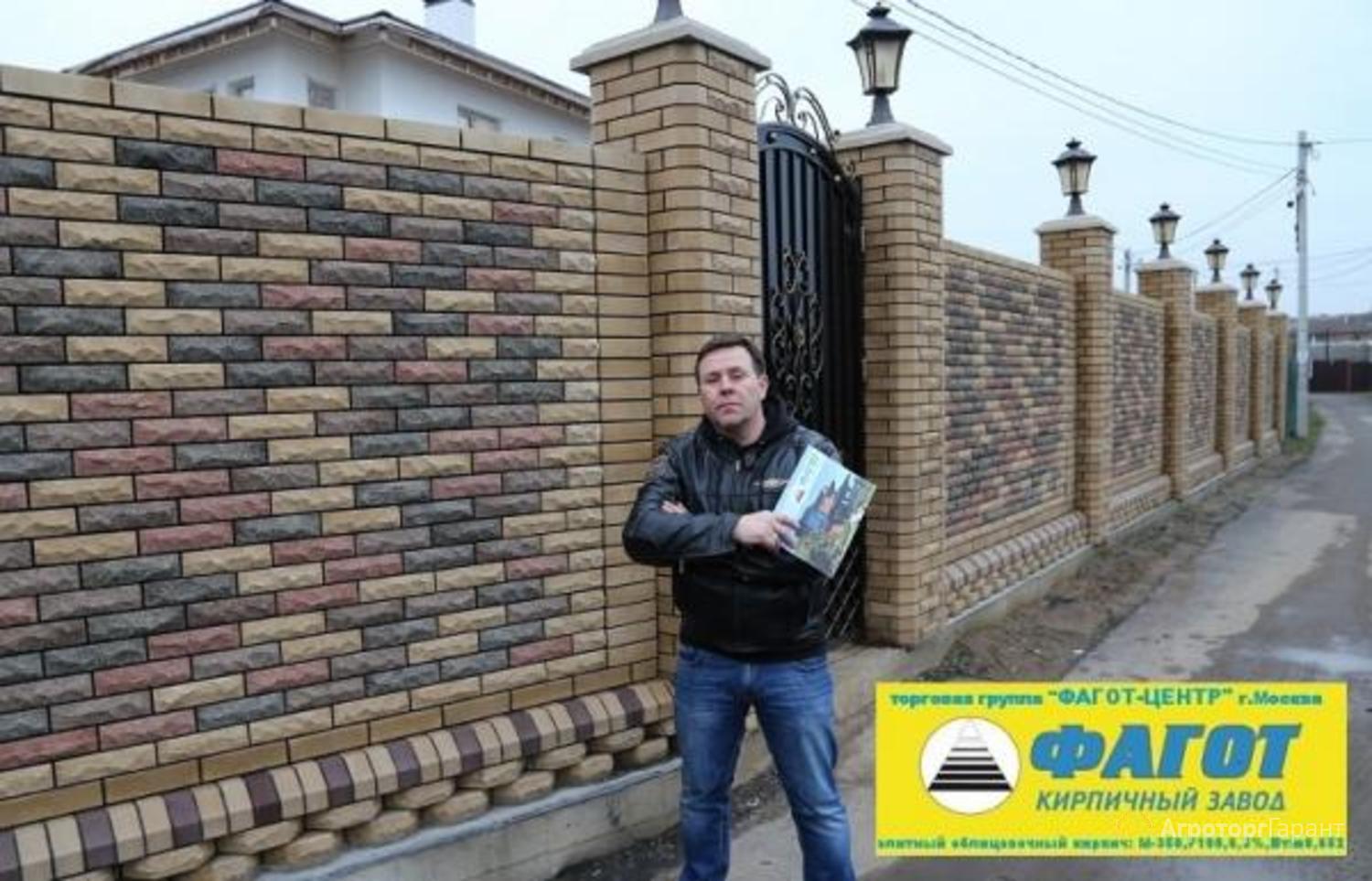

- it is often used in the design of fences, giving them an expensive, presentable look;

- inside the room they decorate one wall or a fragment of it, decorate fireplaces, columns, and install interior partitions from solid bricks.

What types of raw materials are better to use

Since the material will be used exclusively for outdoor work, it is necessary to make the right choice in favor of a brick that is resistant to external influences. Let's take a closer look at the suitable types, their advantages and disadvantages.

Red

Consists of ordinary clay. It is fired at temperatures up to 800C. Depending on the purpose, there is a private and a front one. By filling - hollow or corpulent.

Benefits:

- high strength;

- frost resistance;

- dense.

There are no significant drawbacks.

Clinker

The production technology is similar to red, but the firing temperature is many times higher. Due to this, the clay is better sintered, acquiring greater strength.

Among the pluses:

- resistance to high humidity;

- does not lose its properties with sudden temperature changes;

- durable.

The main disadvantage is the high price.

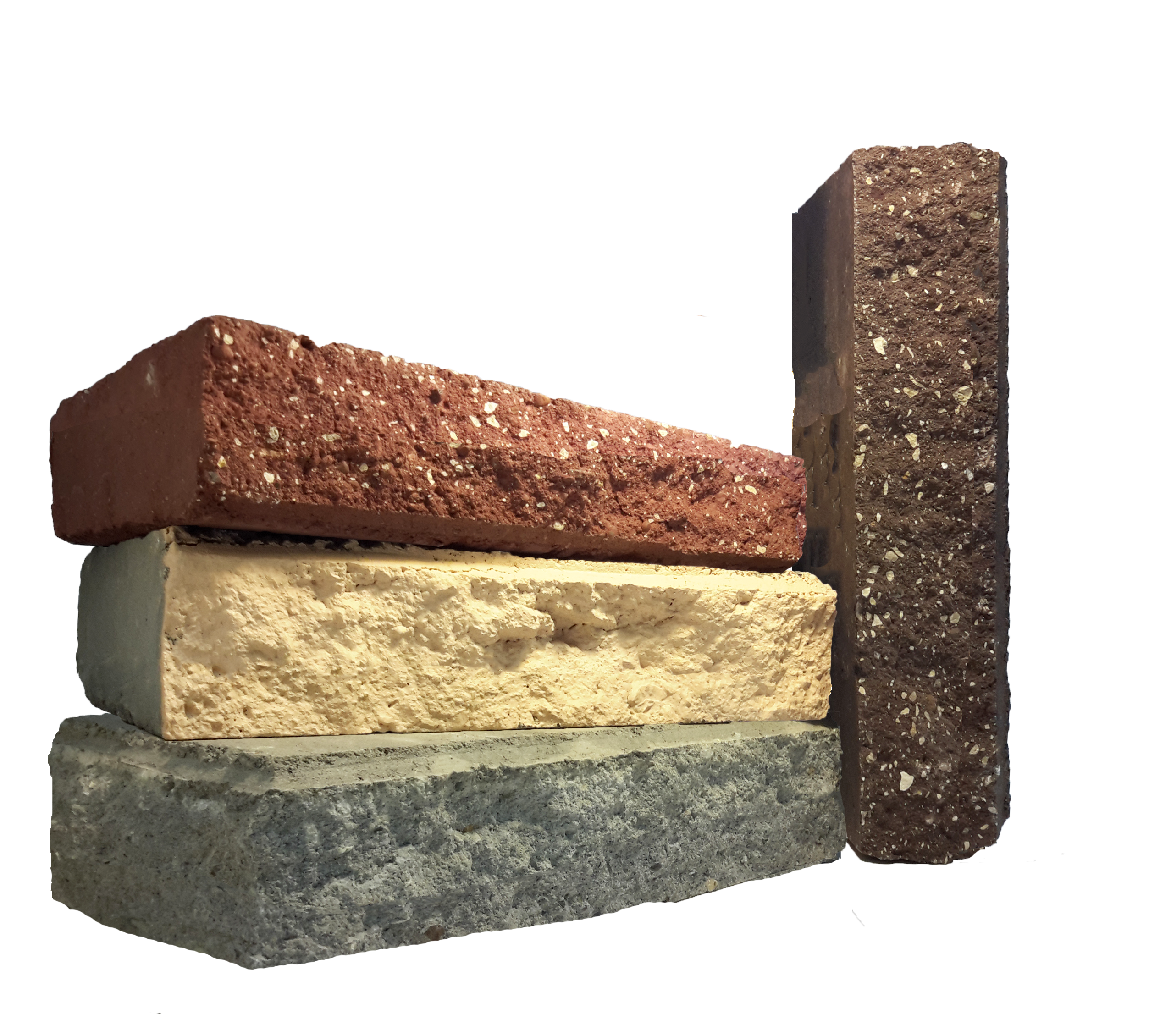

Silicate (white, yellow)

It will be the cheapest in terms of costs. It is made by autoclaving from a mixture of sand and lime. Facial is available in three types:

- single;

- one and a half;

- double.

The latter is only hollow, the first 2 are hollow, full-bodied.

Silicate of a non-standard shape with rounded corners, curved lines, and a relief surface is popular.

A yellow brick fence looks good if you make the decor in contrasting tones of the material.

It is worth highlighting the type of torn or chipped stone, when there are many chips and cracks on an uneven surface.

Among the advantages are availability and low price. The cheapest in this category are white, gray silicate.

Disadvantages:

- low moisture resistance;

- subject to temperature extremes;

- in terms of strength, it is several times inferior to other types.

Facing

This name was given due to the fact that it is used for finishing the outer parts of buildings, basements, walls, fences. The assortment of forms is great. Brick imitating other materials is in demand.

The most popular colors are yellow and its combination with brown. They are chosen for facing facades, building fences.

Apart from the standard benefits, this type of brick does not need to be plastered or painted. The material is initially completely aesthetic and ready for use.

Except for the high cost, no significant deficiencies were found.

Hyperpressed

Such raw materials for masonry are obtained from lime and cement. It has a high density. It will come out of it to build an expensive, but original and reliable fence.

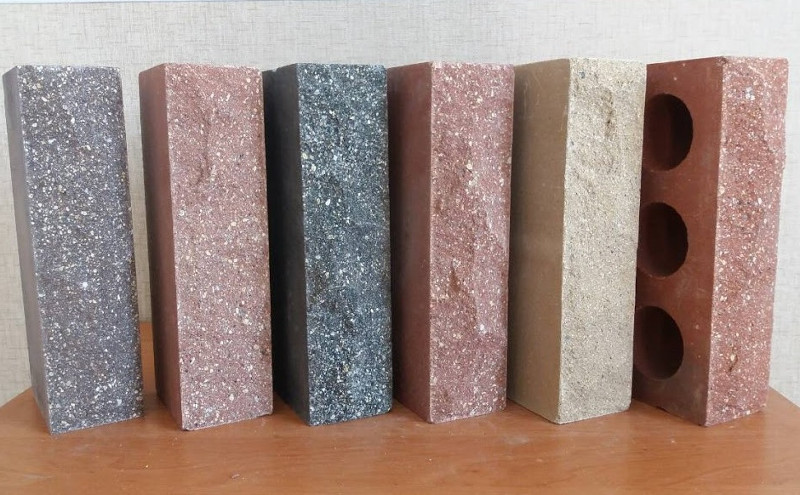

Color spectrum:

- black;

- green;

- mocha;

- chocolate;

- Gray.

If you have to chop a brick, then the texture of the natural stone will be visible on its cut.

The advantages and disadvantages of this material are identical to the previous type.

Thematic material:

- Fence made of brick and profiled sheet

- Installation of a fence with brick pillars

Views

Torn brick is classified not only by its appearance, it is divided by its structure, shape, color, location of the textured cut. For the manufacture of the product, manual and mechanical molding is used. The use of modifiers and plasticizers makes it possible to obtain additional properties, such as resistance to many climatic factors or aggressive environment.

Structure

The facing material is solid and hollow, has a different weight and area of application.

The first type is more durable and heavier. It is used where a high bearing load is expected: for facing the foundation and basement, for a solid concrete fence, for laying a fireplace.

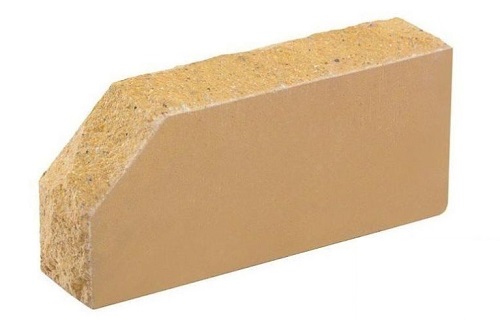

The form

The standard rectangular shape is used for cladding flat surfaces. But there are also columns, arches, stairs, parapets, cornices, doorways, where a stone is required, beveled at an angle, wedge-shaped, twisted or with smooth ends. All this variety makes it possible to make the most of torn brick in facing work.

Textured cut

Cuts on the bonded edges of bricks have proven themselves well in facing openings and corners of buildings. Beveled spoon edges are used for the main design. Corner cuts (45 degrees) are located simultaneously on both adjacent sides, such a product is used for facing columns, window sills, doorways.

Colour

Color plays a big role in imitating natural material. With its help, one can immediately guess what the conditional stone is - sandstone, limestone or granite. The added pigment not only colors the product in the usual brown, gray, brick, white or yellow tones, but can also make it completely unexpected - purple, khaki or fresh greens.

Types of bricks according to manufacturing technology

Fence bricks are divided into types, each of which has its own unique characteristics. Some of the classification criteria are:

The stiffness of the material. The leading item that determines the destructibility and fragility of a brick during physical contact. A dense product will be more difficult to damage, while pieces of a porous specimen will easily break off.

Weather resistant. The masonry expands in the heat and shrinks in the cold, as does every material. Therefore, they choose a product that will not damage the structure in the summer and will not start to crumble in cold weather. A suitable brick stone is checked for the number of cycles during which it does not lose its properties.

Moisture absorption. Brick has pores in its structure

Thanks to them, the blocks transfer heat worse, which is especially important for residential buildings. In addition, the more internal voids, the more water will be absorbed by the material.

Consider specific types of products.

Ceramic

Ceramic bricks are made from red clay. Accordingly, the finished product has a reddish brown color. One of the most common types of such a product due to its low cost. Ceramic bricks go well with other fence materials. It differs in two manufacturing methods: semi-dry pressing of clay or flexible molding.

Physical characteristics of the ceramic frame:

- High material rigidity.

- Moisture absorption - 7% of the total mass.

- 45-50 cycles of frost resistance.

Advantages and disadvantages:

- An inexpensive type of brick.

- Strong, but rather fragile due to the peculiarity of clay.

- Dimension - the finished brick is heavy.

- Rough or raw decorative look.

I like1Dislike

Clinker

Graceful look of masonry.It differs in many textures and colors, which is great for fence and cladding. Of course, you will have to pay an additional amount for a presentable environment.

- Dense material - up to 500 kg per square centimeter.

- Water absorption is the same 7% of the mass.

Controversial material for construction. Here are some of the pros and cons of clinker products:

- Reliable brick. A very dense structure will prevent the fence from falling apart for a long time.

- Many shapes and colors. Such a product is combined with modern and classic materials. The fence will look elegant and expensive.

- Material cost. Due to its appearance, the clinker block is more expensive than similar products.

- Complexity of installation and transportation. For proper laying, a special expensive solution is used. In addition, you will have to spend a lot of time on transportation - the material is heavy, it is easy to damage it.

I like1Dislike1

Silicate

Brick with perfected production technology. Crafted from quartz, limestone or minerals, supplied with no visible holes. Most often used for interior construction, but also used in the construction of fences.

Specifications:

- Frost resistance up to 65 cycles.

- Average material strength between ceramic and clinker versions.

- High coefficient of moisture absorption.

The material cuts sounds and noises well from the outside world. Well suited for load-bearing walls. At the same time, the accumulation of moisture in open areas will lead to rapid deterioration of the fence made of silicate blocks.

I like it I do not like it1

Hyperpressed

This type of building material is made from cement chips, lime, marble and color fillers. All components are tightly bound under the pressure of a special industrial press. The creation technology implies a variety of colors, sizes, structure and purpose of the product. The product is suitable as a facing material for fence posts.

It differs from similar products by a long period of resistance to frost and temperature extremes - 60-70 cycles.

The negative properties of the hyper-pressed version include the high cost and weight of the brick for the fence.

I like it I do not like it1

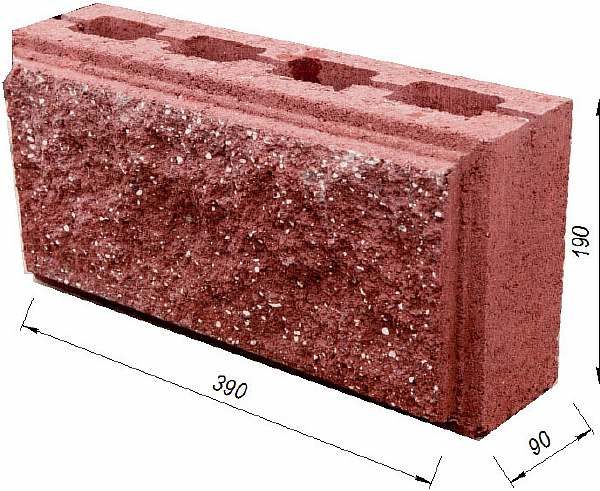

Corpulent or hollow

The general differences between brick blocks include their internal structure. Choose from two large subspecies:

- Holistic structure. This product has a microporous structure. This is more suitable for creating structural walls of a building or fence purlins. Solid brick holds the load and deforms worse.

- Hollow blocks. Most often used as a facing material. They look good and still keep you warm. Of these, it is recommended to make facing for metal piles of the future fence. Also, due to the saving of resources on the cavities, they are slightly cheaper than the second type of brick.

I like1Dislike

Assessment of bricks by site visitors

Ceramic

1

Corpulent or hollow

1

Clinker

Silicate

-1

Hyperpressed

-1

Recommendations for choosing the optimal fence thickness

It all depends on what functions are assigned to the design.

If you want to lay out the fence solely for the purpose of decorating the territory, then half a brick is enough thickness. That is, the material is placed with its long side along the perimeter.

When a fence needs to be built to protect the site from the street and separate it from neighbors, the thickness of the material should be 1-2 bricks. In this case, the long side of the raw material is placed across the fence.

To calculate the required volume of bricks, you will need to know the total area, height, and thickness of the fence.

So, for 1 m2 of fence with 1 brick masonry, you will need about 100 pcs., For 2 brick masonry - 200 pcs.

The height ranges from 0.5 m to 3.5 m. When calculating it, you should take into account the requirements of the current legislation.

Users often search for:

- At what distance from the house can you build a fence

- Caps on the posts of a brick fence

Positive and negative characteristics

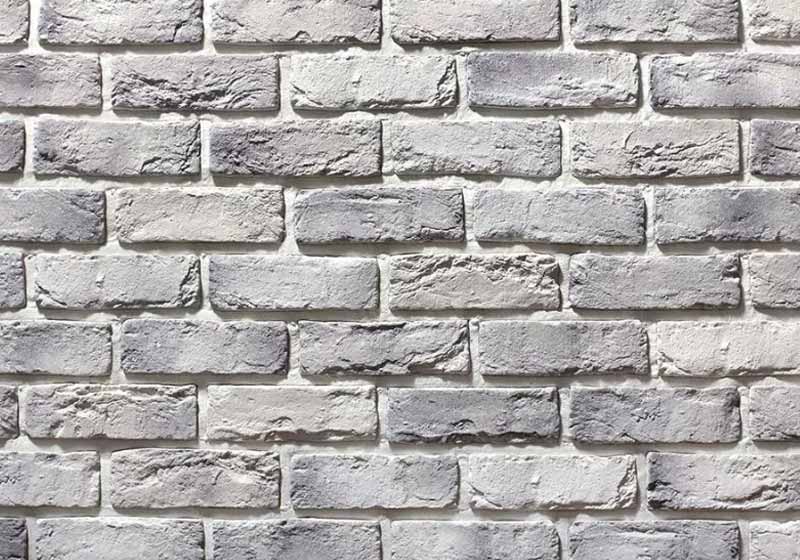

Torn bricks are widely used in interior and exterior design of construction projects. It is often preferred to other facing materials, because it has almost no drawbacks, but it has an impressive list of positive properties:

- has a wonderful appearance;

- thanks to enhanced pressing, it acquires super-strong qualities, especially for solid stone;

- durable;

- the brick is resistant to temperature extremes, fading in the sun, mechanical stress;

- environmentally friendly;

- does not allow moisture to pass through;

- fire resistant;

- It does not require special care;

- easily laid out;

- hollow forms help to keep the building warm;

- imitation of natural stone outperforms the original;

- a wide variety of types makes the work of designers easier.

Pros of brick

Before pouring the foundation under a brick fence, you need to understand if it has any advantages! Or it may be worthwhile to wait and weigh your decision more carefully. But if a person has already decided on the construction of this particular structure, then he will certainly not fail with his choice.

A brick fence has a number of important advantages that distinguish it favorably from other analogues. These include:

Reliability. A fence made of such material will serve as an excellent protection from "accidental" guests and the glances of curious neighbors.

Long service life (at least 10 years). With proper use, such a fence will stand for a long time and will serve not only those who built it, but also their children.

Attractive look. A fence can be built not only for the sake of protection, but also for the sake of decorating the square, because a large number of different ideas can be embodied on it. For example, add small arched arcs or weighty columns to the structure.

If we consider a brick fence as an investment, then this is the most reasonable move that a person can perform.

Fencing technology

Laying a ragged stone fence is almost the same as building a brick fence. But, as in every construction process, there are nuances that only experienced craftsmen know. Therefore, if you strictly follow the construction technology, then all work can be done accurately and a beautiful fence can be built that will meet all the requirements and can stand for more than a dozen years.

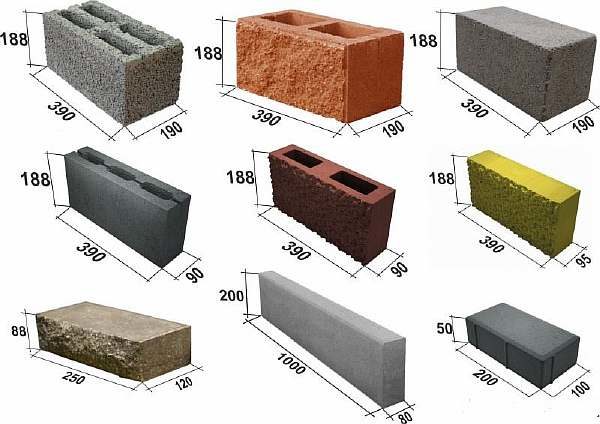

Standard sizes

The torn brick fence is quite heavy. It requires a solid foundation that can withstand significant loads. Therefore, it is not recommended to build a fence made of concrete blocks on sandy soil. In this case, for the construction of the fence, a foundation with a depth of 60–80 cm is required, which leads to a significant increase in the cost of the structure.

Fence in the city

Preparation for the construction of a fence has the following stages:

- Purchase of material and preparation of the required tool.

- Marking the perimeter of the territory.

- Pouring the foundation.

- Installation of supports.

- Block masonry.

- Fence decoration.

Below is a photo of a stone fence.

Stone and blocks

The marking of the local area: step by step instructions

The marking of the territory for the construction of a fence made of torn stone blocks is carried out using pegs and a rope.

All angles should be carefully measured at 90 degrees. If the angle turned out to be more or less than the desired indicator, the territory should be re-marked. At the same stage, the place of installation of the wicket, gates and intermediate supports is marked. The distance between the supports is best done at least 2 m.

Construction installation diagram

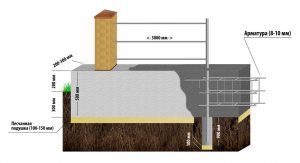

Pouring the foundation

Before building a decorative stone fence, a strip foundation is required. The depth of pouring on ordinary soil is 35–45 cm. The width is selected taking into account the parameters of the fence: height, type and dimensions of decorative bricks, method of laying.

The base is poured in one go.Otherwise, the foundation will have insufficient strength.

Drawing for the installation of pillars

First, you need to make a wooden formwork in the trench. As a rule, plywood with a thickness of 1.8–2.1 cm is used. After that, a sand cushion is covered with a layer of 20–25 cm. To improve the strength characteristics, reinforcement is performed using a reinforcing mesh before pouring. The cross-section of the bars should be 1.5–1.8 cm.

The concrete solution is poured gradually. The hardening time depends on the used cement grade (not lower than M350), but not less than one week. The formwork is removed only after the concrete has fully hardened.

Fastening the supports

For better stability of the fence, anchoring of load-bearing posts is required. It is advisable to choose section shaped pipes 60x60x3, fixed with glasses at the base.

Support assembly

The support post must not be hollow. Between the profile pipe and blocks of decorative bricks, it is necessary to pour concrete, having previously covered the space with small stones.

Laying method

First row bricks are first laid without mortar. This will determine the size of the seam. Subsequently, frost-resistant glue or cement composition is used. It is necessary to lay fresh mortar

If cement gets on the outside of the block, carefully remove it until it hardens. Otherwise, it will be much more difficult to do it later.

Handrail assembly sketch

It is important to control the level of each row during bricklaying. In order for the block wall to be even, it is necessary to apply the same amount of mortar and properly level it

After finishing the masonry, you need to treat the joints with a protective agent. Moreover, it can have different colors.

To make the brickwork look massive, the mortar between the blocks must be deepened. It is impossible for water to get on the decorative stone fixed with cement. For protection, you must cover the fence with polyethylene.

Dimensions (edit)

Decorating

Ragged brick for a fence is produced in color or monochromatic, as well as of various textures. So you can create various artistic compositions using all sorts of options. When combining solid bricks with halves, you can make an elegant composition. As an additional decor, you can organize a hedge near the fence.

A good way to decorate can be seen in the photo below.

In the town

What is it?

Facing brick is called torn because one of its sides is deliberately destroyed, giving the appearance of a natural material. A wide variety of structures, shapes, sizes and shades helps it to be in demand for a variety of tasks.

A feature of torn bricks is its high weight and density (150-250 kg per square meter). A building with such a facing requires a solid foundation, and if the reconstruction of an old building is to be done, it is necessary to first strengthen its foundation. To make it easier for builders, they came up with a hollow brick, which is much lighter in weight than solid brick and can be used in interior design.

Construction stages

Design

To begin with, it is important to determine the size of the fence and use pegs and rope to circle the perimeter. The amount of material is calculated, a drawing of the future structure is drawn up, its shape, color scheme, the presence of other elements, for example, forging, metal profiles are determined

Everything you need is purchased with a small margin. If it is impossible to build a fence on your own, a team of builders is invited, with whom prices and other important points are agreed.

Laying the foundation

A correctly laid foundation for the fence provides the structure with strength and integrity, therefore, it is important to take responsibility for pouring the base. Often, 2 types of foundations are built under a brick fence:

- Tape. Standard tape width 40 cm, depth up to 0.5 m.For reliability, reinforcement with iron rods is carried out, after which everything is poured with concrete.

- Grillage. When installing brick racks, a foundation is formed to a depth of 1.2-1.5 m, and a strip base is poured between the supports using the standard method. This type of foundation is strong and durable, but it is more costly and time consuming.

Bricklaying

The construction of the fence begins with the construction of pillars. A brick block is laid around the iron pipes concreted into the foundation, the masonry method is one and a half bricks. The seams in each row are tied up, and the voids formed inside the posts are filled with construction waste and broken bricks.

When all the supports are built, the construction of the partition walls begins. If the height of the structure is up to 2 m, a single-row laying is carried out, when the height is greater, a two-row method is used. After the erection of each row, the evenness of the wall is controlled with the help of a level and a plumb line. If facing bricks, for example, clinker or chipped, are used to build the fence, additional decorative finishing is not required. When using a conventional, building brick block, facing work is carried out.

Decorating

As a decoration, to give the fence an individual appearance, it is recommended to use a seamless facing brick, each subsequent block of which is connected to the previous special side lock. The product is made by vibrocompression, natural materials are used as components. Such a brick with side locks is easy to lay out on your own, according to its characteristics, the product is similar to lithos and bassoon, which are often used to build fence structures.

Varieties of torn stone

Semi-dry pressing method during production

decorative brick has been known in Russia since 1989. This experience was very

successful, which in the future was reflected in a wide variety of

the method of bricks and blocks. They were distinguished by the relief of the surface, and their

the coating was composed of clay or glass glaze.

In the future, the technology for the production of torn

bricks began to develop, plasticizers began to be added to the composition at factories

and modifiers. Due to this, the resulting product had increased

properties and other characteristics necessary for production.

Decorative for pillar cladding

If you do not plan to create a full-fledged brick fence, but dream of cute block brick inserts, use the facing of the pillars. In this case, a pre-installed metal support with a foundation is lined with blocks. This significantly affects the perception of the fence and improves the decorative characteristics of the integral structure.

Consider the possible types of brick blocks and technologies for sheathing the metal pipes of your fence.

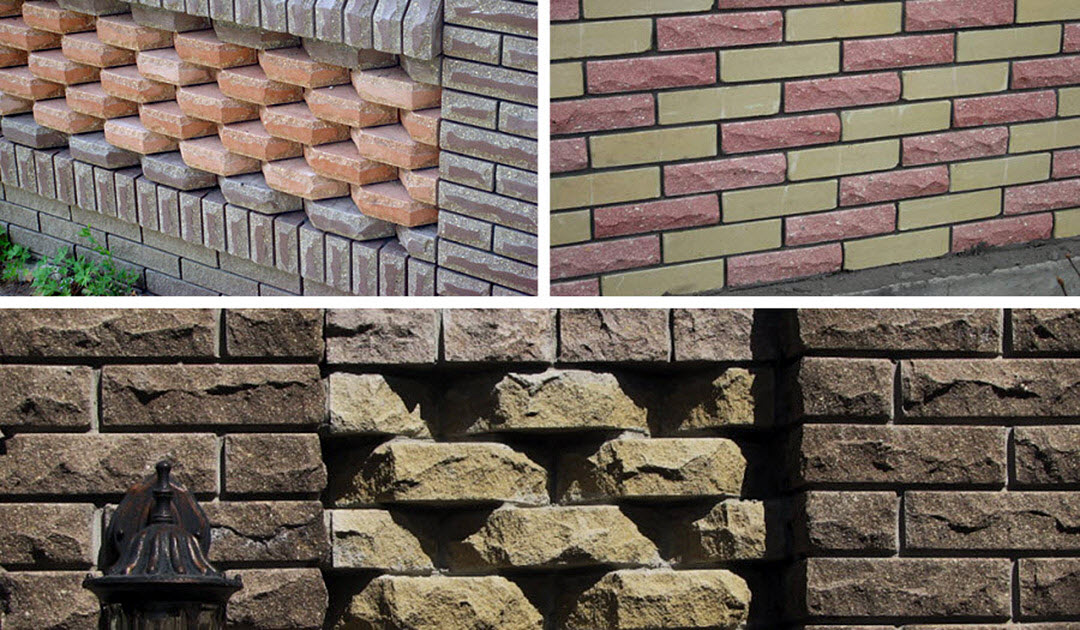

Rustic and chipped

An original method of decorating a pillar. This method requires silicate or hyper-pressed bricks. One of the sides of such a product breaks off to create a natural chipped relief. Then the rest of the blocks for the fence are cast along this relief.

Thus, they create a natural, uncouth appearance of the building. It looks brutal and aggressive, which goes well with the purpose of the fence.

Sometimes, to create a style, the masonry is additionally processed: parts of the block are chipped off to create a torn or chipped structure. Therefore, this method of decorating the cladding is called a torn fence brick.

Shotcrete

A simple and beautiful way to decorate. Clinker or ceramic blocks are sprayed with stone chips. After that, the wall is fired to fix the coating. So the appearance of the surface of the product becomes dull, as if rough, which ennobles the antediluvian ceramic product.

The disadvantages of variations with mineral chips include complex fence cleaning. Dirt adheres better to the uneven plane of the fence, and it is more difficult to clean it out.

Engobing

A special clay or ceramic solution is applied to the bricks. As a rule, it is a solid neutral color. Then the solution is fired or waiting for self-consolidation. This adds a worn look to the masonry and makes it look old.

In addition, a variety of patterns are applied to the not yet cured coating. This will make the post look like masonry.

Curly

Modern technologies make it possible to produce brick blocks of various images and shapes. Experimenting with these types of masonry, you will create a unique surroundings for the fence. With the help of such products, it is easy to build fences without corner intersections, round in shape, with different-sized waves and patterns.

It is not necessary to build a solid fence using such casual blocks. Pillars, partitions, arches - the construction of single elements also diversifies the design.

Moreover, there are products that are not only round or semicircular. Here are the possible shapes of such a brick:

- in the form of a trapezoid;

- diamond-shaped;

- drop figure;

- twisted, zigzags;

- in the form of a cap;

- sharp edges.

Facing works

The process of decorating surfaces with torn bricks is quite simple and consists of two stages.

- Preparation. First of all, the ability of the wall to withstand the powerful load of the cladding is calculated. If necessary, reinforce the foundation or the wall itself. Then a flat surface is created for subsequent work with the material: the cracks are closed, the plane is plastered. The finished wall should be treated with an antifungal agent.

- Directly facing. The adhesive is applied to the primed surface. It should be remembered about the impressive weight of the cladding and do not spare the solution, but at the same time it should not leave the seams, staining the decorative elements. Then everything is simple: a brick is applied, lightly tapped with a wooden mallet and the remnants of glue are immediately removed.

For how the craftsmen make torn bricks, see the next video.

Let’s block ads! (Why?)

Manufacturing

For the production of torn bricks, clay and sand are not used, as is done in traditional cases. Limestone, shell rock, brick and glass breakage, marble and granite chips, screenings of blast-furnace slag and expanded clay are used as raw materials. The filler is mixed with water (no more than 10%), cement, modifiers and dyes.

Torn bricks are made not by burning, but by the strongest pressing with the maximum reduction in the moisture content of the raw materials. Then the product goes through long-term drying. As a result, bricks are obtained that are close in strength to natural stone.

The product is brought to the usual "torn" look in two ways: simple and complex.

- A simple method cleaves the stone using a guillotine-like machine. Each brick collapses in different ways, thanks to which the finished masonry looks as natural as possible.

- The second method involves mechanized cleavage using sophisticated equipment. As a result, each brick has the same "ragged" surface. The attachments allow you to change the structural base that mimics the variety of natural stone.