Manufacturers

Manual whitewash sprayers have been around for a long time. Among the most popular models, it is worth highlighting the SO-20V, KRDP-5 devices (4). Almost all products have similar characteristics, and the main difference is the weight of the device and its cost.

For an overview of the SO-20V manual spray gun, see the following video.

The following domestic and foreign companies are manufacturers of hand-held spray guns: KSOM, Profmash, Auarita, Bosch, Einhell, Forte, Intertool, Miol.

Sprayers allow you to work with lime and chalk solution in rooms with ceiling heights up to 3.5 meters, without the need for additional devices, such as scaffolding or ladders.

The design of sprayers is quite simple, so malfunctions are rather the exception to the rule.

The spray gun nozzle must be made of hard-alloy raw materials, and the elements that will come into contact with aqueous solutions during operation must have a special protective coating that prevents the formation of corrosion.

Domestic products are manufactured taking into account all of the above nuances, and in the tools it is possible to adjust the extension for paint supply based on the height of the working surface, which facilitates processing.

It is interesting: The subtleties of finishing the ceiling made of plastic panels

How do I take care of my device?

In order for the device to serve for a long time without breakdowns and the need for repairs, certain rules must be followed. Before use, you must carefully read the instructions, information from which should be followed during operation. A mechanical spray gun cannot be dangerous to humans, but if used improperly, it will quickly break down.

Before each use of the device, a visual inspection must be carried out. After finishing work, the device must be thoroughly rinsed and dried. This ensures that the machine will last a long time. There are no parts that can quickly fail in the hand-held apparatus. But those simple mechanisms that are there must be carefully looked after.

Do not overload the device. You need to fill in exactly as much paint as indicated in the instructions. Moreover, if it is planned to use an acrylic mixture, then a lubricating additive is additionally added to it.

It should be borne in mind that when working with a mechanical device, a cloud with the smallest particles of paint is very often created.

They will definitely hit everything around, so you need to take precautions. First of all, the master needs to protect his body, and especially his eyes and mucous membranes.

But do not forget that small particles of paint will remain on all the objects around him. Therefore, all elements that should not be painted over must be removed or covered with something.

A manual spray gun (spray gun) is a convenient and economical device for fast and high-quality painting of walls and ceilings with water-based paint or water-lime composition. Even the simplest devices, including those that can be made from scrap materials with your own hands, make it possible to get good results. But before painting the walls, it is worth practicing a little on unnecessary surfaces in order to fill your hand, and further increase the efficiency of using the device.

Peculiarities

When the question arises about finishing work related to the ceiling in the room, there is a need for a convenient and effective tool that will help solve this problem.

When planning to perform work on whitewashing the ceiling or walls, you can use a roller or a brush, but surface treatment in this way will take a lot of time, and the process itself will be associated with discomfort and various difficulties.

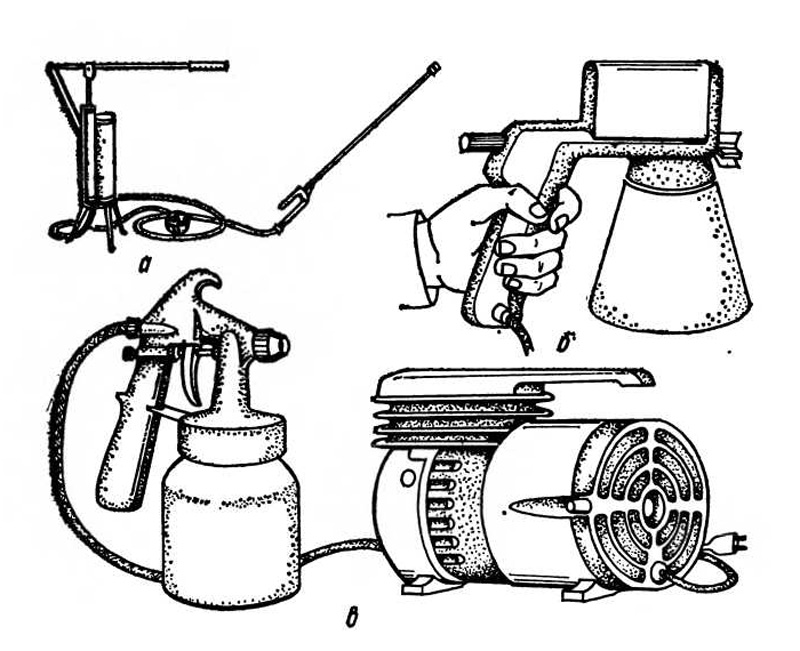

In order to optimize and facilitate such work, on the modern market there are special devices for painting surfaces. They are called spray guns, some call this product a spray gun, a spray gun, and so on. The spray gun is of manual, pneumatic and electric type.

The main feature of working with guns for painting is the level of safety that they provide to the master, because everyone knows that the lime solution is quite caustic, therefore, in contact with the skin of a person, it can cause a burn. When using a brush, such cases occur very often, and the use of a spray gun excludes the presence of such unpleasant situations during finishing work.

The use of a mechanical spray gun for whitewashing does not require a stepladder, since the special fishing rods available in the device will make it possible to paint over ceilings and corners between the ceiling and walls, while being on the floor.

Hand tools will save the time required for painting as they are powerful enough to tackle a large work area, working on a principle that allows you to paint substrates with minimal contamination and splashing.

The standard type of mechanical whitener is a small container into which a coloring compound, lime, chalk solution, or any other liquid substance is pumped.

The main component of the tool is attached to the reservoir - a handle that has a button that controls the course of spraying the composition, the angle of application and the intensity. In addition, the spray gun is equipped with a nozzle from which the solution exits to the base.

Today on sale you can find a large number of modifications of mechanical tools used for whitewashing, they differ in their design characteristics and cost.

For industrial purposes, hand sprayers are rarely used; their main area of application is operation in private houses and apartments.

Another model of hand-held spray guns is considered to be a piston tool; it is notable for its size and a slightly different principle of performing work.

In such a device, air injection is carried out by analogy with a conventional pump when inflating. The container contains several hoses, one of them is connected to the container in which the base treatment compound is located.

The second hose has a sprayer at the end, it is an elongated metal tube with a button and a nozzle.

The advantages of hand sprayers include the following tool qualities:

- simple configuration - the spray gun is very easy to disassemble, which allows, if necessary, to replace any part that has become unusable;

- ease of use - any master can regulate the supply of the composition, even a person with minimal work experience;

- hand-held spray guns are universal devices that are suitable not only for working with lime and chalk, but also for any other type of base colorant - the tool is recommended for use with any finely dispersed colorants;

- the products have a low cost, the most expensive device is considered to be a pneumatic spray gun;

- the applied composition lays down in an even layer;

- there is no need to use additional devices in order to process hard-to-reach areas of the base.

Precautions and preparation

When using a spray gun to paint ceilings, be sure to take care of safety.When spraying, the smallest particles of paint will end up in the air, after which they will settle not only on the floor and other surfaces, but also get into your eyes and lungs. Despite the fact that ceiling paints practically do not contain harmful substances, it is still dangerous to inhale, the same applies to the eyes.

It is clear that working in a respirator is not so convenient, however, this cannot be neglected. If you don't have a respirator, a regular cloth or gauze bandage will do. Also, stock up on glasses, then the paint will not get into your eyes. Before painting, the room must be freed of furniture, and everything that cannot be removed must be covered with foil. If you only repaint the ceiling, the walls are also covered with polyethylene, securing it with masking tape.

Now you need to prepare the paint. As a rule, the packaging always contains the manufacturer's instructions, which indicate the exact proportions. But it happens that there are no such instructions, then you will have to dilute the paint intuitively. The optimal thickness is determined by each artist separately, but the paint should not be too thick or too thin. It is best to spray a little thinned paint on some surface, but not on the ceiling! This way you will see how well the paint spreads and lays down, whether it still needs to be thinned, or already enough.

After diluting the paint, be sure to filter it, because the smallest particles of debris, dry paint or clots can clog the sprayer and leave ugly marks on the ceiling. This point is very important: without filtration, painting the ceiling with a spray gun can take a long time and cause a lot of problems.

Pneumatic device

Whitewashing of ceilings can be done with pneumatic models. Such devices are preferred by professional builders.

The pneumatic spray gun is mainly used for painting large areas. It differs from the manual model in the mechanism responsible for maintaining the required pressure in the tank.

For this purpose, there is a constant pressure compressor. This allows the jet to exit without interruption. The result is a flawlessly painted surface.

Such atomizers are not necessary if they are to be used rarely. Since they are more expensive than manual models and rare use will not justify such a purchase. The main advantage lies in their high performance.

The device works thanks to the air pressure generated by the compressor. Lime or other coloring solution is supplied through the nozzle of the sprayer under high pressure.

And since this pressure is present continuously, then the finely dispersed composition is applied to the surface with a sprayer easily and evenly.

If you follow all the rules for using this type of device, then in a short time you can see an ideal surface on which there is no:

- excess solution;

- smudges;

- divorces.

Manual spray guns

They are used with a small finish area for spraying whitewash and water-based paint. The performance of a hand-held spray gun is low - up to 250 m2 per hour. The working pressure is also small - up to 0.6 MPa, so the devices are not designed to work with viscous compounds - varnishes, putty. Hand-held spray guns can be used to apply liquid antiseptic or fire retardant, as well as to treat garden crops from pests.

The manual spray gun is shown in the illustration. The paint is supplied in it by means of a plunger pump located in a cylindrical body. The pump is controlled by a handle: the painter's assistant moves it up and down.

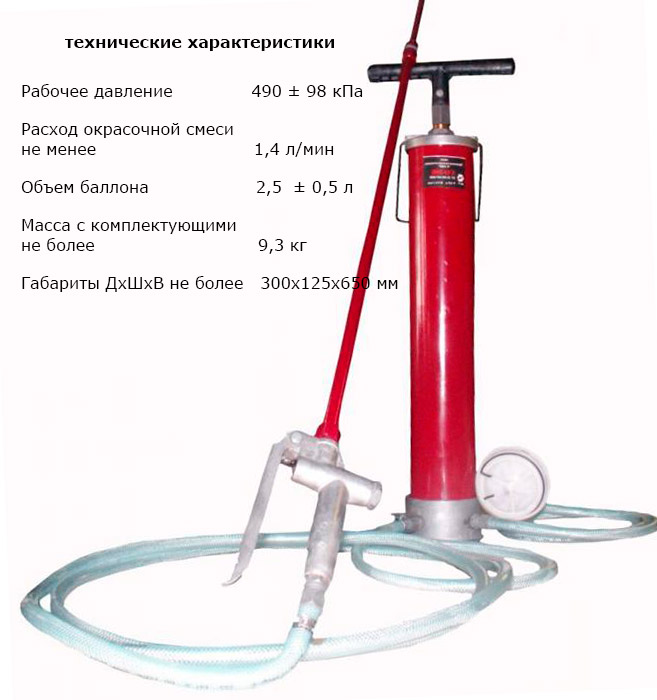

Manual spray gun KROS-1M

In the lower part of the body there is a reservoir for the dye mixture, two hoses are connected to it - suction and pressure.When the pump rod moves upward, a vacuum is created inside the reservoir, due to which paint is taken from the external container through the suction sleeve. To prevent the spray gun from clogging up with solid particles, the end of the hose is equipped with a filter. A suction valve is provided in the reservoir to prevent back movement of the paint.

When the rod moves downward, excess pressure is created inside the pump, and the paint from the reservoir is fed through the pressure hose into the fishing rod. There is a nozzle at the end of the rod, with which you can adjust the spray angle. At its other end, a shut-off valve is installed - a trigger. The rod consists of two parts, allowing you to change its length, which is convenient when painting the ceiling.

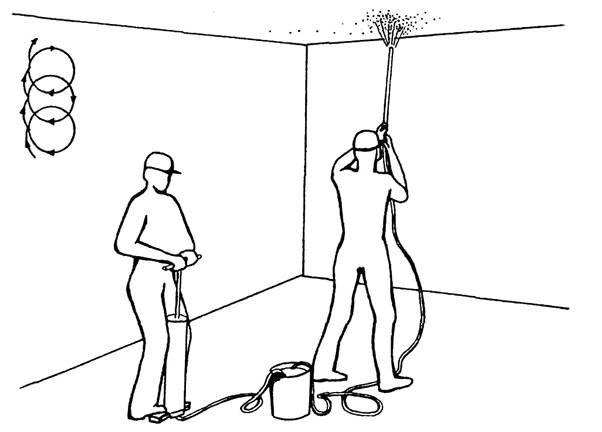

Scheme of work with a manual spray gun

Advantages of hand spray guns:

- low price;

- simple design, reliability;

- no need to connect to an electrical network or a compressor;

- the presence of a long fishing rod that allows you to paint the ceiling without a stepladder.

The disadvantages include the fact that the device:

- has low performance;

- require at least one assistant;

- not suitable for all types of paints and varnishes.

Technical characteristics of the manual spray gun SO-20V

Spray painting

It is better to whitewash from the ceiling, namely from its corner. Although the whitewash tool provides a fairly uniform layer the first time. Still, it is recommended to perform staining in two passes. The first layer should be more dense. After applying it, we give time to dry well. Then we proceed to applying the second, but lower density. The advantages of this staining method are:

- hiding all the flaws, both the ceiling surface itself and the layers of paint;

- longer service life.

If, with all the efforts, the whitewashing ended with the presence of some errors, then you should not be upset. After all, with manual whitewashing of flaws, it turns out much more and much more labor costs. All comes with experience. It is worth practicing several times and the result will not be long in coming.

If, when working with a spray gun, you follow the recommendations presented above, then even a beginner can get a high-quality result.

Prevention and maintenance of manual spray gun

The main rule of sprayer maintenance is timely paint removal.

IMPORTANT! Immediately after use, the pump, hoses, and most importantly - the nozzles must be thoroughly rinsed. Do not fill with water until tomorrow, namely rinse

After that, it is imperative to run the working cycle with clean water, checking the quality of the spray on the nozzles. If this is not done, thin holes will be clogged with particles of dried paint, which will be cemented and it will be difficult to remove it later.

Do not fill with water until tomorrow, but rinse. After that, it is imperative to run the working cycle with clean water, checking the quality of the spray on the nozzles. If this is not done, thin holes will be clogged with particles of dried paint, which will be cemented and it will be difficult to remove it later.

The entire system is then purged with air, dried and assembled into transport position according to the instructions. Store the suction and delivery hose in rings. It is not recommended to hang the hoses from a solid hook or nail, as a crack may occur at the kink.

Before the next use, it is necessary to inspect (for visual detection of breakdowns) and check the tightness of seals and valves. When a malfunction is identified, spare parts are replaced with new ones.

IMPORTANT! The spray gun should be checked long before the start of work so that an unexpected breakdown does not change your repair plans

How to choose a spray gun?

In any hardware store you can find a wide range of similar products. Spray guns differ primarily in the type of work.Mechanical devices will cost significantly less than electrical or pneumatic ones. Therefore, they are in great demand, although they are considered not very convenient.

Before buying a device, you first need to determine for yourself on what area it will be used. If we are talking about home repairs in a small apartment, you can safely purchase a manual apparatus. It will be both more profitable and more convenient.

Before buying a device, you first need to determine for yourself on what area it will be used. If we are talking about home repairs in a small apartment, you can safely purchase a manual apparatus. It will be both more profitable and more convenient.

Mechanical sprayers can also be slightly different. This primarily concerns the volume of the paint tank. If it is too large, it is inconvenient to hold, and if it is too small, you will have to constantly add paint. Therefore, it is worth stopping your choice on the middle option.

Containers for paint can be made from several types of material. Most often, manufacturers offer plastic and metal tanks. Both types serve for a long time, but plastic is lighter and cheaper, so such spray guns are more popular. The paint container can be located below or above the lever. This does not play a big role, and this factor does not at all affect the quality and convenience of work.

Much more important is the size of the nozzle. The best option is 1.5 cm

This will allow the gun to work with most paints. If you take a smaller size, then other than using a spray gun for water-based paint, there will be no more options.

Normal average spray guns will produce about 8 bar of working pressure. This will be enough to work on medium surfaces and to apply paint in a neat and thick layer. A pressure of more than 10 bar will produce a large torch that can quickly paint over large volumes, but in this case the paint is applied in a very thin layer.

If the spray gun is planned to be used for working with putty, it is worth purchasing an automatic version with a wide nozzle and high working pressure. Most often, pneumatic devices are taken for these purposes.

When buying a spray gun, you need to carefully examine it, attach it to your hand to make sure that it is really convenient for them to use and be sure to pay attention to the package bundle. It is desirable that the device weighs not too much

Otherwise, your hands will immediately get tired during work. Many devices come with additional attachments. They can be used for different types of paint, making the device more versatile. However, having too many extra extras would be a waste of money. Such devices will cost more than ordinary ones, so there is no point in overpaying for unnecessary parts.

Tips & Tricks

Before buying a hand-held spray gun, it is necessary to clearly identify the purpose for which the tool will be used. Having decided on this issue, it will be much easier to make the right choice, since the range of modern tools is quite large.

Mechanical sprayers are the most budgetary option for devices, pneumatic tools are expensive, electrical appliances are mid-range products.

The selection of the device is based on the following product characteristics:

- the volume of the solution tank;

- power;

- pressure.

Each parameter directly depends on the other - that is, a larger tank will have a higher performance. The optimal pressure is considered to be 5 bar. Products most often have a tank volume designed for two liters of composition.

The new solution should be pre-tested on any surface before proceeding with the processing of the bases in the apartment, so it will be possible to once again be convinced of the appropriate consistency of the composition. The liquid should be drained before work without fail.This will save time, since the sprayer will be much less clogged.

The effectiveness and uniformity of the treatment will depend on maintaining a uniform spray rate of the whitewash. At the end of the work, the remaining liquid can be usefully used as a treatment for trees in the yard.

Preparation for independent use of a whitewash sprayer includes the following points:

- the efficiency and correctness of the application of the composition will depend on the size of the nozzle orifice, so it is worth adjusting it, bringing it to the smallest size;

- to strain the solution, it is worth using a sieve, the cells of which will be no more than 5 mm, in addition, gauze is perfect for such tasks;

- In order to prolong the life of the hand-held whitewashing tool, regular maintenance of the device should be carried out.

In addition, after each use, the instrument must be thoroughly cleaned and a detailed inspection for possible defects must be carried out. For these purposes, a visual inspection of all structural elements is performed, after which the gaskets are checked, as well as the functioning of the device.

How to work with the tool

The whole process can be divided into two stages: preparation of the solution and equipment and the actual application of lime to the walls or ceiling.

Preparation

The preparatory work includes the following:

- Checking the serviceability of the tool. Even if the master keeps his spray bottle in order, it is worth additionally checking the operability of all nodes by filling the device with a small amount of water. After checking the serviceability, it is recommended to adjust the sizes of the nozzles, making them minimum. This is necessary for an economical and uniform application of the colorant.

- Filtering the solution. If this is not done, then the nozzle holes on the sprayer will quickly become clogged, and the operation of the tool will become poor-quality. You can strain the lime through a fine sieve or through a gauze folded in half.

Despite the fact that using the sprayer you can avoid scalding mortar burns, the jet blowing out of the nozzle not only paints the surface, but also forms a fine suspension in the air. Microscopic particles can accumulate on the skin, causing dryness and irritation of the skin, in the eyes or in the respiratory tract, and on furniture. Therefore, it is recommended to work with gloves, a respirator, covering all areas of the skin with clothes.

The floor and furniture must be covered with plastic wrap. After completing the preparatory phase, you can apply lime to the walls.

Lime application

Having prepared everything you need and pouring the prepared solution into the spray bottle, you should not immediately direct the stream to the ceiling or wall, it is better to try it on a piece of unnecessary cardboard: there may be air in the nozzle, and uneven "spits" will appear instead of a stream of paint. Compared to paints and varnishes, wet lime can be easily removed with a wet rag, but still professionals recommend adjusting the tool on an unnecessary piece of material. Having adjusted the device, you can start working, observing the following rules:

- When painting walls, hold the spray gun perpendicular to the surface, and when painting the ceiling, the angle should be 60-70 °. You cannot "shoot" a jet directly into the ceiling - the solution is liquid, and the jet will slightly smear the painted areas located on the periphery.

- You need to drive the tool smoothly, without stopping in one place.

- It is recommended to start painting from the corners, painting them with spiral or longitudinal-transverse movements.

- The first coat is applied as thinly as possible. It's not scary if the darkening material of the wall peeps through it a little in places - after the second layer is applied, everything will disappear and the surface will turn white like a sheet of paper.

Didn't work the first time, and the layer turned out with errors? Then it is worth remembering how many times you had to paint over the stains left by the brush. A little experience and everything will work out. The third layer will most likely provide a perfect work result.

If you use a spray gun to whitewash with lime, then even a novice master can get an excellent result.

Tool advantages

A manual spray gun is a fairly versatile device. They can not only paint relatively large surfaces. With the help of this simple device, vegetable and berry bushes, fruit trees are sprayed, glue and detergent solutions are applied, rooms are disinfected, and combustible surfaces are impregnated with fire retardants.

For whitewashing with lime it is generally an irreplaceable tool. When hand painting with a brush, it is necessary to carefully protect the rest of the surfaces, since slaked lime is a rather aggressive liquid. The spray gun nozzle applies the composition evenly and accurately. With correct adjustment, there are practically no streaks and parasitic painted surfaces.

This is done so that the whitewash does not smear over time and lasts longer.

The most suitable application of the hand pump is for ceiling painting. This type of painting is usually associated with all sorts of difficulties. To evenly apply paint, you need to quickly move around the room, and doing this with a stepladder is quite difficult. It is especially difficult to reach every corner if the ceiling is more than 3 meters high.

The pressure created by the pump gives a powerful torch of paint at the outlet of the sprayer, which evenly covers the horizontal surface of the ceiling from a distance of up to one and a half meters. How to use a hand-held spray gun correctly?

- Half of the success lies in the correct preparation of the dye solution;

The viscosity should exactly match the instructions for the selected nebulizer. It is better to stir the paint with a mixer (a drill with a nozzle is quite suitable). Before starting use, the solution can be filtered through a sieve or gauze. Despite the filter in the suction hose, there should be no solid particles or uneven fractions in the solution.

Before starting work, a technological pumping of the pump should be carried out to bring the valves into working condition (natural compaction technique);

It is necessary to pump approximately 500 ml of solution into the pump. Then remove the filter of the suction arm from the container, and make 10-20 idle working movements of the rod. In this case, the pump valves will undergo a self-regulation procedure. After that, the intake filter is again immersed in the solution, and by vigorous movements of the rod we bring the pressure in the system to the required value.

Then the spray pattern is adjusted;

To do this, it is necessary to simulate the conditions under which it is planned to paint. In the same room (subject to humidity and temperature), a test surface is placed, for example, from old wallpaper. A training paint coat is applied to it from a fixed distance. By adjusting the nozzle nozzle, working pressure and viscosity of the solution, the best option is selected.

To ensure the continuity of the paint application, it is preferable to work together;

In the video, the master shows how to whitewash the walls and ceiling with a spray gun

In this case, you do not have to interrupt the process and be distracted by the periodic pumping of working pressure.

Painting is done from the corners, then the spray gun is moved in a spiral so that each next layer overlaps the previous one;

The first layer is applied more densely, but without the formation of smudges. After final drying, a second, final layer is applied. It should be less "greasy" and is intended rather to correct the imperfections of the first layer.

The temperature in the room should be within 15-30 degrees above zero, the humidity should not be more than 50%;

The painter and his assistant must be protected from paint on exposed areas of the body, and if the paint contains synthetic solvents, a respirator must be used.

Pneumatic spray gun

The tool is much more expensive than the manual model, but also has a high performance. Ideal for whitewashing large square surfaces. Compliance with the recommendations and rules for applying lime with a pneumatic spray gun allows you to get perfectly whitewashed ceilings and walls in the shortest possible time, on which there are no stains and streaks.

The principle of operation of the apparatus is based on air injection by a compressor, through which a solution is supplied under a high constant pressure through a nozzle in the atomizer. The result of this is the ingress of a finely dispersed composition onto the processed plane. The layer lays down evenly and efficiently. No smudges and stains, no excess solution. Whitewashing with a tool is done quickly, efficiently and with minimal labor costs.