Where is it used?

Super Decor rubber paint has a huge range of applications. A wide variety of surfaces are processed with it, for example:

- All types of wooden materials: plywood, beams, lining, boards, chipboard, OSB and fiberboard. Wooden structures are exposed to moisture. Wood, due to the absorption of moisture vapors and their evaporation, can subsequently contribute to the formation of cracks in the paint layer, but the rubber material can take the form of a modified surface. And its breathability reduces the risk of mold.

- Ferrous and non-ferrous metals, aluminum alloys, galvanized surfaces, paint protects them from corrosion.

- Mineral bases: concrete, gas blocks, gypsum compositions, brickwork, stone surfaces, asphalt, ondulin and slate.

- Paper and mixed finishes: wallpaper of any composition, drywall.

- Products based on synthetic polymers: plastic, rubber, expanded polystyrene, foam, isolon and various films.

- Various types of putty and plaster.

- All kinds of paints.

Due to its properties, the new generation paint is capable of solving many problems in construction.

- If you decorate the roof of a building with it, you will get not only a beautiful appearance with rich color and a pleasant matte look, but also a durable coating. Defects that develop in the material over time can also be covered with a rubber compound to eliminate moisture penetration.

- The same property is useful when processing internal surfaces in swimming pools, bathrooms and other areas for washing.

- Another great advantage of Super Decor is that it is absolutely non-slippery. This is an excellent quality when covering tennis courts, jogging tracks, stadiums, playgrounds. Low susceptibility to wear will keep the paint layer intact for a long time.

- The long service life of the coating ensures the validity of its use for fences and facades of buildings, as well as various elements of the interior.

Application area

Rubber emulsions are universal and are used for all types of paintwork. The paint is well applied and lasts a long time on concrete, wallpaper, putty, brick, chipboard and fiberboard, wood, asbestos-cement, asphalt surfaces and on galvanized iron. The material can be applied to surfaces previously painted with all types of paints: alkyd, acrylic, latex and oil. The emulsion can be used to strip asphalt and running tracks, tennis courts, and can also be used to paint roofs, fences, gazebos, walls and floors. Due to its good plasticity, it perfectly smoothes small cracks and seams, hides irregularities and gives the surface an attractive appearance.

Surface preparation

First of all, all the usual preparatory work should be done:

- Clean the old surface from build-up, crumbling, dirt or old coating.

- Remove all attachments that interfere with work - lights, brackets, mounts, air conditioners and other structures. It will not be superfluous to remove platbands from window or doorways, gutters during the work.

- Inspect the surface and determine the way to seal possible flaws - for small cracks or potholes, putty is enough; in difficult cases, you will have to make a continuous leveling plaster layer from cement mortar.

- For porous surfaces, pre-treatment with a universal primer is required.

- If there are greasy stains, the surface must be degreased.

- Smooth surfaces should be matt with sandpaper.It is also recommended to rinse them with a baking soda solution, rinse with water and dry thoroughly.

- Wooden parts should be impregnated with an antiseptic, metal parts should be cleaned of rust.

Rubber paint consumption

The material is considered economical. Depending on what the base base is made of, the consumption is different. If galvanized steel or black iron is painted, then it will be required for 1 sq. m about 250 grams of paint. For concrete, plastered and brick surfaces - not less than 400 g / kV. m. To paint one square meter of a wooden structure, you will need about 350 grams of paint. When painting slate roofs, the consumption increases slightly - 450 g / m2.

For painting drywall, primed or previously painted walls or ceilings, the consumption of rubber paint is about 150 g / m2. and more.

Features and Benefits

A distinctive characteristic of rubber paints is the ability to form a durable and elastic coating on the surface to be painted, which has high flexibility and water resistance. The enamels are intended for painting complex substrates with low porosity and characterized by a smooth surface and poor absorbency. Hard-to-paint surfaces include laminate, plastic and metal. Previously, for their high-quality painting, it was required to apply special primers that increase the adhesion of the base with an enamel coating and the use of special paints and varnishes.

The demand and high consumer demand for Super Decor rubber paints are due to the following advantages of the material:

- The flexibility and elasticity of the formed film prevents cracking and flaking. When staining wooden surfaces, the wood becomes like plastic, and when wet, the paint layer stretches along with the wood. This ensures reliable protection of wooden surfaces from moisture penetration and prevents the appearance of mold and mildew. This property of rubber paint makes it possible to paint easily deformable surfaces without the risk of delamination and peeling of the decorative layer;

- High wear resistance and durability of the emulsion make it possible to use the material under any conditions. The paint tolerates direct exposure to ultraviolet rays and atmospheric precipitation, it is heat- and frost-resistant and has high waterproofing properties. The paint is not afraid of sudden temperature jumps and retains its properties in the range from -50 to 60 degrees;

- Anti-slip effect makes it possible to use the emulsion for painting floors and roofs;

- Noble appearance. The paint is compatible with any color scheme, which gives a wide scope for creativity and helps to realize the most daring design decisions;

- Environmental safety and hygiene of the emulsion allow it to be used in residential and public spaces without risk to human health. High moisture-repellent properties make it possible to regularly wash the surface without fear of damaging the decorative layer. Despite its high moisture resistance, the paint is good air permeability and allows the surface to breathe. Due to the absence of solvents in the composition, the enamel dries quickly and does not have a pungent odor;

- Excellent adhesion rates ensure excellent adhesion of the paint layer to metal, wood, plastic, slate and any other material. Throughout the entire service life, the paint does not flake, crack or bubble.

- The incombustibility of the material increases the fire safety of the painted room;

- One liter of rubber paint is enough to paint five square meters of surface in two layers.

The main types and firms of rubber paint for the facade

The material is produced in a completely ready-to-use form (the maximum that may be required is some dilution with water up to 5%). There is no need to tint the composition - all colors are made immediately at the manufacturing plant, the user only needs to choose the one he needs.

Flexible facade paint is available in packaging from 1 kg to 40 kg. The container is most suitable for work on site, considering the need for lifting to a height (of the scaffold) and constant stirring of the material, as required by the technology.

The most famous manufacturers of the material include:

- .

- Technoprok.

- SUPER DECOR.

- ProColor.

- NovBytKhim.

From foreign:

- Tikkurila.

- Alpina.

- Caparol.

The relative novelty of the material should be taken into account; as it spreads among consumers, the number of rubber paint manufacturers will also increase.

"Universal"

One of the most popular modern eco-friendly facade rubber paints in Russia is the Universal model from the St. Petersburg company Mitsar. This manufacturer was the first in our country to produce materials of this type. Many companies are now making rubber paint cheaper by adding inexpensive styrene-acrylic latex.

As a result, with periodic contact with water or under the influence of solar ultraviolet radiation, the coating loses its protection from deformation over time. The paint becomes brittle, cracked and peeled less than one month after application. But on the other hand, such paints are cheaper. On the contrary, "Universal" by Mitsar has increased moisture and water resistance properties and can be used in swimming pools and artificial reservoirs.

Despite the name "facade", this coating, due to its properties such as odorlessness and the possibility of applying to many types of surfaces, is successfully used for interior decoration. From the surface painted by Mitsar-Universal it is easy to wash off grease and other contaminants from the walls or ceiling, to eliminate traces of “childish pranks” such as watercolor paint and felt-tip pens. Up to 150 grams of Universal rubber paint from Mitsar is used to paint one square meter of surface. That is 3-4 times less in comparison with analogs at a similar price.

For example, the same Super Decor Rubber. That is, painting the same area with paint from another manufacturer will cost almost four times more. With comparable or even better characteristics, the products of the Russian company Mitsar always have a lower price. Due to more compact and less resource-intensive production. That is why Mitsara paints and varnishes are actively supplied to enterprises within the framework of the State Defense Order. That is, for application to defense products. What does it mean? Paints, enamels and other materials used in such industries must not only meet the strict requirements of the customer, but also - which is obligatory - cost less than offers from other manufacturers.

Useful Tips

In the process of working with Super Decor rubber emulsion, it is advisable to follow some recommendations:

In the process of choosing a material, the purpose of the emulsion should be taken into account. Many manufacturers produce products with a narrow focus, where a specialized paint is provided for each surface.

For example, material for outdoor work contains more frost-resistant additives, and an emulsion intended for concrete contains an increased volume of acrylic latex;

If the repair work is postponed indefinitely, then when buying, you should pay attention to the shelf life of the material. You should also read the accompanying documentation.

This will help to avoid the acquisition of a fake and will act as a guarantor of the high quality of the goods;

- Before painting, the surface of untreated wood must be sanded and treated with an antiseptic compound. Metal bases must be cleaned of contamination and degreased. It is advisable to prime concrete walls, and wash alkyd and oily surfaces with a solution of soda or sodium phosphate;

- It is necessary to paint in calm weather and at a relative humidity of not more than 80%.Direct exposure to sunlight during work is also not recommended;

- To obtain a deeper color and increase the wear resistance of the coating, it is desirable to apply the rubber paint in several thin layers. The time interval between staining should be at least two hours;

- Treatment of a freshly painted surface with antiseptic and detergent compositions can be performed no earlier than 7 days after the completion of work.

How to paint with rubber paint

In order for the surfaces covered with the new "rubber" material to please with their appearance for a long time, it is necessary to carry out a number of works on their preparation for painting. Only in this case the paint will not swell and will show all its unique properties.

Surface preparation, depending on the material of the base base, implies thorough cleaning from:

- dust;

- rust;

- mud;

- outgrowths of lichens and moss (on slate roofs),

- oil and grease stains;

- fungal colonies and mold;

- old flaking coating.

In addition, some surfaces require degreasing (metal, plastic, tiles and others, with a smooth texture). It is not necessary to eliminate small cracks and pores, but large ones do. On glossy surfaces, sandpaper with a coarse grain is required for better adhesion of the paint to the base. For a more durable adhesion of the "rubber" material, it is recommended to rinse the surface treated with sandpaper with a solution of baking soda.

After drying, the surface, if necessary, is putty and impregnated with a primer. The wood is additionally covered with an antiseptic and fire retardant. These substances protect wooden structures from fire and decay.

The technology of applying rubber paint is no different from painting surfaces with any other composition. Can be used:

- roller;

- paint brush;

- spray gun.

The only condition that must be observed is the application of 2-3 thin layers of the paint composition. One layer of great thickness can simply peel off from the surface to be painted. It is also necessary to wait until each layer is completely dry. How much rubber paint dries depends on the type of material used and the brand of paint composition. Each manufacturer manufactures paints and varnishes according to their technical conditions, therefore, the drying time is different.

It is recommended to take a break between applying each layer for 1.5-2 hours so that the composition dries as best as possible. Complete drying to the formation of a hard film occurs in 2-3 hours, and some manufacturers even talk about a daily period, depending on the temperature conditions and the level of humidity.

If the paint is too thick, you can add a little water. Although manufacturers do not recommend doing this, judging by the information on various forums, our home craftsmen dilute the composition with water.

It is recommended to work with rubber paint at an ambient temperature above +5 degrees. In the process of staining, the paint mixture must be periodically mixed, which will help maintain a uniform consistency of the composition and uniformity of color. It is advisable to exclude the formation of a draft, and it is also not necessary to carry out work in strong winds, rain, which can lead to the formation of wrinkles on the film layer. Painted surfaces can be cleaned with a damp method using detergents not earlier than after a week.

Technical specifications

SuperDecor rubber paint appeared on the construction market relatively recently, but in a short time it managed to gain popularity and numerous positive reviews. It consists of water, acrylate latex, coalescent, antifreeze, preservative and special additives in the form of a color scheme and color pigment. The consistency of the paint resembles mastic. It is one of the few materials that can be used to paint galvanized iron.

If necessary, the paint is diluted with water. The use of solvents is not recommended.The drying time of the painted surface is from 30 to 60 minutes and depends on the humidity of the air and the temperature conditions of the external environment. One liter contains 1.1 kg of enamel. Material consumption on painted and primed bases is 120-150 grams per square meter, on wallpaper, chipboard, drywall and fiberboard - 190 g, on concrete and plaster - 250 g. The paint is produced according to TU 2316-001-47570236-97 and has the necessary quality and conformity certificates.

Features and Benefits

Developers of construction novelties in Russia have long been approaching the level of European countries in technology, design and product quality. In most cases, the price factor is also on the side of the domestic manufacturer.

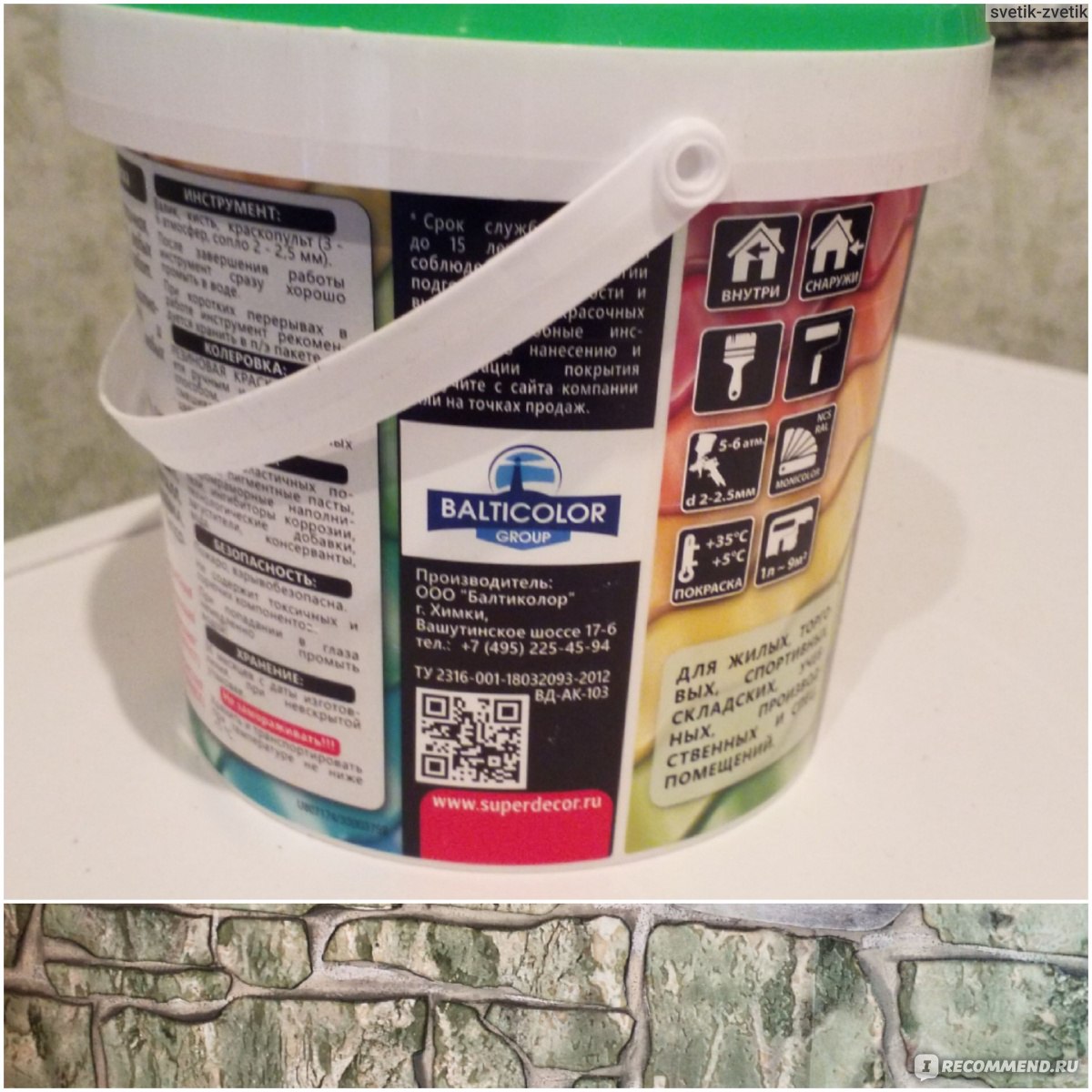

In many hardware stores, you can now find Baltikolor products under the name Super Decor Rubber. The manufacturer positions this material as rubber paint. This is a relatively new development, which is significantly different from the usual dyes for consumers. The material is made from water-based acrylic with various additives to improve performance.

The rubber coating was nicknamed for its appearance. It resembles a thin layer of rubber. An elastic, soft film forms on the surface, covering all microroughnesses. Conventional paints create a hard coating that corrodes easily. The texture of the coating is not embossed, the coating is matte.

The main advantages of Super Decor paint are:

- Excellent adhesion to many types of substrates.

- Frost resistance: the manufacturer guarantees the preservation of all properties of the coating at temperatures from -50 to +80 C.

- High elasticity.

- Resistance to various mechanical influences and changes in natural factors: changes in air temperature, changing seasons, high humidity, and more.

- Easy to clean: painted surfaces can be washed and cleaned even with soapy water.

- Ease of application, the paint dries quickly enough.

- Sustainability is especially important in some cases, for example, when used indoors with a large flow of people. There are no harmful substances in the paint that can be released into the air.

- Waterproofing function.

- The treated surface remains breathable.

- Thanks to special additives, it is resistant to mold and mildew.

- The range of shades will make it easy to choose a color for every taste.

- Long service life. The manufacturer guarantees the preservation of technical properties for 10 years.

- Does not fade.

- Fire safety and fire resistance.

How to use it correctly?

Pretreatment of the base

When applying any composition to the surface, it must be prepared. Otherwise, even the most high-quality and wear-resistant composition can deform, quickly collapse and lose its decorative properties, as well as expose the base itself to negative influences.

Surface preparation is as follows:

- First of all, the base that you are going to paint must be inspected for defects and all dirt must be removed: remnants of past treatments and paints, stains, dust and other debris. Be sure to pay attention to grease contamination. If they are not treated with special compounds, then in these places the paint can immediately peel off, because it will lose its adhesive properties.

- All cracks and chips must be repaired with repair compounds: putty, plaster, cement mixtures. After that, the surface is completely leveled and dust-free.

- Priming is a very important step that should never be skipped. Thanks to the primer mixtures, the adhesion of the paint to the base will improve and its consumption will decrease.

- If you are applying Super Decor to pre-painted surfaces, you need to achieve some roughness by sanding. This will make the paint stronger and last longer.

- For pre-treatment of wooden bases, you can additionally use fungicidal and anti-mold compounds. It will be useful to apply anti-corrosion mixtures on metal substrates.

Paint application

Preparation of paint and work with it must be carried out strictly in accordance with the recommendations on the packaging. After opening the can, stir the composition. If you want a thinner consistency, dilute the mixture with a little water.

You can use both a roller and spray guns or brushes. In the process of painting, do not forget to sometimes additionally stir the mixture. If you carry out processing outdoors, make sure that the air temperature is above zero. True, the manufacturer has a special modification of the dye for work in the cold.

The profitability of rubber paint is ensured by its low cost compared to other types of paints and varnishes and low consumption in combination with a long service life.

Consumption

Depending on the material to be coated, the paint is used as follows:

- For metals - about 250 g per square meter of area.

- For all types of wooden bases and slabs - about 350 g per 1 sq. m.

- For mineral and mineral-treated walls, ceilings and floors - about 400 g / m2.

- In the case of roofing, it is necessary to increase the consumption by 50-100 grams for greater strength.

Advantages and disadvantages

Rubber paint owes its name to the presence of specific ingredients that give it its unique properties. In appearance, the covering film resembles rubber. Even applied in one layer, it pulls together microcracks of 0.5 mm or more. The polymer is able to hide defects in the form of cracks and breaks in the web up to three centimeters in size.

Special additives in combination with an acrylic copolymer make the coating resistant to mechanical, chemical, alkaline, salt, and weathering. In addition, the waterproofing properties of elastic mixtures allow the use of LX in conditions of high humidity. The range of applications is wide: from swimming pools and bathrooms to living and industrial areas. It is often used as a facade paint.

Advantages:

- Adhesion level. The suspension has a high degree of adhesion to any material without the effect of running off: from wood to concrete.

- Heat resistance. The temperature range of reservoir operation is from -55 ° to + 60 °.

- Water vapor permeability. Compared to other materials, elastic paint has a higher transmittance coefficient. This allows you to apply lx on a surface with a loose porous structure: wood, cardboard, foam, etc.

- Drying speed to a solid state - 1-3 hours (depending on the level of humidity in the environment).

- The service life of the overburden is up to 10 years.

- Environmental friendliness. The formulations do not contain toxic and flammable substances; they are used in any enclosed space.

- UF resistance. The UV protection index reliably protects the surface from exposure to ultraviolet radiation. Even under the influence of positive temperatures, the rubber paint retains its base color and is odorless.

- Anti-corrosion properties. The paint is used when working with metal without additional protective equipment.

Most popular brands

Regardless of the versatility of flexible paints, manufacturers subdivide the product according to the field of application and according to the group of building materials. This division is due to the set of components required to maintain performance standards appropriate for each individual group. Therefore, the composition intended for concrete is different from the mixture for working with wood or metal.

Plasti Dip

Manufacturer - USA. Purpose:

- body tuning of vehicles and motor vehicles;

- decoration of ceramic, wood, glass, metal surfaces.

The paint has 3 types of coating:

- gloss;

- fluorescent;

- velvet.

Drying time between layers - 1 hour. Consumption: 150 ml per sq. m.The color palette includes 12 basic colors and more than 20 shades. Shelf life when unopened is no more than 10 months.

Rezolux Universal

Facade paint. Russian leader in the building finishing materials market. The resulting texture is smooth, matte. Material consumption: 150 g / m2. Drying time is 30 minutes. The color range is limited to 8 shades. The shelf life is 12 months.

Farbex

Rubber paint from Ukrainian manufacturers. The material is used:

- for decorative purposes;

- for the protection of metals, slate, tiles, concrete, asphalt, plywood, drywall.

The coating is resistant to moisture, has thermal insulation properties, a flexible elastic base with a high adhesion index. Consumption: 100 g per 1 sq. m.

Rubber paint

A narrow-profile manufacturer of paints and varnishes, including liquid rubber, for the automotive industry in China. Flexible paint is produced in aerosol packaging. One 390 mg can is enough for a five-layer staining of 1 sq. m.

In the Rubber Paint product line, a special place is occupied by "GOODLAC" - an elastic varnish with polyurethane.

Super Décor

Latex mixture. Produced by the Russian paint and varnish plant "Baltikolor". The product is the result of joint research with Finnish specialists. Advertising slogan of the brand: "Colors everything!" fully corresponds to reality. The manufacturer gives a 15-year operation warranty. This paint, in addition to the qualities characteristic of rubber elastic paints, is water resistant.

Facade painting technology with rubber paint

- Stir thoroughly before applying paint. If necessary, dilute with water (no more than 5-10%).

- Works are carried out in dry, preferably calm weather. Air temperature - from + 5 ° to + 30 °.

- The paint is applied by hand (roller, brushes), or by mechanical means - spray gun, air or airless spray.

- The paint is applied in several layers (usually 2 or 3 layers, if necessary, more). The material is applied in thin layers.

- Stir the paint from time to time.

- You can wash a fresh coating one week after application.