Species overview

Repair and connecting clamps are classified according to 2 characteristics: the material from which they are made, and design features.

By design

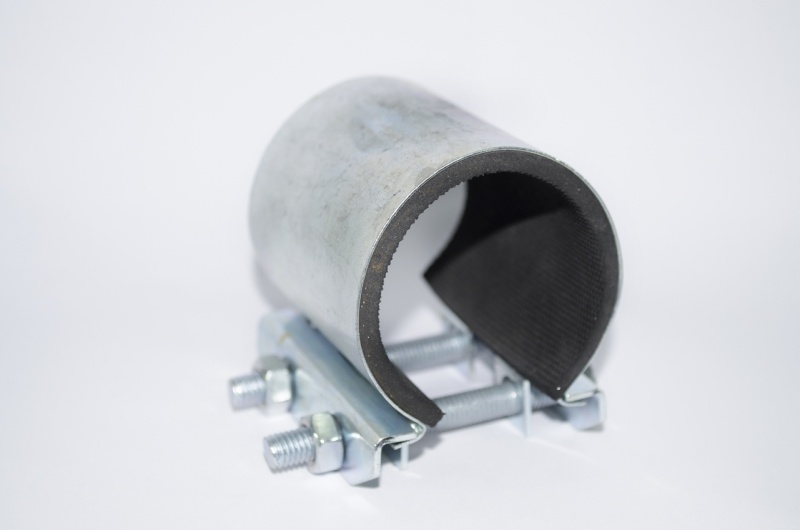

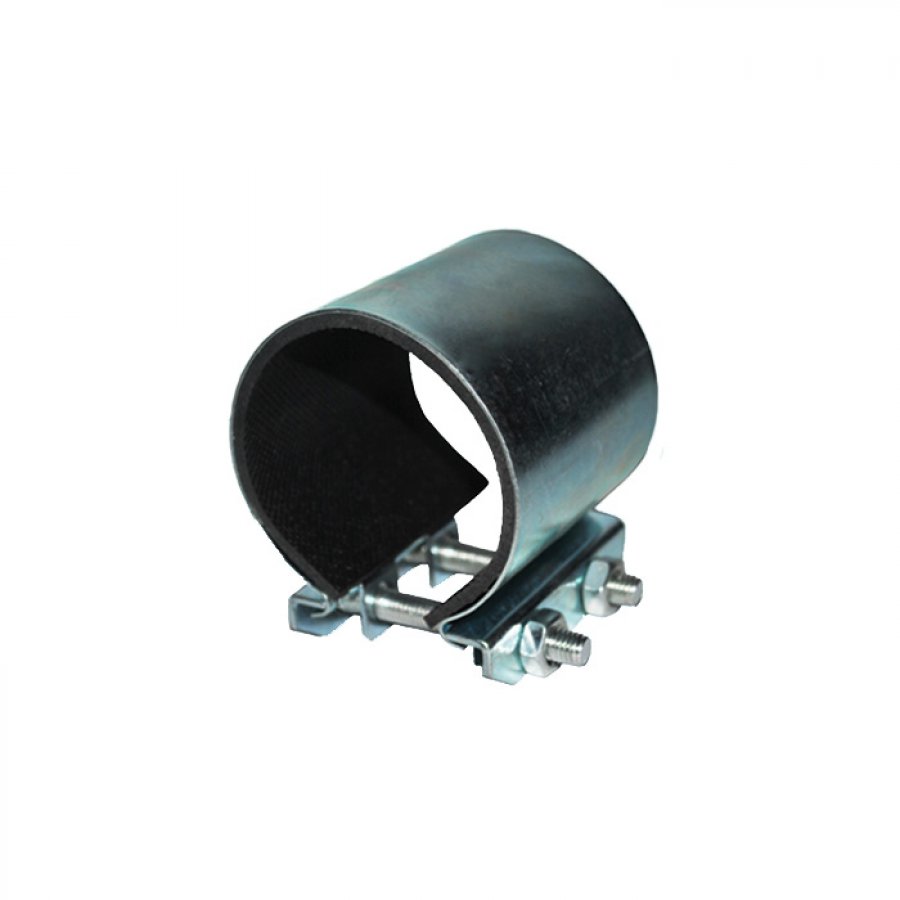

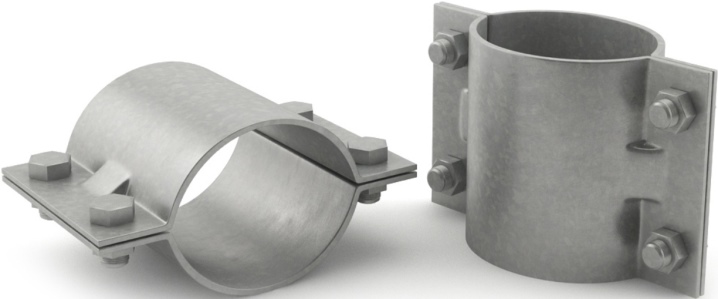

Products can be single-sided, double-sided, multi-piece and fastening. The first look like a horseshoe. There is active perforation on their top. They are intended for the repair of small pipes with a maximum diameter of 50 mm.

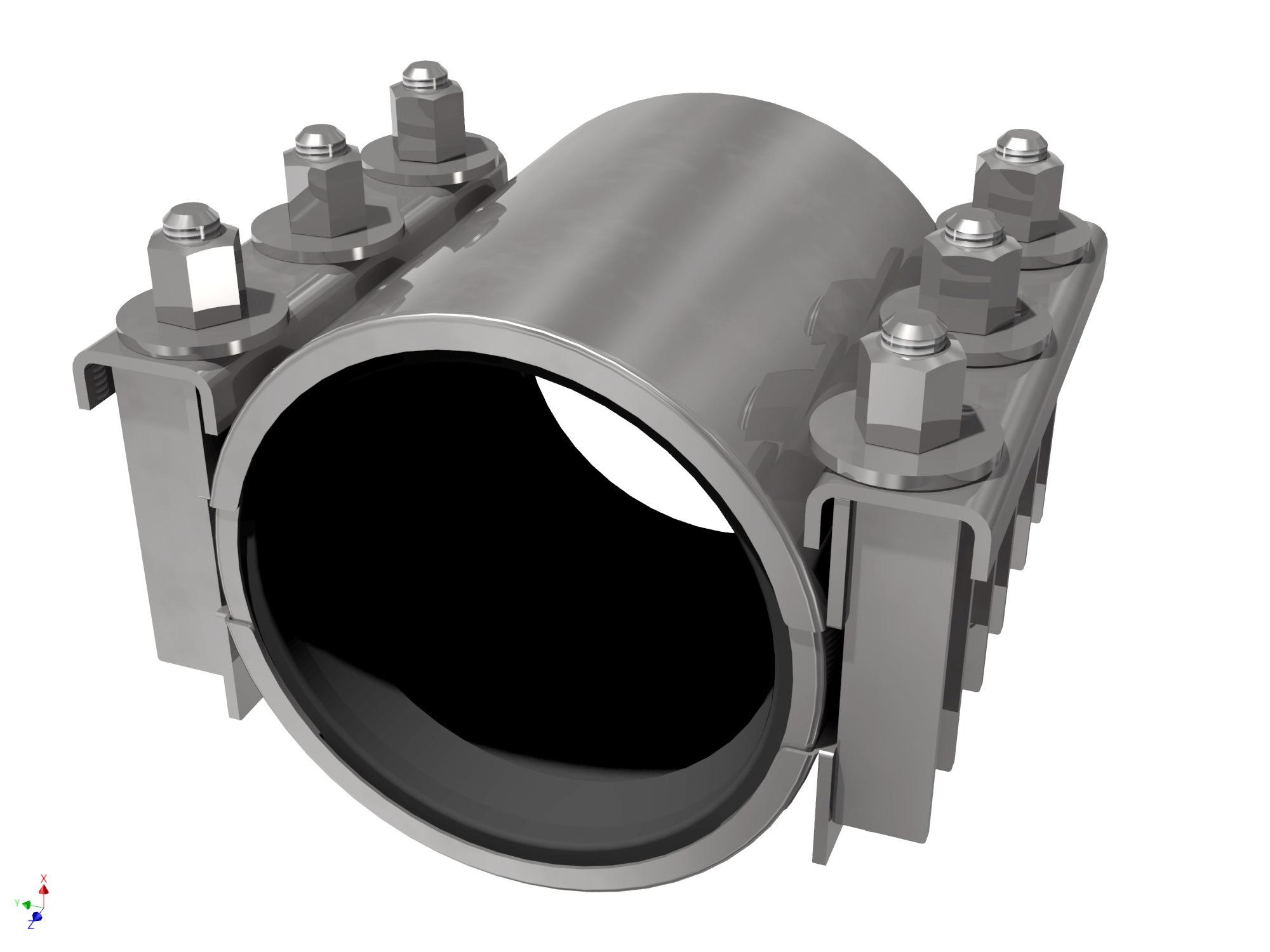

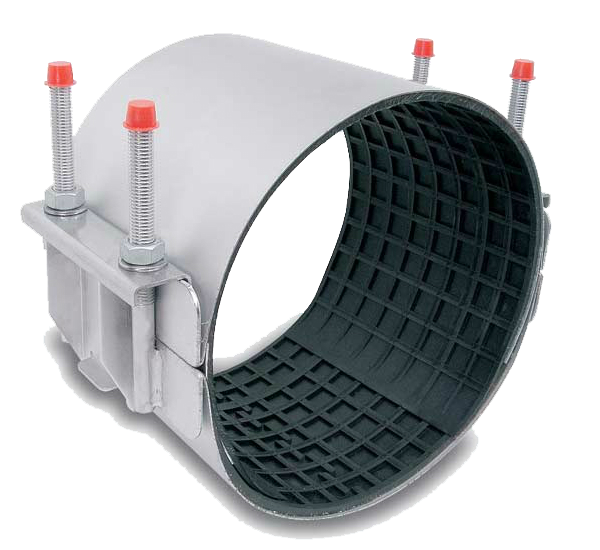

The design of double-sided clamps includes 2 similar half rings, which are connected with 2 screws. The dimensions of such products are selected in accordance with the dimensions of the pipes being repaired.

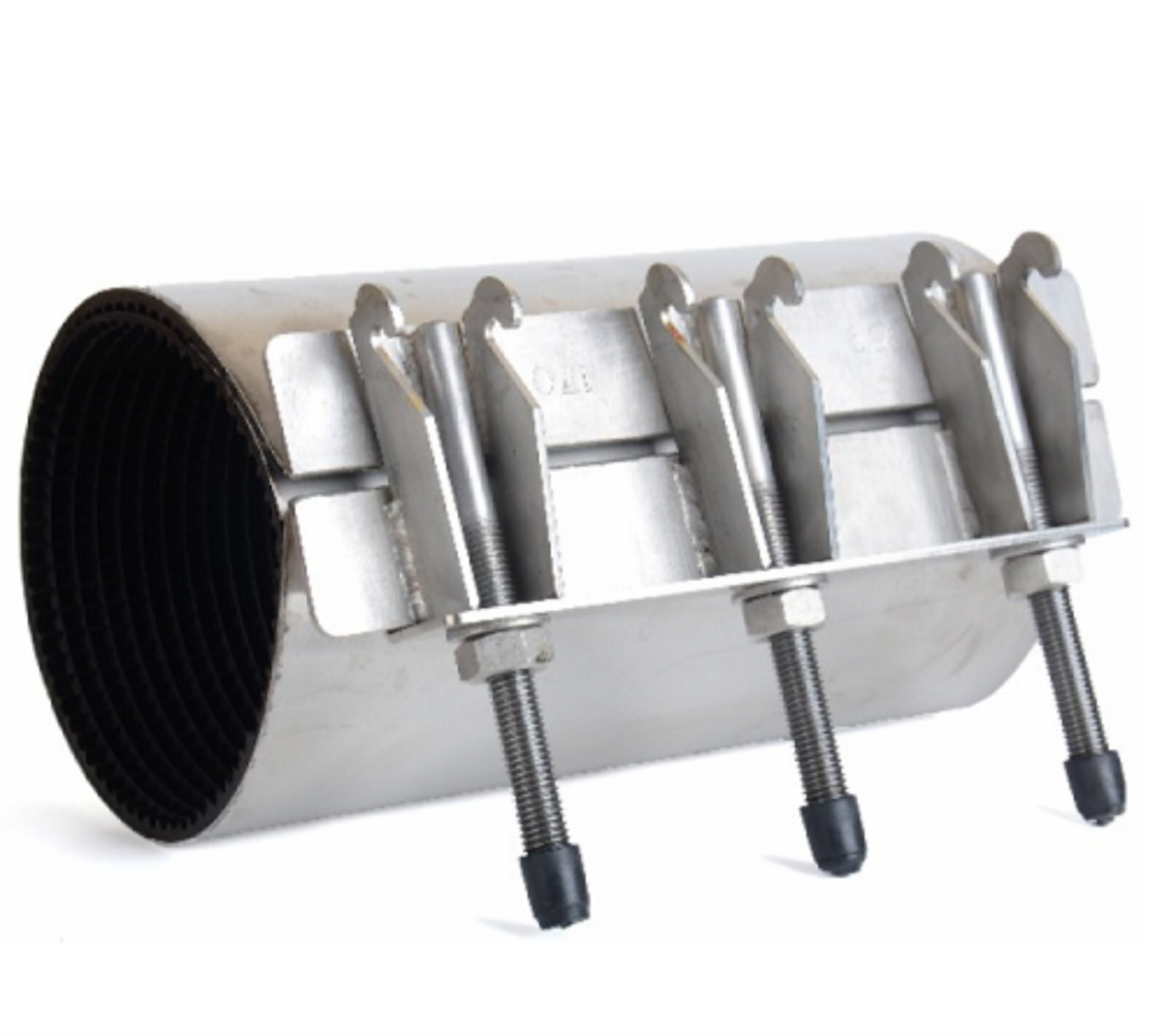

Multi-piece clamps include from 3 working segments. They are designed for the repair of large diameter pipelines. The clamp is often used to secure piping systems. It is mounted to the wall surface with a screw passed through the perforation at the bottom of the product.

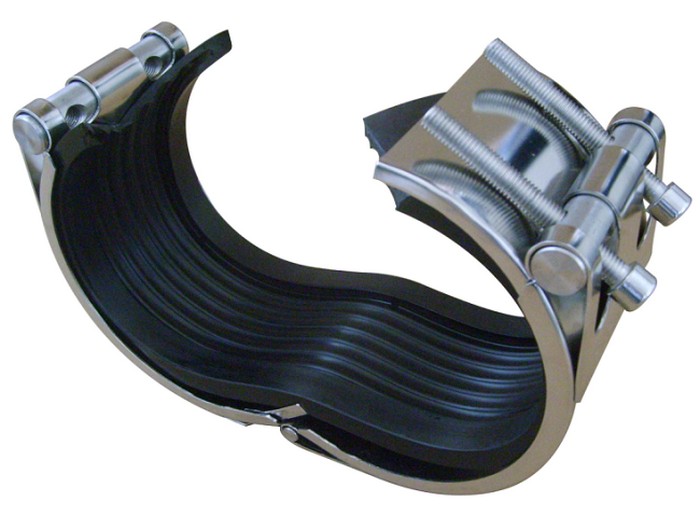

They also produce clamps-crabs - semicircular products with 2 or more bolts designed to tie products on damaged areas of the pipeline. Parts with a cast iron lock are also available for sale. Their locking part includes 2 halves, one of which has a groove, the other has a hole. They are fixed to the clamp band.

By material

In the manufacture of repair water clamps, various metals are used, less often plastic. Most metal products are made from steel. They differ:

- corrosion resistance;

- ease, thanks to which quick and uncomplicated installation is ensured;

- durability.

Steel clamps can be of any design.

For the production of double-sided and multi-piece clamps, cast iron is used. Compared to steel products, cast iron is more durable and wear-resistant. However, they are more weighty and massive.

Mounting

Installing a repair clamp on a problematic section of a pipeline is a simple task that even an inexperienced craftsman can handle. The work must be carried out in a certain sequence.

- First of all, you need to clean the peeling rust next to the damaged pipeline. For these purposes, you can use a metal brush or sandpaper.

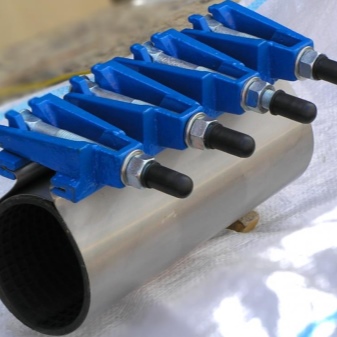

- The clamp fasteners need to be unscrewed, and then the ends should be spread to the optimal width - the part should easily fit on the pipe.

- When positioning the product, make sure that the rubber seal is over the damaged area and completely covers it. In the best case, the edge of the rubber seal should protrude 2-3 cm beyond the crack, fistula or other defect.

- The product is fastened by inserting the fasteners into the holes specially designated for this. Next, tighten the nuts until the damaged area is completely blocked. It is necessary to tighten the fasteners until the leaks are completely eliminated.

The following video explains how to securely fasten the clamp.

Peculiarities

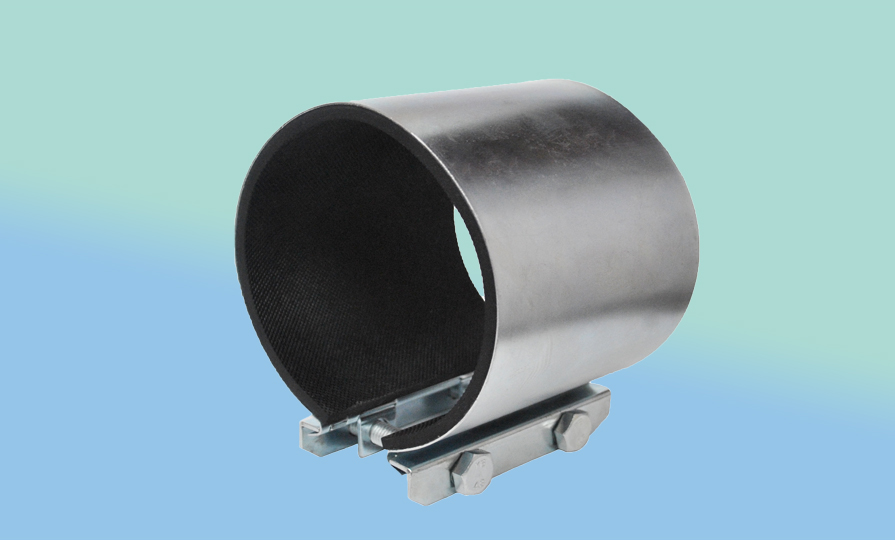

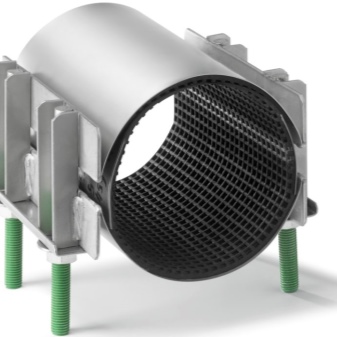

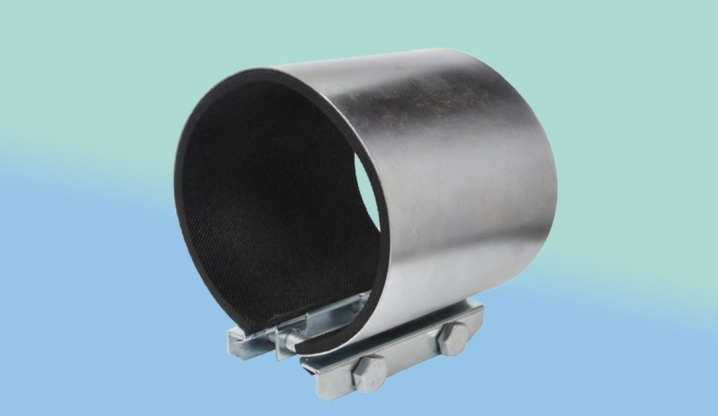

Repair clamps are classified as parts for sealing pipe systems. They consist of a frame, a crimping element and a seal - an elastic gasket that hides the resulting defects in the pipeline. Fixation is done with staples and nuts.

They are recommended for use on straight pipe sections installed in a horizontal or vertical plane. It is not allowed to mount products at joints or bends. Parts can be used for various types of pipes made from:

- cast iron;

- non-ferrous metals;

- galvanized and stainless steel;

- PVC, various types of plastic and other materials.

Repair clamps are installed at the sites of pipeline damage, they restore the functionality of the system and prevent subsequent deformation of the pipes.

Installation of emergency clamps is recommended:

- in the presence of fistulas in pipes resulting from corrosion;

- when rusting metal pipelines;

- when cracks occur;

- in case of breakouts arising from increased pressure in the system;

- in cases of urgent elimination of a leak when it is impossible to shut off the water;

- if necessary, sealing non-functional technological holes;

- in case of poorly performed welding work and leaking seams;

- in case of pipe breakage as a result of mechanical stress.

The advantages of such products include their versatility - the parts can be used not only to repair damage to pipelines, but also to fix horizontally or vertically located pipes. They are easy to install - installation can be done without experience and specialized tools. Clamps are high temperature resistant, durable and affordable. Most types of such parts are made of 304 grade stainless steel, due to which they do not require additional treatment against corrosion.

Clamps are universal - they can be used for pipelines of different sizes, if necessary, the same product can be installed several times. To carry out repair work, it will not be necessary to disconnect the utility networks. However, the use of clamps is a temporary measure. If possible, you should immediately replace the worn-out pipe with a whole one.

Specifications

In the manufacture of the bandage, galvanized or stainless steel with a thickness of 1 to 2 mm is used. Some manufacturers use 1.5 to 3 mm carbon steel. Steel products are stamped. In addition, cast iron can be used to make the bandage. Corrugated rubber acts as a seal. Fasteners are made of galvanized steel or alloy steel.

Description of the technical characteristics of the clamps with a rubber seal:

- the maximum allowable pressure is from 6 to 10 atm;

- working media - water, air and various inert gases;

- the maximum permissible temperature is +120 degrees;

- permissible operating temperature fluctuations - 20-60 degrees;

- the values of the minimum and maximum diameters are 1.5 cm to 1.2 m.

If properly secured, the clamp will last at least 5 years.

Appointment

The repair clamp can be used in the following situations:

- For sealing a pipe that has been damaged by corrosion.

- For sealing leaks due to the formation of holes and fistulas. In this case, you need a repair clamp with a special sealing gasket. It fits tightly to the spot and defect and reliably protects against leaks.

- If the pipe bursts in the transverse or longitudinal direction, then it can be repaired using this product. If such a breakdown occurs on a moving section of the pipeline, then it is better to use a clamp, which will not only close the leak, but also allow the pipe to be fixed to the wall or floor.

- In the case when it is urgently necessary to prevent a leak, but there is no way to shut off the water or drain it from the system.

- The repair clamp is suitable for repairing leaks in the event of a leak in the socket connection of sewer pipelines.

Repair clamps can be used on both vertical and horizontal pipe sections. In fact, it is a band that is firmly fixed to the pipe. It can be mounted on pipes made of different materials - plastic, steel, asbestos cement, cast iron, copper and metal-plastic.

The terms of use for the repair products are as follows:

- The outer diameter of the pipes cannot be larger than the diameter or length of the repair clamp.

- When mounting on pipes with a diameter of 350 mm, the length of the band must be 15 cm longer than the size of the damage.

- For pipes of significant overall dimensions, the length of the repair product should be 20 cm longer than the damaged section.

- For PVC pipelines, the length of the clamp should be 1.5 times longer than the defect to be repaired.

- If it is necessary to repair the fracture site of the pipeline or to join two sections, then the distance between the edges of the pipes should not be more than 10 mm, and the permissible deviation angle is 2-3 degrees.

- The repair product will function effectively only if the area of the damaged damage being repaired is no more than 60 percent of the clamp's working surface area.

- If the size of the defect significantly exceeds the working surface of the repair band, a section of the pipeline is cut out and replaced with a new pipeline, which is fixed with two clamps or couplings.

Specifications

- The material for the manufacture of the band is steel (galvanized or stainless) with a thickness of 1-2 mm. Sometimes carbon steel 20 with a thickness of 1.5-3 mm is used. Forged clamps are made of steel. Some manufacturers make cast iron components for the same purpose.

- A cuff made of cellular corrugated rubber acts as a seal.

- Clamp fasteners are made of galvanized or stainless steel.

- The limiting working pressure is in the region of 6-10 atm.

- The product can be used in an aquatic environment. Also, the working medium is air and inert gases.

- The repair clamp can be used in the following maximum temperature range - 110-120 ° C.

- The nominal operating temperature is 20-60 degrees.

- An element for this purpose can have a diameter of 15 mm to 1.2 m.

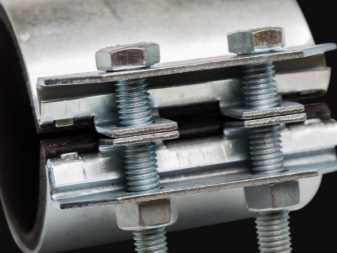

The most popular are single-sided and double-sided repair parts. Thus, a double-sided stamped clamp is made of 20 carbon steel. It is used to repair water supply pipes and consists of the following components:

- Two steel or galvanized stamped half couplings, which are reinforced with stiffening ribs.

- Rubber sealing gasket.

- Connecting bolts with washers and nuts made of stainless steel or galvanized steel.

- The diameter of this clamp can vary from 15 to 600 mm.

Another popular repair element is the stainless steel single-sided clamp. It is made in the form of a solid steel tape (coupling). Its edges are connected to each other using screws and nuts or special fasteners made of galvanized steel.