Which one is suitable for different types?

The selection of the dowel is determined by several factors.

Its appearance depends on the material in which it will have to be fixed. Dowels for solid bricks or concrete have serious differences from consumables used for porous or hollow materials. Correspondence of the design to the material for which it was developed significantly increases the reliability of the fasteners.

So, a simple spacer consumable with two petals can be driven into concrete, and it will be quite enough to hold the corresponding size of the self-tapping screw.

Such a dowel may also be suitable for fasteners in solid brick, but given that it is still a more fragile material, fasteners with 3 or 4 petals may be more suitable for a brick, and even with additional holding devices in the form of various kinds of thorns.

For fasteners in a hollow or porous material, you will have to select a consumable with several active zones, with special complex spacers that allow you to cling to the harder parts of the drilled material. Very popular in the case of a hollow material is a fastener called a "butterfly", which, when tightening the self-tapping screw, forms a complex knot that expands it in the pores of the material.

Dimensions (length and diameter) are determined by the load that the fastener must withstand. To hang a picture or a photo frame on the wall, you can get by with a very small dowel of a simple device with a diameter of 5 mm. The length does not really matter in this case, so you do not need to drill a deep hole. The maximum size of such consumables is 5x50 mm. Dowels under 6 mm differ in a variety of lengths: 6x30, 6x40, 6x50 mm.

Securing heavy equipment or exercise equipment will require more powerful fasteners with a diameter of 8 mm or more. The most popular in terms of sales is the size group 8x50 mm. Often these dowels are marked as 8 x 51 mm. They can be successfully used for the installation of lightweight structures, and used for serious installation work.

Correctly selected dowel size allows the use of a self-tapping screw corresponding to the load. The dimensions of modern plastic dowels are standardized in terms of the ratio of length and diameter.

The table clearly shows the existing variety of dowel sizes:

|

Diameter (mm) |

Length (mm) |

Self-tapping screw diameter (mm) |

|

5 |

25, 30 |

3,5 – 4 |

|

6 |

30, 40, 50 |

4 |

|

8 |

30, 40, 50, 60, 80 |

5 |

|

10 |

50, 60, 80, 100 |

6 |

|

12 |

70, 100, 120 |

8 |

|

14 |

75, 100, 135, |

10 |

When choosing the length of the self-tapping screw, it is important to add the thickness of the material to be fastened, since it is important that the self-tapping screw reaches the bottom of the plastic sleeve when screwing in - only in this case the fastening properties will appear in full. The wrong diameter of the self-tapping screw can also cause poor-quality fasteners: either the petals will not open and wedging will not occur, or the sleeve will be torn, which is also unacceptable, since the adhesion to the material will be broken

The dimensions of the dowels and self-tapping screws determine the maximum loads allowed for the fasteners.

Small dowels with a diameter of 5 mm at any length cannot be used to fix bulky items. They are ideal for hanging a picture, photo frame and similar objects of light weight on the wall.

Fasteners with a diameter of 8 mm can withstand higher loads than 5 and 6 mm dowels. With such fasteners, you can install shelves, wall cabinets, fix furniture. Reinforced consumables with a diameter of 10 mm or more can successfully perform the functions of installing not only decorative materials, but also partitions, large items or household appliances, scaffolding and others.

Another criterion on the basis of which you can choose a fastener is the material of the dowel. Of course, a classic self-tapping screw is screwed into a plastic dowel, more precisely, in its variety: polyethylene, polypropylene, nylon (polyamide).

If you need to mount anything outdoors, it is best to use a nylon plug, as this material retains its properties at high temperature ranges. Any plastic dowels are suitable for interior work. But polyethylene has much higher plasticity.

In special cases, the use of self-tapping screws, in general, will have to be abandoned. For example, for fastening frame structures (windows, doors), gratings, awnings, heavy equipment and in some cases when reinforced fasteners are required, it is necessary to resort to using a steel dowel.

Views

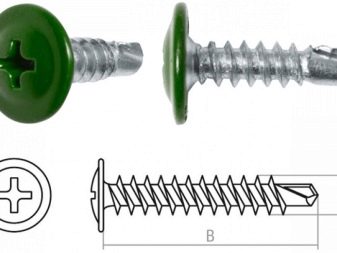

Regardless of the combination of roofing screws into one group and their visual similarity, the classification of products occurs according to three main criteria.

- Hardware for work with a metal base is produced. The end of such a product has a sharp drill with a metal press washer and a gasket. If there is a pre-drilled hole in the material, such a self-tapping screw can be used for metal raw materials with a thickness of up to 6 mm. If you do not drill a working hole, then the fasteners can be operated with material, the thickness of which does not exceed 1.2 mm.

- Self-tapping screws for mounting roofing materials to wooden lathing or fixing wooden elements together. The most common are galvanized steel parts.

- Products for work with sandwich panels and corrugated board. When attaching such self-tapping screws, there is no need to drill holes. Hardware can hold together materials, the total thickness of which does not exceed 12.5 mm.

The differences can be noted in the configuration features.

Metal fasteners are made with a longer drill bit compared to woodworking products. In addition, their diameter will be almost the same as the body itself, since the products will be subject to great stress at the time of installation.

Metal hardware has a slightly different thread - its pitch will be an order of magnitude smaller.

There are three types of drill for roofing screws:

- for woodworking with a drilling thickness of 0.91 mm to 2 mm;

- for metal, where the thickness will vary from 0.91 mm to 5.3 mm:

- for fastening to metal battens with a minimum drilling thickness of 0.91 mm and a maximum drilling thickness of 4.17 mm.

Roofing screws are galvanized or painted. The latter option is most in demand due to the aesthetics of the color combination in conjunction with the additional moisture protection provided by the paint. The most popular are products in white, green and blue, but they are also painted in other colors. As a rule, they are purchased for fixing corrugated board.

Based on the shape of the cap and the installation method, the following types of roofing screws are distinguished:

- ordinary fasteners, for which you need a standard screwdriver;

- products, the head of which has special edges for bits.

In order not to make a mistake when buying roofing screws, you should take into account the thickness of the roof sheathing. Unsuitable products will not be able to securely fix the roofing material to the structure. And it would also be a mistake to assume that the elements for working with metal will exactly fit for installation to a wooden crate. The result of using a large drill for metal will be the formation of a hole of the wrong size, since wood is many times softer. The trace from the self-tapping screw will be larger, and this is fraught with a situation when the product is loosely located in the material.

But a small drill for wood with a large thread pitch will not be able to reliably and smoothly enter the metal, which will also reduce the level of quality of fixing the raw material.

Specifications

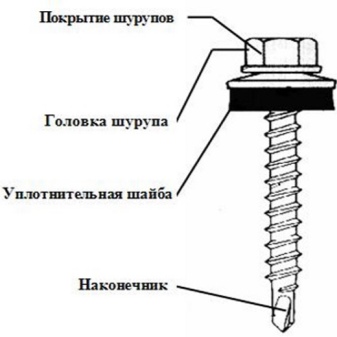

Roofing elements have three components.

- One end is a drill or drill, which facilitates penetration into the material.

- Body with threads. Its presence responds to the screwing of the part into the crate.

- The head responsible for fixing the self-tapping screw.

The hat of the roofing screw is round - the most common option. It can be screwed in with a conventional Phillips screwdriver. There are also instances with a hex head. The size of the product is determined based on the length and diameter. There is a huge selection of roofing screws of various sizes and configurations on sale. The weight of the product directly depends on this parameter.

Special attention should be paid to such a self-tapping component as a washer, since this part, made of metal and rubber by heat treatment, tightly fixes the element to the structure.

Painted products are processed with special compounds and fired, due to which colored products retain their color for a long time. You can be convinced of the quality of such products even during installation - if the coating peels off, then you should doubt the reliability of the purchased products.

There are general characteristics for this group of products:

- their size can be as follows: 4.8x19, 5x25, 5x32, 5x38, 5.5x19, as well as 6.3x25, 8x29 mm;

- the weight of the package will depend on the size of the packaged products - for example, in a package weighing 1 kg there may be a different number of self-tapping screws;

- the price of the product, as well as the weight, depends on the size of the product.

By wood

Wood screws are used to join wood products as well as plywood. It is best to use such fasteners in tandem with expansion dowels. It is necessary to have self-tapping screws for wood both in city apartments and in private houses.

The design features of wood screws can be found in the video.

The video shows the varieties of such hardware, as well as the fastening technology.

Wood screws are of various types and sizes. Their distinctive features:

- Cross-shaped connector.

- Countersunk or semicircular head.

- Sparse thread pitch.

- Sharp tip.

The adhesion of the materials to be joined will be more reliable if there is a large thread pitch.

The coating of the hardware is selected depending on the conditions of use. Self-tapping screws with a press washer (sharp) are also used, which tightly connect thin parts.

The coating is used:

- Black.

- Yellow or white.

- Silver.

For fastenings of 2 wooden elements, black ones are often used. For this, the holes need not be drilled. To attach other elements to the tree, yellow or white are used (in this case, you must first drill a hole in the parts to be joined). Silver are intended for a more durable connection of sheet material, particle boards or wood.

For the convenience of selection, table 1 of the sizes of wood screws is presented. It indicates the nominal diameter (diameter of the leg together with the thread), the length of the self-tapping screw with the head, the inner diameter (the diameter of the leg without the thread), and the width of the head.

Table 1. Dimensions of wood screws.

| Nominal diameter, mm | Length, mm | Outer thread diameter, mm | Internal thread diameter, mm | Head width, mm |

|---|---|---|---|---|

| 2,5 | 12-25 | 2,25 – 2,55 | 1,1 – 1,5 | 5,1 |

| 3,0 | 12-45 | 2,75 – 3,05 | 1,5 – 1,8 | 6,0 |

| 3,5 | 12-50 | 3,2 – 3,55 | 1,75 – 2,15 | 7,0 |

| 4,0 | 16-70 | 3,7 – 4,05 | 2,0 – 2,5 | 8,0 |

| 4,5 | 25-80 | 4,2 – 4,55 | 2,22 – 2,7 | 8,8 |

| 5,0 | 30-120 | 4,7 – 5,05 | 2,52 – 3,0 | 9,7 |

| 6,0 | 40-240 | 5,7 – 6,05 | 3,22 – 4,05 | 11,6 |

For metal. In order to select a self-tapping screw of the required length, measurements of the thickness of the parts to be connected are first made. When connecting two elements, the self-tapping screw must enter the wood by at least 1/4 of the thickness of the wood.

Self-tapping screws for metal are available with a drill end and frequent threads. Their diameter is proportional to the length of the product. Several types are used:

- Black coated.

- Bug.

- With a press washer (drill).

- White zinc coated.

For mounting drywall to metal, black coated hardware is used, which will be described below. For mounting wood, thin sheet material to metal, self-tapping screws with a white zinc coating are needed, which protect against corrosion.Such hardware is strong enough due to cementation of the product surface.

A self-tapping screw with a press washer (drill) is needed to fasten steel sheets to metal. This will be discussed in the sections below. Self-tapping screws called bug are used to connect thin metal materials. They have a phosphate coating and a semi-cylindrical head.

To work with metal, self-tapping screws with a nominal diameter of 3.5 to 5 mm are used. Their technical characteristics are presented in table 2.

Table 2. Selection of self-tapping screws for metal.

| Nominal diameter, mm | Length, mm | Outer thread diameter, mm | Internal thread diameter, mm | Thread pitch, mm |

|---|---|---|---|---|

| 3,5 | 10 – 50 | 3,2 – 3,55 | 1,75 – 2,15 | 5,0 |

| 4,0 | 60 – 100 | 3,7 – 4,05 | 2,0 – 2,5 | 10,0 |

| 4,5 | 110 – 120 | 4,2 – 4,55 | 2,22 – 2,7 | 15,0 |

| 5,0 | 125 – 220 | 4,7 – 5,05 | 2,52 – 3,0 | 20,0 |

For metal with a drill. When working with metal, only special hardware should be used. The right choice will ensure a high-quality connection of materials for a long period of time.

The end of a self-tapping screw for metal is often made not sharp, but with a drill. Due to this, the hardware is easily screwed into solid material. The main advantages of this design of products for metal:

- No additional perforation required.

- Installation work is carried out faster.

- The connection of parts is done better.

In order to choose the right self-tapping screw from Table 2, it is necessary to measure the thickness of the parts to be joined. For a firm attachment to the metal, the self-tapping screw must enter the base to a depth of 10 mm.

Calculation example: the thickness of the attached part is 30 mm + 10 mm (the minimum depth to which the hardware must enter the base) = 40 mm. In total, a self-tapping screw with a length of 40 mm is obtained.

How to choose the right one

For the correct selection of a furniture screw, it should be taken into account in what material it will be installed. The choice of head will depend on the applied force and space, which will be available when screwing

It is also important to choose not only the type of head, but also the pattern for the tool used.

With the correct selection of the bit, a firm grip of the fastener with the screwing tool is ensured. Only in this case the screws smoothly, evenly enter wooden plates, drywall, chipboard, MDF.

Some important nuances that will help buyers of fasteners much better navigate their variety, as well as make the right choice:

- color - screws of the same batch must be kept in the same color scheme. This indicates that all products have undergone the same processing in similar conditions, and also have the appropriate strength, corrosion resistance;

- parameter - the sizes of one batch of products should not visually differ from each other, and also comply with standards;

- step - the load between the threads should be evenly distributed;

- hole - the slot should be characterized by clarity, symmetry, and be deep enough;

- marking - the standard designation of screws is a number in which the first number is the size of the thread diameter, the second is the length of the product from its very head to its sharp tip.

In order to efficiently assemble and install furniture elements, you need to use such a convenient, affordable assistant in fastening work, such as a screw. This type of furniture screed will not only simplify the assembly and installation procedure, but will also be invisible after the installation process is completed, due to its unique structure. All structures and foundations fixed with such fasteners will retain their shape, appearance, properties for a long time.

Specifications

Considering the roofing screws (they are hardware or fasteners), as they say in the section, we can say that they consist of three parts with different functional purposes. It:

- A drill, or a drill on the point of a self-tapping screw, facilitating self-drilling.

- The body is threaded for screwing and deepening the fasteners into the lathing of wood or metal.

- A hat, or head, used to screw in a self-tapping screw and further fix the roofing material.

Due to the specificity of the application, roofing screws are made from strong grades of hydrocarbon steel. Subsequent zinc coating ensures their protection against corrosion damage. In addition to galvanized ones, on sale you can find copies made of "stainless steel", but their cost is much higher.

As for the shape of the hats, in addition to the standard round shape, for a Phillips screwdriver, self-tapping screws with a figured hex head are produced. It is more convenient to work with such fasteners and therefore it is most popular when installing roofs.

When talking about dimensions, we mean the ratio of the diameter to the length of the product. As for roofing screws, the existing range of sizes is wide enough and provides reliable fastening of roofing materials with different profile configurations. Of course, the size also affects the weight of the product.

But the most distinctive feature of this type of fastener is its complete set with a special washer. The washer is a combined metal and rubber structure under the influence of high temperatures. Having a round shape, it is designed to press the material more tightly to the lathing while simultaneously sealing the hole under the screw head.

The table below shows some comparative characteristics of the most common fastener samples:

|

The size |

Outside diameter mm. |

Drill diameter mm. |

Drill length mm. |

Washer diameter mm. |

Rubber thickness mm |

Approx. weight per 1000 pieces kg | |

| 4.8x19 | 4,62 – 4,8 | 3,9 | 5,5 – 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 3,10 |

| 4.8x25 | 4,62 – 4,8 | 3,9 | 5,5 – 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 3,70 |

| 4.8x32 | 4,62 – 4,8 | 3,9 | 5,5 – 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 4,20 |

| 4.8x38 | 4,62 – 4,8 | 3,9 | 5,5 – 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 4,80 |

| 4.8x50 | 4,62 – 4,8 | 3,9 | 5,5 – 6 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 5,80 |

| 5.5x25 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 – 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 6,33 |

| 5.5x32 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 – 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 7,55 |

| 5.5x38 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 – 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 7,84 |

| 5.5x50 | 5,28 – 5,46 | 4,55 – 4,7 | 7,5 – 9 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 8,40 |

| 6,3x25 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 9,45 |

| 6,3x32 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 9,50 |

| 6,3x38 | 6,05 – 6,25 | 5,4 – 5,55 | 8 – 9,5 | 13,8-14,2 | 2,8 – 3,2 | 0,8 – 0,9 | 10,45 |

Well, and the last, maybe directly and not related to technical characteristics. To ensure an aesthetic match with the roofing material, manufacturers paint the top and fastener washers in different colors.

Painting, produced by powder paint mixtures with further firing in muffle furnaces, should retain this most aesthetic appearance for as long as possible. And if the paint lags already at the installation stage, this is a sign of poor-quality fastening material.

Reiki three-dimensional

The modern Italian firm produces fasteners that are placed perpendicularly and vertically at an angle, using T-type rails, created by extrusion from a high-strength steel alloy. They are produced in several modifications designed for multilevel loads.

The fastening system should be selected according to the size range of cross-sections of the beams to be combined and the dynamic and static loads acting on them.

During installation, the rack base is attached to the beam by means of self-tapping screws. Then, on the end part, attached to the base of the log beam, a groove is created of the same size as the rack shelf. In the absence of perforation, the shelf is equipped with a lag and the connection is fixed with self-tapping screws.