How much does a chipboard sheet weigh?

Kitchen weight

The weight of a kitchen set naturally depends on its composition. Usually, the weight of an average Russian kitchen varies in the region of 400-550kg (with a total length of mounted furniture of 4-5 meters along the wall). To inform the transport company, an average value of 500 kg is used, while the volume of cargo is in the region of 1.5-2 cubic meters. The maximum package length in 99% of cases does not exceed 4 meters, and a car with a maximum body length of 3.5 meters is used for transportation (in 90% of cases, transportation in a body no more than 3 meters long is allowed).

For more accurate calculations, you can use the following values: Weight of one cubic meter of chipboard (frames and other materials made of chipboard) = 600 kg Weight of one cubic meter of MDF (facade panels of the AlvaColor series) = 750 kg Weight of one cubic meter of wood (facade elements of the AlvaNatural series) = 800 kg (for 'heavy' types of wood, in particular oak / beech) Weight of one cubic meter of glass (products from it) = 2000 kg Weight of one cubic meter of artificial stone = 200 kg Weight of one cubic meter of natural stone (products from it) = 2500-3000 kg

Thus, the weight of the facade measuring 72x60 cm for the Mirella kitchen set will be 0.72 * 0.6 * 0.018 * 600 = 4.6 kg, and taking into account the packaging and fittings (handles), it can pull all 5 kg, with a volume of 0.012 m3. For reference, the weight of the 60cm base cabinet frame is 19.4kg, taking into account additional fittings, it can be rounded up to 20kg, with a volume of 0.047m3. The weight of one meter of 38mm laminated tabletop is 1 * 0.6 * 0.038 * 600 = 13.68kg, taking into account the packaging, it can be rounded up to real 14kg / m. The weight of the hob is 7-10kg, with a volume of 0.06m3. The weight of the built-in oven is 30-40kg, with a normal volume of 0.25m3. The weight of the built-in refrigerator is from 40 to 80 kg, depending on the size and model, the volume of the package is not less than 0.26 m3 and reaches 0.8 m3. The weight of the dishwasher is 35-50kg, with a volume of 0.21-0.26m3. The weight of a sink made of artificial granite is 6-12kg, with a volume of 0.07-0.2m3. When calculating the weight of products made of glass, or containing glass (front-showcase), the weight of the packaging should be taken into account. This usually adds 12-20kg per 1m2 of packaging.

To obtain more accurate data for, for example, air transportation, we recommend that you contact your regional distributor with an appropriate request, who will calculate the exact weight and dimensions of any particular order.

Peculiarities

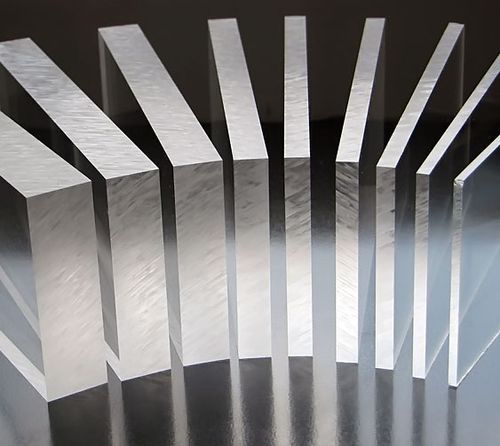

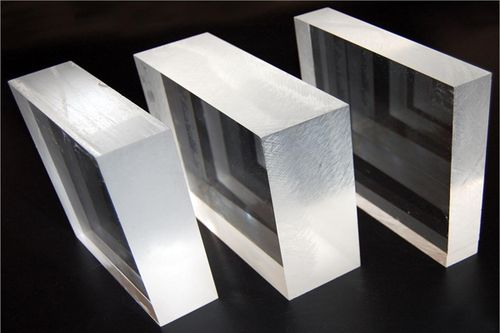

Organic glass (PMMA) is produced in two types in accordance with GOST standards:

- TOSP - plasticizers are added to the material, due to which its physical and mechanical properties are improved. The material is easy to mold. It is used for the manufacture of complex structures, containers, souvenirs. The main difference is the wide color palette.

- TOSN - plexiglass without plasticizers. Resistant to sudden changes in temperature and chemicals. Color - transparent, produced in blocks.

Advantages of acrylic glass:

- strength - it is not easy to break it when compared with traditional glass, so many things began to be produced from acrylic;

- ease of processing is a very useful property for design: the material can take on the most unusual shapes;

- low weight - it has become much easier to move such glass;

- transparency - even colored items have a high degree of transparency.

- moisture resistance - the material is resistant not only to water, but also to many chemical elements.

According to the manufacturing method, organic glass can be of several types.

- Extrusion (low molecular weight).It is made by the method of continuous extrusion of the finished mass through a forming extruder. Then the workpieces are cooled and cut into sheets of certain sizes.

- Injection molding (high molecular weight). This material has better characteristics than extrusion glass. It features a smooth and transparent surface, shock and crack resistance. Withstands high temperatures and is not exposed to chemicals. It is made by pouring a liquid mass between two planes with further hardening.

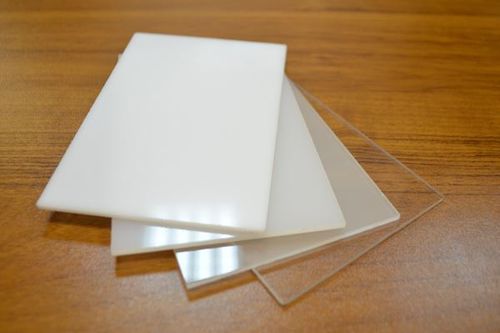

- Sheet. To add haze or light scattering, polystyrene is present in the composition. The ability to transmit light varies from 25 to 75%.

How much does a chipboard sheet weigh

If you decide to make furniture with your own hands, have developed a design, calculated the sizes of parts, have decided what you will build your dream furniture from, then you can safely purchase the necessary parts. The most popular and demanded materials for furniture are chipboard and OSB. Chipboard - chipboard - a material made by pressing wood chips with their bonding substances - organic resins. It is quite easy to use, resistant to mechanical damage, stable material. OSB (OSB - Oriented Strand Board) - oriented strand boards, also made from wood chips, in the same way, only in it, each subsequent layer of wood is laid across the previous one. Basically, such a slab consists of four layers. Accordingly, OSB is a more durable, rigid, moisture resistant material.

It is very important to know how much a chipboard or OSB sheet weighs. There are several factors that affect the weight of chipboard, OSB

First, of course, is the size. For example, a Kronospan chipboard sheet (Kronospan) is manufactured in the following formats: 2750mm x1830mm and 2800mm x2070mm. And the OSB plate has different sizes. For example, Kronopol slabs are 1250mm x 2500mm or 2070mm x 2800mm. Secondly, the weight of the chipboard and OSB board is influenced by its thickness. Using the same example from Kronospan, we have polished chipboards with a thickness of 10, 16, 18 and 22mm. The third factor is the compaction density. It is varied depending on the manufacturer and, accordingly, the pressing method. Another important factor is the raw material - the wood from which the material is made, with a binder, since it can be more or less dense, and, accordingly, heavy.

Considering all these factors, it is easier to figure out how much a chipboard or OSB sheet weighs and why. For example, the weight of a 12mm chipboard sheet - 2440mm x 1830mm format is 39.1kg, 10mm OSB board, 2500mm x 1250mm format - 20.6kg, chipboard weight 16mm, 2750mm x 1830mm format - 58.7kg.

Naturally, if all possible options for plate formats are systematized into a certain scheme or table, then it will be quite easy for you to calculate the dimensions of chipboard or OSB sheets for organizing their transportation. Below is such a "magic wand" - a table in which the weight of various plates has already been calculated, depending on their sizes and manufacturers.

Obviously, the weight of two sheets of the same thickness, the same length, but different widths is significantly different.

And this is important when transporting an unsuitable transport. Since, for example, a plate that is too thin will be quite fragile and brittle, which makes it difficult to preserve during transportation

Or, depending on the method of pressing the wood, the sheet may not be completely stable, that is, it may bend.

We hope that with the above table we have made the task of transporting chipboard or OSB much easier for you, and now you can easily calculate the total weight of the required material and select the method of transportation. This is taking into account the weight of the chipboard board, and the dimensions of the OSB, and the dimensions of both each sheet separately and all sheets in a bundle.

Particleboard and OSB are widely used in the construction of cabinet furniture, are easy-to-use materials.However, without practical skills and certain knowledge, it will not be easy for you to navigate the organization of quick and easy transportation of plates or finished parts of your furniture. And we will be happy to help you deal with this task. Contact us

Thickness of sheets

According to the manufacturing technology, glass is of two types:

- molding;

- extrusion.

Most likely, there is no need to explain what casting is. But let's say a few words about extrusion. The polymer usually fails to melt like metal. The temperature of irreversible decomposition into fractions in polymers is usually lower than the melting point. But the polymer can be heated to a soft-flowing state, like a dough.

This polymer "dough" is pushed through a slot, the width and thickness of which correspond to the corresponding parameters of the future formation. The length can theoretically be anything you like, in contrast to the injection version, strictly limited by the size of the mold.

However, it should be remembered that the way extrusion glass is made does not have the best effect on its properties. As a result of "pushing" through the gap, stresses arise, which are "preserved" during solidification. These tensions can make themselves felt later. This defect can manifest itself, for example, in the form of cracking of the formation or spalling of pieces from it during sawing.

The width of the plexiglass is produced in different versions, it all depends on the application. For construction, the seams must be strong and, of course, there must be a choice in width. For example, if you plan to install a canopy, a visor made of glass, then a sheet with 5mm and 8mm will be sufficient. But for a luminaire, the sheet should be about 1mm or 2mm thinner in thickness.

The thickness of the sheets is from a maximum of 25mm to a minimum of 1mm. Thickness of 20 millimeters and more is used relatively rarely, for example, for the manufacture of unbreakable "armored" glass for panoramic windows. In household and private construction, plexiglass is usually used with a thickness of 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 7 mm, 8 mm, 9 mm, 10 mm.

Extrusive plexiglass is produced in a variety of versions: transparent, matte, colorless, light-transmitting, colored. This is exactly the glass that is used for the manufacture of lamps, apartment decor. The thickness of the layers does not exceed 1 to 5 mm. All material is used most often for the manufacture of advertising structures, and volumetric parts are made from it.

Dimensions of plexiglass sheet

The industry today produces sheets up to ten meters, but it would be complete madness to transport such a layer, therefore, after production, such material is usually cut into more convenient sizes by two and three meters.

Standard layers of molded glass with a width of 3020 mm, and a length of 2020 (photo) are used for various purposes. In terms of thickness, they have the same meaning as in the extrusion version. Cast glass is produced in colored, matte, textured form, and differs from the first type of glass in shock resistance and heat resistance.

In the construction market, more and more layers are adjusted to the standard, in order to more conveniently transport the buyer to the construction site.

Glass, which is produced by the extrusion method, can be produced in unlimited size, according to the standard, the material should not exceed 2040 × 3040 mm. Only the requirements of the customer can change such a standard.

How to choose and buy laminated chipboard: leading manufacturers

As mentioned above, each manufacturer puts on the market its own options for the size of chipboard, which is due to the capabilities of its equipment.

Laminated chipboard with a glossy surface

The characteristic dimensions of the Egger laminated chipboard sheet are 2800x2070 mm. This uniform size does not prevent the Austrian company from successfully competing in the European and domestic markets.Indeed, in addition to excellent environmentally friendly raw materials and a huge range of color solutions, it also offers its customers a good selection of board thickness options - 10, 16, 18, 25 mm and even non-standard 19 mm, which also distinguishes its products from competitors.

Unlike the only universal size of laminated chipboard Egger, the Syktyvkar plywood plant offers its customers a choice of 3 sizes of laminated chipboard Lamarty - 2800x2070, 2750x1830 and 3660x1830 mm with a thickness of 10, 16, 18 and 26 mm. Affordable prices, high-quality raw materials and a wealth of color solutions allow Lamarty laminated chipboard to successfully compete for its place in the domestic market with foreign companies.

Related article:

Another Austrian company Kronospan produces laminated chipboard in two standard sizes - 2620x1830 and 2800x2070 mm. At the same time, Kronospan offers a solid selection of slab thickness options (8, 10, 12, 16, 18, 22, 25 and 28 mm), as well as a wide palette of shades, rich textures, durability, environmental friendliness and reliability.

SwissPan produces laminated chipboard in the following sizes:

- 2750x1830x10 mm;

- 2750x1830x16 mm;

- 2750x1830x18 mm;

- 2440x1830x16 mm;

- 2440x1830x18 mm;

- 2440x1830x22 mm;

- 2440x1830x25 mm.

Chipboard of large thickness is perfect for the manufacture of wardrobes, kitchens and bar counters

The products of this company are in great demand among manufacturers of kitchen furniture and wardrobes.

The laminated chipboard of the Nevsky Laminat plant is produced in one size - 2440x1830 mm with a sheet thickness of 8, 10, 16 and 22 mm. The specified size of laminated chipboard sheet 16 mm thick is the most demanded among consumers. Good quality, low price and compliance with European standards, as well as a wider selection of colors and textures, explains the stable demand for its products in the domestic market.

What affects the cost of laminated chipboard boards

The cost of the slab is determined not only by the dimensions and thickness of the chipboard sheet, the price of the material also depends on:

- the quality of raw materials (whether it contains, for example, foreign inclusions in the form of bark, or, on the contrary, is made from the same wood species);

- the amount of harmful substances in the composition;

- whether a decorative coating was used in its production and which one - veneer, paper, melamine film, special varnish;

- the appearance of the finished product;

- country of production.

The edge of the board cut into the required parts must be laminated with a special tape

In the case of laminated chipboard, these factors are somewhat leveled, because only high-quality sanded chipboard sheets are used for manufacturing, without foreign inclusions, and most foreign companies have long since opened domestic production.

The cost of various sizes of laminated chipboard 16 mm

The price for a 16 mm thick laminated chipboard sheet from different manufacturers will vary somewhat. So, to buy Egger chipboard, you will have to pay, depending on the color and decor, from 1913 to 4220 rubles. For comparison, the price for a 10 mm laminated chipboard sheet is 1,762 rubles. (white basic) and 3292 rubles. (halifax oak tobacco). The price for a 16 mm laminated chipboard sheet from the Kronospan company ranges from 1,046 to 2,080 rubles.

The most popular boards for furniture production are 16 mm thick boards.

The price of a sheet of laminated chipboard 16 mm 2750x1830 mm from Lamartie is from 204 to 457 rubles / m2 (on the official website, the cost is indicated per square meter, and not per sheet of chipboard, this should be taken into account when calculating the price). You can buy a laminated chipboard sheet on a moisture-resistant basis from the Nevsky Laminat plant for approximately 1500 rubles

It is not recommended to saw the slab on your own. Considering the peculiarities of the material, its edge will simply crumble and chips will form. True, large construction stores often provide their customers with free sawing and edging as a bonus when buying laminated chipboard.

Manufacturers

The KINPLAST company presents a lighter version of EKOPLAST, in which weight reduction is obtained due to savings in the parameters of the partitions inside the material. Because of this, the thickness of the sheets is slightly different from the standard value. The same manufacturer offers another version of lightweight panels called NOVOGLASS.In this material, the thickness does not differ from the standard one, and the weight is reduced due to the walls and partitions.

Yug-Oil Plast is another largest manufacturer from Russia, producing lightweight panels under the Berolux trademark. These panels differ in typical thickness and weight, identical to the mass of NOVOGLASS panels. But this manufacturer did not stop there and released another material under the Sotalight trademark. Compared to the Berolux model, the Sotalight is even lighter. But the brand "Siberian Greenhouses" from the same manufacturer is the most popular material for substitution among sellers. Many dishonest sellers present it as 4mm thick honeycomb polycarbonate boards, when in fact they are only 3.5mm thick.

Let's sum up

Unfortunately, all manufacturers' panel weights and thicknesses provide the basis for various tricks. Reducing the mass of the material necessarily leads to a decrease in strength and other qualities. Therefore, you should definitely familiarize yourself with the inscriptions on the labels. Although even in this case, it is easy to make a mistake. And even the guarantee of normal sheets of standard properties cannot guarantee you that you will not be mistaken in this kind of tape measure, which is the choice of cellular polycarbonate.