How to calculate the amount of cinder block?

After that, the cube is converted to the selected value and divided by the resulting volume of material. 1 m3 = 1,000,000 cm3 or 1,000,000,000 mm3, then consider a specific example.

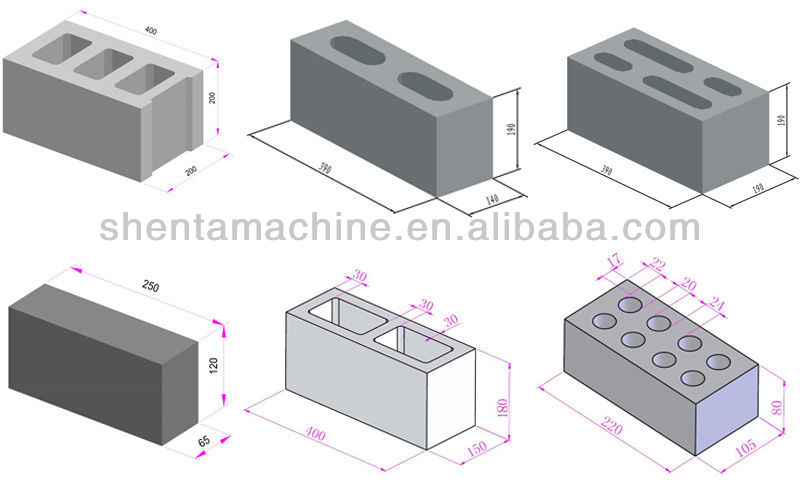

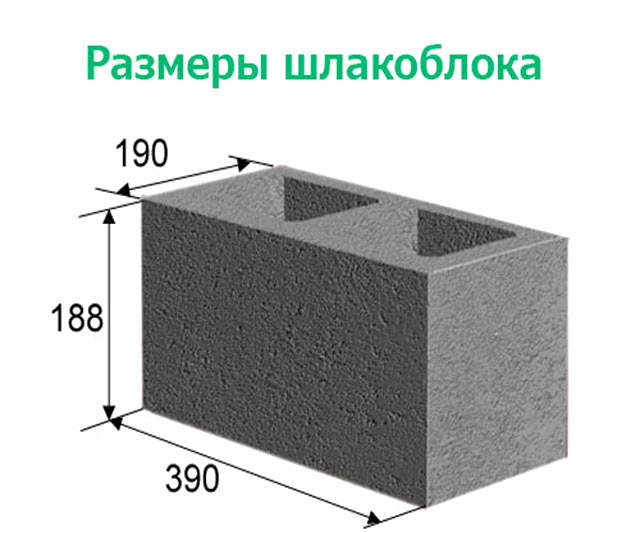

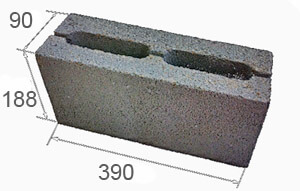

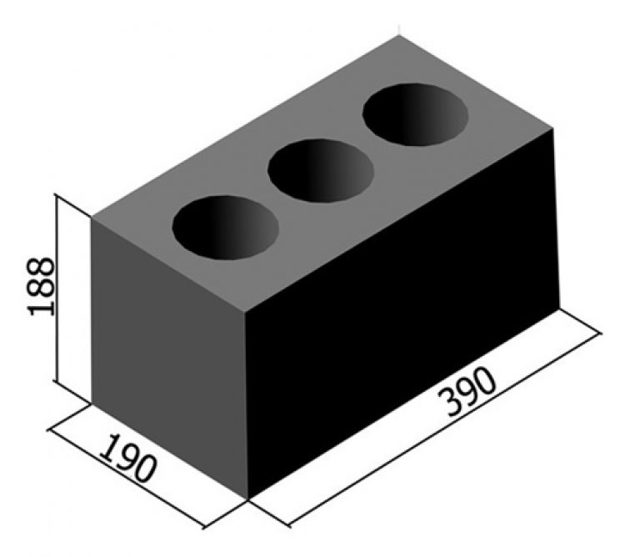

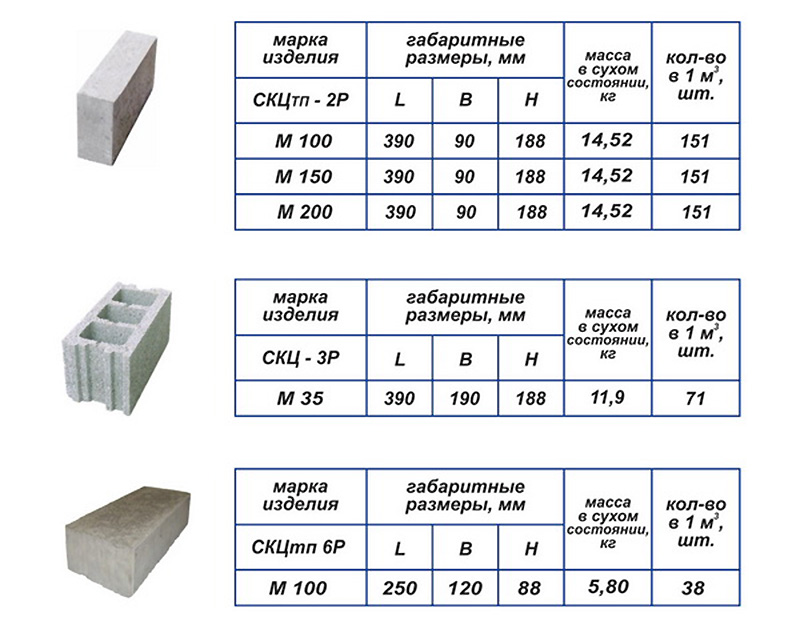

A cinder block for load-bearing walls of a standard size has parameters: 390 millimeters - length, 190 millimeters - width and height. To begin with, let's determine the volume of one block 390 × 190 × 190 = 14079000 mm3. And now let's see how many such products will be obtained in one cube 1,000,000,000/14079,000 = 71 pieces, and the result will be the same regardless of the units of measurement taken.

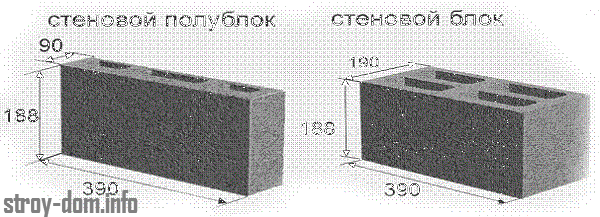

Next, we will determine the number of partition blocks per one cube of volume. It should be noted that such products have a standard size of 39 centimeters in length, 12 cm in width and 19 cm in height. Let's try to calculate in a different way, taking the value of cinder blocks in centimeters. As in the previous example, we calculate the volume of one product 12 × 19 × 39 = 8892 cubic meters. centimeter. And now we find out how many such cinder blocks can fit in one cube with a volume of 1,000,000/8892 = 112 pieces.

When buying any wall materials, you need to take 5-10 percent more. This is due to the possible destruction of blocks during transportation, as well as loading or unloading. It should be noted that in cinder-concrete masonry, a certain volume of the wall will go to the construction of mortar joints, therefore in one cube of the mounted wall there are slightly fewer blocks from the calculated one, although this amount may not be taken into account.

Material history

Residential and public buildings, factory workshops, fences and barriers were erected from cinder block. Many of these buildings have survived to this day in a very satisfactory condition. Previously, cinder blocks were made of concrete, where ash was used as a filler. It could be blast-furnace slag - waste from the metallurgical industry, or the remains of coal formed after its combustion during the operation of boiler houses, power plants, heat and power plants (CHP).

The use of waste for the manufacture of building stone also solved the problem of their disposal. Today, despite the name, ash content in a concrete solution is not considered mandatory. Consists of crushed granite, expanded clay, cullet, broken brick and cement mortar.

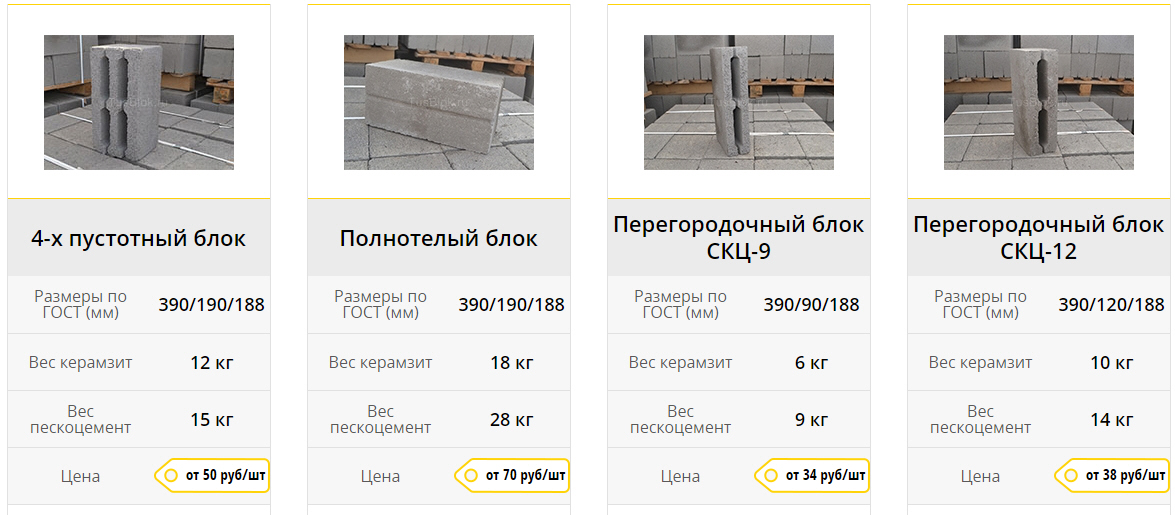

Cinder block weight, characteristics and dimensions, prices

By the weight of one cinder block, its quality is checked. This means that the greater the mass, the thicker the walls and the better the solution is mixed during production in the process of vibration. The degree of hardening also plays a role. The block should stand for about three weeks, previously it should not be used. Experienced builders determine the quality in this way: the stone is weighed, if the indicator has significant deviations from the standard, it is thrown from a height of a meter. A small piece may break off from a properly made block. In the case when it falls apart, it is judged about looseness, which indicates a discrepancy between the parameters.

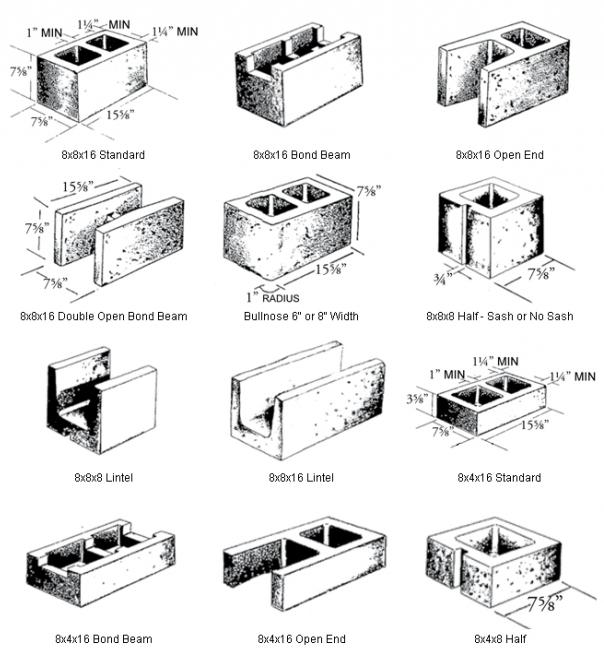

- Varieties of cinder blocks

- Specifications

- Pricing

Main types and parameters

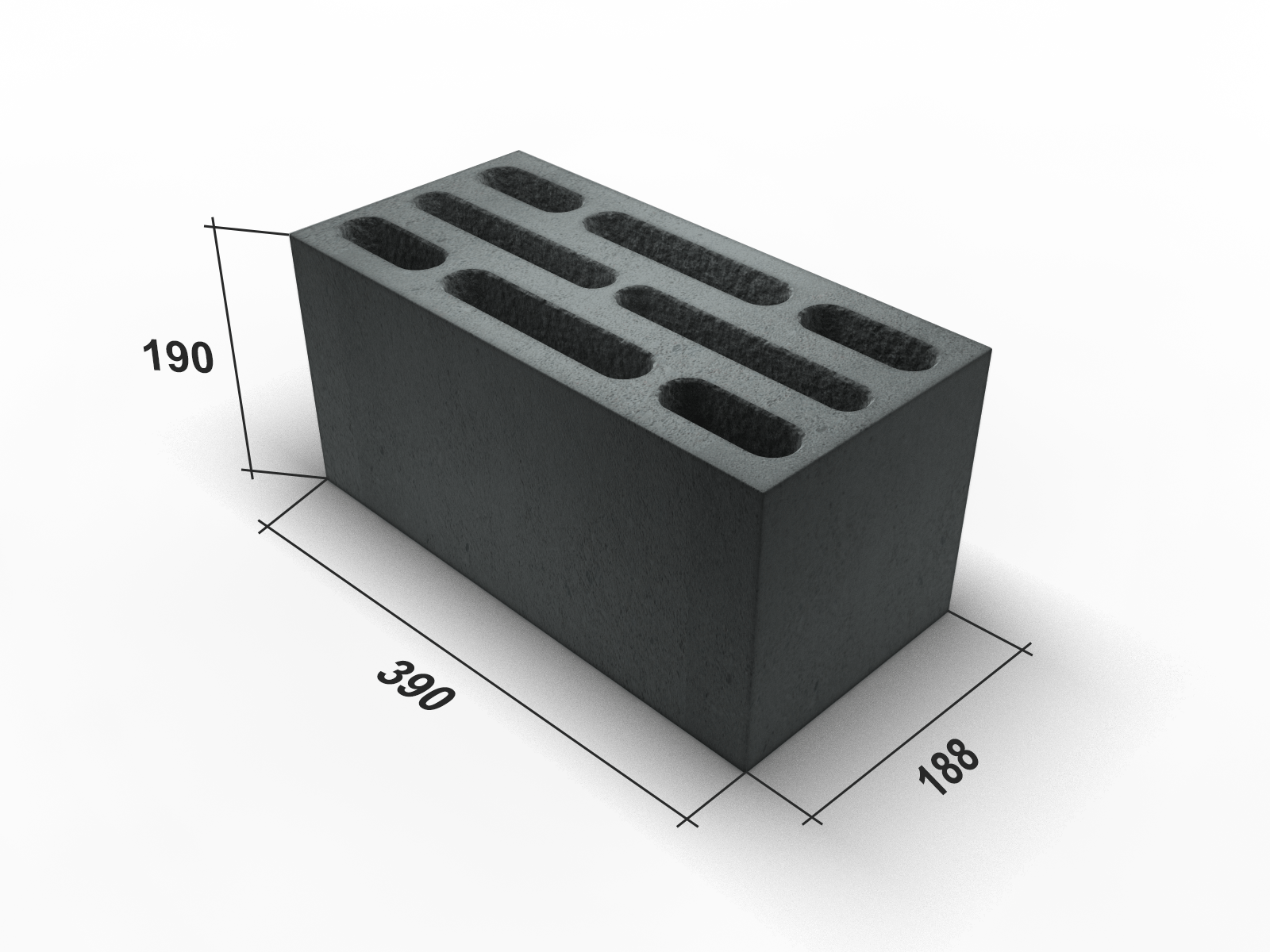

The cinder block size standard depends on the fillers. In addition to blast-furnace or granite slag, sand, pebbles, gravel, crushed stone screening, expanded clay, sawdust are used. Also suitable as a plasticizer are volcanic grains - perlite. The characteristics of each raw material affect the technical characteristics of the cinder block.

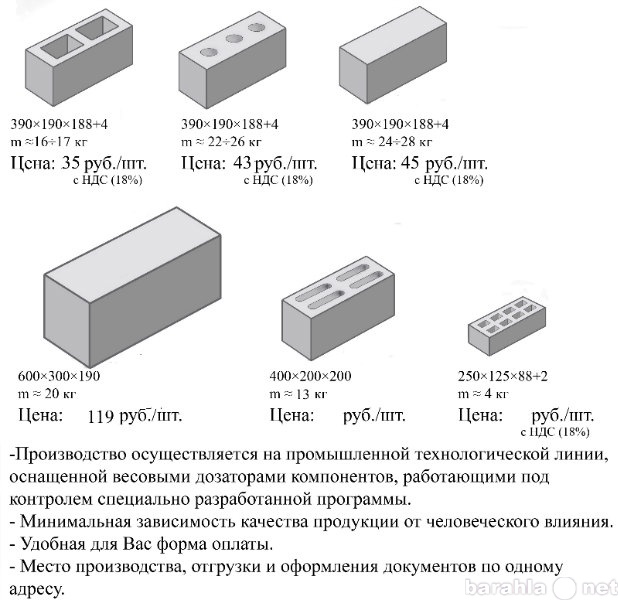

1. Solid stone is suitable for the arrangement of the basement, foundation, supporting structures. Strength is provided by crushed stone, sand and pebbles added to the concrete base before processing on a vibrating machine. Depending on the amount of raw materials, the brand is determined - M100 and M125. The weight of a solid cinder block 390x190x190 is 25-28 kg. It copes well with heavy loads, but is unable to retain heat in the room.

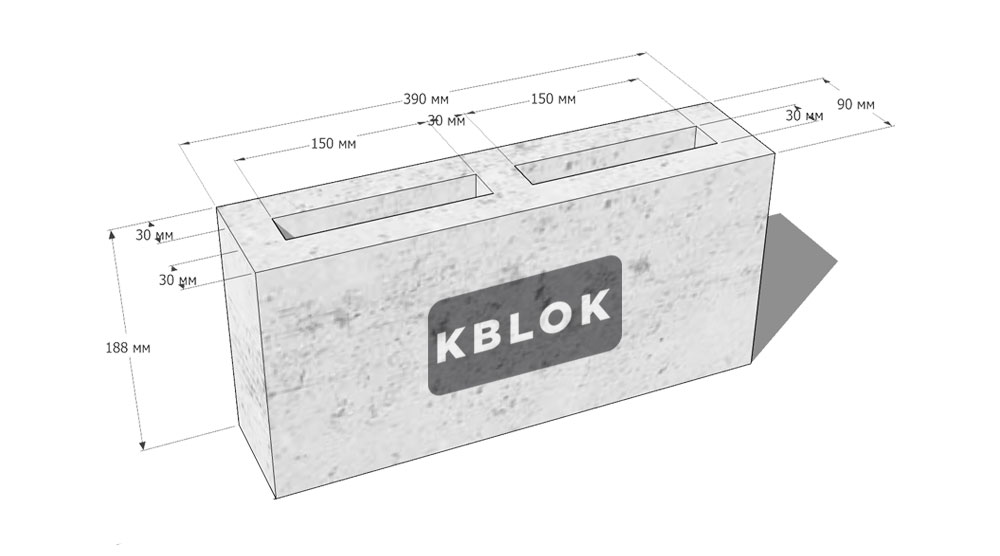

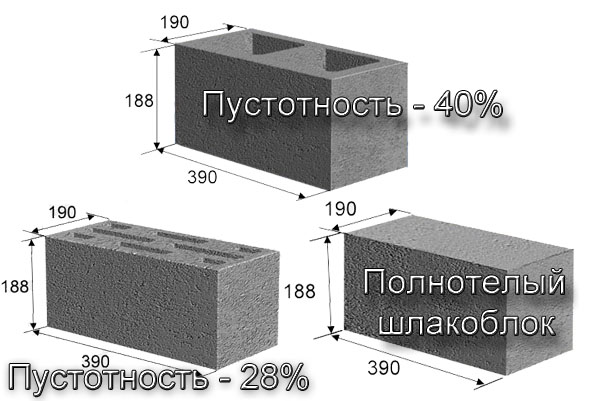

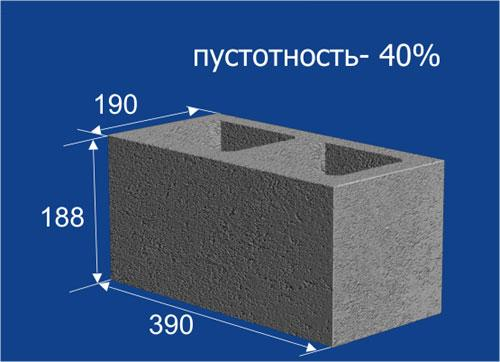

2.For the construction of walls and interior partitions, a cinder block with two or three channels is used, the percentage of which does not change. Here the void index plays a role, from 28 to 40%. Blocks with rectangular internal cavities are easy to cut, which is convenient for installation. Depending on whether expanded clay or sand acts as an additive mixture, the following brands are released for sale: M75 and M50. The weight of a hollow cinder block ranges from 18-23 kg. There are two sizes: 390x120x188 and 390x90x188. Some blocks are made using special shapes to obtain a decorative textured surface.

Stone with a coefficient of 40% has the highest thermal conductivity and low strength. It is used in conjunction with other categories for protection from the cold. The half-block weighs 10-15 kg, the brand is M35. It has two wide channels for plasticizers, which are lightweight mixtures of sand, sawdust, combustion waste.

When calculating the required amount, parameters are taken into account, since the weight depends on its voidness. The preparation of concrete implies the inclusion of plasticizing substances in the solution that provide frost resistance and water resistance. After vibrocompression, blocks are formed, which are laid to dry for at least 10 hours.

In the geometry of the blocks, deviations with an error of plus or minus 3 mm are allowed. In the event of a greater violation, the masonry will be uneven, with seams of different thicknesses. This will lead to difficulties in construction and unnecessary consumption of mortar. Compliance with the production technology ensures simple operation and short construction time. Hand-made production is possible, but the standard of block quality and execution in size is achieved subject to the use of special equipment and a multi-cell form.

Properties and characteristics

In addition to ordinary building materials, a block is produced in a color palette and with an imitation of rock stone or brick. For this, polyurethane molds are used, which allow texturing the side surface, which eliminates the need for additional finishing, especially for facades and plinths. Hollow cinder block 400x200x200 is suitable for the design of sidewalks and pavements.

Pros and cons of the material

The appearance of cinder blocks is directly related to the natural human desire for waste-free production. In the postwar years, production in the USSR developed at a rapid pace. Metallurgical plants are literally overgrown with mountains of slag. Then the decision came to use this waste to create building materials.

Slag served as a filler for a cement-sand mixture. The resulting mass was molded into large "bricks". The finished blocks were too heavy - they weighed 25-28 kg. To reduce weight, voids were made in them. Hollow specimens were slightly lighter - from 18 to 23 kg with standard dimensions.

The name cinder blocks is still used today, although not only slag, but also other components are used as fillers. In modern blocks, one can find granite screenings or crushed stone, river gravel, broken glass or expanded clay, volcanic mass. Small business is most often engaged in the release of cinder blocks. Small private enterprises produce building blocks on vibrating machines, filling several forms with a cement mixture at once. After molding and tamping, the "bricks" gain strength for at least a month.

Cinder blocks are endowed with certain advantages and disadvantages.

- The advantage of block building material, first of all, is its low cost. That is why the material is in great demand.

- This building material also has other positive characteristics. For example, blocks do not change their size after laying out. The structure will not shrink, which means that the design calculation will not be adjusted during the construction process.

- The strength and hardness of the "big brick" determine its service life.This is no less than 100 years! Durability is not calculated, but time-tested. There are many buildings of the middle of the last century that "stand firmly on their feet." The houses did not lurch or crumble, only the facades require cosmetic repairs.

- Blocks react poorly to ultraviolet light and temperature extremes. The material is not edible for rodents and insects.

- Due to the increased size, construction is proceeding at a rapid pace. Much less masonry mix is used for laying blocks than, for example, for a brick wall of similar dimensions.

- Street noises are not audible behind the cinder block wall, because it is capable of absorbing sounds.

- Finally, if you have simple equipment and desire, the blocks can be made at home, which will further reduce the cost of construction.

The disadvantages of a building material are no less than advantages.

These include the following characteristics.

- Nondescript appearance.

- Problematic of fastening to walls due to voids in the body of the block.

- The need for cladding to make the structure attractive and protect the building material from the effects of external moisture.

- Fragility. If dropped during work, during transportation or loading, the unit may break.

- High thermal conductivity. Without additional insulation, the structure retains heat poorly.

- Wide tolerance limits. Dimensions may differ significantly from the nominal value.

Weight of one cinder block

The mass of the cinder block directly depends on its actual volume: the stone can be full-bodied or hollow. There are three categories of slag wall stones on the market, so we will bring each group into a separate weight category:

- Corpulent. The absence of voids increases the strength of the cinder block, but makes it much heavier. Such stones can be used for load-bearing walls and foundations, their weight varies between 25-29 kg.

- Hollow. Such a stone is usually used only for the construction of walls, including supporting structures. The weight of one piece is 12-23 kg.

- Semi-block. In such a stone, voids prevail, so the material is used only for interior partitions. Cinder block weight: 9-13 kg.

According to GOST 6433-99 "Concrete wall stones", the density of hollow cinder blocks should not exceed 1650 kg / m3, and full-bodied - no more than 2200 kg / m3.

Naturally, in addition to the% of voidness and density, the size of the stone also affects the mass of the stone, therefore the large-sized cinder block 200 200 400 will have the greatest weight.

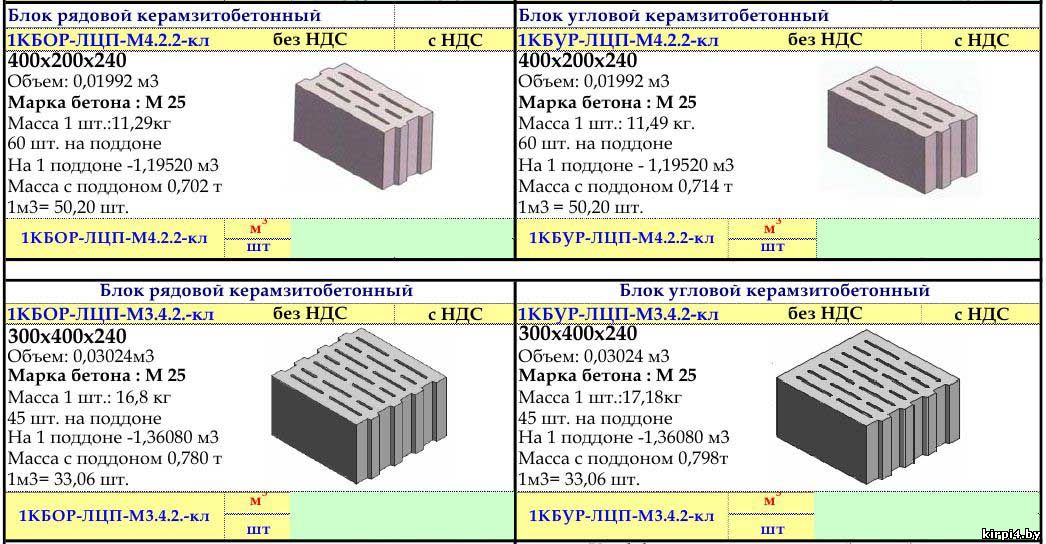

| The size | Block composition | Emptiness,% | The weight | Note |

| 390x190x188 | Sand-cement | 40 | 10 | Open bottom |

| 390x190x188 | Sand-cement | 40 | 12 | Closed bottom |

| 390x190x188 | Expanded clay concrete | 40 | 10 | Closed bottom |

| 390x190x188 | Sand-cement | 30 | 14,5 | Closed bottom |

| 390x190x188 | Sand-cement | 28 | 16 | Closed bottom |

| 390x90x188 | Sand-cement | 30 | 10 | Two-hollow |

| 390x90x188 | Expanded clay concrete | 30 | 9 | Two-hollow |

| 390x190x188 | Sand-cement | — | 28 | Corpulent |

| 390x190x188 | Expanded clay concrete | — | 25 | Corpulent |

| 400x200x200 | Sand-cement | — | 29 | Corpulent |

| 400x200x200 | Expanded clay concrete | — | 26 | Corpulent |

Cinder blocks pros and cons.

The pluses of the blocks include:

- durability and strength;

- resistance against fungi and rodents;

- fire resistance;

- rather low thermal conductivity (especially hollow);

- light weight and increased dimensions, allowing you to quickly build;

- variety of forms of blocks and voids in them;

- simplicity of manufacture allows to set up production outside the factory.

Along with the advantages, the blocks also have the following disadvantages:

- low level of noise absorption;

- high level of water absorption;

- high thermal conductivity (full-bodied products);

- it is difficult to carry out communication through them.

These disadvantages explain their frequent use for the construction of ancillary buildings (garages, summer kitchens, etc.), as well as an inexpensive facing material, curbstone and paving slabs.

What deviations are allowed in the production of cinder blocks

Blocks that have the following flaws are not subject to implementation:

- deviations of length and width are more than 3, and heights are more than 4 mm;

- the curvilinearity of the horizontal edges is more than 3 mm, and the vertical ones - 2 mm;

- the depth of the shells exceeds 4 mm;

- sagging and depressions more than 2 mm;

- chips on the edges of more than 5 mm in depth with a length of more than 50 mm.

Independent production of cinder blocks

Handcrafted amateur builders get by with cinder blocks made on their own directly at the construction site. To do this, they need shape and materials (water, cement and fillers). Construction waste (fragments of bricks, glass, etc.) is often used as the latter. This construction method saves significant funds.

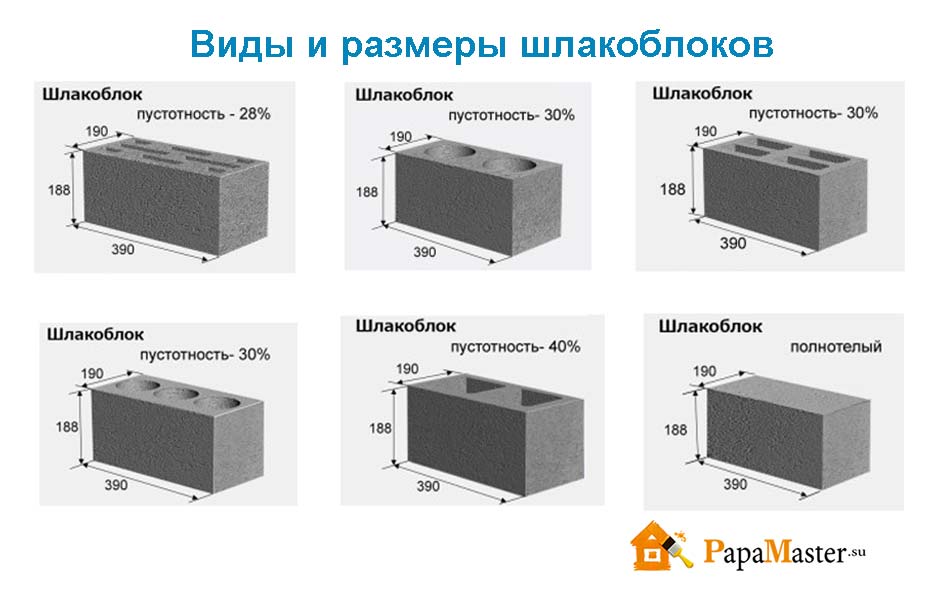

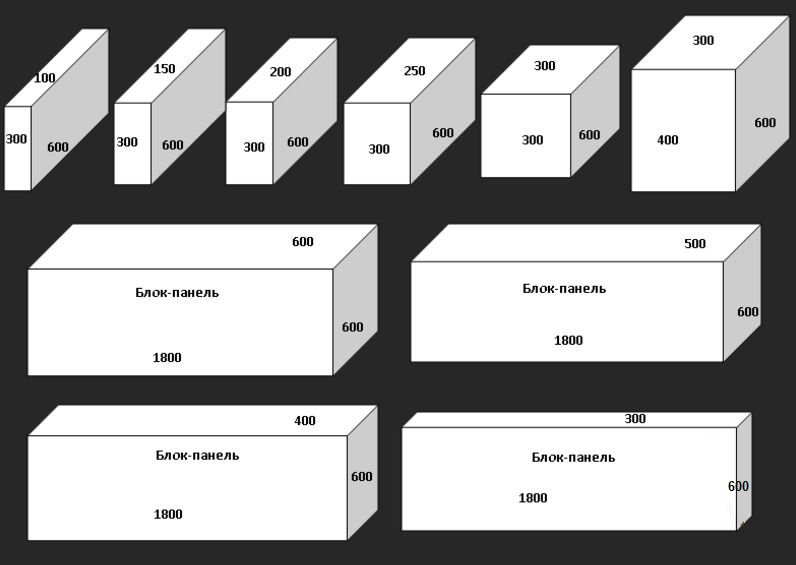

Cinder block size: standard and required amount for construction

Knowing the height of the cinder block, as well as other standard material parameters, you can easily convert these values into m³. It is much more convenient to use this unit of measurement, since the amount of cinder block required for construction is usually calculated, in m³.

To calculate the required number of blocks, there are special formulas and calculators

When starting construction work, it is extremely important to correctly and accurately determine the right amount of material. Since the standard parameters of cinder blocks differ from the sizes of the usual bricks, the calculations also take place according to a completely different scheme.

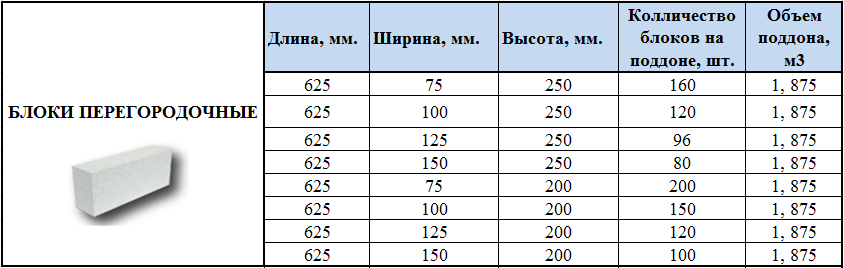

First of all, you need to know how many cinder blocks are in the cube. In order to calculate the volume of each unit, the width, height and length of the building material should be multiplied in cm. Further, 1 million cm³ must be divided by the resulting number. As a result, it will be possible to determine how many cinder blocks are in one cube. There are usually 72 standard cinder blocks in one m³.

Many believe that one pallet of cinder-concrete blocks is equal to 1 m³. This is a misconception that often leads to errors during calculations. A standard pallet holds 60 stones, which is slightly less than 1 m³.

Knowing the exact dimensions of the cinder block, it is easy to calculate the required amount

Calculation of the amount of material, dimensions of cinder blocks and prices

During construction, it is important to know how many blocks are needed for 1 m². In these calculations, the wall thickness plays an important role.

For example, for the construction of 1 m² of a wall, the thickness of which is equal to half of the whole block, you will need 13.6 pieces. If the wall is formed into a whole block, the amount of material should be doubled, that is, 27.2 stones will be needed. It should be borne in mind that in practice fewer blocks are required, since the thickness of the mortar joint is not taken into account during the calculations.

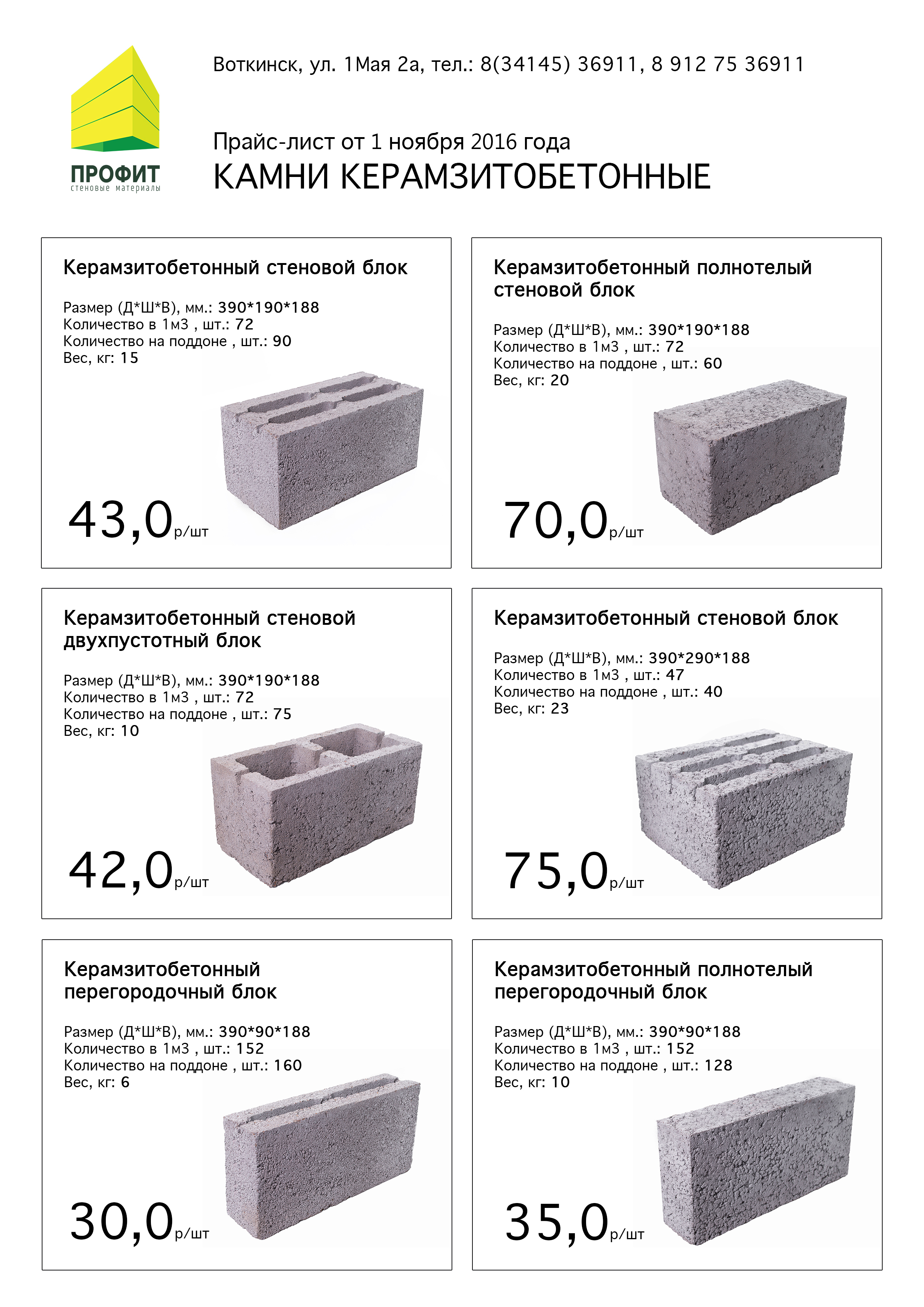

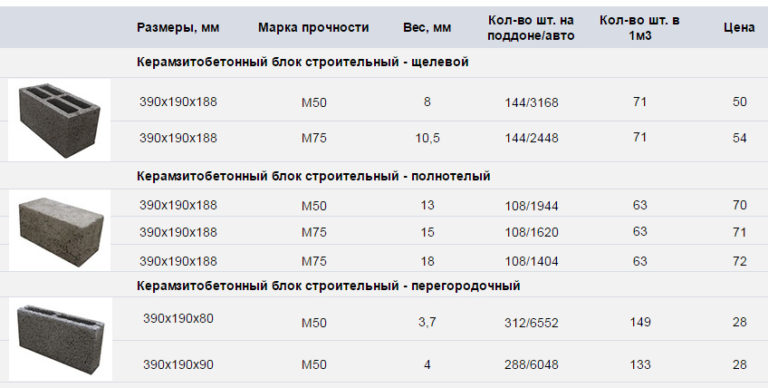

As for the cost, the most expensive are the basement and foundation blocks M100-125. Wall and partition stones M50-75 are a little cheaper. Thermal insulation products are budgetary, but their strength is low - M35.

Table of sizes and prices for cinder blocks of different types and brands:

| View | Size, cm | Brand | price, rub. per piece |

| Corpulent | 40x20x20 | M50 M75 M100 |

27 30 34 |

| Full-bodied with expanded clay | 39x19x19 39x9x19 |

M75 M50 |

43 27 |

| Two-hollow | 38.8x19x18.8 | M75 | 35 |

| Three-hollow | 39x19x18.8 | M50 | 31 |

| Four-hollow | 39x19x18.8 | M75 | 28 |

| Partition hollow | 39x12x19 39x9x18.8 |

M75 M50 |

26 17 |

| Decorative | 39x19x18.8 | M75 | 65 |

It should be noted that the price is approximate, since how much one cinder block costs is influenced by a lot of factors, including the manufacturer, and the cost of the expanded clay concrete block is twice as high as the price of a cinder block.

How to make the right choice

What should you look for when purchasing a piece cinder block stone? You need to use the services of certified manufacturers. This approach can fully guarantee the high quality of the building material.

It is also necessary to inquire about the exact composition of the starting ingredients, the environmental certificate of suitability for use in residential construction.

It is advisable to familiarize yourself with the laboratory test protocols, find out strength characteristics such as frost resistance, weather resistance, water resistance.

An external examination is required. The product must have the shape of a regular parallelepiped. The dimensions of the edges should not differ by more than 1 ... 2 mm, both on one stone and on any other randomly selected one from the proposed batch. The concrete on the outer surfaces must be smooth, without any traces of looseness or underworking. The voids must be symmetrical and in no case connected with the outer planes in the form of cavities.

Advantages and disadvantages of cinder block

The advantages of this wall material include:

- Relatively low price of the product.

- Due to the large size of one block, the construction time is significantly reduced, which means that the cost of work becomes cheaper.

- The masonry technique is simple, you can do it yourself, yourself.

- Varied composition of concrete aggregate. You can always choose the material that suits you in terms of its characteristics.

- Long service life. The standard operating time is 100 years.

- Using a decorative cinder block, you do not need to spend money on plaster or facing the building.

- High sound insulation. Like any concrete, cinder block absorbs sound.

Disadvantages of cinder blocks:

- Heavy weight of some types of products.

- Unsightly appearance. If it is impossible to buy a decorative cinder block in your area, then it is difficult to find a master who can beautifully lay out this wall stone.

- After the accident at Chernobyl, they began to treat this product with caution. There were, and even now, there are many rumors that the results of his radioactivity test are unpredictable, and the presence of a bouquet of elements of the Mendeleev system in the blast-furnace slag can be potentially hazardous to health.

But whoever is forewarned is forearmed. And this very significant (maybe hypothetically) drawback can always be counterbalanced with the advantage of # 4.

The main thing is to take a responsible approach to the choice of the manufacturer. Find out on what equipment it works, how the production technology is being followed, what kind of filler it uses, and where it comes from.

Cons of cinder blocks

But, despite such a number of advantages, cinder blocks have their own disadvantages, which you should also know about when choosing this material for the construction of buildings.

- the characteristics of blocks in the same batch can vary significantly when made at home;

- if the material of the filler of the blocks is subject to destruction (for example, sawdust), then the actual service life of the walls made of such material may be lower than the calculated one;

- when buying industrially produced cinder blocks, you can purchase material that is not environmentally friendly - production waste can emit harmful substances;

- cinder blocks are rather difficult to plaster due to poor adhesion of the plaster to the material of the blocks;

- blocks are subject to destruction under the influence of freezing moisture penetrating into the pores of artificial stones (when erecting walls from cinder blocks, it is recommended to install cornice overhangs of sufficient length with gutters for drainage of rainwater and a reliable blind area around the perimeter of the walls).

As you can see, there are also disadvantages. But for the construction of a bath, a garage or small utility rooms, they are not decisive, and cinder blocks are quite suitable for the construction of their walls. Therefore, one should not be afraid to opt for this material if a comparison of the cost of construction shows that construction from cinder blocks will be cheaper than brick walls or the construction of a log house.

How many cinder blocks in a cube

With such dimensions, 3 × 5 = 15 blocks will fit in one row on a pallet.

It is known that the weight of a hollow cinder block corresponds to 13 kilograms, a full-bodied 20 kilograms.From this value, it can be determined that the mass of one row of products will be the next 15 × 13 = 195 kg. Taking this value into account, you can find out that the maximum number of rows on a pallet will be no more than five 1000/195 = 5, therefore there will be 5 × 15 = 75 pieces of such cinder blocks in one pallet.

Now let's deal with solid blocks. As we have already said, the mass of such a product corresponds to 20 kilograms, so one row will weigh 15 × 20 = 300 kilograms. This means that no more than three rows of such products can be stacked, which is 3 × 15 = 45 pieces of cinder blocks in a pallet.

Home »Materials for giving.

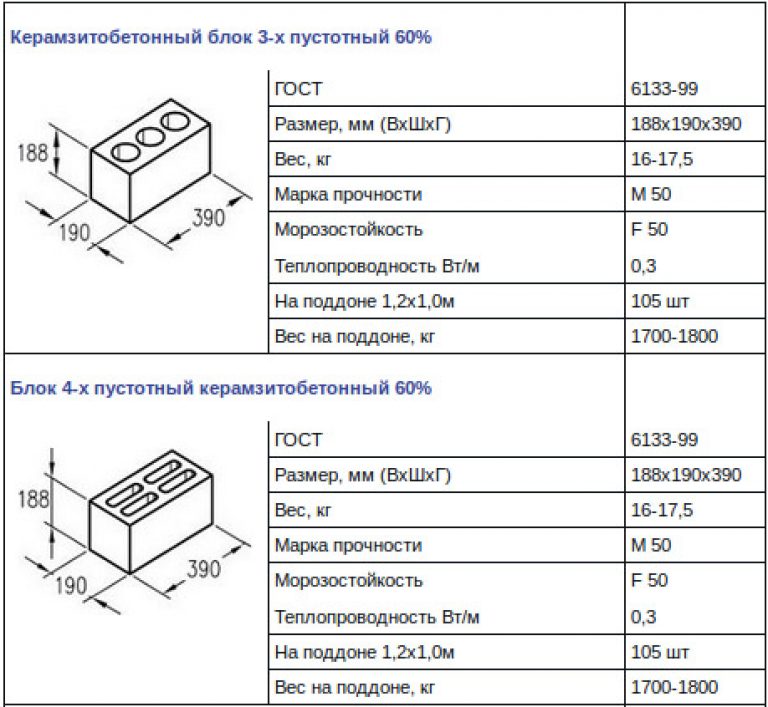

Unit specifications

Along with the dimensions, its technical characteristics, which are spelled out in GOST 6133-99, are of great importance.

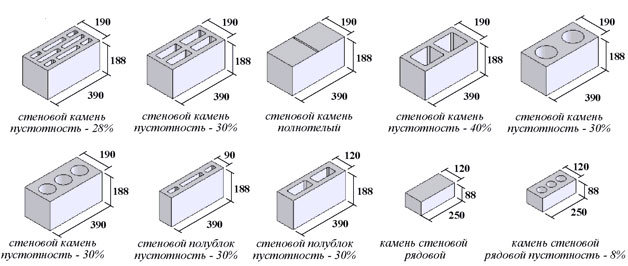

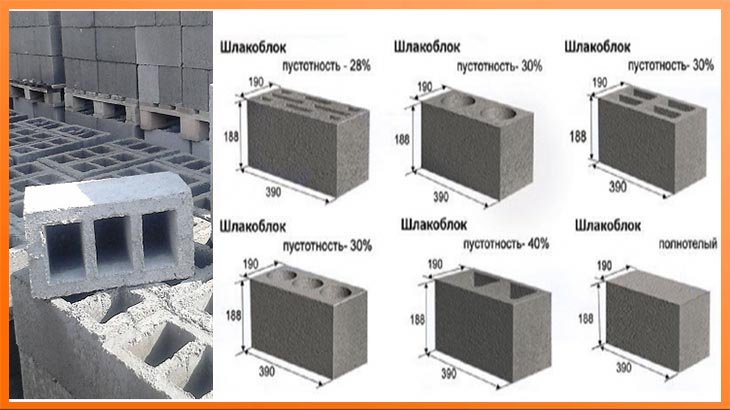

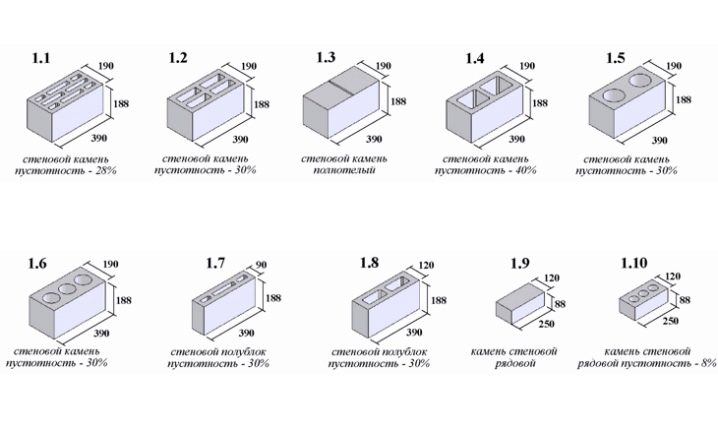

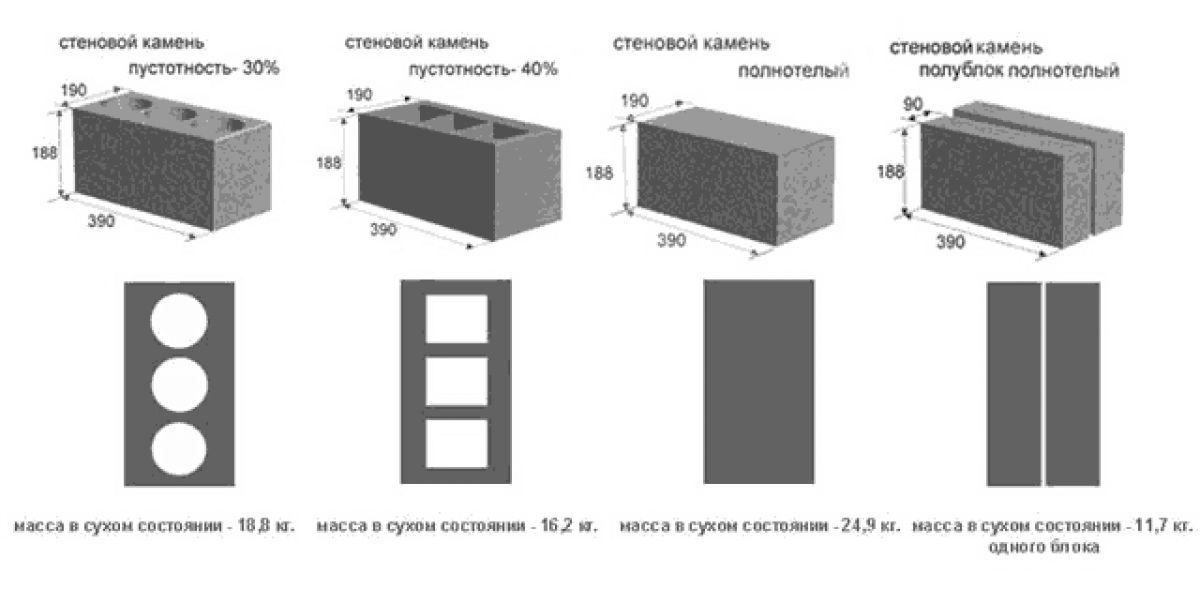

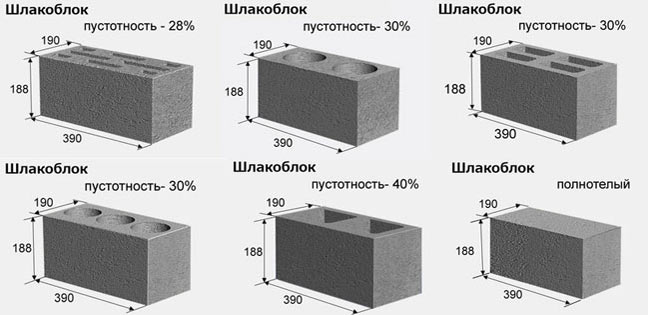

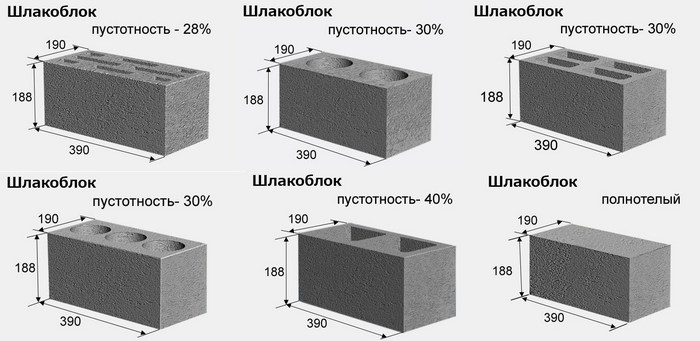

Emptiness

This indicator is understood as the total volume of cavities (in% of the total volume), which are empty spaces of a certain shape. In accordance with this, there are 2 classes of products:

- Hollow (voids are from 30 to 40%).

- Corpulent - does not contain any cavities.

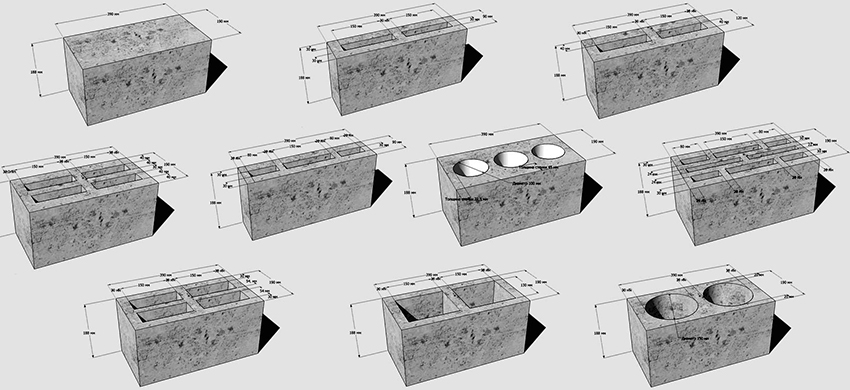

In this case, the unfilled parts can be of different shapes, which can be clearly seen in the diagram.

The weight

The weight of the block is determined by its dimensions and the presence of voids. Accordingly, there are 3 types of products (see table).

| Class | dimensions, mm | Weight, kg |

| corpulent | standard | 25-28 |

| hollow | 18-25 | |

| slag half-block | 390*120*188 | 10-15 |

Strength

The strength of this material is defined as the ultimate load (in kilograms) that 1 square centimeter of the surface of the finished product can withstand (kg / cm2). Expressed as an indicator of brand strength:

- M35;

- M50;

- M75;

- M100.

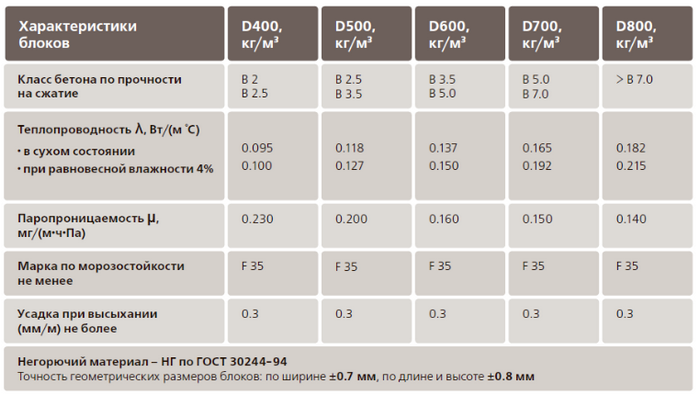

For example, the M75 can withstand the maximum pressure of 75 kilograms per square centimeter, and the M35 - 35 kg / cm2. The strength of the product directly depends on its composition, which can be clearly seen from the table.

Thermal conductivity

The indicator is defined as the amount of heat that a 1 meter thick cinder block passes through when the temperature difference between the outside and inside the building is 1 degree Celsius. Accordingly, it is measured in W / (m * oC).

The thermal conductivity coefficient of the finished product is rather low among building materials and ranges from 0.27 to 0.64 W / (m * oC). For comparison: for concrete, this figure is about 1.25-1.75, for stone, 1.45.

Low thermal conductivity is associated with voids that contain air. It conducts heat very poorly, respectively, the heated medium with difficulty gives off excess heat to the outside.

Consumer qualities and advantages of the cinder block

Along with the dimensions and its other technical parameters, the consumer qualities of the material are also interesting, which make it possible to choose it correctly for the construction of a particular structure:

Types of building blocks

There are several types of block products, each of which has its own special characteristics and performance.

There are several types of block products, each of which has its own special characteristics and performance.

There are several types of block products, each of which has its own special characteristics and performance.

- The cinder block is solid or monolithic - a fairly durable material. Scope - construction of load-bearing structures: foundation elements, construction of the basement. The weight of such a product is about 28 kg, and the dimensions are 390 * 190 * 190. It perfectly withstands any load, but does not retain heat well.

- The hollow cinder block has high thermal insulation properties, the field of application is the construction of partitions and walls. The product itself is quite light, weighing no more than 22 kg. The lightness of the product is due to the large number of voids.

- A lightweight block with two large cavities filled with sand, sawdust and other lightweight materials added in the right proportions. The level of voidness is 40% according to GOST, weight is about 15 kg, dimensions are 400 * 200 * 200 mm. The scope of the product is insulation of structures.

- The partition product has two or three recesses, and the main distinguishing feature is the presence of a rectangular void, which makes up 30% of the total volume. Product weight is 13 kg, size 90 * 90 * 188. Scope - the device of interior partitions.

- Foundation type or wall artificial stone, used for laying the foundation. It is able to protect the foundation from negative influences, the material itself does not crumble and does not give strong shrinkage.

- Colored blocks are used in the construction of fences or for decorating structures. For its manufacture, a crushed red brick mixture is added.

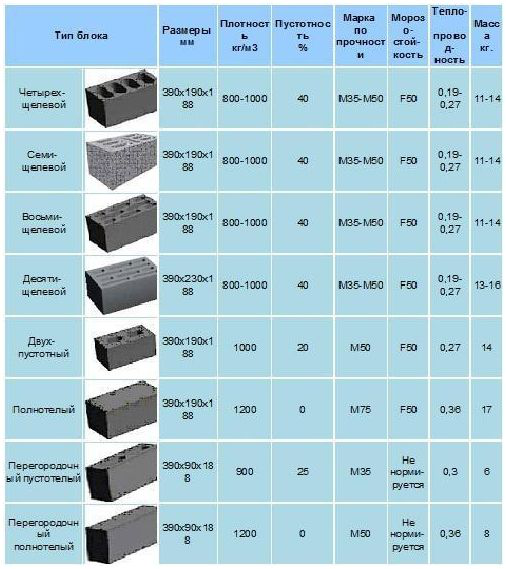

The photo shows the characteristics of products, taking into account the level of voidness and dimensions

Characteristics of products, taking into account the level of voidness and dimensions

Characteristics of products, taking into account the level of voidness and dimensions

The process of manufacturing the material is carried out strictly according to the requirements of GOST and is divided into three important stages:

- using a concrete mixer, the components are mixed in the right proportion;

- the finished solution is placed in wooden molds, to give strength and remove unnecessary voids, use vibration treatment;

- thanks to special additives, it is possible to shorten the drying time of the block, the production time is 96 hours.

The temperature regime for storing the material is no more than 20 degrees, while the room should be with high humidity.