Description and types

For the production of standard bricks, clay is used, which is immediately mixed with water. The mixture is then necessarily fired at high temperatures. It is from it that irreversible chemical processes are formed.

When buying a standard brick, you need to pay attention not only to the indicators of its quality, but also to the type, size and manufacturer. Thanks to the combination of all the criteria, the brick stands out with its individual characteristics, which directly affect the performance

In addition to its improved characteristics, standard brick stands out for its long service life and strength. As a result, builders may not worry about the quality and durability of the erected structures. That is why facades of such a plan are rarely repaired.

Solid brick is actively used in the construction of load-bearing and reinforced structures, construction of the base, stove and fireplace.

Corpulent

It is highlighted with the symbol "M": 075, 100, 125, 150, 175.

M-150

With regard to frost resistance, it is within 50.

Refractory cladding

This standard brick is specially manufactured for the purpose of finishing and masonry of stoves.

In addition, it is able to maintain all of its performance even at the highest temperatures. There are standard bricks that are resistant to high temperatures, of the following types:

based on quartz and carbon;

Quartz

fireclay. Here is its size;

Chamotny

When buying such material, be sure to pay attention to the presence of the marking. The number will correspond to the fire resistance of the brick

Refractoriness

As a rule, this marking corresponds to the letter W. Technological features of conventional bricks for cladding:

- frost resistance - 50;

- heat conductivity - 0.8-0.95;

- the presence of voids - 7%;

- moisture absorption level - 8%.

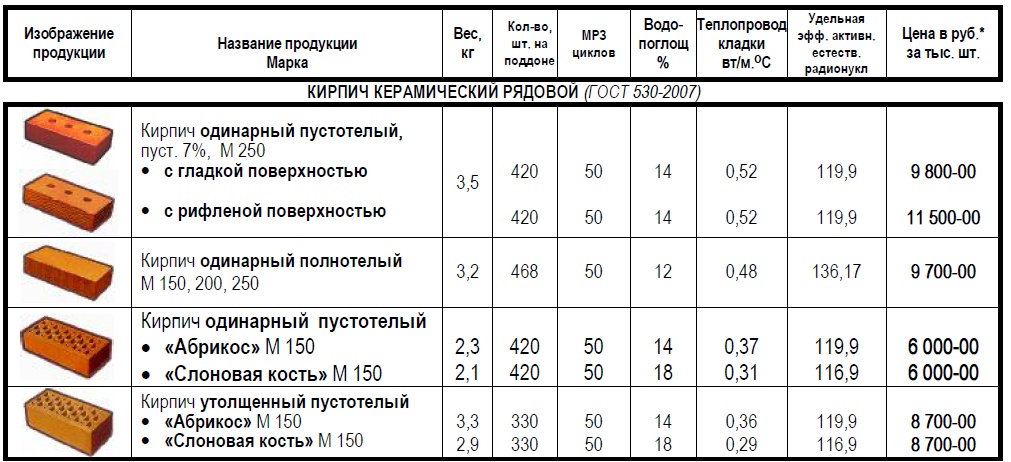

Ceramic

This red brick cannot be replaced during foundation work, because it stands out for its maximum strength indicators.

Here are its pros and cons. At the same time, different brands of product strength are distinguished, which start at 150 and end at 300.

Ceramic briquettes are distinguished by the following technological indicators:

- frost resistance: from 50 to 100;

- moisture absorption: from 5-15%;

- heat conductivity: from 0.70 W / (mK);

- the presence of voids: no more than 13%;

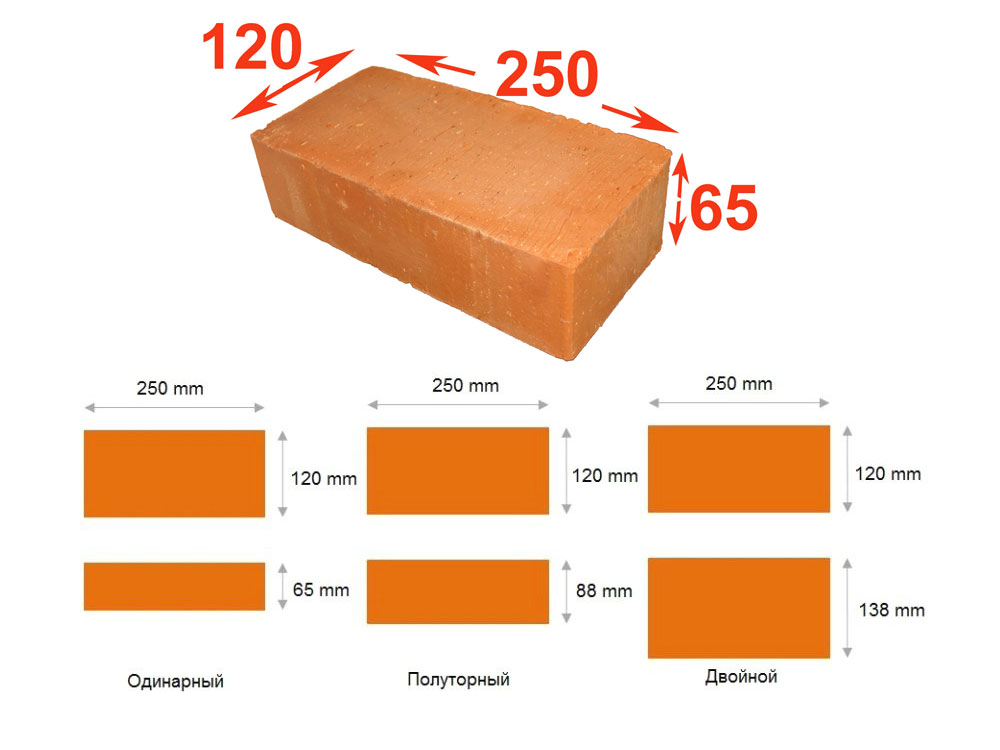

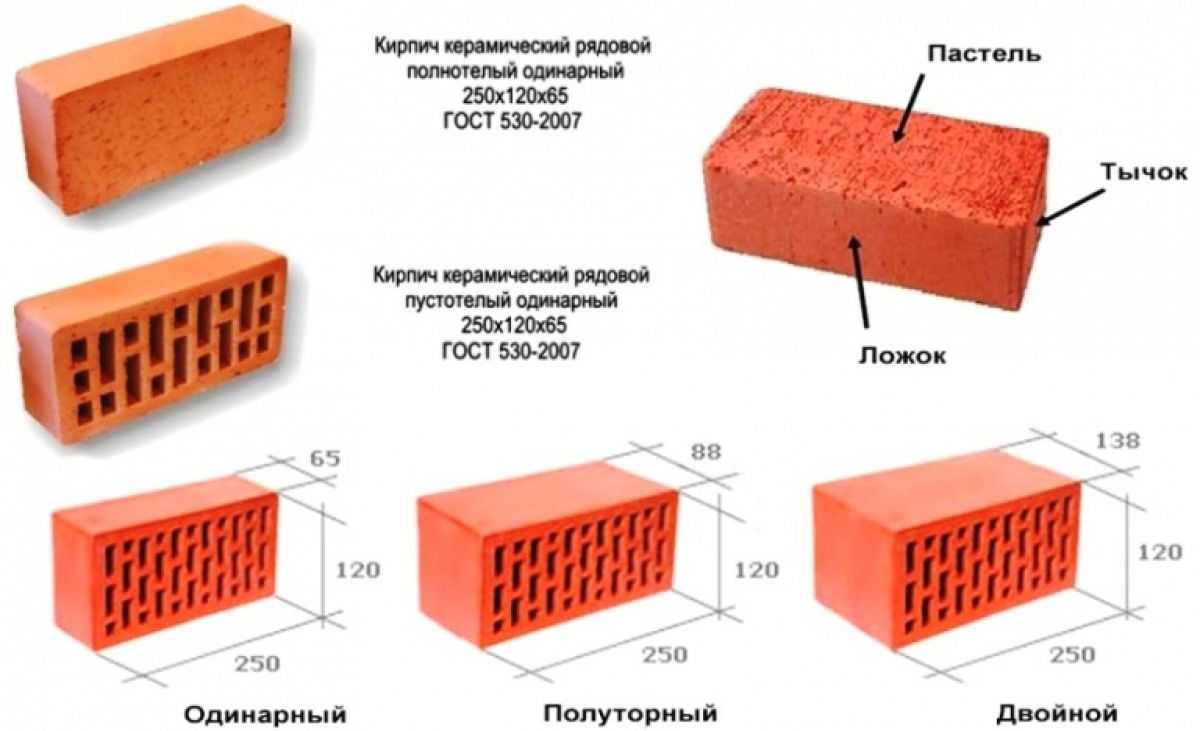

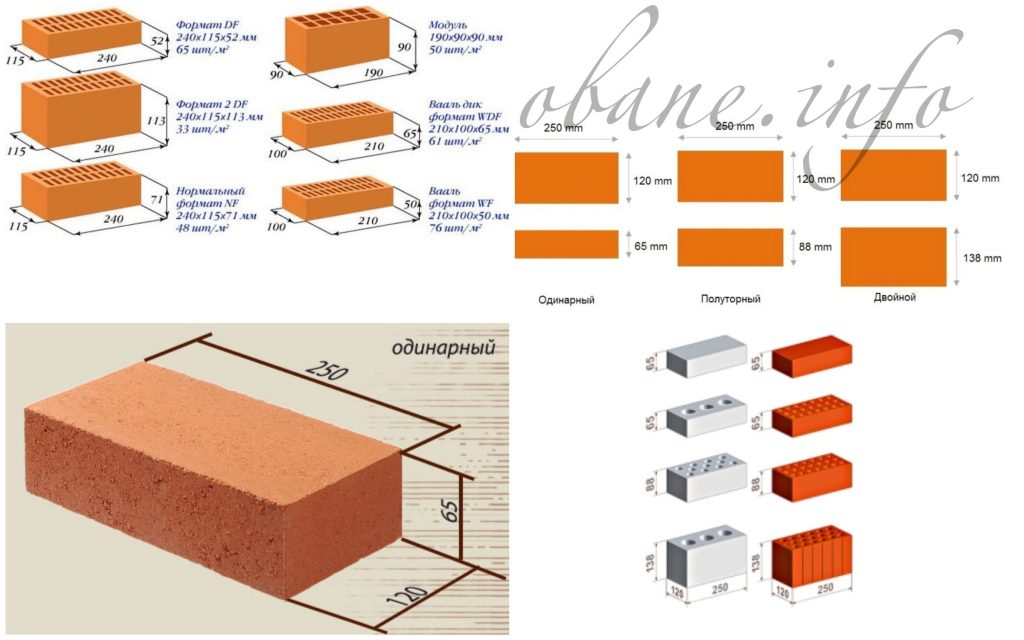

Red brick size:

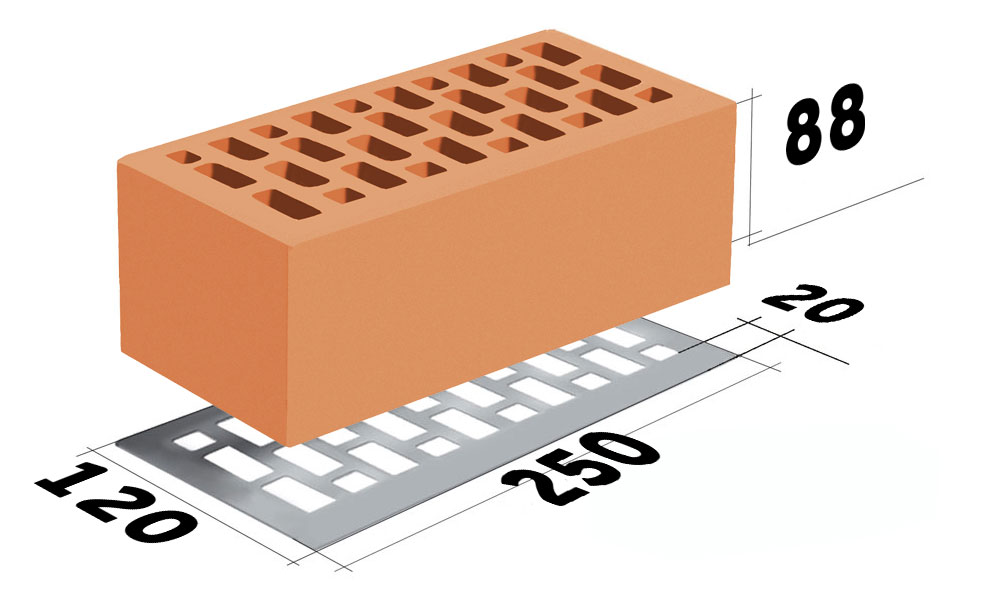

single standard size: 250x120x65mm;

Standard

one and a half corresponds to the same dimensions, but its length is 88mm;

One and a half

double 250x120x138mm;

Double

euro brick has dimensions of 250x88x65mm;

Eurobrick

modular: 288x138x65mm.

Modular

Double red brick is popularly called this type "loaf", its weight reaches 7 kg

If you pay attention to the strength indicators, then this material significantly exceeds the options that were described above.

Technical features include:

- frost resistance 150;

- moisture absorption 11%;

- conducts heat 0.50 W / (mK);

- the presence of voids up to 13%.

Specifications

Basement

This material should not be inferior in strength to its ceramic counterpart, but in addition, the basement brick should retain heat as much as possible and resist the appearance of condensation. In terms of strength, it can be of two types: 125 and 150. For basement rooms, the best option is solid ceramic briquettes.

Basement

In this case, such brands "M" are popular: 200, 250, 300.

Plinth briquettes are distinguished by the corresponding technological characteristics:

- frost resistance 100;

- moisture absorption 12%;

- thermal conductivity 0.51 W / (mK);

- the presence of voids 13%.

Read about the dimensions of the basement brick.

Stove

To use the material in question for laying the stove, it is rational to use heat-resistant and most durable types. Here is the size of the oven brick.

Bake

To date, for the implementation of these goals, briquettes are used that fully correspond to the sizes:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

In addition, when buying a standard or any other type of red brick, you should pay attention to its quality. For more information about the dimensions of the oven brick, see the video:

For more information about the dimensions of the oven brick, see the video:

What is considered a marriage?

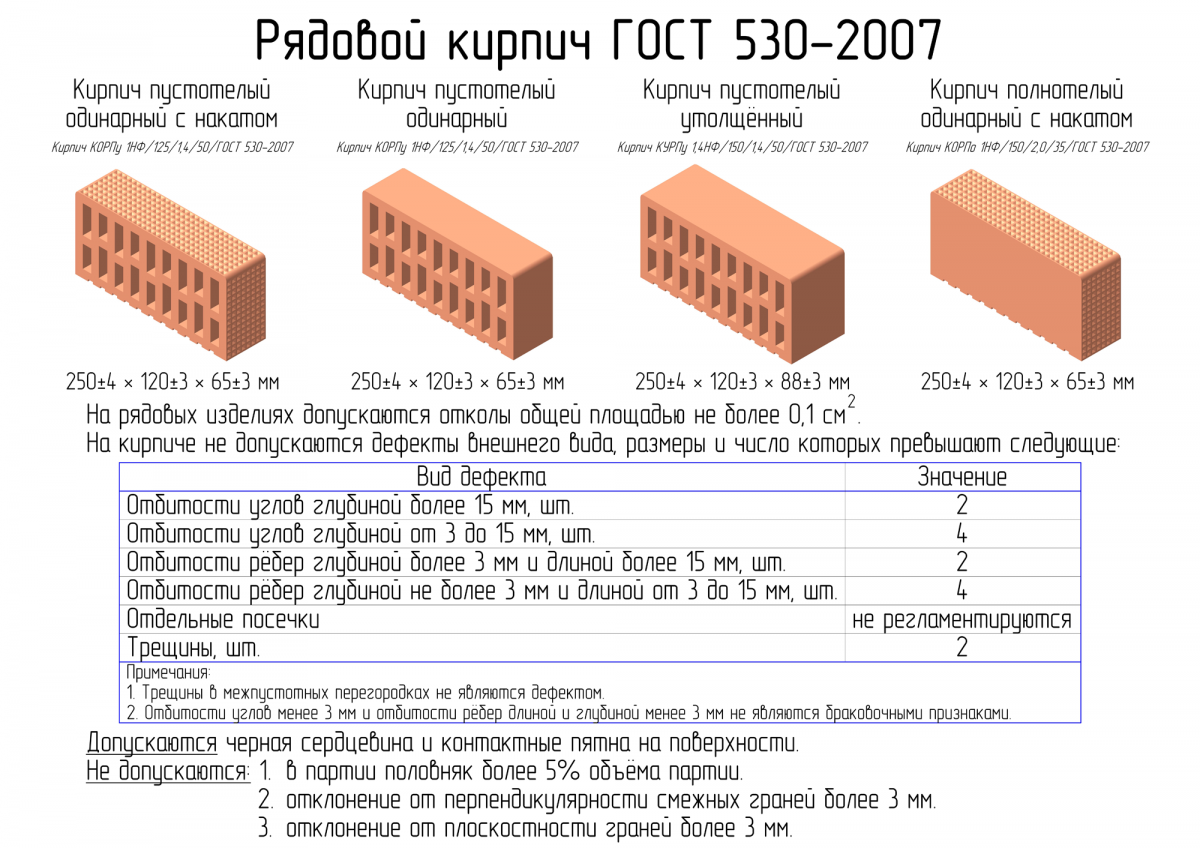

In addition to the listed types of bricks, defects can also affect the dimensions. In GOST, the permissible deviation rate is established at which significant deformation of the structure will not occur.

The standards provide less stringent requirements for building bricks, the facing option should practically not have deviations, at least noticeable to the eye. This is due to the purpose of the application, the aesthetic component is impossible with unequal sizes.

So deviations in the facing brick of more than the following parameters are not allowed:

- the presence of chips at the corners that take more than 15 mm;

- cracks, any of which are a sign of deformation and soon failure;

- ribs that are beaten off by more than 3 mm in width and 15 mm in length.

Such material is scrapped; it is not considered suitable for building cladding. At the same time, a facing brick is considered within the normal range, where the dimensions can be any, for example, 250x60x65, but the deformation is less than the requirements described below:

- the corner is broken off the brick, but the area of the defect is no more than 15 mm, while such deformation can be observed only at one of the corners;

- in total, the length should not lose more than 40 mm;

- when the ribs are deformed, the broken edges should not exceed: for a depth of more than 30 mm, and for a length of more than 15 mm.

You can evaluate various photos in which the design of the facades is made of high-quality bricks, while the marriage will be worse, the aesthetic appearance is much less attractive, and the integrity of the structure does not meet the standards.

Facade

The architecture of houses is practically unlimited in the choice of texture, shape and color.

Yellow

The texture of the brick, as well as its visual effect, are varied, while this does not damage the strength of the structure.

Red brick, sizes and varieties and defects

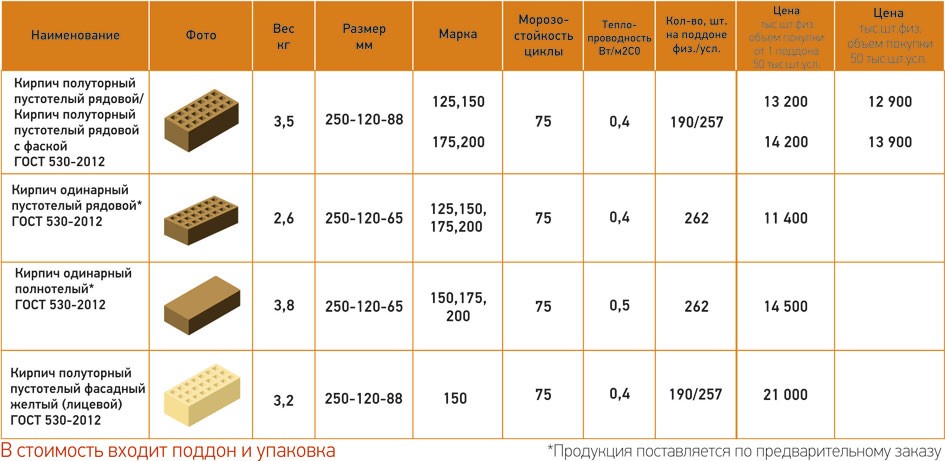

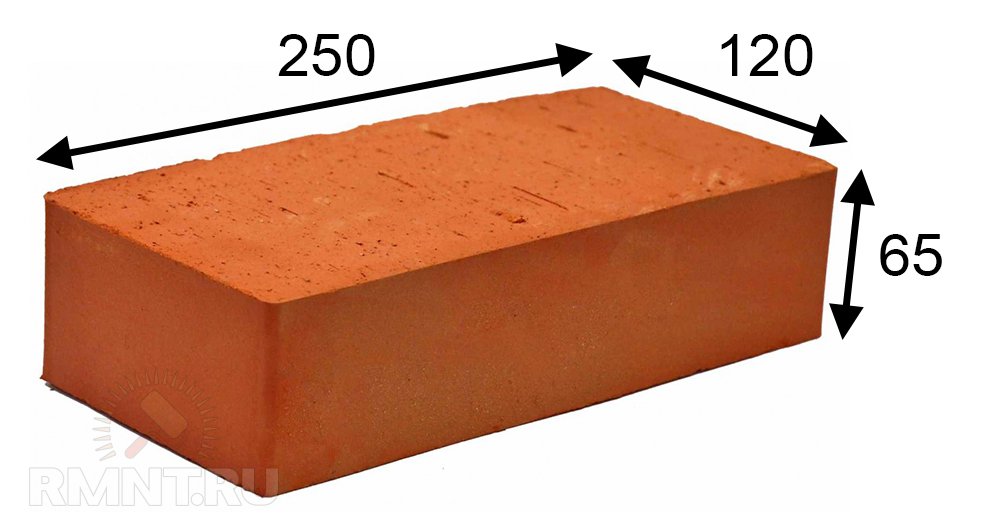

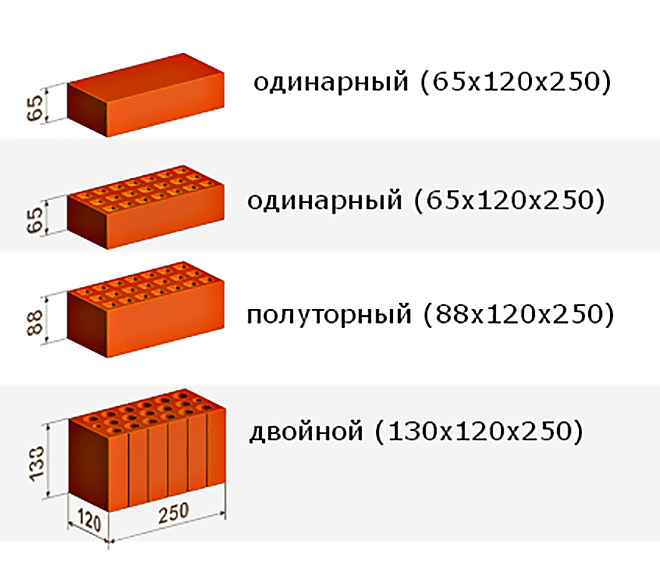

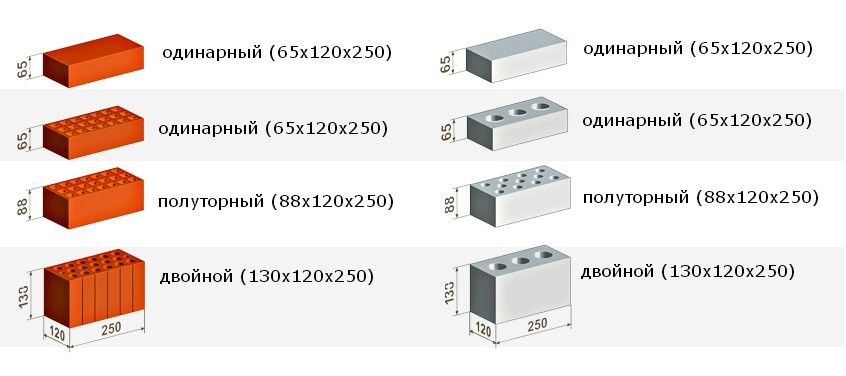

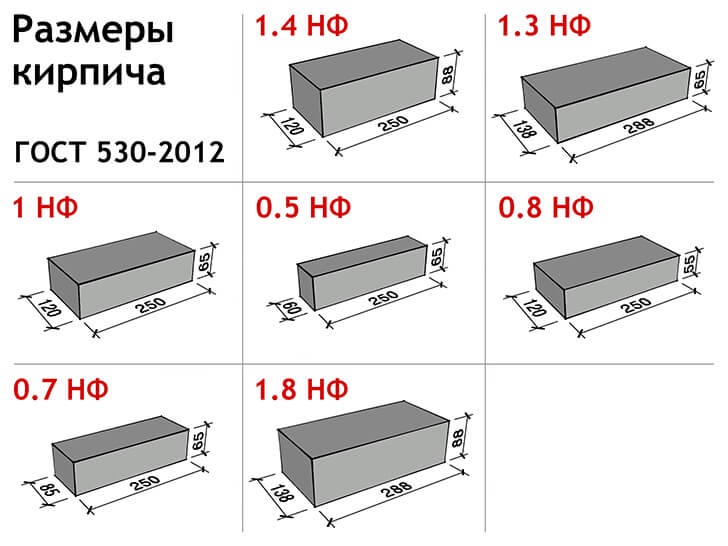

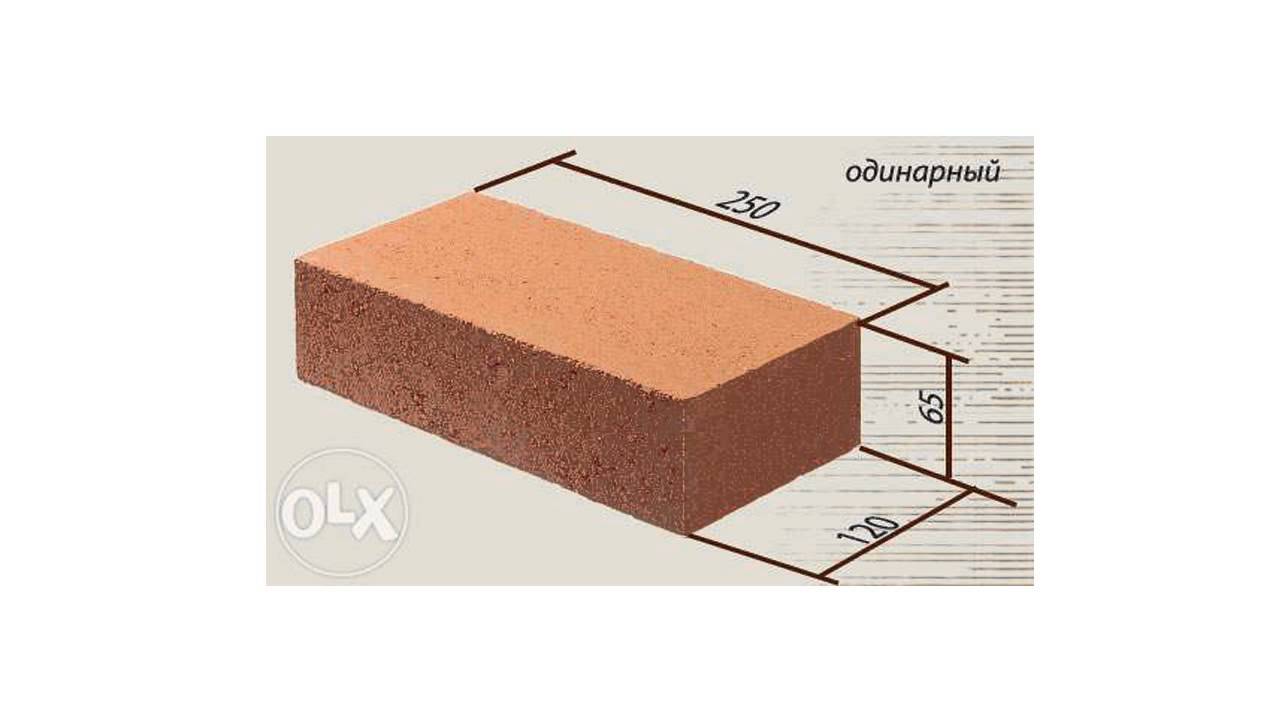

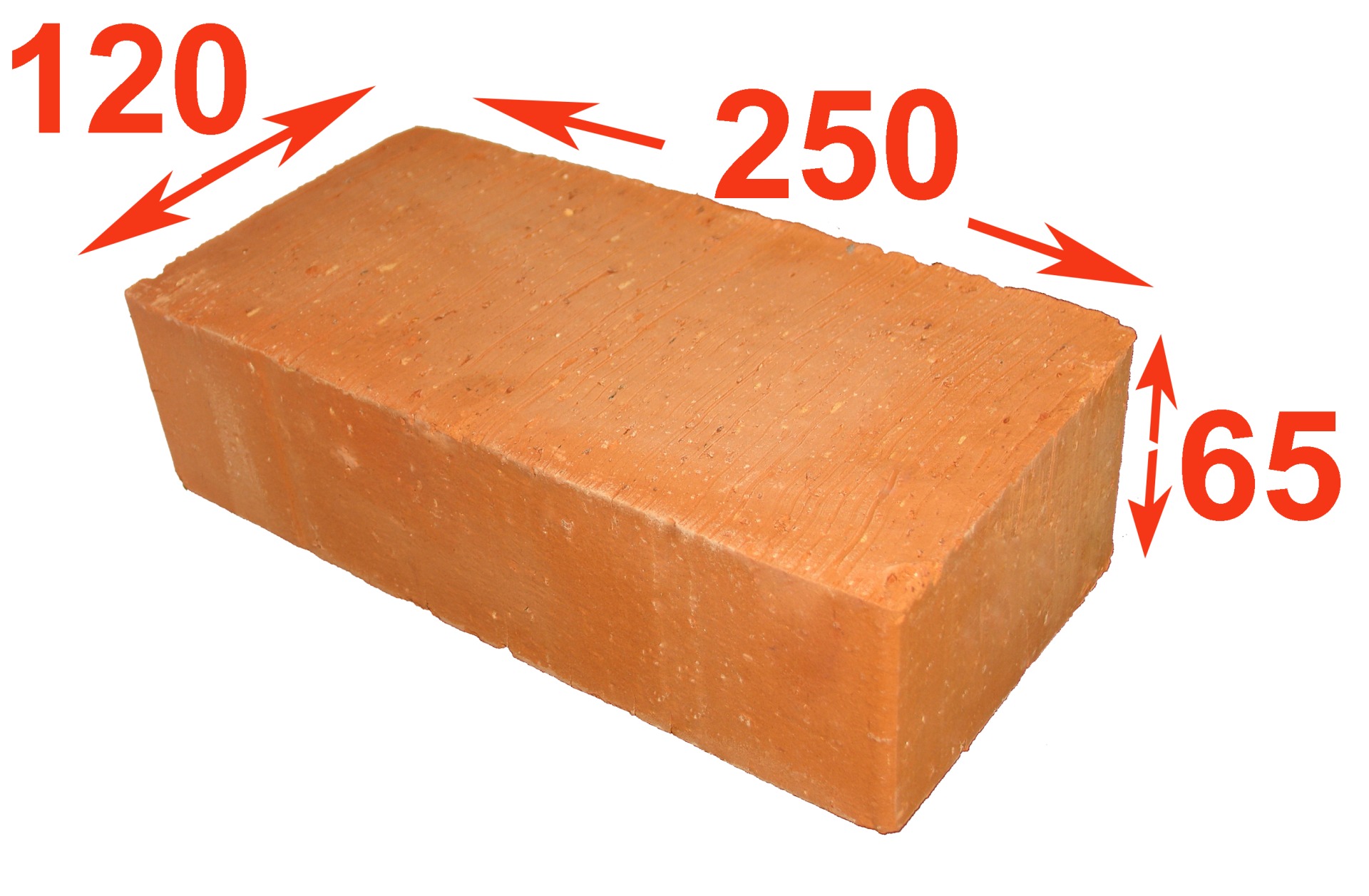

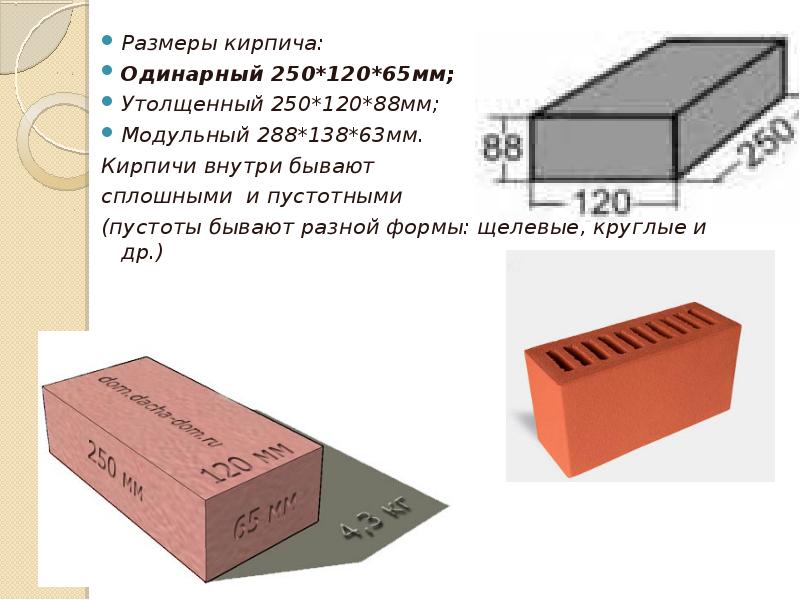

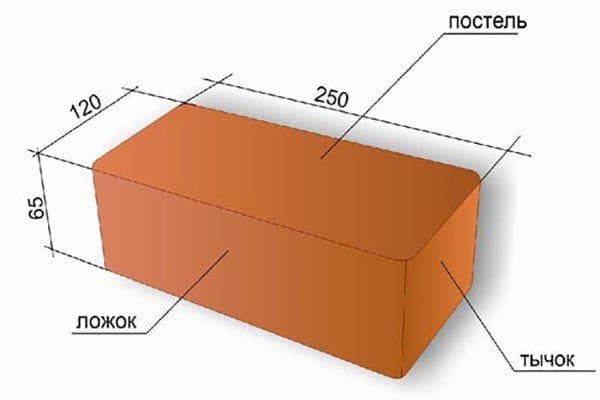

The dimensions of ordinary red brick are standardized by the requirements of GOST 530-2007, products are produced in the following standard sizes:

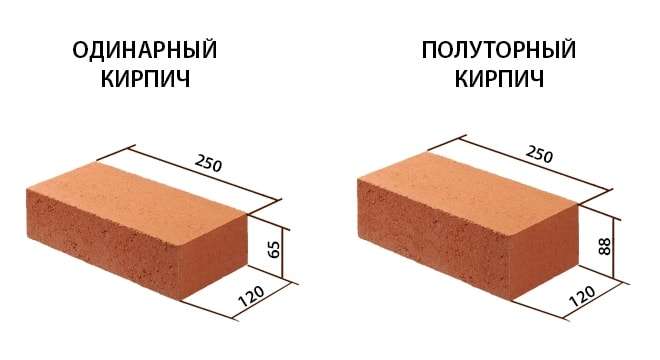

- Normal format, it is also single, the dimensions of an ordinary red brick are 250 × 120x65 mm;

- One and a half, thickened, in this case the thickness is increased, the remaining dimensions remain the same - 250 × 120x88 mm;

- Double, large format, overall dimensions - 250 × 120x138 mm;

- Modular, normal format, overall dimensions 288 × 138x65;

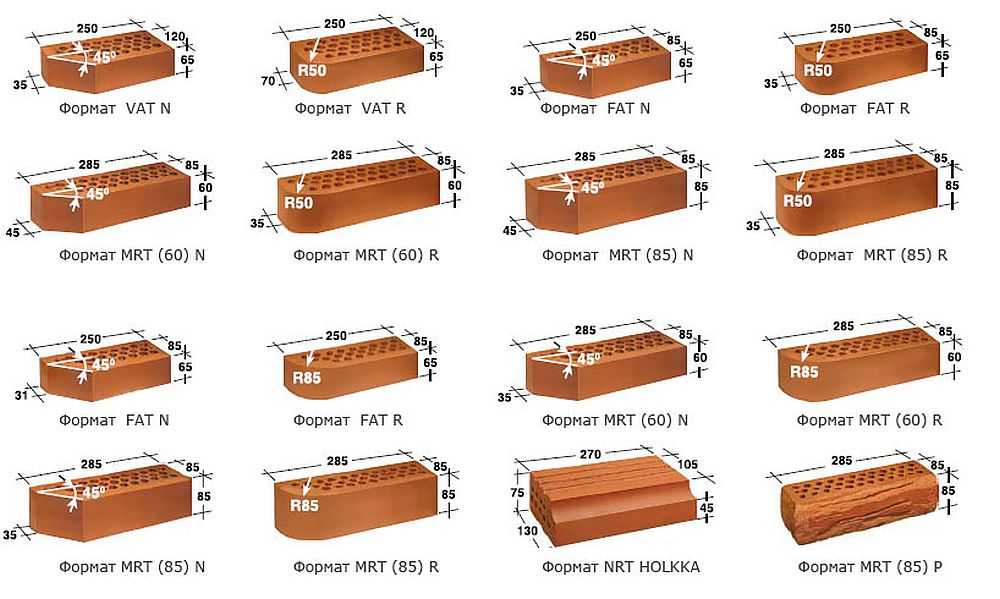

- "Euro" - a standard that came from Europe, has several types, the most famous size is 250 × 85x65 mm, this standard is also spelled out in GOST.

It should be noted that GOST allows the execution of bricks with deviations from the standard. Therefore, the dimensions of the red brick may differ slightly from the control dimensions.

"Effective", it is a hollow brick, the structure of ceramics is clearly visible

Separately, it is necessary to note wedge-shaped products intended for the assembly of vaults and arches, this type of product is heat-resistant, and has a narrowed shape along the edges.

Kiln Wedge Brick

Dimensions of standard red brick

The dimensions of this building material are fully regulated by GOST, the height of the red brick can change depending on the operating conditions and its purpose, within the limits and sizes provided for by the system of state standards.

The dimensions of the hollow and the dimensions of the full-bodied red brick are similar, in this regard, only the scope of their operation differs.

Slotted or hollow, is actively used to fill openings in monolithic and frame structures, to assemble walls, create partitions, while a corpulent one is operated under high loads: the foundation of a house, basements, load-bearing walls.

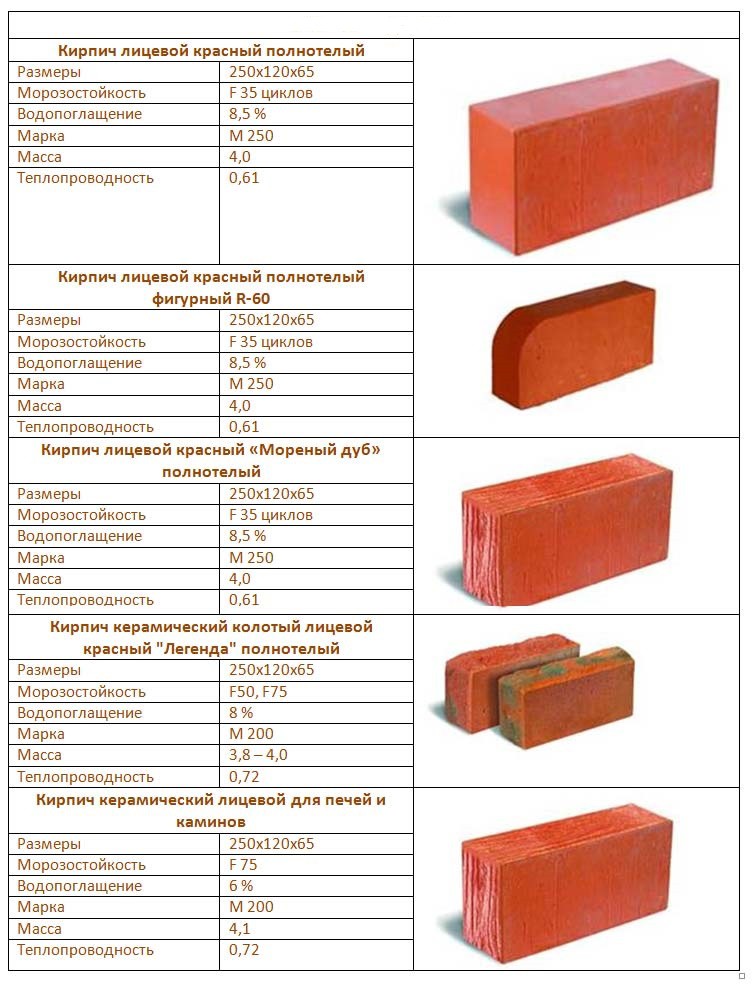

Dimensions of red facing brick

Facing or facing bricks are used for outdoor laying, decorative finishing of the walls of structures. The design and size of the facing brick is selected based on the project.

The size of a single facing brick is completely similar to the standard size - 250 × 120x65 or Euro 250 × 85x65 mm.

Dimensions and designations

Dimensions of oven red brick

A stove brick, from an ordinary one, is distinguished by the ability to endure the effects of an open flame and high temperatures for a long time, the area of its operation is the creation of devices operating with high temperature loads, the lining of such structures and equipment operating under the influence of an open flame. Distinguish between refractory red and fireclay bricks.

The price of a red oven brick is usually higher than that of an ordinary one. This is a result of the fact that other raw materials and technologies are used for the manufacture of these products.

The overall size of the oven brick, unlike other types, can be conditionally divided into two types:

- Rectangular products with the dimensions of single and thickened bricks 250 × 120x65 mm and 250 × 120x88 mm;

- Wedge-shaped products according to GOST 8426-75, products of a special shape: distinguish between radial-longitudinal and radial-transverse.

Red brick for the foundation, dimensions and features

For laying a foundation, a brick must have increased moisture resistance and reduced water absorption, since the foundation is most susceptible to moisture. The overall size of an ordinary red brick is selected based on the technical requirements of the house project. In addition, the products used for the construction of the foundation must have high bearing characteristics, since the foundation accounts for most of the bearing load of the structure.

When choosing a material for basement floors, you need to pay attention to the choice of material according to physical parameters: frost resistance, moisture permeability, and others. Strength is also extremely important, the product in the masonry will bear the entire weight of the structure

For the foundation, it is necessary to select a high-quality, well-fired material, without defects arising from a violation of the technology of its production and storage.

For the foundation, it is recommended to use an ordinary solid brick. Dimensions - 250 × 120x65 mm single and 250 × 120x88 thickened. The double size of red brick for a plinth is rarely used.

Fold down the oven? Easily!

Masonry features

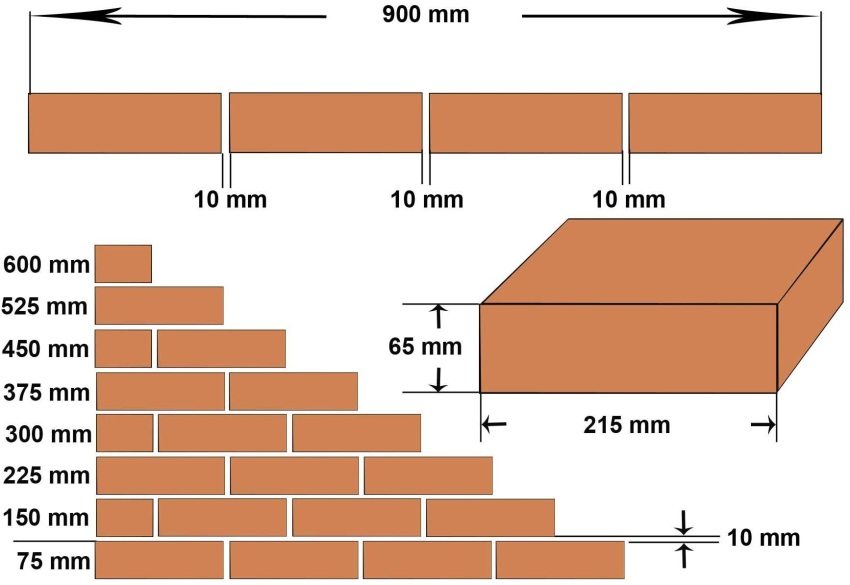

In the process of laying bricks, it is most often laid on the largest edge, and so that the load is distributed over at least 2 underlying parallelepipeds. At the same time, in order for the walls to come out strong and durable, the masonry is made with an offset, called dressing. A brick in a wall can be positioned both along and across it, that is, to address the wall surface with the smallest edge (poke) or narrow long (spoons).

A masonry of 0.5 bricks is determined in square meters. If the wall is laid out in brick or thicker, then the volume, expressed in cubic meters, is used for measurement.

When calculating the wall, the width should be a multiple of 0.5 bricks. During the design period of the surface, the thickness of the vertical masonry seam is taken into account, taking it as 10 mm, although in fact it fluctuates within 8-12 mm. Two bricks laid with a poke, taking into account the width of the masonry joint (120 + 10 + 120 = 250 mm), make up a module equal to the length of a whole single product. In each row (when using a single product placed on the bed), vertical seams can be placed every 120 or 250 mm. If laying on the edge, the seams will pass through 65 mm.

If the walls are erected without additional air gaps and insulation, then their vertical dimensions will correspond to the sum of the vertical edges of the used building materials plus the thickness of the masonry joints (12 mm for horizontal joints). To calculate the vertical dimensions of brickwork, there is a special formula: N × R + (N-1) × T, in which the designations correspond to the following values:

- R is the vertical parameter of the brick (65 mm for a single size or 88 for one and a half);

- N - row number;

- T - seam thickness.

In order not to make calculations for each row, you can use a ready-made table of the vertical multiplicity of masonry:

| Row number | Row number | Row height with masonry mortar (mm) | |||

| 1NF | 1,4NF | 1NF | 1,4NF | ||

| 1 | 77 | 100 | 19 | 1463 | 1900 |

| 2 | 154 | 200 | 20 | 1540 | 2000 |

| 3 | 231 | 300 | 21 | 1617 | 2100 |

| 4 | 308 | 400 | 22 | 1694 | 2200 |

| 5 | 385 | 500 | 23 | 1771 | 2300 |

| 6 | 462 | 600 | 24 | 1848 | 2400 |

| 7 | 539 | 700 | 25 | 1925 | 2500 |

| 8 | 619 | 800 | 26 | 2002 | 2600 |

| 9 | 693 | 900 | 27 | 2079 | 2700 |

| 10 | 770 | 1000 | 28 | 2156 | 2800 |

| 11 | 847 | 1100 | 29 | 2233 | 2900 |

| 12 | 924 | 1200 | 30 | 2310 | 3000 |

| 13 | 1001 | 1300 | 31 | 2387 | 3100 |

| 14 | 1078 | 1400 | 32 | 2464 | 3200 |

| 15 | 1155 | 1500 | 33 | 2541 | 3300 |

| 16 | 1232 | 1600 | 34 | 2618 | 3400 |

| 17 | 1309 | 1700 | 35 | 2695 | 3500 |

| 18 | 1386 | 1800 | 36 | 2772 | 3600 |

If building material of other parameters is used, then according to the above formula, you can easily draw up your own table, according to which, during the masonry process, control is carried out using the ordering - slats with divisions corresponding to the masonry rows.

Dimensions and weight according to GOST

Standard sizes of single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of the red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

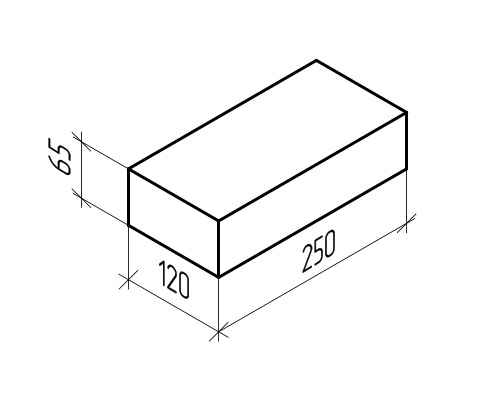

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is the dimensions of single elements provided for by GOST that are a kind of reference point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number indicates its proportions of the ratio with a single one.

So, the size of one and a half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

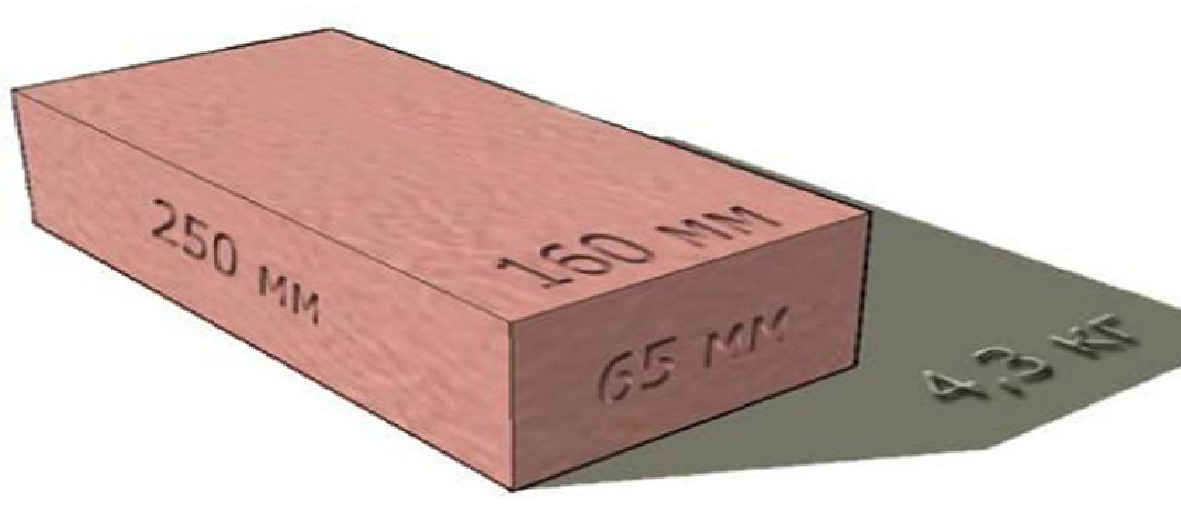

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick.It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

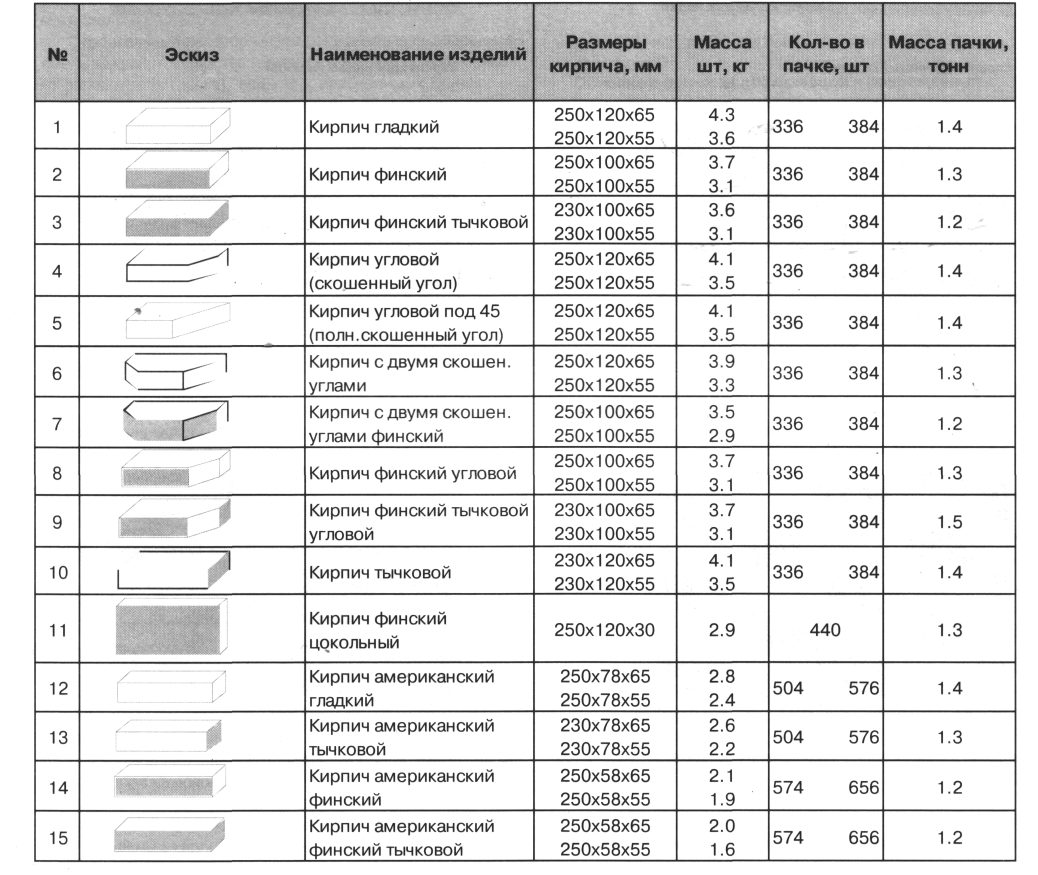

Standard type brick size - Table.

Brick is a stone of the correct form of artificial origin, which is very widely used in construction.

He has three surfaces:

- the bed is the largest;

- spoons - medium;

- butt is the smallest surface.

Dimensions and marking of bricks from domestic manufacturers.

In the table below, you can find out the size of the required brick block, as well as its marking, which is used in our market.

| Name | Dimension marking | Dimensions, mm. | Name marking |

| Single | 1-NF | 250x120x65 | O |

| "Euro" | 0.7-NF | 250x85x65 | E |

| Modular single | 1,3-NF | 288x138x65 | M |

| One and a half | 1,4-NF | 250x120x88 | Have |

| Thickened brick with horizontal voids | 1,4-NF | 250x120x88 | UG |

| Double brick (stone) | 2,1-NF | 250x120x140 | TO |

| 3,7-NF | 288x288x88 | ||

| 2.9-NF | 288x138x140 | ||

| 1,8-NF | 288x138x88 | ||

| 4,5-NF | 250x250x140 | ||

| 3,2-NF | 250x180x140 | ||

| Large-format stone (porous ceramic block) | 14,3-NF | 510x250x219 | QC |

| 11,2-NF | 398x250x219 | ||

| 10,7-NF | 380x250x219 | ||

| 9,3-NF | 380x255x188 | ||

| 6,8-NF | 380x250x140 | ||

| 4.9-NF | 380x180x140 | ||

| 6.0-NF | 250x250x188 | ||

| Stone with horizontal voids | 1,8-NF | 250x200x70 | KG |

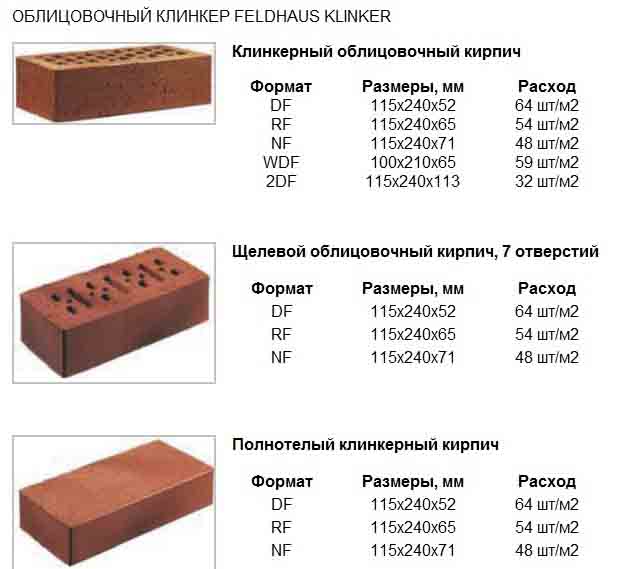

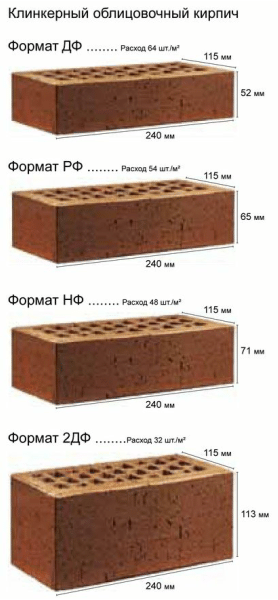

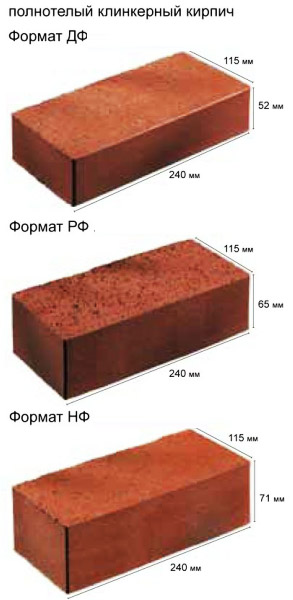

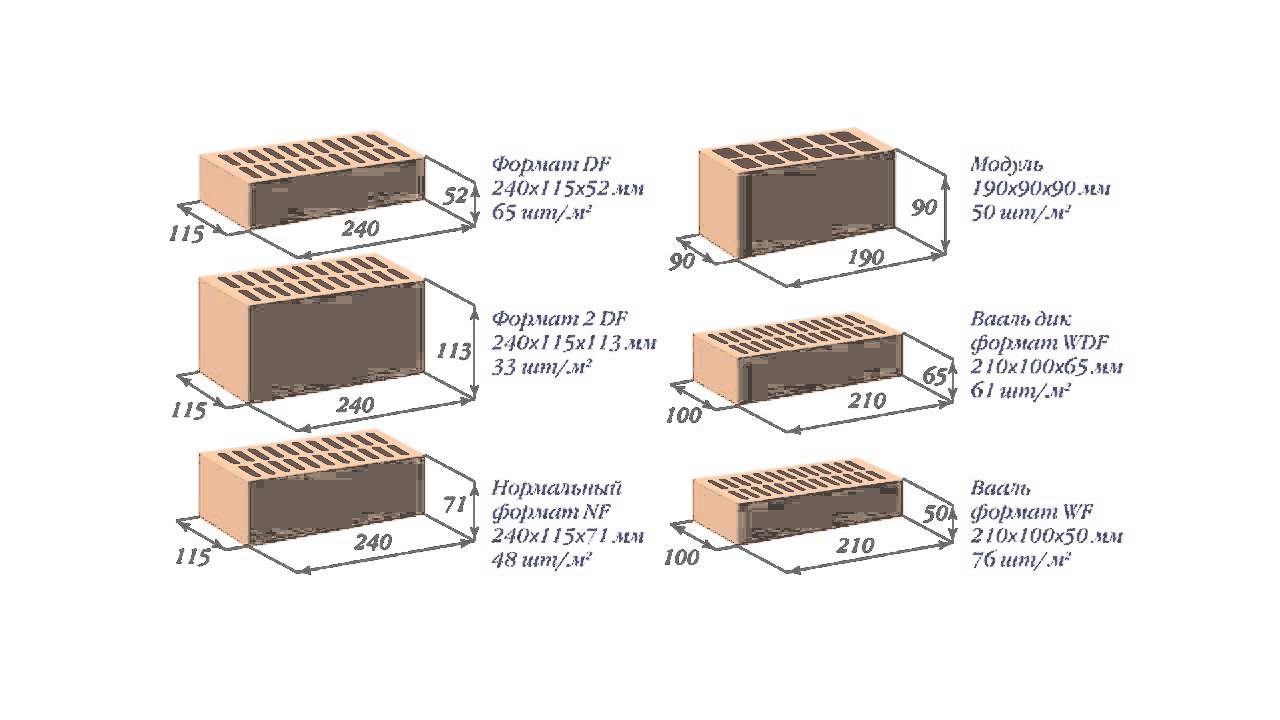

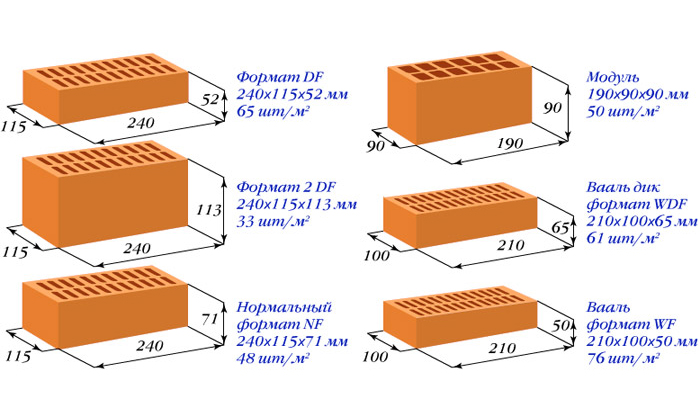

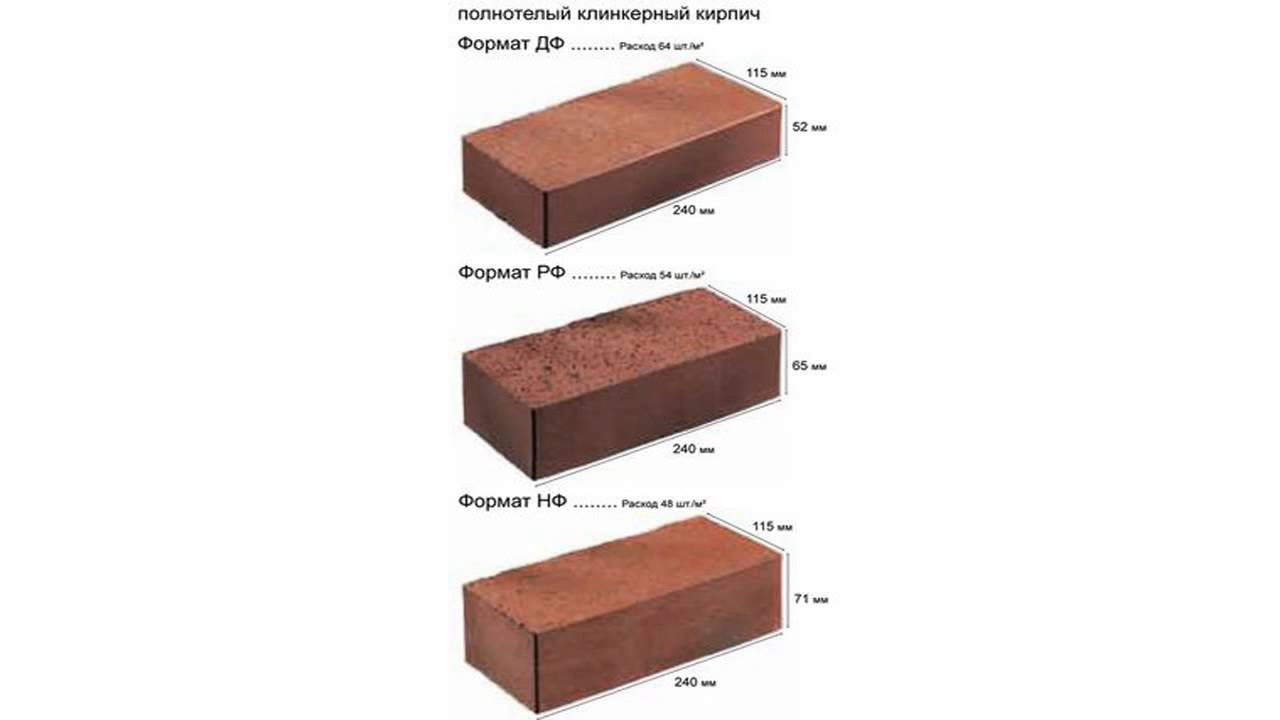

Size marking of European bricks.

Foreign manufacturers have completely different standards and sizes differ from domestic ones. Therefore, for complete convenience, the following table of brick sizes is presented:

| Marking | Dimensions, mm |

| DF | 240x115x52 |

| 2DF | 240x115x113 |

| NF | 240x115x71 |

| RF | 240x115x61 |

| WDF | 210x100x65 |

| Wf | 210x100x50 |

Knowing the size is good, but you also need to know the species, and there are many of them.

Red brick size.

The standard size of a red brick product was introduced at the beginning of the 19th century, and finally established itself relatively recently, in 1927, and is 250x120x65 mm.

Often such dimensions of single ceramic bricks are called normal or basic format. It is a product of this size that is considered the most convenient for the production of wall masonry work, more precisely, for alternating the arrangement of bricks when bandaging the masonry.

The size of the silicate brick.

SC is used in many cases when high strength is required from the building.

A brick is produced with the following dimensions:

- single - 250 mm long, 120 mm wide and 65 mm thick. The weight of the product depends on its type - hollow or corpulent;

- one and a half - or thickened, with the same length and width, the thickness of the product is 88 mm;

- double - or silicate stone, has a thickness of 138 mm.

There is a whole category of SC of non-standard size and shape rather far from a parallelepiped. These products are designed to form various architectural elements: arches, rounded corners, vaults, and so on. Their dimensions are regulated by TU and annexes to GOST.

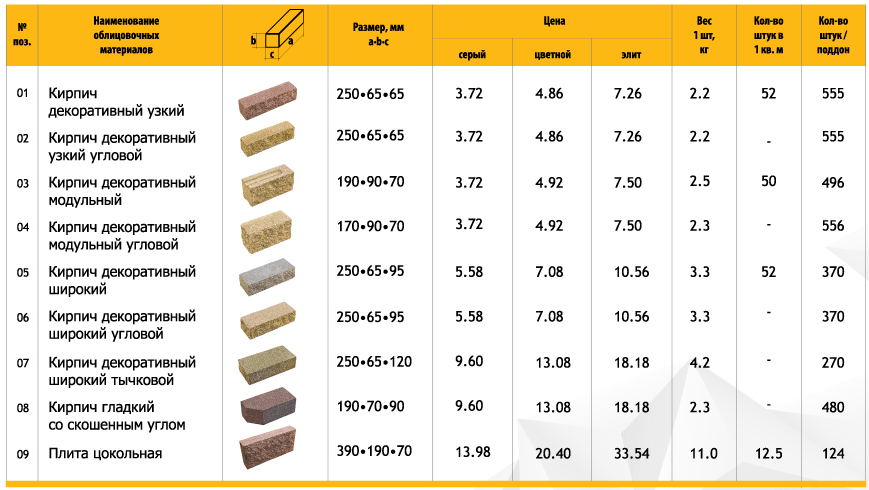

The size of the facing brick.

The usual size of decorative bricks can have the following parameters - 250x120x65 mm, 250x90x65 mm and 250x60x65 mm.

As you can see, the height can change, but the length and width of the brick remain unchanged. The only exceptions are the elongated elements, the parameters of which are 528x108x37 mm.

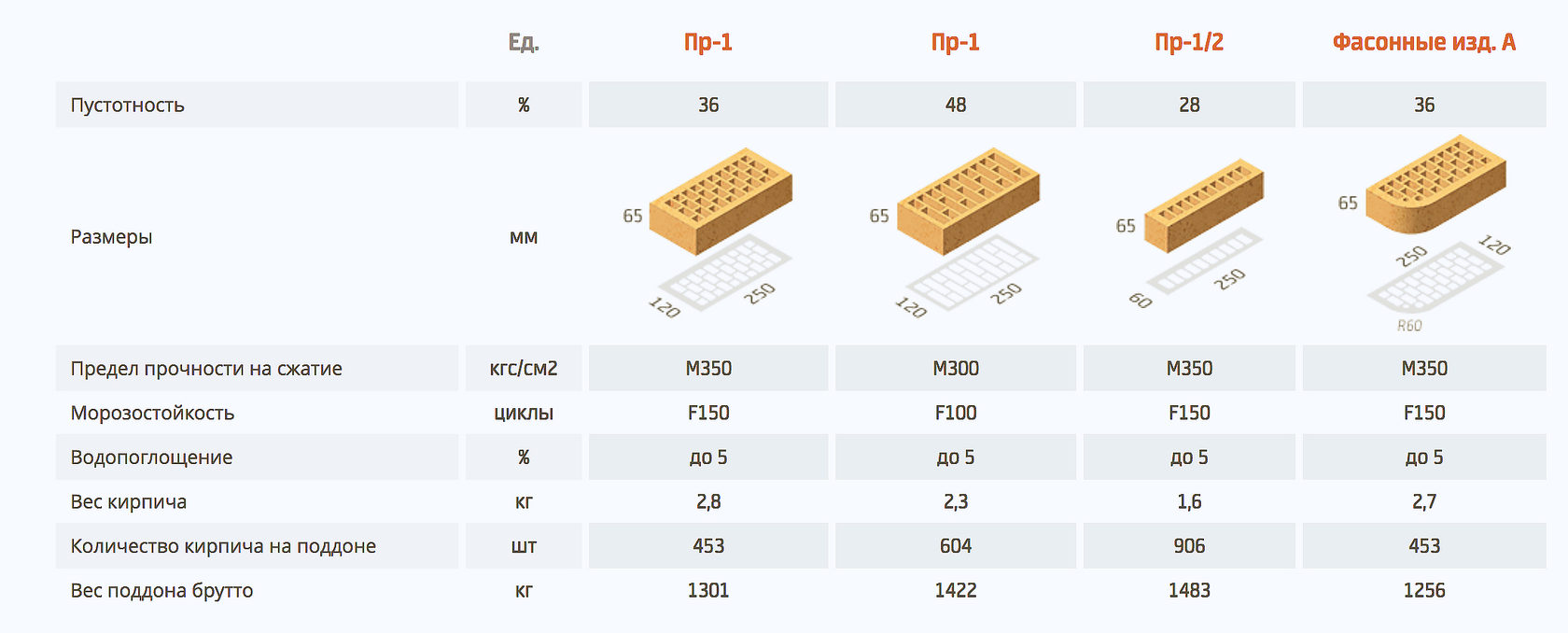

Dimensions of ceramic bricks.

KK is full-bodied, hollow, porous. The first modifications are made using a similar technology in various forms, into which the clay is filled. A unique technology is used in the production of porous ceramics.

The dimensions of the KK are as follows:

- single, perhaps the most common type. The standard dimensions of a single ceramic brick are 250 × 120 × 65, as you know, the dimensions of building materials are indicated in millimeters;

- the size of a one-and-a-half ceramic brick differs from a single one only in height, it is 88 millimeters, and the length and width remain unchanged.

- double, also higher than the standard, single, its height is 138 millimeters with the same length and width.

What are the markings of bricks.

Each batch of bricks is marked by the manufacturer, all information about the product is indicated on the marking in an alphanumeric code. It is not difficult to decipher the marking, it consists of: marking the name of the product, letters P - for privates, L - for obverse; size designations and designations: Po - for corpulent, Pu - for hollow; grades for strength and frost resistance; medium density class and designation of GOST.

For example: Brick KORPu 1NF / 100 / 1.4 / 50 / GOST 530-2007.

Marking of ordinary ceramic bricks, hollow, thickened, size 1.4NF, strength grade M150, average density class 1.4, frost resistance grade F50.

Or: Single silicate brick, ordinary grade for strength 150, grade for frost resistance F15 will be marked: Brick COP-150/15, GOST 379-95.

Material parameters

The price of a material depends on its size and production. Of course, the more raw materials are spent on it, the higher the price will be. After all, the weight is greater. But sometimes what is more expensive is more profitable. Therefore, when choosing, there can be only one instruction, this is to make the correct calculations.

Attention: when calculating, it is imperative to take into account waste. They will be there anyway

Only unlike clay material, silicate waste can be used in few places.

Silicate brick weight:

Silicate brick

The production of silicate bricks is carried out in autoclaves under high pressure. This is one of the differences from the production of clay material.

- The composition of the brick includes sand, this is in the region of 92-94%. Lime is also used as an additive. Its volume fluctuates around 3-5%. Various additives are also used for the quality of products, which make up about 2%.

- This technology makes it possible to make high-quality and durable material. For example, hollow materials have increased sound insulation and heat insulation. Therefore, they can be perfectly used for the construction of partitions indoors.

- The frost resistance index ranges from 15 to 50 freeze and thaw cycles.

- This material can have almost any color. It all depends on the dye added.

Attention: This material has a significant drawback, it absorbs moisture strongly and therefore cannot be used for the manufacture of the foundation and basement of the room. The weight of the silicate brick depends on several parameters.

In the first place is the composition of the material, in the second place is the manufacturing technology. But the average weight of a brick is around 2.5 kilograms

The weight of a silicate brick depends on several parameters. In the first place is the composition of the material, in the second place is the manufacturing technology. But the average weight of a brick is around 2.5 kilograms.

The volumetric weight of a silicate brick directly depends on its dimensions. They are quite different. There is one and a half material, there is also a single one.

Material selection rules

You make the choice yourself. Here you will need to look at the following components:

First of all, decide on the height of the wall. Here you will need to select a brick not only by weight, but also take into account its height. It will be possible to save on this;

Construction requires the use of quality materials. Therefore, do not take damp bricks on pallets. It dries very badly;

The price of color will be more expensive

Pay attention to this when choosing.

Be sure to take into account the weight, because for partitions it is better to take hollow material. True, here you will use up more solution.

But the wall will be lighter.

If you will be laying bearing surfaces, then it is better to use solid material here. It will withstand heavy loads.

When making a choice, you should never rush. There are always calculations before buying. Look at photos and videos, make an analysis. Construction does not tolerate errors. After purchasing the material you don't need, you will spend not just money, but you can make a poor-quality structure.

Some subtleties of brickwork

The seeming simplicity of building brick walls at first glance hides many secrets that beginners need to know:

- First of all, you should evaluate the quality. Each block should be free of cracks and large pores.

- When using masonry reinforcement, the thickness of the seams must exceed the thickness of the reinforcement by at least 5 mm.

- It is better to decorate the facade with bricks, which have beveled edges. This will allow you to lay out arches and columns beautifully.

- Before placing the block in the masonry, it should be moistened with water for better bonding with the mortar.

- To avoid uneven settlement of the building, bricks should be laid simultaneously along the entire perimeter.

- The strength of the wall being erected depends on the observance of the brick dressing system relative to each other during the laying. For more information on how to lay bricks correctly, see this video:

If you decide to build on your own, listen to the advice of experienced craftsmen: start with a less significant structure, for example, a farm building. Having consolidated theoretical knowledge with skill and practice, you can start building brick walls yourself.

A builder, especially a beginner, will help to correlate the sizes of bricks with a table in which the parameters of building materials of this type are collected and clearly presented. Long gone are the days when people sculpted clay parallelepipeds for themselves and in determining their size adhered only to their own designs.

The larger the brick, the faster the house is built, however, too large dimensions can affect the functionality and strength of the building.

Now, for the convenience of designers, manufacturers and builders, the dimensions of building materials are standardized and any of the parameters (length, height or width) must be a multiple of the parameters of a single brick provided for by GOST.

A single size is indicated by marking 1NF, for products of other parameters in the marking, instead of a unit, a number is put down, indicating the proportion according to which this product is related to a single one. Moreover, the products do not necessarily change at once on all faces.