Solvent R-5 - complex chemistry in construction

Solvents are special formulations designed to react with a binder and at the same time reduce the viscosity of the paint. This is their main difference from thinners used to lower the viscosity of paints and varnishes.

What is this solvent?

In the modern paint and varnish industry, a huge variety of organic and inorganic substances are used as solvents. To improve the quality of the resulting products, manufacturers usually use mixtures. They are called numbered.

Organic composition P-5 is used for diluting various paints to obtain a working viscosity, as well as for thorough cleaning of painting tools and equipment.

The popularity of this mixture is due to its excellent performance characteristics. The large number of components that make up this mixture determines its broad specialization and, in addition, the ability to dissolve a variety of organic substances.

Characteristics and application of R-5

This solvent in its appearance is a completely colorless or slightly yellowish transparent liquid without the presence of visible suspended inclusions. This mixture has a rather pungent specific odor.

Solvent R-5, the composition of which includes 30% butyl acetate and acetone, as well as 40% toluene, is one of the most active and aggressive. Therefore, its use in works requires special care and accuracy. In some cases, it may be more appropriate to use weak formulations.

This combined mixture is purchased for diluting paintwork products (paints and varnishes), based on the resin PSH-LS and PSH LP. In addition, it interacts well with other substances based on rubber, polyacrylic and epoxy, organosilicon resins and other film-forming components.

This combination is added to paints and varnishes in small portions with constant stirring until the final product is given the required viscosity. The shelf life of the finished composition does not exceed 1 year from the date of manufacture. Solvent R-5, GOST 7827-74, is produced in appropriate proportions in large mixers at factories, but for laboratory needs it is easy to prepare it yourself.

This solvent mixture is widely used, but not universally applicable. In some cases, it is more expedient to use the R-5a solvent. It is derived from the previous one, and its only difference is that the mass fraction of one of the components, namely butyl acetate, should not exceed 30%.

These solvent mixtures contain aromatic hydrocarbons, amines, halogen derivatives and ketones, which can cause various skin diseases as well as serious poisoning. The vapors are irritating to the respiratory tract and eyes.

With prolonged contact, solvents can have a negative effect on the bone marrow and blood. When working with these mixtures, it is necessary to put on special clothing, as well as use gloves, a respirator and goggles.

Safety and precautions

The solvent is an unsafe substance and can have a negative effect on the human body

When working with it, it is important to observe precautions and safety.

- Store in a tightly closed, fully sealed container, away from fire and heating appliances. It is also necessary to avoid exposing the container with the diluent to direct sunlight.

- The solvent composition, like other household chemicals, must be safely hidden and out of the reach of children or animals.

- Inhalation of concentrated vapors of the solvent composition is very dangerous and can cause poisoning. In the room where painting or surface treatment is carried out, forced ventilation or intensive ventilation must be provided.

- Avoid getting the solvent in the eyes or on exposed skin. Work must be carried out in protective rubber gloves. If the thinner does get on open areas of the body, you must immediately wash the skin with plenty of water using soap or slightly alkaline solutions.

- Inhalation of high concentration vapors may damage the nervous system, hematopoietic organs, liver, gastrointestinal tract system, kidneys, mucous membranes. The substance can enter organs and systems not only by direct inhalation of vapors, but also through the pores of the skin.

- In case of prolonged contact with the skin and lack of timely washing, the solvent can damage the epidermis and cause reactive dermatitis.

- Composition R-647 forms explosive flammable peroxides if mixed with oxidizing agents. Therefore, the solvent should not be allowed to come into contact with nitric or acetic acid, hydrogen peroxide, strong chemical and acidic compounds.

- Contact of the solution with chloroform and bromoform is fire and explosive.

- Spraying with solvent should be avoided, as this will quickly reach a dangerous degree of air pollution. When spraying the composition, the solution may ignite even at a distance from the fire.

You can buy R-647 brand solvent in building materials stores or in specialized markets. For household use, the solvent is packaged in plastic bottles from 0.5 liters. For use on a production scale, packaging is carried out in cans with a volume of 1 to 10 liters or in large steel drums.

The price for a solvent of the R-647 brand is on average about 60 rubles. for 1 liter.

For a comparison of solvents 646 and 647, see the following video.

Solvent 646

Composition and specifications

This composition is used for dissolving and diluting various paints and varnishes, removing stains, cleaning surfaces and tools from paints and varnishes. The GOST standard describes its composition:

- acetone - 7%;

- ethyl cellosolve - 8%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- butanol - 15%;

- toluene - 50%.

Also, solvent 646 is made according to TU, with the differences that the content of toluene and acetone is reduced in it. This is due to the fact that toluene and acetone can be used in the production of drugs.

The description of solvent 646 includes the following specifications:

- appearance - a clear, colorless or yellowish liquid without suspension, not stratifying, without precipitation,

- boiling point - 59 С,

- flash point - -7 С,

- autoignition temperature - 403 С,

- the density of the solvent is 646 - 0.87 g / cc, due to this it mixes well with other solvents and paints and varnishes,

- specific gravity - 0.68 kg / l,

- water content - 0.09%,

- acid number - 0.06 mg KOH / g,

- coagulation number - 40 g / o,

- volatility (ethyl ether) - 12,

- does not freeze

- does not leave dull or whitish spots.

Application

The solvent R 646 is used to dissolve and dilute various varnishes and paints. Initially, it was intended to dilute nitro paints and nitro enamels. Later it was found that the 646 solvent is also effective in relation to other types of paints and varnishes, as well as epoxy or glyphthalic primers, melamine amide, alkyd, epoxy paints and varnishes, putties, and the film was distinguished by gloss and strength.

It is used to bring paints and putties to the desired viscosity, to dilute thickened paints, putties, film-forming varnishes, and gives shine. After drying, the whitish film and the smell of the solvent do not remain. Paints and varnishes with the addition of solvent 646 form a film faster than paints and varnishes without it, have a beautiful gloss. Also used in the production of nitro paints, nitro varnishes, nitro enamels.

It is quite aggressive, especially against plastic, so it should not be used on plastic surfaces. Solvent 646 can be used for degreasing, and it is one of the most effective formulations for this purpose, but due to its activity, the surface properties must be considered. For plastic, use less aggressive products.

Consumption per 1 square meter for degreasing is approximately equal to:

- for outdoor surfaces - 0.147 kg;

- for metal and wooden surfaces indoors - 0.12 kg;

- for concrete - 0.138 kg.

For surfaces that will be affected by water and other aggressive factors, the consumption per square meter is 0.169 kg.

Security

Solvent 646 is toxic, its environmental hazard class is 3. When inhaled, it causes a narcotic effect - headache, dizziness, disorientation, as well as irritation of the eyes, respiratory tract, effects on the gastrointestinal tract, liver. With prolonged inhalation, toxic damage to the liver, bone marrow, changes in the composition of the blood are possible, which lead to serious consequences. Therefore, it is necessary to work with P 646 solvent in a room with good supply and exhaust forced ventilation or outdoors. To protect the respiratory system, use a respirator (such as a "petal").

If it comes into contact with the skin, it does not cause burns, but with prolonged interaction with it, contact dermatitis is possible. It should not be allowed to come into contact with the eyes, work must be carried out with gloves and goggles, and upon contact with the skin, the substance is immediately washed off with soap and water.

It is volatile and flammable, so care must be taken when handling it. The flammable solvent is extinguished with sand, foam, sprayed water

It is stored in an airtight container, in places where the direct rays of the sun do not fall, at a temperature of -40 to +40 degrees. You cannot store it outside. In the room where the composition is stored or work is in progress, the occurrence of any sparks must be excluded. Do not smoke near containers with the substance.

R 646 is sold in metal drums for industrial use and in 1-10 liter cans for domestic use. It is completely ready to use, no additional preparation is required. The warranty period during which the composition retains its properties is 12 months.

This is interesting: Wooden ceilings in the apartment - the pros and cons

Carrying out works

Thinner 647 is a flammable liquid. Product R-647 belongs to the 3.1 class of flammable liquids. During work, sparks, smoking and open flames should be avoided. Air mixtures and vapors are also explosive. Air pollution from solvent vapors will pass quickly when the room temperature is 20 degrees Celsius above zero. When spraying a solvent, air contamination passes through even faster.

Experts note that with careless handling, the composition may ignite at a distance. Accumulations of volatiles are heavier than air and travel along the ground.

Interaction with effective oxidants (hydrogen peroxide, acetic acid and nitric acid) can cause explosive peroxide. Despite the fact that the solvent of the above brand can be used to clean plastic surfaces, the substance is aggressive towards some of its varieties.

Peculiarities

Solvents include rapidly evaporating reagent mixtures consisting of several active components. They dissolve organic substances and form homogeneous compounds with them.

The main task of the solvent is to dilute paints and varnishes, giving them the required working consistency, therefore, certain requirements are imposed on them:

- lack of any reaction with paints and varnishes;

- high evaporation rate;

- the composition must be non-hygroscopic;

- the interaction of the solvent and the coloring composition should take place without any effort.

The solvent affects the paint only at the moment of its application, after which it evaporates without a trace. Each paint and varnish product corresponds to a certain type of solvent.

Thinner number 646 is a universal composition with a wide range of uses.

The active components of P646 are:

- toluene - 50%;

- butanol - 15%;

- butyl acetate - 10%;

- ethyl alcohol - 10%;

- ethyl cellosolve - 8%;

- acetone - 7%.

The latter does not contain acetone, it is considered not so active, due to which it is used on coatings that require the most careful and delicate handling, for example, when working with plastic. In all other cases, it is worth giving preference to the 646 brand.

Today, solvent manufacturers are conducting research aimed at reducing the concentration of toluene and acetone in the reagent. This is due to the fact that these substances are often used in the manufacture of synthetic drugs.

Security measures

The manufacturer of Solvent 646 reminds you that this is a flammable liquid and must be handled and stored with extreme care. It is recommended to use a closed sealed container for this.

Store the substance away from any sources of heat, electrical devices and sunlight, out of the reach of children.

Solvent vapors are toxic! When working in closed rooms, it is imperative to create good air ventilation. Work should be done in a respirator, protective gloves and goggles.

Prolonged skin contact can cause dermatitis. If the substance comes into contact with the skin (mucous membranes), thoroughly wash the contact areas with warm water and soap.

solvent 646

Photo of solvents

We also recommend viewing:

- Which parquet varnish is better to choose

- Quick-drying, odorless paint for interior use

- The best spray paint in spray cans

- Best water based paint

- How to choose a facade paint for outdoor use

- Which oil paint is best

- Best interior wall paint

- What paint for wallpaper for painting is better

- DIY paint tinting

- How to choose an epoxy paint

- How to choose the best wood wax

- Best Heat Resistant Varnish

- Which decorative paint is best

- The best enamel paints

- Which drying oil is better to choose

- Best Waterproof Bathroom Paint

- How and how to remove or remove old paint

- How to choose an impregnation for wood

- Instructions on how to paint the walls with your own hands

- Which varnish for wood is better to choose

- How to choose a bituminous varnish

- How to calculate paint consumption per 1 m2

- What is alkyd paint and how to use it

- Types of liquid glass

- Water-based dispersion paint

- Best Fire Retardant Paint

- How to choose a color for paint

- Fire retardant composition for wood

- Powder painting at home

- Glue-based paint

- Best wall paint

- Painting tools and accessories

- How to choose the best paint roller

- Tips for choosing floor paint

- What is the advantage of Tikkurila paint

- The best textured wall paints with effects

- Types and applications of spray paint

- How to choose white paint

- The best varnishes for metal

- Step by step instructions on how to paint the ceiling

- TOP of the best yacht varnishes

- Best acrylic primer

- Types of the best paints for metal

- The best paint for wood

- How to choose the best ceiling paint

- Varieties of wood stains

- Review of the best rust converters

- What is the best wood preservative

- How to choose a paintbrush

- The best water-based paint for walls and ceilings

Types of solvents

White Spirit

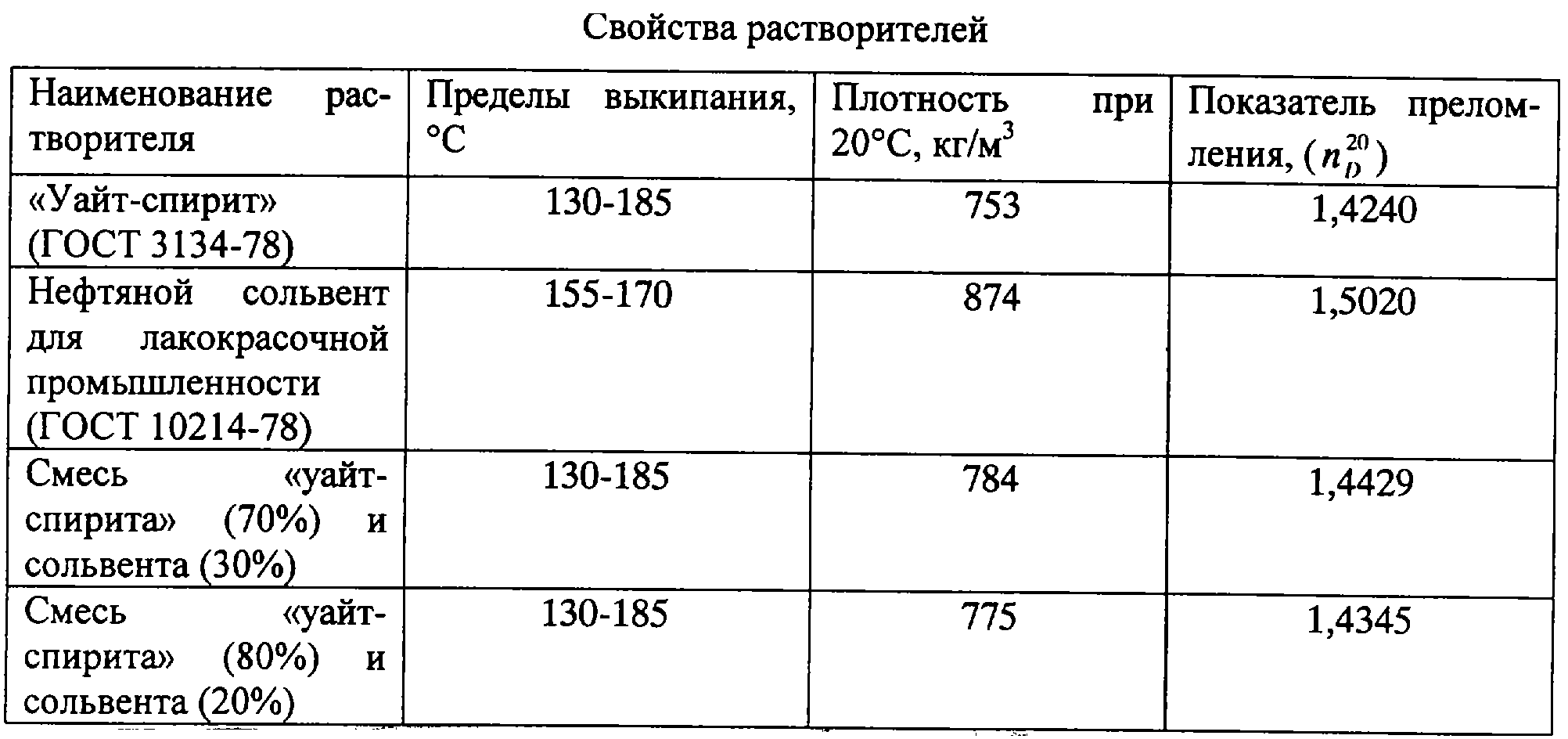

Solvent gasoline is a product of petroleum distillation. Its physical characteristics are as follows: clear, colorless liquid. Purpose: dissolution of nitro paints and some types of resins, as well as oil paints. In the case of paints and varnishes, the dosage of white spirit must be limited to 10% of the total mass of the paint and varnish material.

Turpentine

Colorless, often transparent, sometimes with a reddish or dark red tint, a liquid that is usually used in diluting paints and accelerating the drying of paintwork. Turpentine is mainly used to dilute oil paints

Turpentine is highly flammable. Wood (unrefined) turpentine is obtained by dry distillation of wood; Gum turpentine - by distilling the resin of coniferous species The first must undergo additional processing, due to which the coloring components contained in the wood turpentine will disappear from the solvent composition.

To understand whether you are satisfied with the quality of turpentine, it is necessary to mix oil and turpentine in equal proportions to the surface. If, after a day, a strong film remains on the paintwork, the quality of the solvent is undoubted.

Gum turpentine, or, as it is also called, turpentine oil, is more environmentally friendly than wood turpentine: it is distinguished by a calmer smell and lightness.

Turpentine is also used to degrease coatings, despite the high cost of this solvent, which is justified by the high quality of the working material.

Acetone, amyl acetate, ethyl acetate

Solvents used in the case of nitro paints. Since these substances mix quite easily with water, care must be taken not to get into them: this can cause whitening of the transparent film. If you add butyl alcohol solvents to the composition of these substances, then the gloss of the varnish film will significantly improve.

Solvent

Commercial coal is a mixture of aromatic hydrocarbons, which are obtained in the by-product coke production in the process of rectification of purified fractions of crude benzene. Physical characteristics of the solvent: it is a transparent colorless liquid, it is produced in three grades - A, B, C, which differ among themselves by the following parameters: boiling point, density, small fluctuations in the content of chemicals such as sulfur and phenols in the composition.

Solvent is a high quality paint thinner, however, due to its toxicity, the solvent is not as popular as turpentine. The solvent is used only for diluting pentaphthalic and glyphthalic paints.

Dichloroethane

The next solvent to be mentioned. This colorless, low-flammable liquid with a chloroform odor also tends to turn yellow due to exposure to sunlight.

Driers

These are special additives that increase the decorative effect, as well as the water resistance of the ready-made dye composition. In addition, they can significantly reduce the amount of time required for drying oil paints, varnishes, drying oils, and oils. However, these additives have a rather serious drawback: when using them, the paint and varnish coating becomes extremely fragile, and therefore it is recommended, if possible, to do without their use in surface treatment.

Scope of application

R646 brand solvent is used when performing repair and finishing works. Its purpose is to effectively dilute paints, as well as varnishes and nitro enamels. The product works well for all types of paints and varnishes.Recent studies have shown that P646 works well with alkyd, epoxy and melamine products, various types of putties and primers.

It has proven itself well in the following types of repair and finishing works:

- to bring paints to the required viscosity;

- for thinning thickened and film-forming varnishes;

- in the manufacture of nitro-varnishes and nitro-enamels;

- the solvent is often added to the putty and primer in order to increase the elasticity and create the required viscosity, which makes it possible to technologically level the surfaces to ideal smoothness.

In addition, with its help, painting tools are cleaned from hardened paint, returning them to working condition.

Degreasing of surfaces is considered to be a separate direction of use of solvent grade 646. If the surface is not degreased before applying the primer, the coating will begin to peel off in place of the remaining grease stains, and the adhesion (adhesion of the finish to the base) will significantly deteriorate. All thinning compounds can perform a degreasing function. However, the use of P646 has its own specifics.

This solvent is considered the most aggressive among its counterparts, its use requires special care. Acetone, which is an active component of the solvent, can damage the base, make its structure inhomogeneous, and lead to the appearance of irregularities

Acetone is especially aggressive to plastic, therefore it is not recommended to degrease plastic surfaces with it.

Any work with P646 is recommended to be carried out at a temperature of 5-30 degrees Celsius and a relative humidity of the room not higher than 85%.

The substance is toxic and volatile, therefore, when working, it is optimal use a respirator and gloves... It is recommended to wear special goggles to protect your eyes. If the substance comes into contact with the skin, the affected area should be treated with warm water and soap. If the solvent gets into the eye, you will have to immediately seek medical help at the nearest clinic.

The solvent is a highly flammable material.

Some "craftsmen" recommend pouring a solvent into gasoline to increase the octane number of the fuel, as well as to clean the nozzles and valves of the car's fuel system. Nevertheless, there are very few confirmed successful results of such actions, which means that there are no guarantees of its effectiveness.

Solvent R 4

Composition and properties

P 4 is an organic solvent containing aromatic hydrocarbons, ketones and ethers. It consists of 62% toluene, 26% acetone, 12% butyl acetate. The mixture of these components effectively dissolves and liquefies various paints, varnishes, resins and other organic substances.

There is a variety of it - the solvent R-4a, a feature of which is the absence of butyl acetate in the composition.

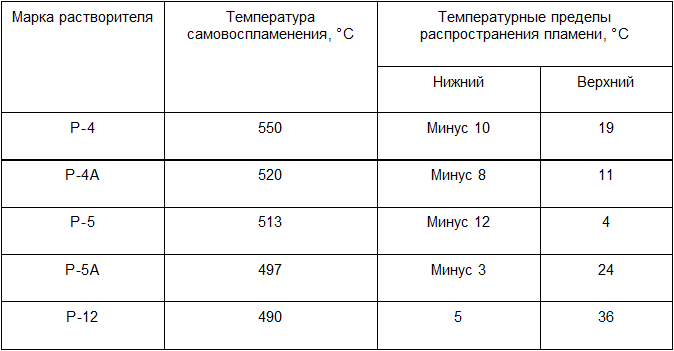

This tool is manufactured in accordance with GOST 7827-74. R-4 GOST is produced with the following technical characteristics:

- looks like a clear liquid without color or yellowish, without suspension (P-4 and P-4a look the same);

- water content - 0.7%;

- volatility - from 5 to 15;

- acid number, mg KOH / g - no more than 0.07;

- coagulation number - not less than 24%.

Application

This tool is used to dilute and dissolve varnishes, putties, enamels, primers, paints marked with XB, XC, HSL, EP, Vinicolor, Vinicor, Evikor, Evinal, HS-500 primer-enamel.

Also R-4 is used for washing dishes, hands and arms after working with paints and varnishes.

This solvent is suitable for dissolving and thinning enamels, varnishes, primers and putties with markings XC, XB, PVC, MS, EP-0020, except for XB-124 gray and protective enamel. The R-4a modification of this solvent can also dissolve the gray and protective enamel XB-124.

It is volatile, and its use is based on this: after adding a solvent to the paint and applying it to the surface, it quickly hardens and forms a film.

Security

Solvent R 4 is toxic, fire and explosive, therefore, when working with it, safety precautions must be observed.

- It is necessary to store the composition in fireproof ventilated rooms, away from sunlight, in sealed containers;

- it is also necessary to work with the solvent in rooms with good ventilation;

- avoid contact with eyes;

- work in protective gloves, avoid contact with skin, in case of contact with skin, wash off with plenty of warm water and soap.

Due to the fire hazard of the solvent in the room where it is stored and worked with it, sparks, open fire, and smoking must be excluded. In case of fire, P-4 is extinguished with foam, carbon dioxide, sprayed water. It should be remembered that vapors of the solvent and its components (butyl acetate, acetone, toluene) are heavier than air, can accumulate near the floor and are explosive.

The toxicity of the drug is manifested by narcotic effects (dizziness, headache, disorientation, blurred consciousness with prolonged inhalation), irritation of the eyes and other mucous membranes, and coughing. With prolonged inhalation of vapors, poisoning is possible, similar in symptoms to food, toxic damage to the nervous system.

Therefore, when working with a solvent, you should use protective equipment (goggles, gloves, respirator), work only in a well-ventilated area. If the product comes into contact with the skin, it must be washed off, if in the eyes, rinse them and seek medical attention.

Types of solvents

White Spirit

Solvent gasoline is a product of petroleum distillation. Its physical characteristics are as follows: clear, colorless liquid. Purpose: dissolution of nitro paints and some types of resins, as well as oil paints. In the case of paints and varnishes, the dosage of white spirit must be limited to 10% of the total mass of the paint and varnish material.

Turpentine

Colorless, often transparent, sometimes with a reddish or dark red tint, a liquid that is usually used in diluting paints and accelerating the drying of paintwork. Turpentine is mainly used to dilute oil paints

If you choose between refined and unrefined turpentine, then for painting surfaces you should pay attention to refined turpentine

Turpentine is highly flammable. Wood (unrefined) turpentine is obtained by dry distillation of wood; Gum turpentine - by distilling the resin of coniferous species The first must undergo additional processing, due to which the coloring components contained in the wood turpentine will disappear from the solvent composition.

To understand whether you are satisfied with the quality of turpentine, it is necessary to mix oil and turpentine in equal proportions to the surface. If, after a day, a strong film remains on the paintwork, the quality of the solvent is undoubted.

Gum turpentine, or, as it is also called, turpentine oil, is more environmentally friendly than wood turpentine: it is distinguished by a calmer smell and lightness.

Turpentine is also used to degrease coatings, despite the high cost of this solvent, which is justified by the high quality of the working material.

Acetone, amyl acetate, ethyl acetate

Solvents used in the case of nitro paints. Since these substances mix quite easily with water, care must be taken not to get into them: this can cause whitening of the transparent film. If you add butyl alcohol solvents to the composition of these substances, then the gloss of the varnish film will significantly improve.

Solvent

Commercial coal is a mixture of aromatic hydrocarbons, which are obtained in the by-product coke production in the process of rectification of purified fractions of crude benzene.Physical characteristics of the solvent: it is a transparent colorless liquid, it is produced in three grades - A, B, C, which differ among themselves by the following parameters: boiling point, density, small fluctuations in the content of chemicals such as sulfur and phenols in the composition.

Solvent is a high quality paint thinner, however, due to its toxicity, the solvent is not as popular as turpentine. The solvent is used only for diluting pentaphthalic and glyphthalic paints.

Dichloroethane

The next solvent to be mentioned. This colorless, low-flammable liquid with a chloroform odor also tends to turn yellow due to exposure to sunlight.

Precautions when using this thinner: a prerequisite when working with this substance is the use of rubber gloves, since the thinner, due to the specific chemical composition, can significantly affect the skin of your hands

Driers

These are special additives that increase the decorative effect, as well as the water resistance of the ready-made dye composition. In addition, they can significantly reduce the amount of time required for drying oil paints, varnishes, drying oils, and oils. However, these additives have a rather serious drawback: when using them, the paint and varnish coating becomes extremely fragile, and therefore it is recommended, if possible, to do without their use in surface treatment.

Ideal solvents for some resins are substances such as gasoline and kerosene. They are also used for washing hands that are stained with paint and for cleaning work tools.