Installation rules

Even if you have chosen the right anchor bolt equipped with a nut, focusing on the size and weight of the object to be fixed with it, improper installation will nullify all your efforts. There are a number of simple rules, the observance of which will allow you to provide the fastener with the required level of reliability and durability.

Stages of anchor bolt installation

The installation algorithm for an anchor bolt equipped with a nut is as follows.

- In the structure in which the installation of such a fastener is to be performed, a hole must be drilled. The diameter of the hole should be such that the spacer sleeve fits into it with some interference. To complete this procedure, you need a hammer drill and drill of the appropriate diameter.

- In order for the one equipped with a nut to form a reliable connection, the hole in which it is installed must be thoroughly cleaned of construction dust and pieces of material crumbled during drilling. If the hole is small, you can use a conventional medical bulb and a brush of the appropriate diameter to clean it. In the event that the hole for has a significant length and large diameter, then a vacuum cleaner can be used for high-quality cleaning.

- Once the hole has been prepared, the anchor bolt can be inserted. Although many experts recommend mounting anchor bolts with the object to be fixed, there is an easier and more efficient way to accomplish this procedure. On the anchor bolt installed in the hole, the nut is tightened - until the spacer sleeve is expanded to such a state that the fastener is securely fixed. Then, when the anchor is securely fixed in the hole, you can twist the nut from it, leaving its threaded end free in order to put on the object to be fixed. After that, you just have to put a washer on the threaded end and screw on the nut.

Varieties of anchor bolts

The classification of anchor bolts offered by modern manufacturers is made according to many parameters. They all fall into two categories:

- with mechanical fixation;

- the use of chemical adhesive fillers;

- on the vibro-checker.

In the first case, the reliability of the fastening is ensured by creating conditions that significantly increase the friction force. In the second, fastening is added to the initial effect (mechanical fastening) through the use of reliable adhesive joints. In this case, the effect of adhesion is used - the ability of the adhesive to penetrate the pores of the material where the sleeve is placed. To implement the attachment, you need a tube of adhesive and a special gun. First, glue is squeezed into the hole. Then the anchor bolt is driven in. Such anchors are used to fasten structures in some brands of aerated concrete or in walls made of a material with a porous structure.

In more detail, the types of anchor bolts are classified according to the following parameters:

- purpose and field of application;

- form of design;

- geometric dimensions;

- type of attachment;

- head shape;

- bushing material.

More details on the purpose and scope of application are given below.

The following types of anchor bolts are distinguished by the form of design:

- hook-shaped design;

- with a ring fixed on the tip;

- with a fixed nut;

- stud anchor.

The installed hooks are used for the subsequent installation of hinged structures. Products are attached to the finished rings, which have a hinged system on ropes or cables.There are anchor bolts with a fixed nut. This allows you to set the screw-in depth of the anchor. The latter design is secured on both sides. They are tightened with a nut. Most often, such bolts are equipped with a tapered working part of the sleeve. The use of such a design allows you to choose the most optimal pressure on the walls of the hole, that is, the adhesion force of the anchor and the wall.

Anchor studs are classified into HAS and HST designs. They allow working in concrete that is prone to cracking. With their help, through fastening is carried out.

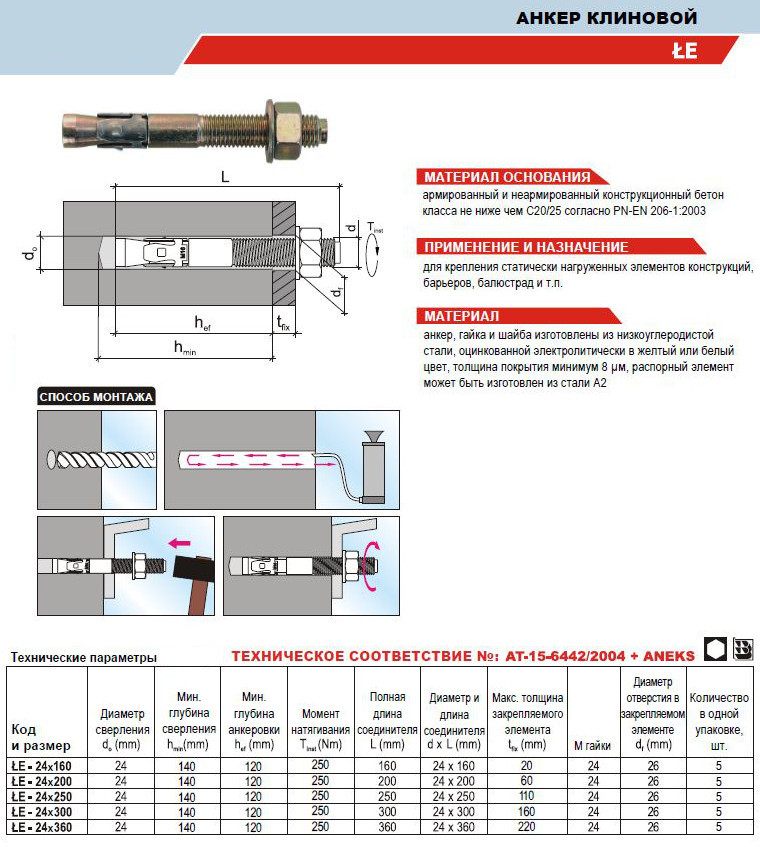

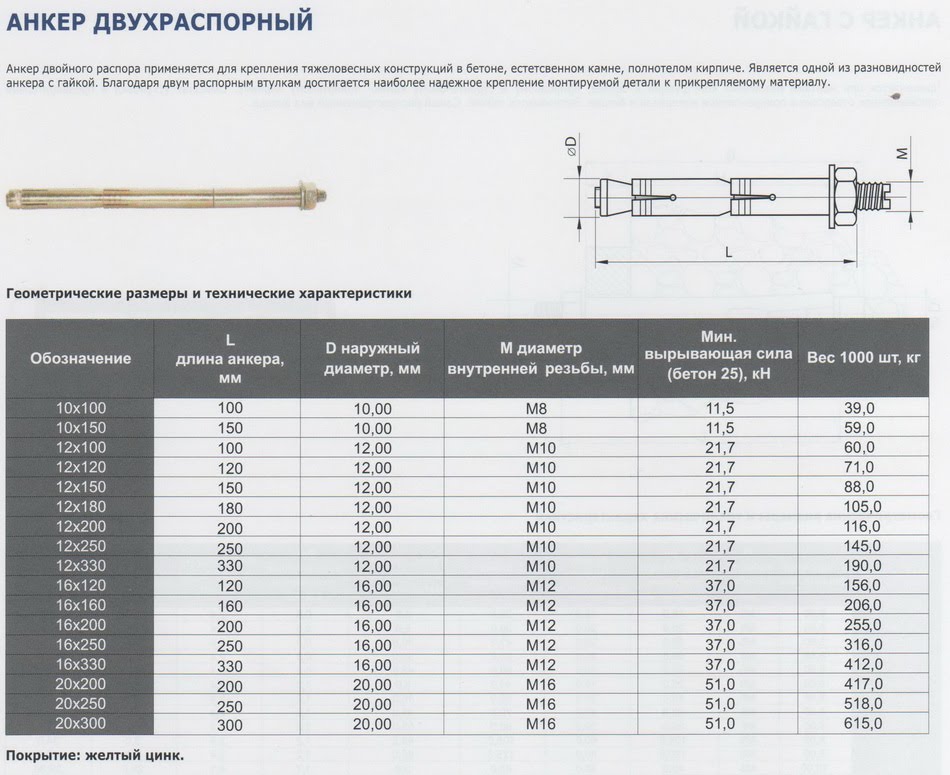

According to the type of fastening in the wall or ceiling, anchors are divided into two categories: expansion and wedge. The most widespread is the first type. In practice, one and two spacer structures are used. The product of the second type is equipped with two sleeves, which makes it possible to increase the resistance and improve the reliability of the fastening.

According to the shape, the heads of the anchor bolts are made under the key or for a screwdriver. In the second case, the most common are the grooves for a Phillips screwdriver.

Depending on the type of fastening, they are subdivided:

- conventional anchor bolt;

- bolt with sleeve and nut;

- spacer-type collet bolt;

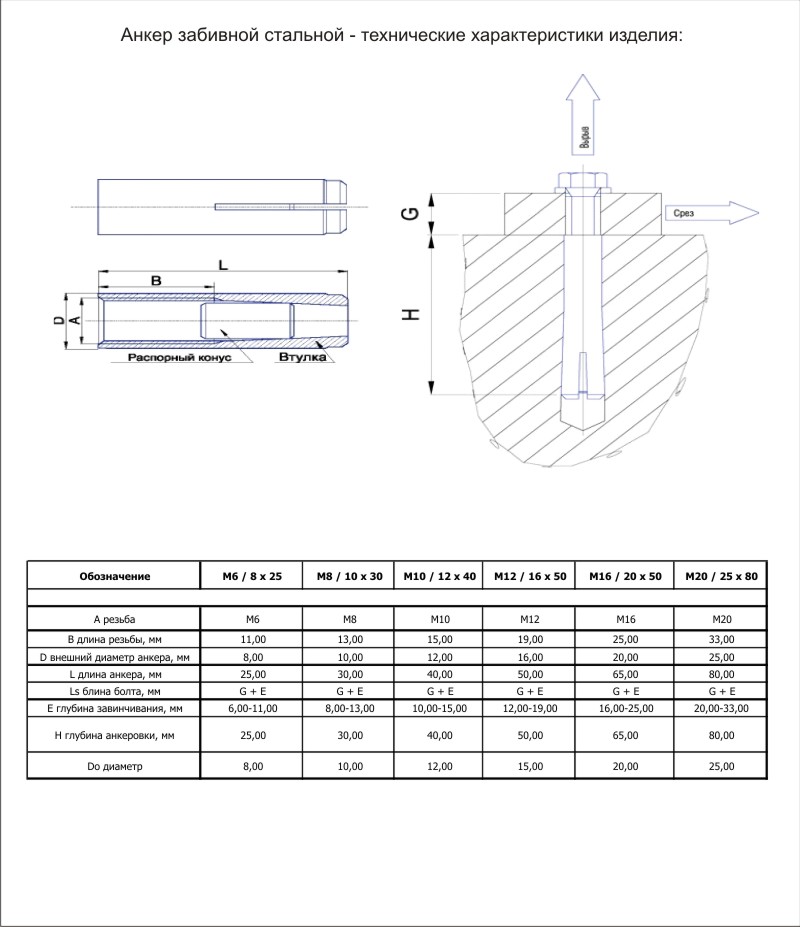

- driven anchor bolt.

All these designs work on the principle of expansion of the sleeve at the moment of tightening the bolt rod. The collet bolt has the most complex bushing design. There are four cuts on its surface. Therefore, at the moment of screwing in, its end takes the form of four petals, which makes it possible to increase the reliability of the installation. The drop-in anchor has a tapered sleeve with internal slots. As the anchor is driven into the hole, the sleeve contracts, the central notched parts expand.

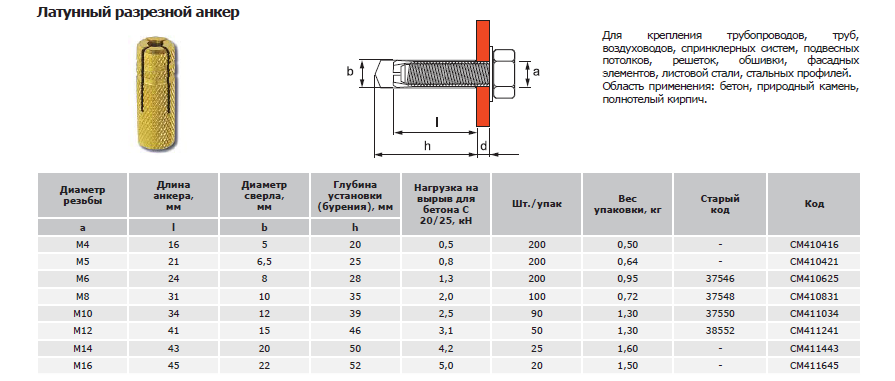

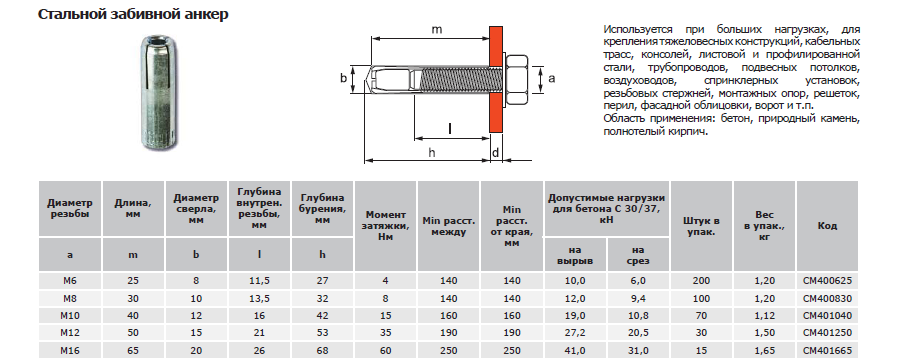

Anchor bolts are made of steel or brass. In accordance with standards and building codes and regulations, steel is selected depending on the application and operating conditions of the fastener. In some cases, individual grades of carbon steel are used, for example, VSt3kp2; for low-temperature conditions, low-alloy steel of 09G2S-8 grade or their analogs is used.

Expansion anchor: choice depending on the application

The expansion anchor is a fastener made stainless or carbon steel... One end of the fastening bolt has a thread for fixing, and the other is equipped with a special sleeve, which expands due to the action of the fastener. This anchor design allows for maximum joint strength.

Another advantage is the ability to remove fasteners without destroying the surface of the connected elements. Where space anchors are used and how to choose the right device for a specific purpose, read on.

Range of use for expansion anchors

The main advantages of the expansion sleeve anchor bolt are:

- ease of installation and dismantling. No special tools are required to install / remove the fastener. It is enough to prepare a punch and a hammer;

- strength. Products are made of steel (carbon or stainless steel) and are coated with a zinc layer for additional strength, which protects the steel from corrosion;

- resistance to mechanical damage and chemical attack;

- fastening efficiency.

Expansion anchors are used:

- in construction. With the help of fasteners of this type, it is possible to assemble and install individual elements of large prefabricated structures, for example, electrification poles, scaffolding, road fences, and so on, as well as to fasten ready-made structures to vertical or horizontal bases;

- at home. With the help of anchors with spacer sleeves, window frames, doors, stairs, lamps and other devices are fastened.

How to choose a stop anchor

The choice of anchor should be based on the following parameters:

- bolt varieties;

- overall dimensions of the fastener;

- manufacturing company.

Anchor type

Expansion anchors of the following types are manufactured by modern manufacturers:

- Washer bolts are the most common type of anchor bolts. Widespread popularity is achieved due to the ease of fastening and maximum strength. Washer anchors can be used for concrete, brick and other monolithic bases, as well as bases with low porosity.

- Anchors with fixing nuts are mainly used for fastening heavy and large objects, since a pre-installed nut allows you to reduce the time for fixing and, accordingly, holding the object "in the air".

- Expansion anchor with ring or hook. Such a fastening element is used when it is necessary to suspend individual items, for example, a ceiling lamp. The fastening element is pre-installed in the base (ceiling) and then a structure is hung.

- Stud anchor is used for through fastening of structures or individual parts. Studs are usually equipped with washers and lock nuts.

Fastener dimensions

For strong fixation, it is required not only to choose the right type of anchor bolt, but also to pre-determine the dimensions of the fastening element.

Bolts are currently available in various lengths and diameters. The selection of overall dimensions is made depending on the weight of the structure to be fixed. The greater the weight of the object to be fixed, the larger the expansion anchor must be used.

Popular manufacturers and their features

Many anchor bolt parameters (dimensions, safety factor, etc.) depend on the manufacturer of the fastener. The main manufacturers of expansion anchor bolts today are:

- Hilty Company (Liechtenstein). Fasteners are made of zinc-coated steel. The variety of the range of expansion bolts allows fixing structures with different dimensions (HSA or HSV for small shapes and HSL 3 or 3G for large objects), as well as the use of bolts in seismic areas (HST marking).

- Fischer company (Germany). The anchors are characterized by increased strength, which allows the use of fastening bolts in various climatic conditions.

- Anker-DV company (Russia). A wide assortment, reasonable price category, as well as high quality make it possible to choose expansion anchors for both industry, construction and domestic needs.

Thus, expansion anchors are the most common types of anchor fasteners, since they can be used in almost any conditions and are able to hold even objects of high weight and large overall dimensions.

Application area

Anchors, which in accordance with the regulatory document (GOST 26778-90) are called self-anchoring bolts, are strong fasteners with which you can securely fix various objects on structures made of solid materials. The high reliability of fixation provided by such an anchor is explained by the fact that its entire outer part adheres to the inner surface of the hole with a high frictional force, forming an exceptional holding capacity.

The spacer fastener will demonstrate its high efficiency only if it is installed in a material that has a high density. Thus, the principle of operation of such an anchor is fundamentally different from the principle of operation of a dowel, the outer part of which contacts the inner surface of the hole only at separate points, and not along its entire length. Accordingly, the spacer type fastener is able to provide a significantly greater reliability of the joint being formed.

GOST 28778-90 Self-anchored spacer bolts for construction. SpecificationsDownload

Expansion anchors are used to secure a variety of structures under significant load

Unlike the dowel, which is mainly made from polymeric materials, strong metals are used for the manufacture of anchors - carbon steel, brass, etc.In the event that such a fastener is made of steel, it is additionally protected against corrosion by applying a white or yellow zinc coating to its surface.

The working part of the spacer type is a hollow sleeve, on the side of which longitudinal cuts are made, forming expanding petals. In the inner part of such a sleeve there is a spacer element, which, when the anchor is driven into a previously prepared hole, expands the petals, which contributes to reliable fixation of the fastener in the hole. The upper part of such a fastener is a stud, on the threaded part of which there is a washer and an adjusting nut.

The figure shows the simplest design of an expansion anchor with a solid sleeve along the entire length

Installation of the expansion anchor does not present any particular problems, does not require the use of complex equipment and the availability of special skills from the performer. This process consists in the fact that such a bolt is carefully hammered into a previously prepared hole until it stops, and after it is securely fixed, objects that need to be fixed are hung on its threaded part.

It is most effective to use such various objects on structures made of dense materials with good adhesion (concrete, brick, natural stone, etc.). In the event that there are internal cracks in structures made of concrete and any other materials into which such a bolt will be mounted, the load that the fastener can withstand will be significantly reduced.

The design of the anchor for critical fastenings is more complex, but it allows the use of fasteners even under vibration loads

Today, anchor-type expansion bolts, the parameters of which must comply with the requirements of GOST 26778-90, are successfully used to carry out the installation of such items and products as:

- heavy and oversized window and door frames;

- elements of staircase structures;

- elements of various types of suspended ceilings;

- lamps and chandeliers;

- scaffolding for construction and finishing works;

- gates and wickets;

- elements of various communications (air ducts, cable routes, water pipes, etc.);

- balustrades and consoles;

- various products made of steel and differing in significant weight.

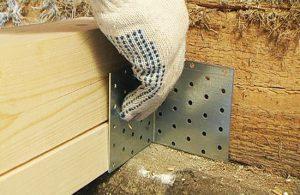

Fastening the lag to the expansion anchor

The most significant characteristics of expansion anchors, for which they are appreciated by experts, are:

- extremely high strength and reliability;

- resistance to mechanical damage, exposure to negative environmental factors;

- the convenience of use;

- the speed of creating fasteners.

Methods for mounting a lag on a concrete floor

Installation work consists in laying wooden beams on prefabricated or monolithic reinforced concrete foundations.

An important condition for the high-quality performance of work is the correct choice of fasteners and adherence to the technological scheme for placing the lags on the surface of the base:

- The beam should be installed across the line of light from the windows, parallel to the window or doorway. A gap of 25-30 mm must be left between the walls and the profile.

- If sound insulation is needed, then the substrate under the logs is laid in a continuous strip along the entire length, without gaps.

- Mounting holes and seams between prefabricated elements must be filled with cement-sand mortar grade not lower than M150.

- The lags must touch the surface of the floor slabs without gaps. It is recommended to fill the voids between the timber and the base with fine sand or fill with polyurethane foam.

- The minimum length of the spliced bars should be ≥ 2 m. Short profiles should be connected with their ends to each other anywhere in the room with an offset of the seams in parallel logs by 0.5 m.

- In the doorways of adjacent rooms, it is necessary to put a widened beam protruding 50 mm beyond the partition on both sides. This is done so that the topcoat in different rooms rests on the same base.

- The horizontal level of the profile laying is checked with a two-meter rack and pinion tool.

- Before the device of the finishing flooring, the space under the floor is cleaned of chips, shavings and debris.

Fastening with self-tapping screws

When fastening to self-tapping screws, it is recommended to use hardware with a nickel-plated surface complete with plastic plugs that have a protruding edge for the screw head. The diameter of the screw is 3.5 mm, the length is selected taking into account the height of the log - 50-150 mm.

Through holes are drilled in the logs 0.5-1.5 mm smaller than the screw diameter. Holes for plugs are drilled in the floor slab using a perforator. Then a nylon dowel is inserted into the concrete floor and the profile is laid. Check the alignment of the holes and screw in the self-tapping screw. The horizontal level of the lags is adjusted with fasteners and substrates, loosening or tightening the connection.

Anchoring

Anchors provide stronger anchoring than nail dowels or screws. The principle of installing the fixtures is the same as for self-tapping screws, but instead of a nylon dowel, a spacer metal sleeve is inserted into the base. The optimal diameter of the fastener is 6-10 mm, the length is 50-150 mm. Due to the high density of the connection, one anchor is enough for 1 m of timber.

Fastening the lag to a metal corner

Fastening with corners.

Fastening with corners.

The profile is fixed on either side to the base of the floor using a dowel or anchor. The lag is placed in the cavity of the corner and screwed with a screw. The distance between the fixings depends on the length of the room and should be 35-50 mm.

The same procedure can be done with metal perforated brackets. In this case, the bar will be covered on both sides by the shelves of the device.

Adjustable lags

There are 4 types of adjustable fasteners for the sub floor:

- plastic supports (posts);

- studs with nut and washer;

- polymer bolt stand;

- threaded bushings.

The most convenient prefabricated designs with threaded through couplings, which can be of the following sizes:

- 0.45 x 0.45 x 2.0 m;

- 0.45 x 0.70 x 2.0 m;

- 0.45 x 120 x 2.0 m.

They are supplied with threaded studs for adjusting the profile lift and dowels for fixing the stud bolts to the base.

Fastening of adjustable lags.

Fastening of adjustable lags.

Assembly order:

- Before installing the structure, plastic bolts are screwed into the holes in the profile, on which the logs will rest.

- The bars must be placed parallel to each other with a pitch of 350-375 mm.

- Then holes are drilled in the concrete base for the installation of vertical connections. A dowel-nail is inserted into this place through the rack.

- With the help of a special key, turning the mounting rack left and right, adjust the horizontal level of the log.

- The dowel-nail is driven in until it stops, the reliability of the connection is checked and the next profile is passed.

Fastening the lag to concrete pillars

Under the logs installed on, 1-2 layers of waterproofing material (roofing material, etc.) are laid, the edges of which should extend beyond the boundaries of the base by 30-40 mm. On top of the insulation, a fiberboard substrate is placed in one layer. The profiles are fastened using dowels or self-tapping screws.

The joining of the timber must be done only in the center of the monolithic support. Alignment of the lag level is performed by changing the thickness of the pads.

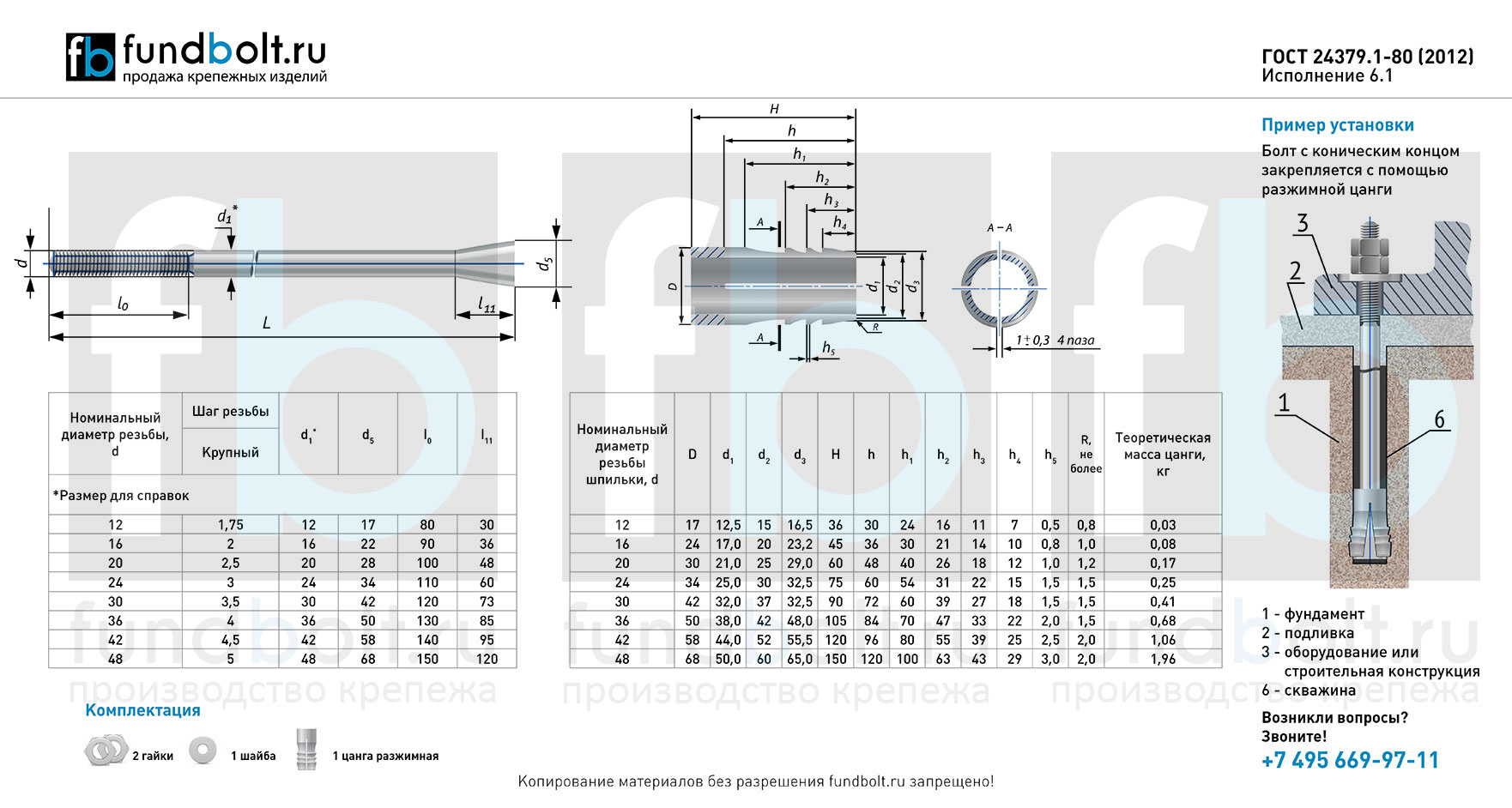

EXAMPLES OF CALCULATION OF SELF-ANCHORING TAPER BOLTS

Example I.

Determine the diameter d self-anchored tapered bolt with caulking

(type I) and the required depth of its embedding in the foundation made of concrete of class B12.5,

at design bolt load R = 30 kN, its distance from the edge

foundation l cr = 12 cm, bolt spacing l s = 25 cm, with multiple repetitive loading N

= 1012 cycles.

R b a =

145 MPa - design tensile strength of bolts,

R b t =

0.66 MPa - design tensile strength of concrete of class B12.5.

Using the formula (3), we determine the diameter of the bolt

Using the formula (2), we determine the design resistance of the bolt to fatigue

destruction

Checking the bolt

fatigue endurance according to the formula (4)

Because P3 Q =

0, P 3 = P3 p = R(1-χ). V

in accordance with clause 3.15 of these Recommendations, χ =

0.3, then

R s = 30 (1-0.3) = 21 kN.

According to the table. 8 of these Recommendations at the number of cycles

N = 1012 and determine Krb: Krb =

0,96.

According to the formula (5)

find the depth of the bolt embedment.

Into the calculation we enter

coefficient Kdl = 0.85 (for bolts with caulking), since Kdl = 0.85

Given

distance between anchors l δ = 25cm = 15.6 d > 10d and, therefore, Kp = 1.0.

Distance

bolts from the edge of the foundation l cr = 12cm = 5.5 d

According to the table. 7 define

coefficient Вкр = 1.18, then the embedment depth will be: h3, kr = 14.7 × 1.18 = 17.3 cm.

We accept

bolt embedment depth equal to 17 cm.

Example 2. Determine the diameter d

self-supporting conical bolt with collets (type II) and its embedment depth h3

for fastening equipment to a column with a section of 30 × 30 cm made of class concrete

B30 (R bt

= 1.3 MPa) under the action of transverse forces Q = 5 kN and longitudinal forces Рпр = 20

kN. The equipment is fixed to the column with four bolts without shims. Distance

from the edge of the column to the axis of the bolt - 8 cm, between the bolts along the height of the column - 25 cm

(see fig. 10).

Rice. 10 for example 2

Condition of clause 3.12 of these Recommendations

is fulfilled since Q = 5 kN ≤ 0.5 Рпр =

0.5 x 20 = 10 kN.

Design effort

per bolt (see clause 3.12 of these Recommendations) is

In accordance with

nn. 3.15 and 3.16 real

Recommendations χ = 0.25 and f = 0,3.

Using formulas 8-10, we determine the required tightening force

bolts

R R s = (1 -0.25) × 20 = 15 kN;

R s = 15 + 4.2 = 19.2 kN R

= 0.9 × 28.6 = 25.8 kN

Using the formula (3), we determine the diameter of the bolt

We accept

anchor bolt with a diameter of 16 mm.

Using the formula (5), we find the depth of the bolt embedment.

Meaning

coefficient Kdl in accordance with clause 3.7 of these

0.9 of the recommendations accepted. It is necessary to take into account the influence of the edge and the distance between

bolts for their bearing capacity.

l cr = 8 cm = 5 d ... By column width l δ = 30-8.0 × 2 = 14cm = 8.7 d ... By

column height l δ = 25 cm> 10 d.

In accordance with paragraphs. 3.9 and 3.11, according to table. 6

and 7 of these Recommendations determine the values of the coefficients

Kp and Vkr:

Kp = 1.11; Vcr = 1.30.

Embedment depth

taking into account Кп and Вкр is:

h = Кп × Вкр ×h3

= 1.11 × 1.30 × 9.5 = 13.7 cm.

We accept

embedment depth of bolts 14 cm.

install the bushings in accordance with clause 3.13 of these

Recommendations.

Application

5

Installing and securing anchor bolts

Several special steps are required to secure the anchor to the base

To begin with, it is very important to choose the right anchor bolt in terms of size and weight.

Remember that finishing the material is unable to withstand this mount, therefore it must be screwed right through to the concrete or brick base.

Thus, calculate the thickness of the coating and take into account the immersion of the bolt into the concrete by another 50 mm. In this case, the anchor will be installed correctly.

The drill, which will make the hole in diameter, should be about half a millimeter smaller than the bolt itself. This is done so that the anchor bolt is installed into the wall with little effort and the fastening is therefore more reliable.

Find the right drilling equipment. To do this, be sure to consider the type of base. Next, you need to drill holes in the marked places.

Clean the surface of the base and the hole itself from dust and dirt. Insert a sleeve into the hole and drive it there. Then insert the stud into the sleeve and screw the nut onto it. Tighten very carefully, as soon as the nut reaches the sleeve, secure it with a special wrench.

Anchor packaging usually indicates how many turns of the wrench are required to securely tighten without causing damage. In some cases, it is permissible to completely immerse the nut into the cladding layer to the base. But for this, only specialized nuts are used.

This information will also appear on the bolt packaging. In this way, the anchor bolts are fastened.

Concept, purpose and application of anchor fasteners

Anchor is a type of fastener that is driven in, screwed in or inserted into the base and is able not only to be fixed in it, but also to hold an additional structure.

Translated from German, anchor means "anchor".By the method of action on the base, fasteners of this type really resemble an anchor - the working part of the anchor expands when fastened and holds the connection on the base.

Fasteners of this type are used when working with solid base materials - concrete, brick, natural stone. The anchor allows you to hold sufficiently massive or dynamically loaded structures, for example, sanitary ware, air conditioners, wall-mounted TVs, sports equipment, suspended ceilings, etc.

Expert opinion

Torsunov Pavel Maksimovich

The versatility and reliability of the anchor connection allows them to be used when working with other materials. For example, there are anchors for fixing in porous and lightweight materials, for connecting furniture elements. This type of fastening connection has found its application even in dentistry - the anchor pin is fixed in the root canal of the tooth and serves as a support for a filling or microprosthesis.

FOUNDATION BOLT TIGHTENING TOOL

Table 25.

Hand tool for tightening foundation bolts

|

Tool name and brand |

Torque range |

Manufacturing plant |

|

Yaw keys, double-sided, |

Perm plant |

|

|

GOST |

||

|

GOST |

M 16- M 56 |

|

|

GOST |

M64-M140 |

|

|

GOST |

M 64- M 140 |

|

|

GOST 16983-80 E |

M16-M42 |

|

|

Colic assembly wrenches (with open |

M10-M24 |

Also |

|

Key multiplier brand: |

M27-M36 |

« |

|

KM-70 |

||

|

KM -130 |

M30-M42 |

|

|

KM-200 |

M42-M56 |

|

|

KM-400 |

M48-M64 |

|

|

KM-600 |

M64-M76 |

|

|

KM-800 |

M64-M100 |

|

|

Yaw keys with self-tightening jaws, |

M14-M24 |

Gorky plant |

|

Ratchet wrench, colic, with set |

M14-M30 |

Also |

|

Ratchet wrench with articulated |

M42-M140 |

Noginsk experimental plant |

|

Special mounting keys, type KT-22r, |

M22-M36 |

Also |

Table 26.

Power tool for tightening anchor bolts

|

Specifications |

Electric wrenches |

Pneumatic wrenches |

||||||||

|

EEZ116 |

EEZ117 |

IEZ 113 |

EEZ114A |

EEZ118 |

EEZ115A |

EEZ112 |

IPZ111 |

IPZ112 |

IPZ113 |

|

|

The largest diameter of the tightened bolts, mm |

12 |

12 |

16 |

16 |

27 |

27 |

48 |

12 |

14 |

18 |

|

Maximum tightening torque, N.m |

63 |

63 |

125 |

70 |

70 |

210 |

63 |

100 |

100 |

250 |

|

Electric motor power, W |

120 |

120 |

180 |

180 |

210 |

210 |

120 |

— |

— |

— |

|

Voltage, V |

220 |

36 |

220 |

36 |

36 |

220 |

220 |

— |

— |

— |

|

Current frequency, Hz |

50 |

200 |

50 |

200 |

200 |

50 |

50 |

— |

— |

— |

|

Working air pressure, MPa |

— |

— |

— |

— |

— |

— |

— |

0,5 |

0,5 |

0,5 |

|

Specific air consumption, m3 / min |

0,7 |

0,7 |

0,9 |

|||||||

|

Weight (without cable), kg |

3,1 |

3,1 |

3,8 |

3,5 |

5,2 |

5,2 |

12,0 |

1,9 |

2,2 |

3 |

|

Manufacturer |

Konakovsky plant |

Rostov plant |

Vyborg plant |

Moscow plant |

Table 27.

Tool for checking the tightening of anchor bolts

|

Tool name and brand |

Adjustable torque range, Nm |

Manufacturer |

|

Torque wrenches KD-60 |

10-600 |

Noginsk experienced |

|

Limit ratchet wrenches |

||

|

KPTR-8 |

10-80 |

Also |

|

KPTR-30 |

80-300 |

|

|

KPTR-60 |

300-600 |

|

|

KPTR-130 |

600-1300 |

|

|

Hydraulic tongs complete with trolley |

up to 10,000 |

Minmontazhspetsstroy |

- Recommendations 14 On the issuance of licenses for construction products

- WB Letter 11-258 / 7 Methodological recommendations on the procedure for organizing and holding tenders for the placement of centralized investment resources (temporary provisions)

- GOST R ISO 10075-2-2009 Ergonomic principles for ensuring the adequacy of mental stress. Part 2. Design principles

- GOST R IEC 60079-30-2-2009 Explosive atmospheres. Distributed resistive electric heater. Part 30-2. Design, Installation and Maintenance Guide

- GOST R ISO 22742-2006 Automatic identification. Bar coding. Linear barcode and 2D symbols on product packaging

- GOST R ISO / IEC 37-2002 Consumer goods. Instructions for use.General requirements