Cement consumption

After calculating the required amount of the mixture, it remains to find out how much and what brand of cement should be purchased. At the same time, it is always better to buy cement "with a margin" - in case of unforeseen consumption or large errors in calculations.

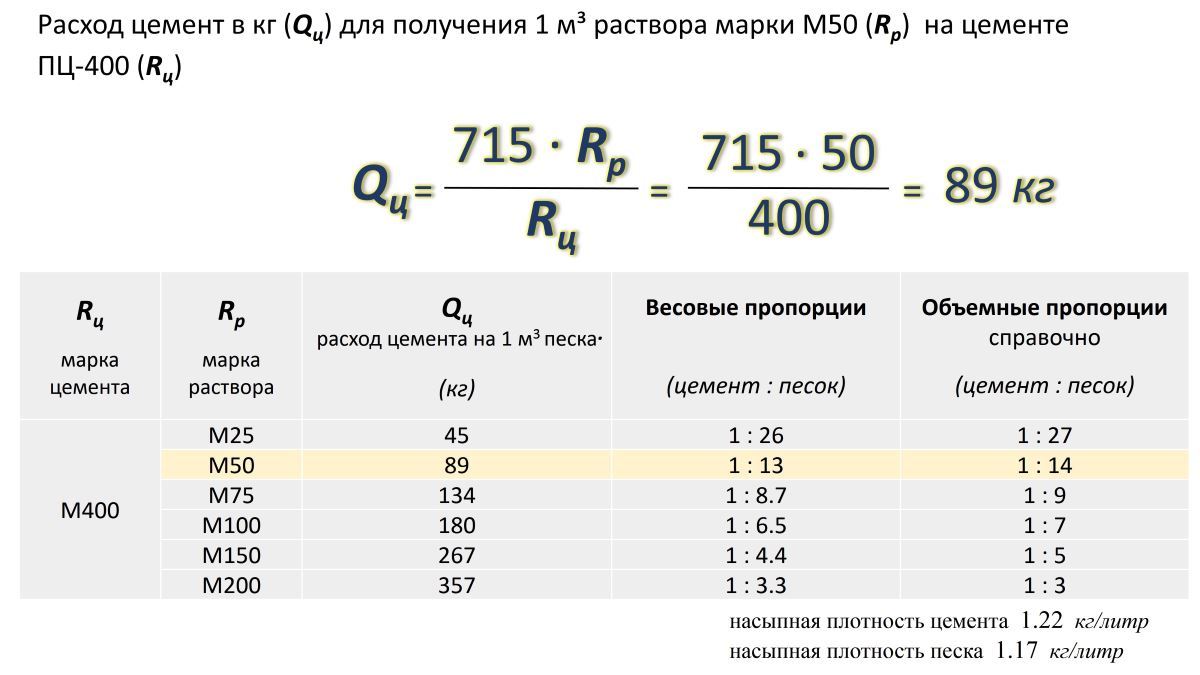

If a total of 20.0 m3 of the mixture is required, and the proportion of the mortar is 1: 3, then the resulting value must be divided by 4. You get 5.0 m3 of cement. However, cement is not measured in cubic meters; it will have to be converted into kilograms. To do this, you need to know the density of the hardener, which can be very different for different brands. On average, the value is approximately 1300 kg / m3. Taking into account the knowledge of this indicator, it remains to make simple calculations: multiply the density by the volume. Thus, we get 5.0 * 1300 = 6500 kg, or about 130 bags, taking into account that the weight of each bag is 50 kg.

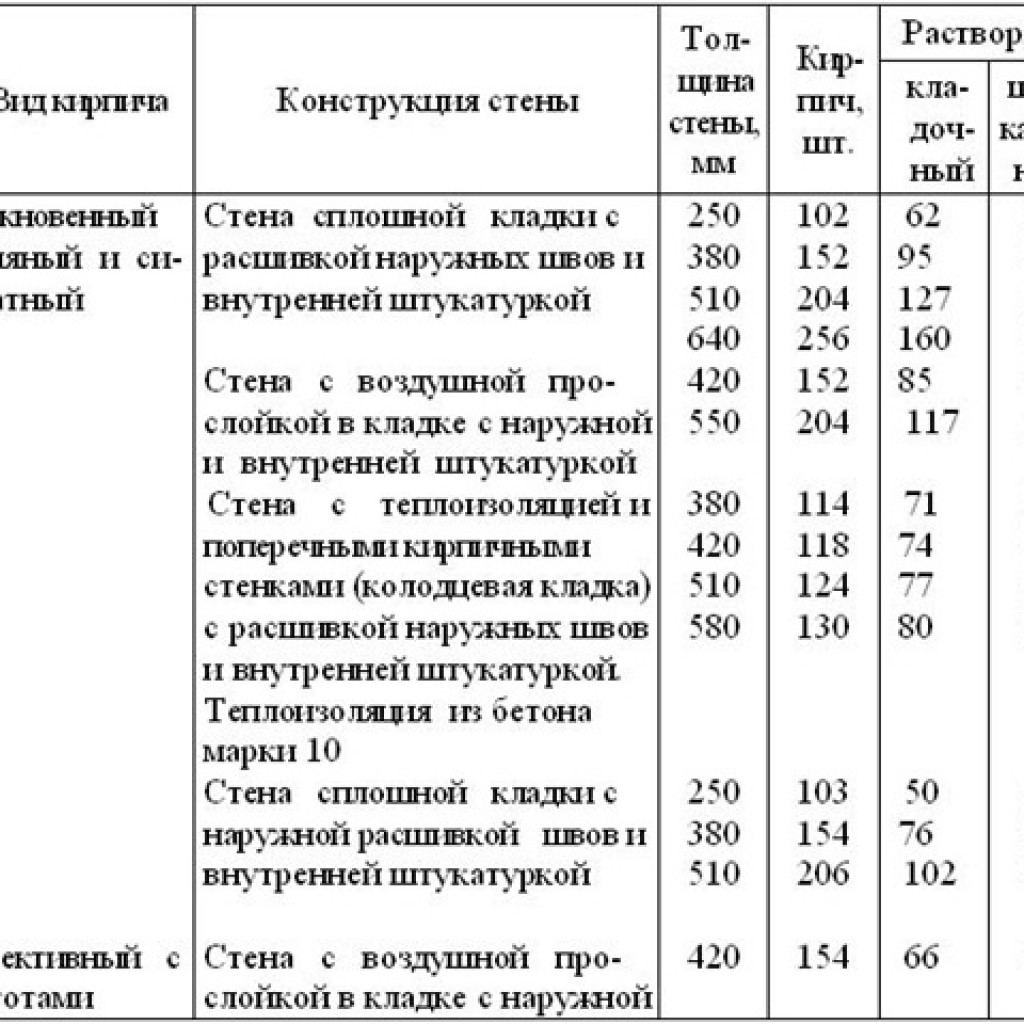

Consumption of mortar for 1m3 of brickwork

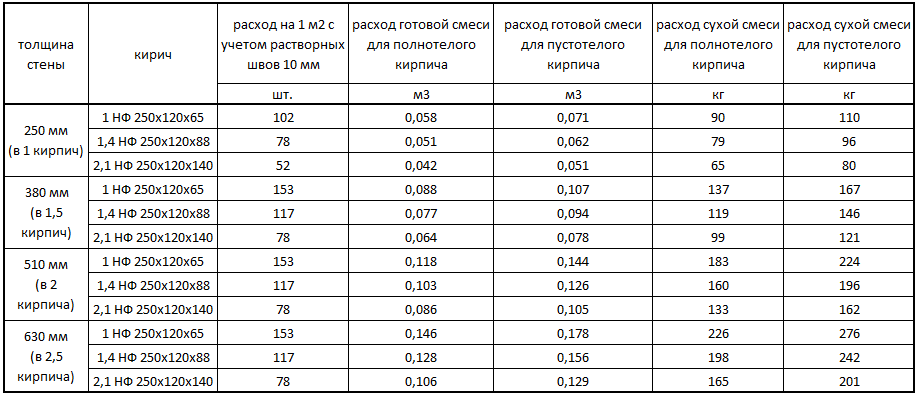

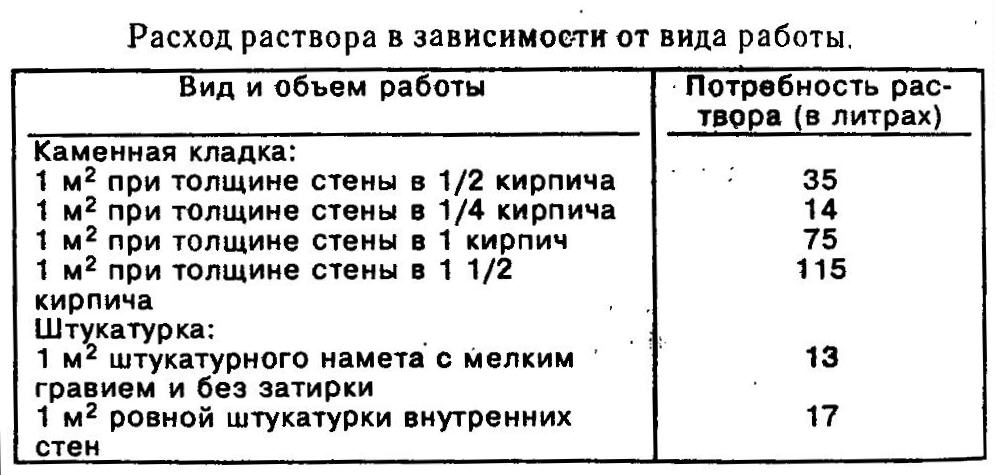

Approximate mortar consumption per 1 m2 of masonry

Most builders calculate the consumption of mortar for masonry approximately, but there are certain subtleties that are very important to consider. So, the rates of mortar consumption per 1 m3 of masonry can be different, and this is what will be discussed below.

A little about brickwork

As you know, the use of bricks in construction is an extremely widespread phenomenon. Buildings made of this material are distinguished by high reliability rates, they retain heat well and transmit much less noise compared to structures made of some other materials.

Factors affecting the costs of the cement mixture

What affects the consumption of the solution

The criteria on which the volume of mortar consumption per 1m2 of masonry depends are as follows:

- The thickness of the walls of the structure, which can be 1, 1.5 and 2 bricks.

- The type of cement used for the anchorage.

- The type of building materials used, which can be either solid or hollow from the inside.

The principle of manufacturing building anchoring material:

Depending on which components are included in it (sometimes structures such as clay, lime are used), the consumption of mortar per m3 of masonry may be different.

Professional skills of the one who mixes ready-to-install cement:

- It is believed that in such work there is nothing difficult and even an inexperienced owner can do it with his own hands.

- However, a very common reason for overspending is that, due to his inexperience, the master uses more material than the instructions require.

Based on what type of cement is used in the fixing composition, some conclusions can also be drawn.

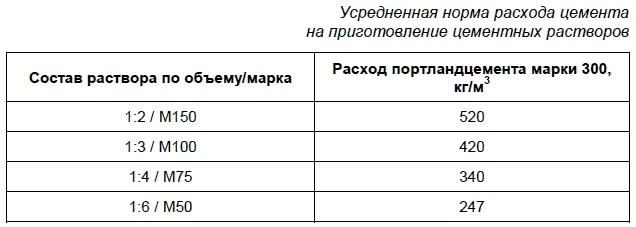

How much dry raw material is required for 1 m3 of building mixture?

Each type of cement has its own measures.

So, studying the rates of mortar consumption for laying partitions in ¼ bricks, dry raw materials are used in the following quantities:

- Cement brand "M50" - 2.5 kg.

- Mixtures of type "M75" need 4 kg.

- For cement grade "M100" you need to apply 5 kg.

There are some other ways to take measurements:

- If the installation is carried out in 1 brick, then the mortar consumption per 1m / sq of masonry will be approximately 75 liters.

- When designing partitions of 1.5 elements, this parameter will change and will be equal to 110 liters.

The amount of cement per cubic meter

The required amount of cement for the preparation of 1 m3 of building composition:

- Professional specialists use such measures very often, since the principle of all calculations lies in the basis of the volume.

- It is believed that in order to prepare 1 m3 of the composition, at least 400 kg of cement will be required (in other words, standard bags of 50 kg).

- At the same time, the consumption of masonry mortar per 1 m3 of masonry will be about 0.25 m3 of the resulting composition.

- It is these proportions that are taken as optimal and used in construction.

Cost rate

Despite this, in certain sources, the data may differ slightly, the reason for which may be the presence of different styling options.

The previously indicated rate of mortar consumption per cube of masonry is suitable for the standard installation procedure and may well be taken into account when building a brick building on your own.

With long-term storage, the technical characteristics of the material are significantly reduced, and the cost of such an error is very high:

For example, the cement brand "M400" after six months of its acquisition in its properties will correspond in its properties to the brand "M200" or "M100".

Tools used to calculate composition costs

When calculating the cost of the consumption of cement mixture for the installation of bricks, it is necessary to take into account the list of tools required for this procedure.

These include:

The use of a cement composition when installing shell rock

First of all, it should be noted that the consistency of the anchoring structure for mounting the shell rock must have certain viscosity parameters.

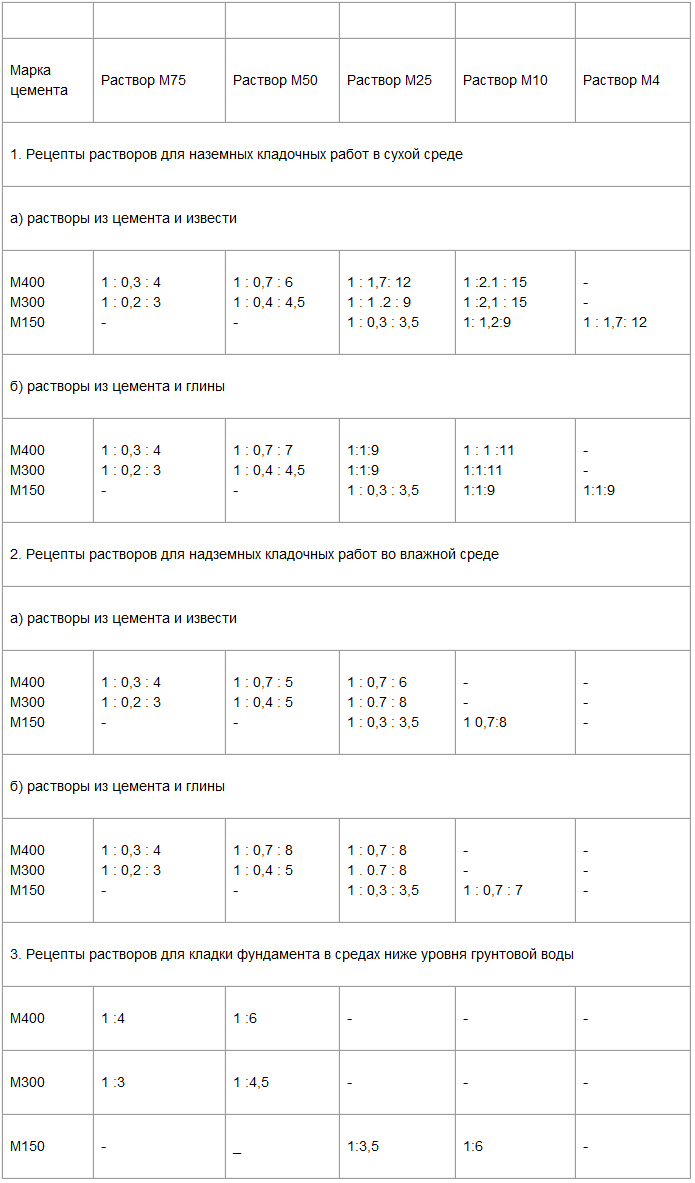

Varieties of solutions and their applicability

The connecting link between brick blocks is a mixture of a binder component with filler and water. The most common are 4 types of solutions.

- Cement-sandy. It is diluted with water, its proportions depend on the brand of cement, the method of masonry. When solidified, this option is the most durable, but when deviating from the technology, it is prone to cracking;

- Limestone - in it the cement is replaced by quicklime; plastic, but washed out by rains, therefore, it is suitable only for the installation of internal walls;

- Mixed - cement and sand are diluted with liquid slaked lime (milk of lime). The combination combines the best qualities of the first two options;

- With a plasticizer - a polymer additive is mixed with cement and sand (fraction 2 mm) to increase the plasticity of the mixture. It is easier to make such a solution from a dry building mixture by adding water according to the manufacturer's instructions.

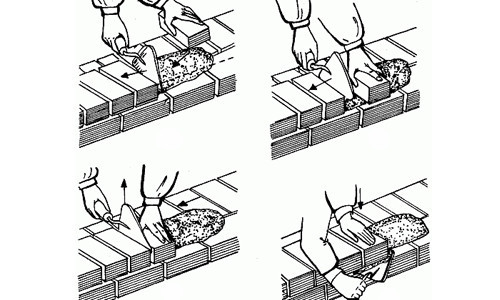

Despite the composition, the requirements for the quality of the mixture are almost the same. All ingredients are cleaned of lumps, sand is sieved, liquid lime is filtered. To prepare the solution, first thoroughly mix the powder components, then slowly pour in cold liquid (20 ° C) and mix thoroughly so that setting does not occur. The process is accelerated using a concrete mixer or a rotary hammer with a whisk attachment.

Consumption of mortar per cube of brickwork

How much to prepare mortar for masonry walls? This is determined by several conditions:

- the skill of a bricklayer;

- the structure of the brick block - products with voids take more mortar mixture;

- type of brick - hyper-pressed and face silicate absorbs mortar less than ceramic or ordinary silicate with a rough surface;

- the thickness of the wall.

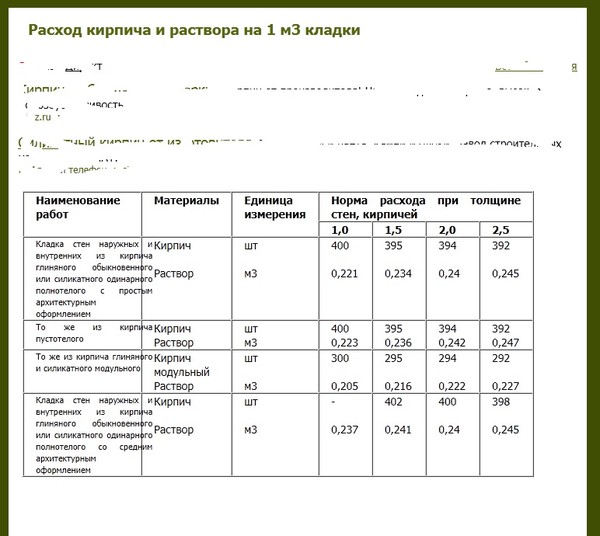

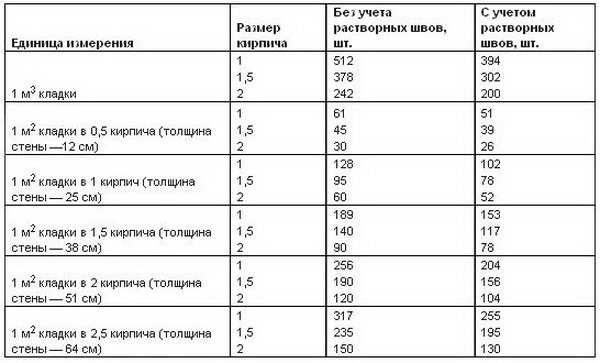

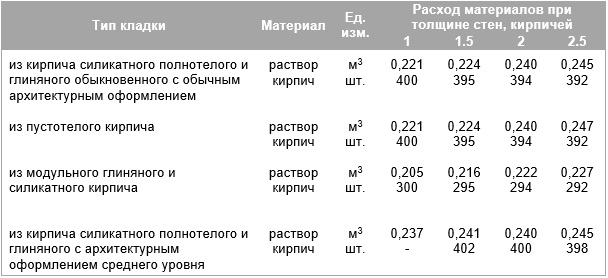

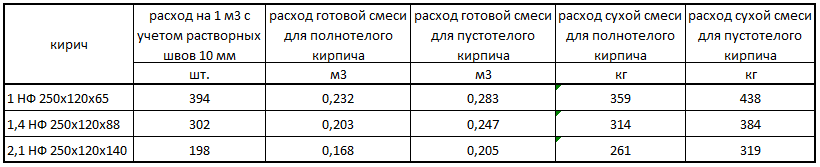

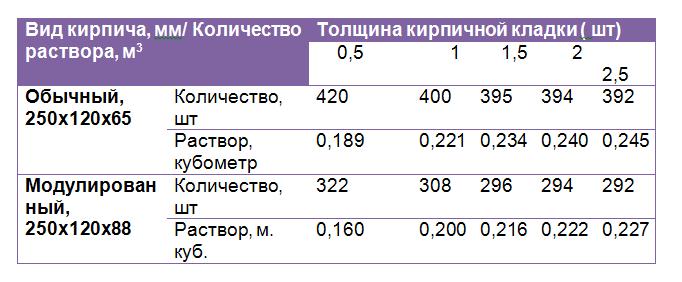

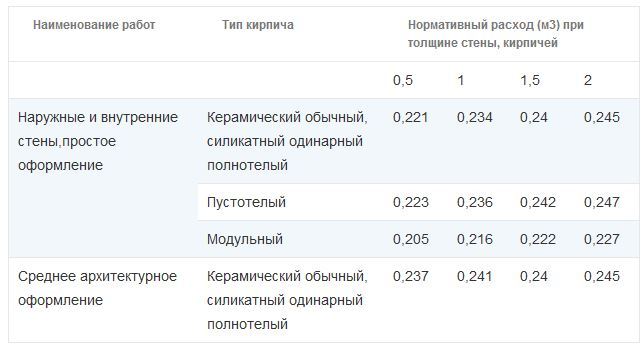

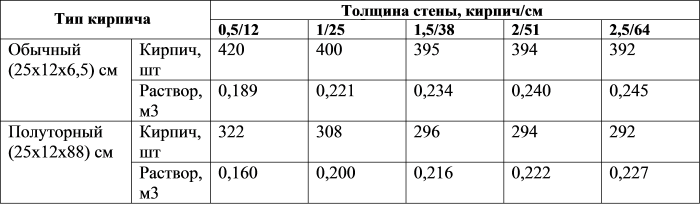

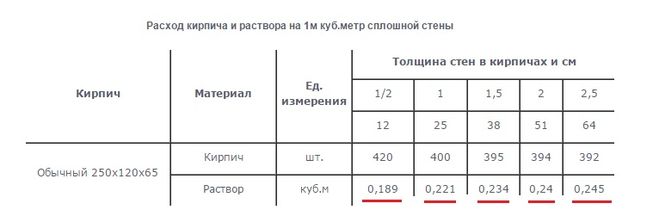

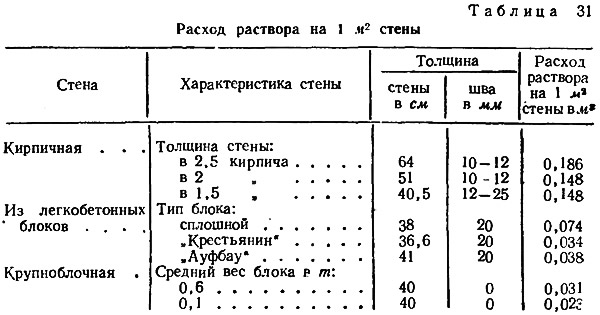

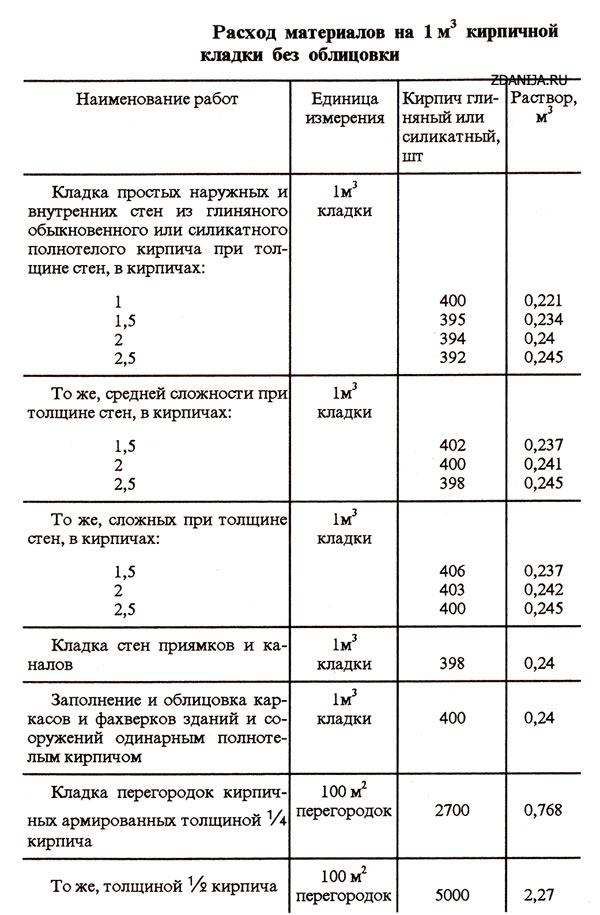

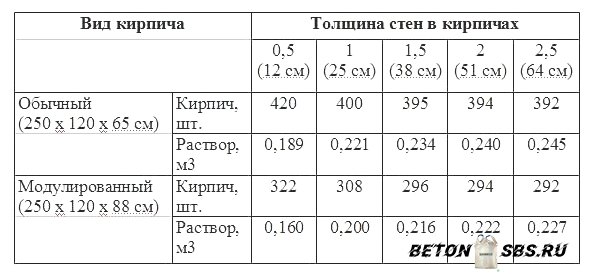

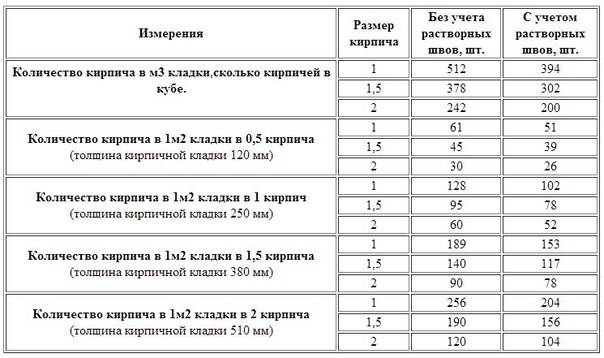

The average consumption of mortar per 1 m3 of brickwork with a standard joint thickness (12 mm) is approximately 0.23 m3. More accurate information is given in Table 1.

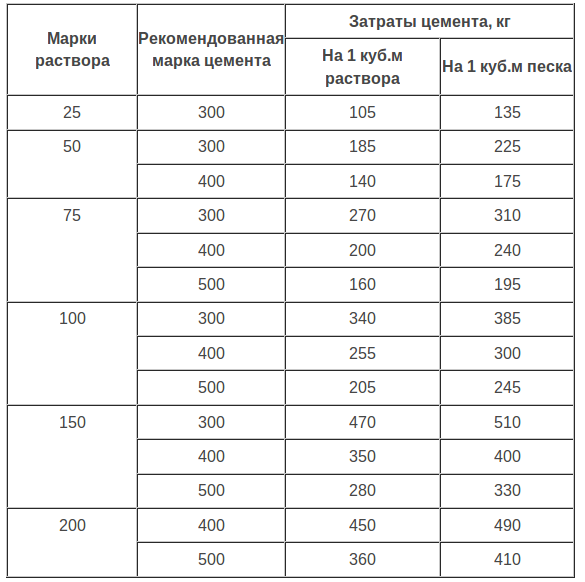

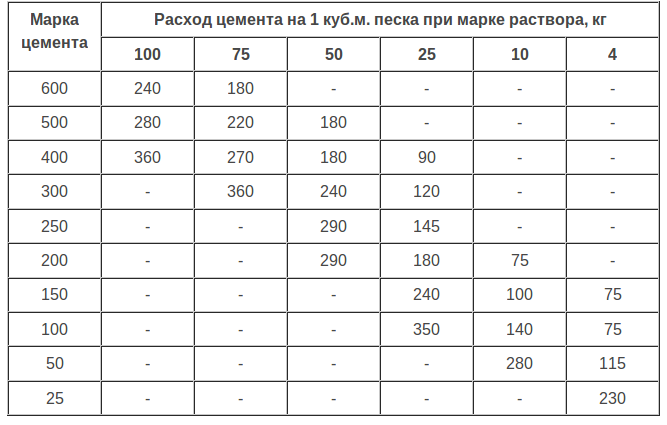

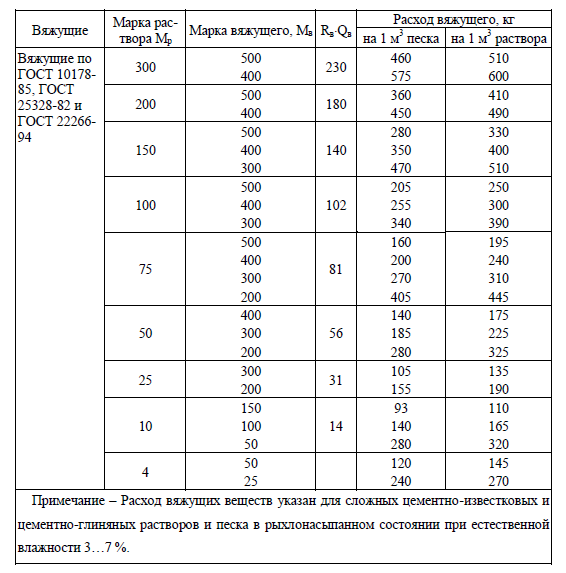

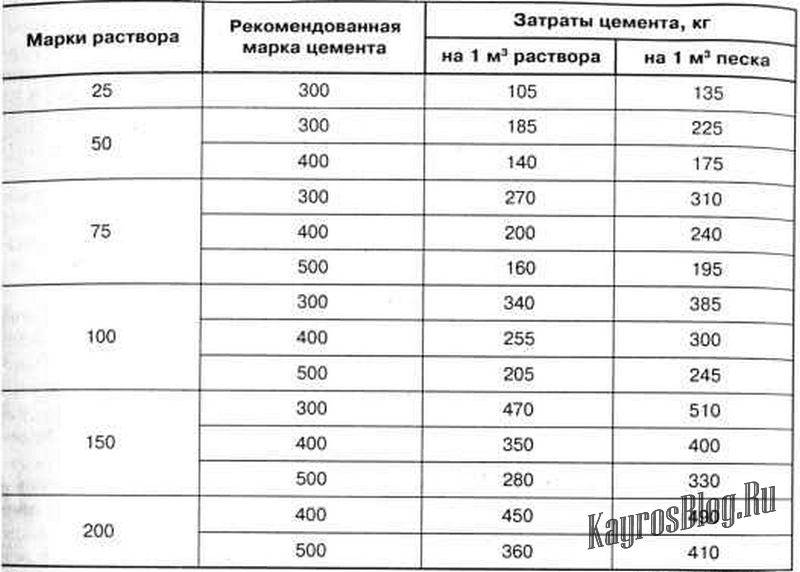

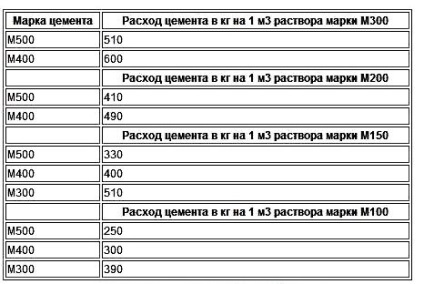

Consumption of cement for brickwork

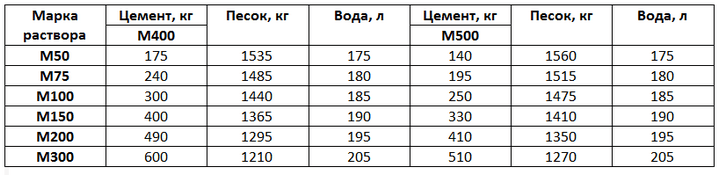

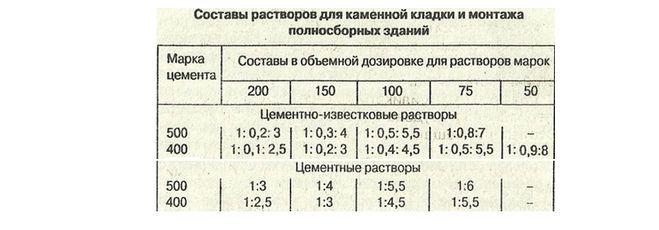

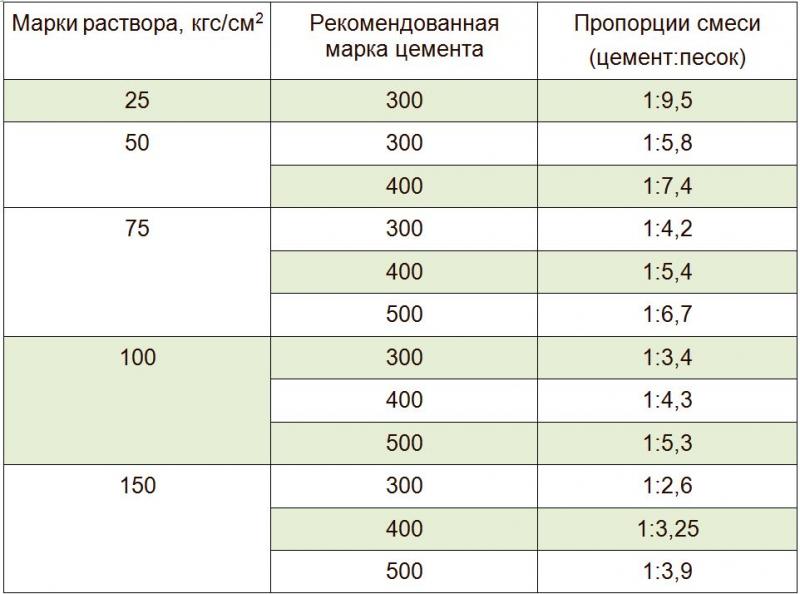

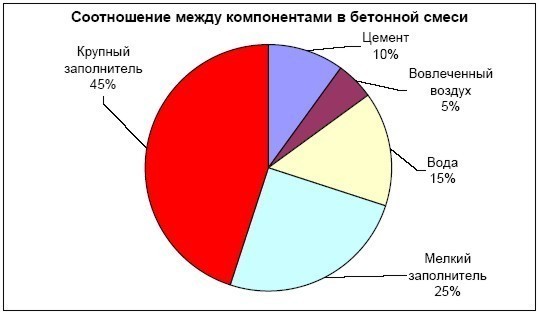

The composition of the mixture for the construction of a brick wall varies depending on the quality of the initial components, weather conditions, and the number of storeys of the building. To mix the ingredients correctly, you need to know: a 10 liter bucket holds 14 kg cement or 12 kg of sand.

- The cement slurry is flexible in terms of proportions. It is characterized by the degree of strength: the less it is, the lower the required grade of cement and the lower its percentage (1 part per 2.5 - 6 parts of sand). For cement M400 is characterized by a ratio of 1.3, for M500 - 1. 4. The volume of water (on average 0.5 - 0.7 liters per 1 kg of cement) depends on the desired density of the mixture, the type of brick, air temperature - in the summer heat, the solution should be more fluid.To increase its plasticity, experienced bricklayers add a little washing powder or dishwashing liquid to the water. For 1 cube of the finished solution 1.4, 410 kg of M500 cement and 1.14 m3 of sand are needed. Knowing that 0.24 m3 of mortar is consumed per 1 cubic meter of an ordinary wall in one brick from a silicate block 250 x 120 x 65, the consumption of cement per cube of brickwork is determined as follows: 0.24 x 410 = 98 kg. Accordingly, when using cement M400 (proportion 1. 3) a cubic meter of the mixture contains 490 kg of cement, and 117 kg is consumed per 1 m3 of masonry.

- The cement-lime mortar is suitable for use within 5 hours, and in summer at +25 o - no more than an hour, therefore, a calculation is also desirable for it. 1 cubic meter of the mixture requires 190 kg of cement M400 - M500, 1.5 m3 of sand, 106 kg of hydrated lime and 475 liters of water. For a cubic meter of masonry, an average of 46 kg of cement will be needed.

Cement consumption for brickwork during cladding

In this case, the developer is interested in how much the binder mixture will be consumed per square meter of the wall. It depends on the water absorption of the building material, the season of work, the voidness and porosity of the blocks. The norms are laid down in SNiP 82-02-95, but the real numbers are always higher, so you should buy a ready-made mortar or cement with a margin.

To save on consumables, 2 factors should be noted:

- the larger the dimensions of the brick, the less mortar will go;

- the higher the% of voids and pores, the higher the consumption of the mixture will be.

From this point of view, it is optimal to use ceramic or silicate double bricks sufficient strength grade. This choice will allow you to achieve savings of 20% mortar mixture. Table 2 shows comparative data on the consumption of mortar per square meter of the wall.

Cooking technology

Cement can be of any brand, and, accordingly, of different strength. For the construction of brick buildings, the M200 or M300 brands are usually used, for the construction of the foundation - M500. Sand is needed in order for the solution to acquire an astringent consistency; without it, the cement will turn into a mixture without adhesive qualities. Water is needed to react the sand and lime, which is contained in the cement powder.

Depending on the method of masonry and the size of the bricks, the mixture will be consumed in different ways.

The volume of water is approximately half the volume of cement.

The cement mortar, which holds the bricks together, very quickly loses its plasticity, so here you need not only skill, but also the ability to calculate the speed of your own work in advance, so as not to spoil the resulting cement mortar, which over time begins to dry out and crack. With the help of special additives, it is possible to obtain quickly solidifying or, conversely, slowly thickening solutions, hydrophobic, colored or white cement mixture.

Mixing the mortar is a crucial stage, on which the strength of the future building and the reliability of the masonry depend.

You can prepare a cement mixture with your own hands or using special equipment. The use of a concrete mixer is a more convenient, quick and high-quality option, especially for the preparation of large volumes of the composition

It is important to achieve complete uniformity, to exclude the formation of lumps

Pour 1/2 volume of water into a concrete mixer, add a little detergent for better plasticity, and then add sand and cement.

It doesn't matter in which order you add the ingredients to prepare the mixture. The most important thing is that the prepared cement solution for work does not bubble and does not have lumps and seals.

To obtain one cubic meter of cement mix, you will need 1 m³ of sand and 0.25 m³ of cement.

When mixing by hand, it is important to adhere to the correct ratio so that the mixture is homogeneous in the end. In this case, sand and cement are mixed in a separate container and only in dry form.

After the mixture acquires a uniform gray color, water is poured into it in small portions using a funnel made. The resulting mixture is thoroughly mixed until smooth.

Please note that it is better to use clean and free water. Choose a detergent according to your taste, but it should have excellent solubility in water and not settle on the bottom.

Together, you can add any plasticizer, which today are presented in a wide range in any hardware store.

The sand should also be cleaned, without clay and other impurities, sifted through a sieve. If you decide to use colored cement for decorative solutions, remember that dyes significantly reduce the quality and hardness of the mixture.

How to calculate the wall masonry with a calculator?

The ways brickwork Brick is the most demanded and widespread building material, serves for a long time and pleases with a neat appearance. Today there are several types of bricks for the construction of buildings:

- a brick made of clay and other fillers is called adobe;

- ceramic, the most used, of fired clay;

- silicate made from sand and lime;

- with the addition of cement - hyper-pressed;

- clinker, from a special composition;

- refractory.

Such materials are used both for laying a house and for building additional finishes in the future, creating a facade, and interior structures. Fireclay bricks can withstand high temperatures and various heating and cooling cycles without loss of strength.

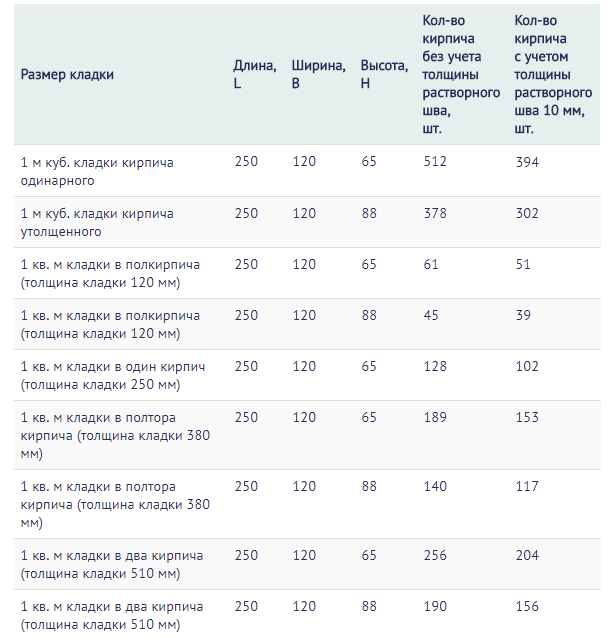

Bricks can be hollow, porous, the most common the standard size of this product - 250 × 120 × 65 mm, with preliminary calculations of the consumption of bricks, the masonry dimensions of the brick increase by 10 mm for each parameter.

Consumption of mortar for 1m² of masonry

Construction work using a cement-based mortar involves the advance purchase of all the components that make up the mixture.

Brick laying scheme.

Particular attention is paid to such an indicator as the consumption of cement, and its preparation, since this material cannot be procured for future use due to increased hygroscopicity and, as a result, a rapid transition to a state of unusability. First of all, you need to decide on the brand of material that corresponds to your type of work, since certain types of mortars are required for certain purposes (cement-sand, slag-cement, concrete and others)

The type of brick used is determined according to the project. For example, a plastic pressed ceramic product is popular for masonry walls due to its frost and moisture resistance. Hollow ceramic bricks have low thermal conductivity, however, they can reduce the weight of the structure by 25% and the thickness of the walls by 20-25%. Ceramic material cannot be used for ovens, chimneys and chimneys. When laying the foundation, solid pressed bricks or concrete heavy blocks are used, and for the outer walls - silicate hollow bricks or lightweight concrete blocks

First of all, you need to decide on the brand of material that corresponds to your type of work, since certain types of mortars are required for certain purposes (cement-sand, slag-cement, concrete and others). The type of brick used is determined according to the project. For example, a plastic pressed ceramic product is popular for masonry walls due to its frost and moisture resistance. Hollow ceramic bricks have low thermal conductivity, however, they can reduce the weight of the structure by 25% and the thickness of the walls by 20-25%. Ceramic material cannot be used for ovens, chimneys and chimneys. When laying the foundation, solid pressed bricks or concrete heavy blocks are used, and for the outer walls - silicate hollow bricks or lightweight concrete blocks.

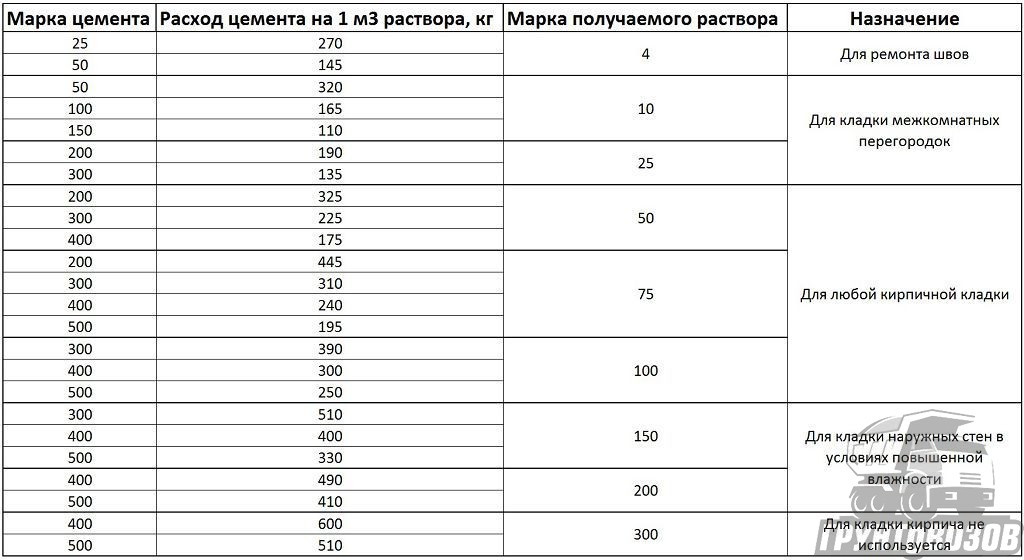

The strength of the structure directly depends on the brand. For example, if you are making a floor screed, you need a mixture from M200 to M300, for masonry brick walls or foam blocks, it is best to use a mixture with a hardness from M50 to M100, for foam blocks - from M50 to M100, and the manufacture of a foundation requires strength from M200 to M300.

Scheme of a masonry masonry using a solution.

After the grade of material, mortar and type of work are determined, it is necessary to select a suitable grade of cement. When making a cement-sand mixture, it is necessary that the grade be two to three times higher than the grade of the solution. For example, for the M200 composition, M400 or M500 cement will be required, and for concrete blocks it is necessary that its grade is six to eight times higher than the grade of the mixture.

Of course, the consumption of materials depends on many different factors, for example, such as: the size of the structure, the thickness of the seams between the rows, the size of the block, and many others. However, the average values of consumption indicators per 1m2 can be calculated using the tables below.

Consumption rate of cement for 1m2 of masonry

The consumption rate of cement mortar per 1m2 of brickwork directly depends on the thickness of the latter: the thicker the wall, the more material is required. For walls with a thickness of a quarter of a brick per 1m2 of masonry, you will need:

- 5 kg of cement in a solution of the M100 brand;

- 4 kg for the M75 brand;

- 2.5 kg for the M50 brand.

Brickwork scheme.

Cement mortar is consumed approximately the same for brickwork, about 300 kg per 1 m3 (0.25-0.3 cubic meters of mortar per 1 cubic meter of surface). A cement to sand ratio of 1: 4 allows for optimum stiffness, mobility and adhesion. If other components are added to the batch, such as clay, limestone, marble, synthetic additives, etc., the ratio decreases down to 1: 9. For the preparation of concrete, the consumption of cement should not exceed 500 kg per 1 m3. The exact characteristics of concrete are fixed by GOST, but it is allowed to change the proportions for the manufacture of concrete to obtain certain characteristics of viscosity, density and drying time of concrete. To prepare the masonry mix, you will need the following tools:

- mixing and measuring container (bucket or trough can be used);

- mortar mixer or perforator with mixer attachment;

- shovel.

To make a batch, sand and cement are first mixed in a dry form, then gradually, in small portions, water is added. The solution should become homogeneous, whole, not spread much. Brickwork will last longer and concrete will be more durable if the cement mix is properly prepared. Such designs can provide high reliability and durability.

When planning the construction of any building, you must first calculate the need for brick and mortar

As you know, the most expensive component of any building mixture is considered a binder (cement or lime), therefore, when building walls, it is important to calculate the cement consumption per square meter of a brick wall to be erected.

It is known that cement powder during long-term storage absorbs moisture, which deteriorates its properties, therefore it is recommended to buy it before work. It should be noted that the calculation of the consumption of the solution is necessary for its rational use during the work shift.

Several types of building mixtures are used in construction:

- cement-sand mortar has maximum strength, but when laid it can give small cracks. The strength of such a solution depends on the method of installation, the proportions of the constituent components and the grade of cement;

- in lime mortar, cement is replaced by another type of binder - lime. It is plastic, but it can be washed out with water, which is why lime mixtures are used for laying internal walls;

- mixed building mixtures to which both cement and lime are added are considered the best option;

- there is also a cement-sand mortar with the addition of a plasticizer, which improves the plasticity of the mixture for masonry walls.

Regardless of the composition, the same requirements are imposed on all types of solutions.Ingredients need to be cleaned of large particles, lime is usually filtered through a metal sieve, and sand is sieved. At the moment, the solutions are mixed using a concrete mixer, and if it is necessary to prepare a small amount of the mixture, use a drill or a perforator with a special nozzle. In the latter case, the dry components are first mixed, and then water is added.

In construction, the concept of mortar consumption per cube of masonry is more common. Under standard conditions (compliance with dressing seams within 12 millimeters), this figure is 0.23 m 3.

If we talk about the consumption of cement per square meter (1 m 2) of brickwork, then the indicators here are not the same, it all depends on the thickness of the wall and the brand of the mortar used. If you take an ordinary finishing brick, then with a M100 solution you need 5 kilograms of 400 grade cement, when using an M75 solution - 4 kilograms, M50 - 2.5 kilograms.

Consumption rate of cement for 1m2 of masonry

The consumption rate of cement mortar per 1m2 of brickwork directly depends on the thickness of the latter: the thicker the wall, the more material is required. For walls with a thickness of a quarter of a brick per 1m2 of masonry, you will need:

- 5 kg of cement in a solution of the M100 brand;

- 4 kg for the M75 brand;

- 2.5 kg for the M50 brand.

Brickwork scheme.

Cement mortar is consumed approximately the same for brickwork, about 300 kg per 1 m3 (0.25-0.3 cubic meters of mortar per 1 cubic meter of surface). A cement to sand ratio of 1: 4 allows for optimum stiffness, mobility and adhesion. If other components are added to the batch, such as clay, limestone, marble, synthetic additives, etc., the ratio decreases down to 1: 9. For the preparation of concrete, the consumption of cement should not exceed 500 kg per 1 m3. The exact characteristics of concrete are fixed by GOST, but it is allowed to change the proportions for the manufacture of concrete to obtain certain characteristics of viscosity, density and drying time of concrete. To prepare the masonry mix, you will need the following tools:

- mixing and measuring container (bucket or trough can be used);

- mortar mixer or perforator with mixer attachment;

- shovel.

To make a batch, sand and cement are first mixed in a dry form, then gradually, in small portions, water is added. The solution should become homogeneous, whole, not spread much. Brickwork will last longer and concrete will be more durable if the cement mix is properly prepared. Such designs can provide high reliability and durability.

Calculation of the required quantity

For each square meter, you will need about 0.2 - 0.25 cubic meters of mortar.

For each square. m you will have to leave 0.2 - 0.25 cubic meters. m.

To calculate what consumption will be spent per sq. m you need to calculate how many square meters the building is. Please note that with a building thickness of 1 brick, you need approximately 75 liters. If the thickness is 1.5 bricks, then the consumption is approximately 115 liters.

For one square. m, if the wall thickness is a quarter of a brick (excluding losses), we need:

- M100 brands - 5 kg.

- M75 brands - 4 kg.

- M50 brands - 2.5 kg.

In this case, the proportions should be calculated 1: 4, i.e. 1 part of the binder and 4 parts of the aggregate. For example, to prepare a solution for 1 cubic meter. it will take 8 bags of 50 kg each, one part of sand is 50 kg. To prepare a strong mixture, cold, purified water (up to +20 degrees Celsius) is usually used.

Sand is used as a filler, the grain size should be no more than 2.5 mm. Do not forget that before mixing everything, the sand must be sifted from debris, stones and shells.

Calculation of mortar and brick per 1 cubic meter:

One cubic meter of wall will need about 400 pieces. bricks, but it is better to take 10 pieces with a margin. Consumption of 0.23 m3 per 1 cubic meter is considered to be the norm. but for professional builders, 0.25 is often gone.

The consumption of mortar for masonry depends on many subtleties that must be taken into account.Often, lazy builders use hollow bricks, which have depressions and cells, instead of the usual material to make their work easier. Thus, they increase the consumption of mortar. Other types of bricks will have a completely different consumption, because using the usual building materials, such as modular or silicate, you do not have to fill the cavities and cells with an additional amount of mortar.

For example, if you take a hollow material for laying a new wall, given that the thickness of this wall will be 1.5 bricks, then 395-400 bricks are needed for 1 cube of masonry, which is 0.23 cubic meters. and if you build the same wall, but at the same time use silicate or modular material, it will take 0.21 cubic meters.

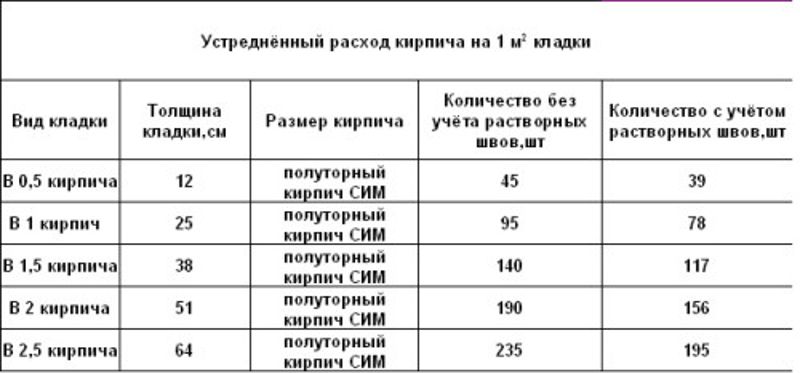

Calculating the number of bricks

The number of bricks depends on its size, as well as the way it was laid.

Single (1), one and a half (2) and double (3) are the size of the brick. It is calculated without taking into account / taking into account mortar joints, the sequence below does not change.

For one cube. m. of a brick wall you will need:

For one square. m. (12 cm) you will need:

For one square. m. (25 cm) you need:

Determination of cement content

It should be remembered that the mortar for masonry begins to harden quickly enough, so it is not worth preparing it for future use.

The necessary calculations are easiest to perform, taking as a basis a masonry of 1 m3; consisting of 400 bricks. On average, 0.25-0.3 cubic meters of solution are needed for laying it. Knowing this, you can make simple approximate calculations and determine the required consumption of the binder per 1 m2; walls of any thickness.

Calculations are performed in the following sequence:

- calculate the area of the wall by multiplying its length by width;

- determine the estimated amount of work on the masonry, multiplying the area of the wall by its thickness. It should be noted that the construction of load-bearing structures is usually carried out in 1.5 or 2 bricks. Their thickness will be 38 or 51 cm, respectively.Internal partitions are made in 1 or 0.5 bricks, which will be 25 or 12.5 cm.For example, we give a calculation for the construction of a wall lined with 1.5 bricks, the area of which is 12 m2: 0.38 x 12 = 4.56 m3;

- the estimated amount of the mixture for a given amount of work. 4.56 x 0.25 = 1.14 m3; It should be borne in mind that the estimated need can vary both up and down, depending on the material used and the experience of the master. Therefore, the calculated amount is quite approximate.

- knowing the required ratio of components, we determine the required need for cement: 1.14. 5 = 0.23 m3;

- since the weight of 1 m3 of cement is 1300 kg, then in this case you will need: 0.23 x 1300 = 296 kg.

The weight of one bag of cement is about 50 kg. This means that you need to use 5 bags to build the example wall. Similarly, you can determine the approximate consumption of a binder for any brick structure.

Considering that masonry joints are the weakest point of the walls, the proportions of binder and aggregate must be strictly observed. A change in dosage in either direction can lead to the production of so-called oily or lean solutions. Their use will worsen the technical characteristics of the buildings being erected.