Do-it-yourself plastering

Apply three coats of plaster

Apply three coats of plaster

After we have calculated the required amount of material and purchased dry components, we proceed to work.

Step-by-step instruction:

- Preparing the surface. We clean the wall from dust and flaking building materials. We clean out rust and oil stains.

- We prime the surface in 2-3 layers, each subsequent layer is applied after the previous one has dried.

- Apply the plaster in three layers. First of all, we spray a solution of medium consistency on the wall, this can be done with your hands, with a spatula, or thrown from a ladle. Then we grind the composition over the surface with a rule or a trowel: apply 4-5 mm thick on a concrete surface, up to 7 mm on a brick surface, and up to 10 mm on wood.

- The second layer is the main one. We knead the solution a little thicker than for spraying. With a spatula or trowel, apply the composition to the wall and rub it over the surface, level it.

- The last layer is applied with a thickness of no more than 4 mm, for which we prepare a more liquid solution. Apply a cover on the moistened base coat. After setting, but before the surface is dry, grout. For more information on plastering without beacons, see this video:

A variety of wall plastering is finishing on beacons, which allow you to create a perfectly flat surface.

A variety of wall plastering is finishing on beacons, which allow you to create a perfectly flat surface.

The guides are set strictly in level at a distance slightly less from each other than the width of the rule. Lighthouses can remain in the wall or be removable.

Lead the rule from the bottom up

Lead the rule from the bottom up

Stages of plastering lighthouses:

- We fill the area between the lighthouses with a solution, level it using the rule. We fill in all the voids and carefully level them.

- We carry out a cover, we rub the surface well.

Be sure to study the calculations of the plaster consumption before starting work.

Be sure to study the calculations of the plaster consumption before starting work.

Repair is not complete without leveling the walls and performing plastering work. The cement-treated surface serves as a reliable base for finishing.

In order not to be mistaken when purchasing materials for self-repair or to control builders, you need to know how much material is consumed. After studying this article, you can easily calculate these indicators.

Determine how much cement, sand, gravel and water is in a cube of concrete.

4 June, 2013 - 12:35 Concrete is one of the most demanded materials in construction. Such popularity of concrete is explained by its excellent properties: compressive strength, ease of forming and laying, waterproofing, water resistance, low price.

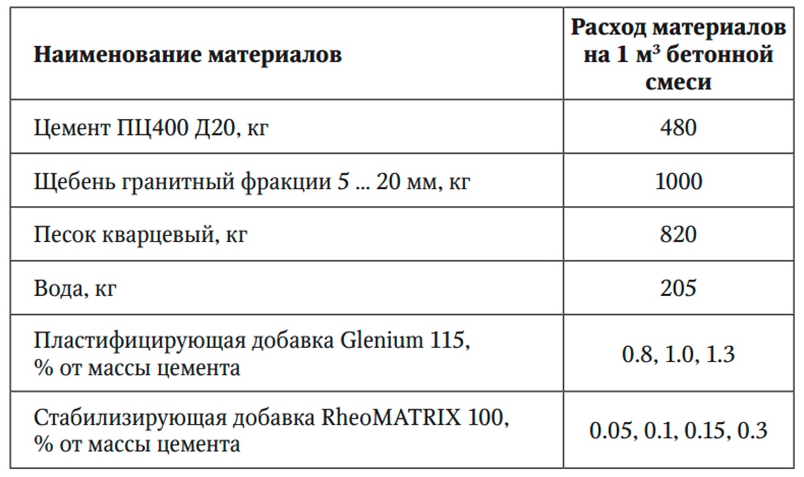

For the manufacture of concrete, cement, water and so-called aggregates are used, which can be coarse (crushed stone) or fine (sand). Builders often face the question of how to mix concrete correctly. It is at this stage that it is usually required to determine how much cement is in a cube of concrete.

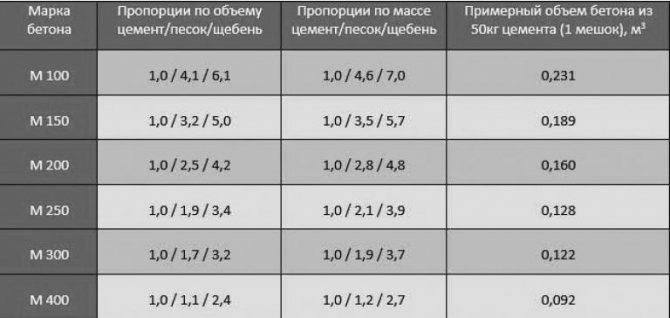

Today, there are a large number of concrete grades that differ in their composition, or rather, in the volume or mass ratio of its constituent components. For example, to create 1 cubic meter of 100 grade concrete, 200 kg of cement is required, to create 1 cube of 400 grade concrete, 360 kg of cement is required.

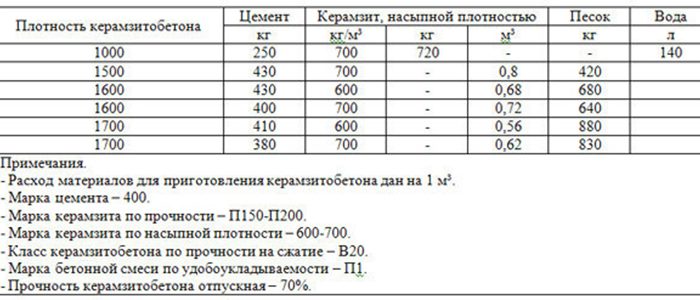

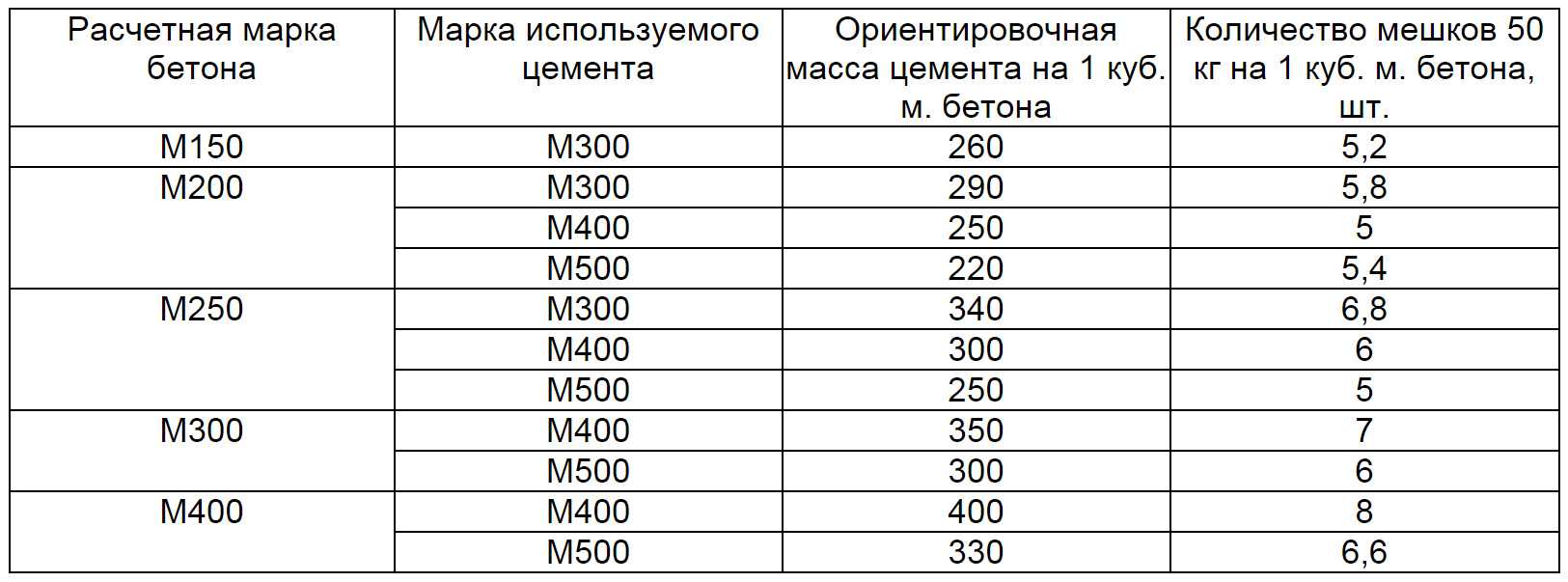

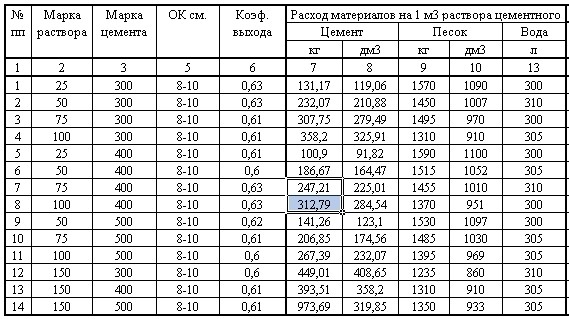

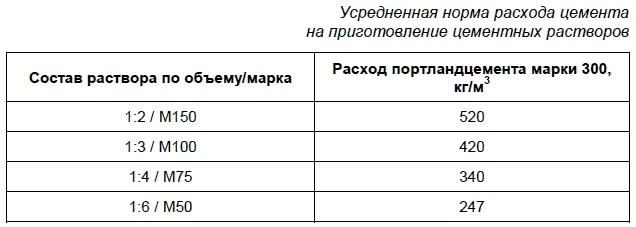

There are special tables from which you can understand not only how much cement per cube of concrete is required, but also the percentage of other concrete components in the finished composition.

So, for example, for the most running grade 300 concrete, it is necessary to mix 382 kg of M400 cement, 705 kg of sand, 1080 kg of crushed stone and 220 liters of water. For concrete of 100 brands, you will need 214 kg of cement (M400), 870 kg of sand, 1080 kg of crushed stone and 210 liters of water.

In general terms, you can determine how much sand is in a cube of concrete, according to the following scheme:

1 volume fraction of cement in grade 100 concrete accounts for 4.1 shares of sand and 6.1 shares of crushed stone; for concrete grade 150, the ratio of cement (M400), sand and crushed stone is 1 to 3.2 and to 5.0; for concrete M200 - 1 to 2.5 and to 4.2; for М250 - 1 to 1.9 and to 3.4 (cement: sand: crushed stone); for 300 1 to 1.7 and to 3, "; for 340 1 to 1.1 and to 2.4.

Table 1. Proportions of cement, sand and crushed stone by concrete grades

| Concrete grade | proportions cement: sand: crushed stone | |

| cement grade 400 | cement grade 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 : 1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

Knowing these proportions, you can not only easily find out, for example, how much rubble is in a cube of concrete, but also knead absolutely any amount of high-quality concrete without much difficulty.

Table 2. Relationships between the class and concrete grades in terms of strength.

| Brand | Class | Strength, kg / cm2 |

| M-100 | B7.5 | 98,2 |

| M-150 | AT 10 | 131,0 |

| M-150 | B12.5 | 163,7 |

| M-200 | B15 | 196,5 |

| M-250 | B20 | 261,9 |

| M-350 | B25 | 327,4 |

| M-400 | B30 | 392,9 |

| M-450 | B35 | 458,4 |

| M-500 | B40 | 532,9 |

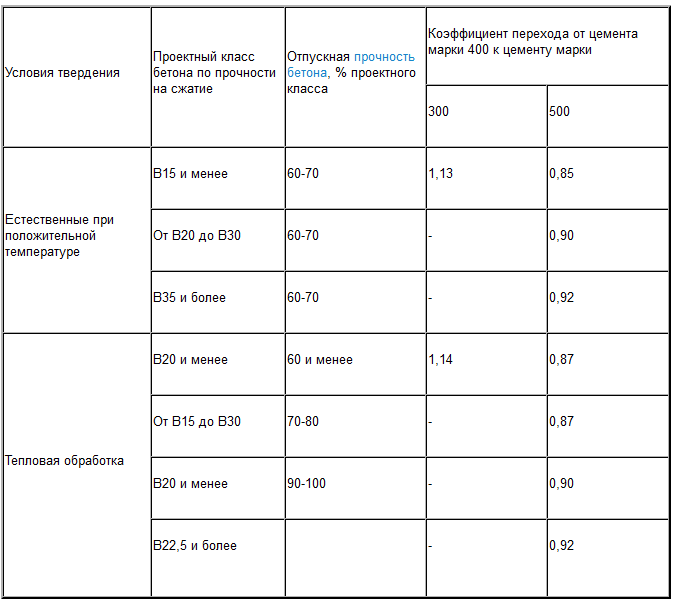

It is important to note that the physical and mechanical properties of the concrete will depend on the grade of cement used to make concrete. So, if instead of cement M400 add cement M500, the grade of concrete will increase (say, instead of 200, it will become 350)

In order to get good concrete, you should choose crushed stone, the grade of which will exceed the grade of concrete that we want to get by 2 times.

Simple concrete mixing scheme

If for construction you do not need factory accuracy, and there is no need to strictly maintain the grade of concrete, you can use a simplified scheme: take 0.5 parts of water, 2 parts of sand and 4 parts of crushed stone for 1 part of cement. For the manufacture of 1 cubic meter of concrete, the weight fractions of the components at this ratio will be as follows: cement - 330 kg (0.25 cubic meters), water 180 l (0.18 cubic meters), sand 600 kg (0.43 cubic meters), crushed stone 1, 25 tons (0.9 cubic meters).

How much cement, sand, gravel (crushed stone) and water is needed to get a cube of concrete:

M50 concrete

- Portland cement M400 - 380 kg. (1)

- Gravel - 608 kg. (1.59)

- Sand - 645 kg. (1.69)

- Water - 210 l. (0.55)

M75 concrete

- Portland cement M300 - 175 kg. (1)

- Crushed stone - 1053 kg. (6.02)

- Sand - 945 kg. (5.4)

- Water - 210 l. (1,2)

M100 concrete

- Portland cement M300 - 214 kg. (1)

- Crushed stone - 1080 kg. (5.05)

- Sand - 870 kg. (4.07)

- Water - 210 l. (0.98)

M150 concrete

- Portland cement M400 - 235 kg. (1)

- Crushed stone - 1080 kg. (4.6)

- Sand - 855 kg. (3.64)

- Water - 210 l. (0.89)

M200 concrete

- Portland cement M400 - 286 kg. (1)

- Crushed stone - 1080 kg. (3.78)

- Sand - 795 kg. (2.78)

- Water - 210 l. (0.74)

M250 concrete

- Portland cement M400 - 332 kg. (1)

- Crushed stone - 1080 kg. (3.25)

- Sand - 750 kg. (2.26)

- Water - 215 l. (0.65)

M300 concrete

- Portland cement M400 - 382 kg. (1)

- Crushed stone - 1080 kg. (2.83)

- Sand - 705 kg. (1.85)

- Water - 220 l. (0.58)

M350 concrete

- Portland cement M400 - 428 kg. (1)

- Crushed stone - 1080 kg. (2.5)

- Sand - 660 kg. (1.54)

- Water - 220 l. (0.51)

p.s. The sequence of laying materials in a concrete mixer affects the quality of concrete.

DIY construction

Now let's move on to laying the first block. It must be laid in the highest corner after the wall has been marked with a fishing line. Then - in each of the corners it is necessary to lay one block - and stretch the rope between them. But now you can already lay the rest of the elements of the future building. Using a cement-sand mixture - we lay them around the perimeter. But, of course, where it is supposed to make the entrance / exit from the building - they do not need to be laid.

Laying should start from the corners, only with bandaging, i.e. - with a shift in half a block. If you cannot shift by half, then keep in mind that the shift must be not less than 80 mm... In essence, these are the same bricks, but of a much larger size. Not in terms of properties, of course, but in terms of the structure of the masonry. Therefore, they fit - according to the same algorithm.

Window openings, as a rule, have a height of 4–5 rows of gas foam blocks masonry from the foundation. Under this opening, it is necessary to perform reinforcement, and reinforcement should be started from the third or fourth row - it depends on which of the rows the window will be located from - from the fourth or from the fifth.

To correctly perform the reinforcement, it is necessary to make two parallel grooves using a wall chaser. Although for these purposes, you can use a grinder. On each side, these grooves must extend beyond the width of the future window by at least 300 mm.Now, as you may have guessed, reinforcement is laid in these grooves, and then it is fixed using a cement-sand mortar. Next, we continue to build the wall in the same way as before the reinforcement procedure.

Above door and window openings, it is necessary to install special lintels using a reinforcing belt. This must be done to increase the reliability of the building. For these purposes, the gas blocks / foam blocks in the shape of the Latin letter "U" will be useful to us.

Thus, the process of building a house or building for household needs - a garage / greenhouse - goes on. As you can see, for a person who has already dealt with repair and construction work, this is not at all difficult to do. And if the blocks have handles (recesses) on the sides for more convenient transportation, this will significantly speed up the construction process. But the block shapes are described in another article on our website.

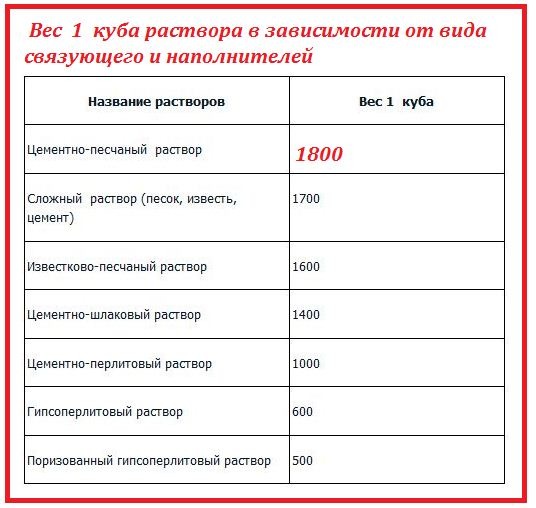

Calculation of the quantity per 1 cubic meter

Consumption per 1 m3 of concrete is calculated from the proportion of the main components. Based on the required amount, the solution is mixed from individual ingredients or based on ASG (sand and gravel mixture). According to the standard, the ratio of cement, sand grains, gravel part and liquid is 1: 2: 4: 0.5. The quantitative consumption of cement per 1 m3 of concrete or other ingredients varies depending on the quality of the selected initial mixture products. According to the testimony of the builders, the weight of the finished cube of the mixture is 1.5-1.8 tons. You can find out the exact weight for planning transportation and time for mixing by calculating how many square meters of buildings you need to fill.

There are certain proportions for the components of the mixture, which make it possible to make a quality material.

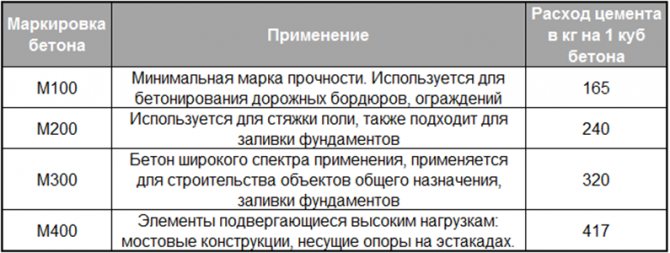

Cement component

The amount of cement affects the strength of the finished product. The choice of brand depends on the future loads of the finished building. As an astringent substance, the number of bags of cement is strictly regulated. With an increase in the brand, a decrease in the quantitative value occurs. It is not recommended to arbitrarily change the ratio set by the manufacturer. The weight of one cubic meter of the finished mixture depends on the rate of consumption of cement for preparation. A well-chosen component guarantees the durability of the structure and the absence of cracks on the surface.

The amount of material depends on its brand and the purpose of the finished product.

Crushed stone or gravel

The correct consistency and compliance with the parameters is provoked by the addition of solid particles. Builders use gravel or its analogue - crushed stone. The recommended size of grains of crushed stone is up to 70 mm. The fractions are designed to fill the small clots of air in the concrete. The amount of crushed stone in 1 cube depends on the kg of cement. On average, there is up to 20 percent off weight of all dry components. The ratio of sand to crushed stone in concrete also correlates with the size of the fractions. As a rule, the latter is 1.5-2 times more sand grains.

Sand as a sealant

Small particles are designed to fill the voids between rubble or gravel. The result is a natural sealant. In a cubic meter of concrete, the ratio of sand to cement is 1: 2. If it is necessary to mix with special characteristics, the proportion changes and the number of particles in the composition is increased. The changes require careful calculation of the quantity per square meter of the building or per cubic meter of liquid mixture.

Mixing liquid

The amount of water poured in depends on how plastic the material will turn out to be. The consumption rate of concrete M300 or M200 directly depends on the consistency. The quantitative standard is set by the property of the finished solution - plasticity. A predetermined number of liters of water is used to stir and combine the dry ingredients. On average, it takes twice as much cement. Industrial water cannot be used, as it contains impurities. The liquid is added at the end in small portions, adjusting the fluidity. Builders warn: too much water leads to inconvenience during work and loss of concrete quality.

Consumption depending on wall thickness

When laying blocks, the mortar consumption will be approximately two times less than for brick walls. In construction, blocks with dimensions 39x19x18.8 cm, 39x30x18.8 cm and for partitions 39x19x9 cm are used. Two types of products are produced - solid and hollow. In this case, the consumption of cement when laying hollow blocks will be increased by 20%.

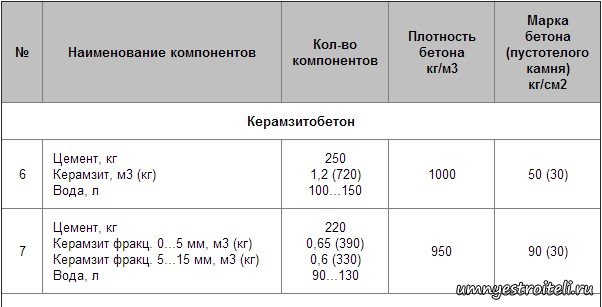

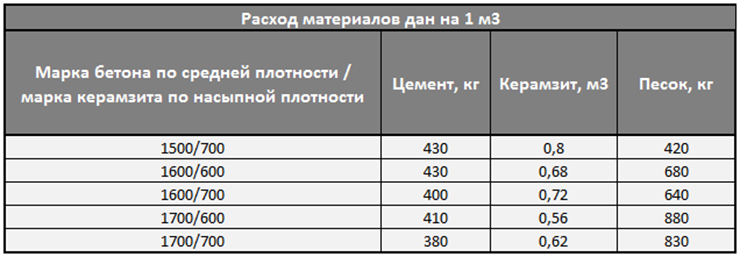

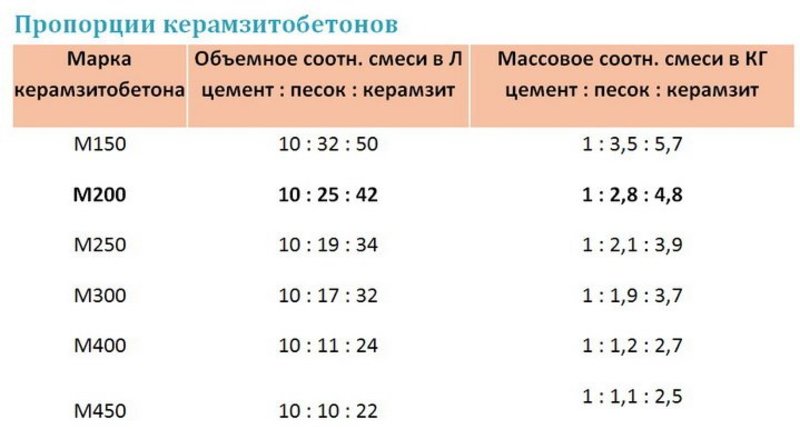

Average solution consumption for 1 m3 of masonry made of expanded clay concrete blocks is 0.12 m3, such indicators will be observed with a uniform thickness of joints from 8 mm to 12 mm. Since expanded clay concrete blocks do not differ in particular evenness of overall dimensions and errors in length and height can be from 2 cm. In this case, it will be difficult to determine the amount of mixture for laying work.

Preparation of the mixture

The intermediate layer should be no more than 3 cm thick, it is better to use expanded clay. For the device of the screed, the consumption of materials will be 1: 2 (expanded clay and sand concrete). Expanded clay granules will provide a light weight of the solution, such laying will be economical and at the same time the strength properties will not be reduced. When pouring the screed, the reinforcement should be laid. This procedure will prevent cracking after the mortar has dried.

When the consumption rate of sand concrete is known, the next step is to make the correct batch. The work is recommended to be performed in the following sequence:

- a container of the required size is filled with warm water, from about +15 to +25 degrees. For one kg of sand concrete, the water consumption is 180-230 ml;

- A dry composition is added to the water;

- The mixture should be thoroughly mixed until even the smallest clots disappear. As a result, the solution should be homogeneous.

It is necessary to use such a sand-concrete mixture within two hours. Works with a solution of the M300 brand, it is recommended at t from +5 to +35 degrees. It will take a day for complete drying, and it is allowed to walk on the screed only after 7 days. Dismantling of the formwork is carried out on the second day. The full strength characteristics of sand concrete structures will acquire in 28 days, as well as conventional concrete structures.

Cement consumption for masonry

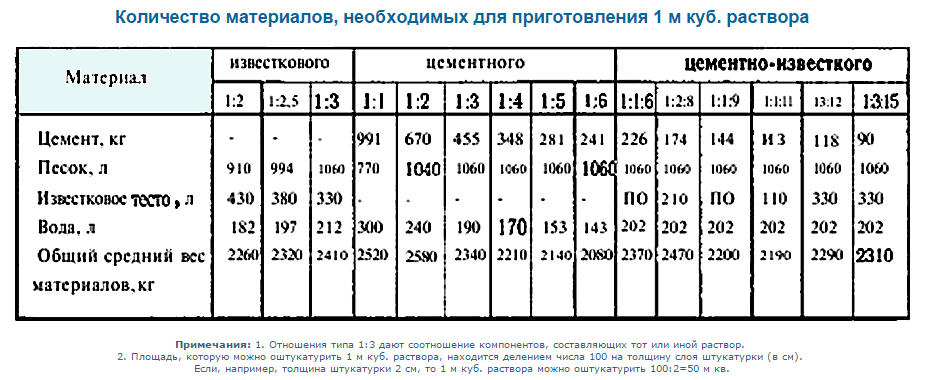

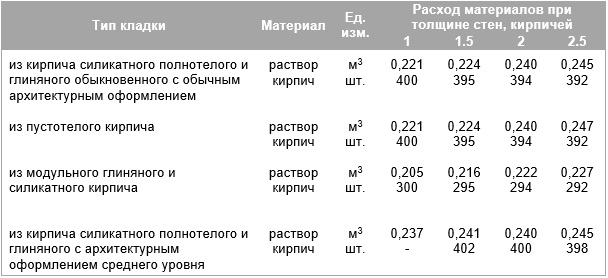

When preparing a cement-sand mortar for brickwork, take into account that at least 75 liters of M100 grade mortar will be required for the construction of 1m2 of a wall 1 brick (250 mm) thick. The proportion of cement (M400) - sand here is 1: 4

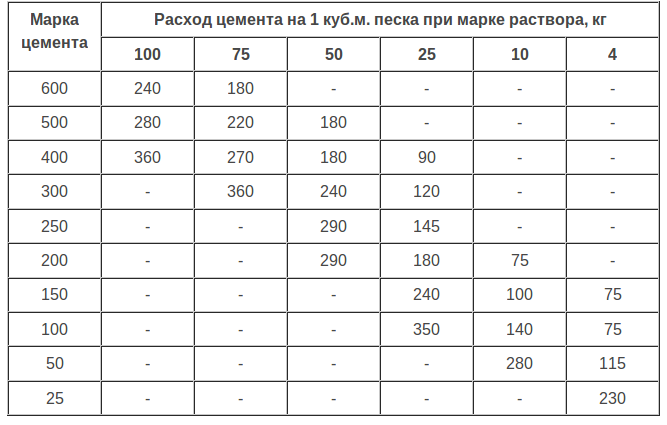

The consumption of cement for laying bricks with this ratio will be 250 kg per 1 cube of sand.

Water, as we have already said, is taken at the rate of 1/2 of the total weight of the cement used.

Translating into "bucket norms" understandable to everyone, we will say that for one 10-liter bucket of cement (M500) we need four buckets of sand and 7 liters of water. We calculate the amount of water based on the weight of the cement in the bucket (10 liters x 1.4 kg x 0.5 = 7 liters).

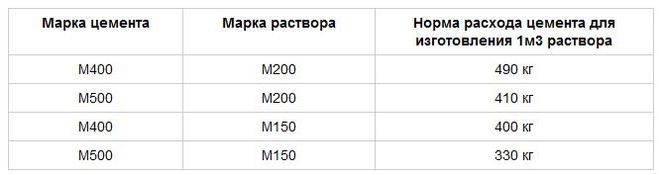

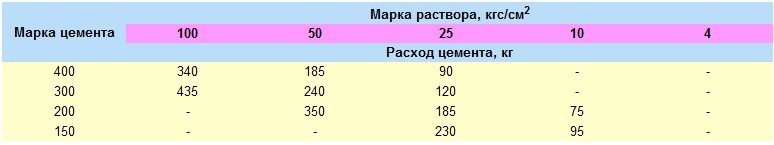

To quickly determine the need for cement masonry mortar for walls of different thickness (per 1 m3) you can use the following table:

|

Brick type |

Wall thickness in bricks |

|||||

|

0,5 (12cm) |

1 (25cm) |

1,5 (38cm) |

2 (51cm) |

2,5 (64cm) |

||

|

Normal (250x120x65mm) |

Brick, pcs. |

420 |

400 |

395 |

394 |

392 |

|

Solution, m3 |

0,189 |

0,221 |

0,234 |

0,240 |

0,245 |

|

|

Modulated (250x120x88mm) |

Brick, pcs. |

322 |

308 |

296 |

294 |

292 |

|

Solution, m3 |

0,160 |

0,200 |

0,216 |

0,222 |

0,227 |

What solutions are used for brickwork

For brickwork, the mortar can be prepared in different proportions, with the addition of various additives and mixture components

Before starting any work, it is important to determine the type of masonry mortar.

The most important role in construction is played by cement mortar

In modern construction, the following mixtures are mainly used:

- the usual "cold solution". The composition contains cement, sand and water. The simplest, classic method of making a strong mixture is used everywhere today. After the cement mortar hardens, the wall acquires sufficient strength and bearing capacity. This mortar can be prepared in various proportions, it all depends on the desired grade of the final solution and the grade of dry cement. M400-500 cement is mainly used and it is prepared 1 to 4;

- cement mortar with lime.Portland cement and lime are used at the same time. Thanks to the combination of the composition, it is possible to significantly save on cement, and the structure is durable and with a sufficient level of moisture resistance. If necessary, additional dry components are added to the composition to increase frost resistance, water resistance and viscosity;

- lime mixture. Quicklime is added to the mixture as a hardener instead of cement. The advantage of the solution is the high plasticity of the composition for a long time. The main drawback preventing the active use of the mixture is that the material absorbs moisture, which makes the use of a number of insulation materials inaccessible and leads to the risk of wall destruction in the long term.

It is important to study the technology for preparing the mixture before making the solution.

Correct mortar proportions

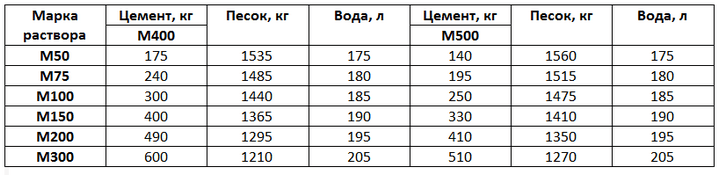

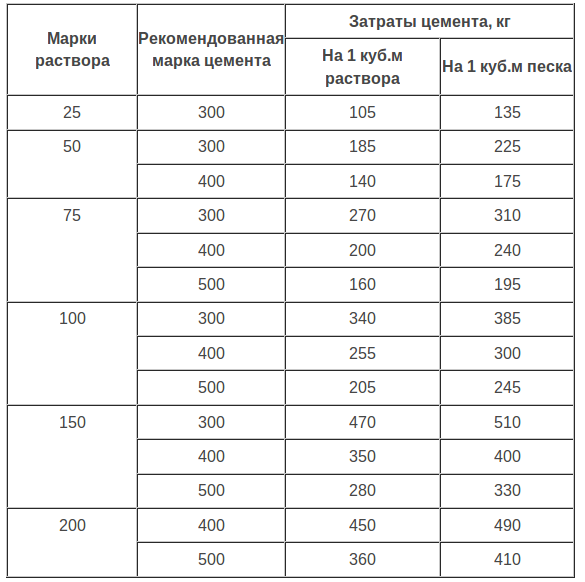

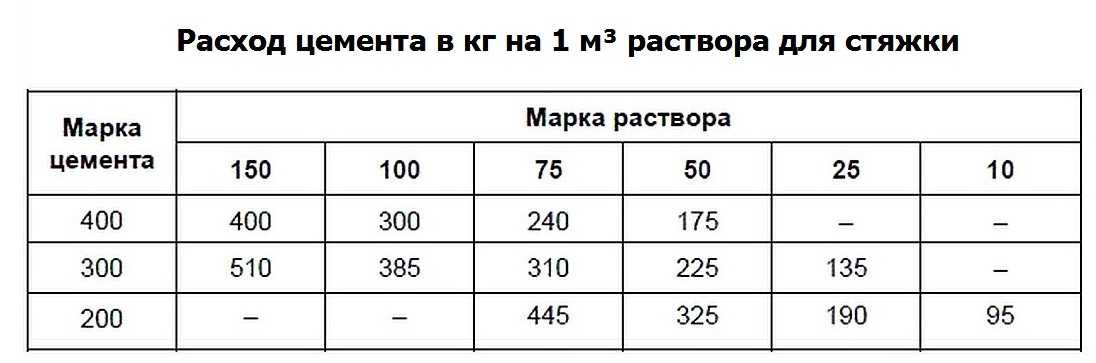

The amount of cement powder per cubic meter depends on the planned grade.

- For masonry work, heavy lime and clay compositions are used, containing about 420 kg of cement and 1.1 cubic meters of sand.

- For finishing activities, mortars with a similar amount of sand and 710 kg of cement are used.

- The plaster mix consists of 0.78 cubic meters of sand, 310 kg of cement. Lime is suitable as a filler.

In household construction, the following is most often used:

- M200 (class B15). It is characterized by high compressive strength. They are poured over platforms, paths, foundations for curbs. 1 m3 requires about 240 kg of Portland cement.

- M250 concrete. For large and low-rise buildings.

- M300. For monolithic foundations, construction of walls and ceilings. When mixing 1 cubic meter, 319 kg of cement will be needed.

Compliance with the correct proportions of the solution is the main condition for obtaining quality products. The accuracy of the bookmark must meet the following requirements: cement is calculated up to 1 kg, crushed stone - up to 5 kg.

1. Concrete for the foundation.

For pouring, a solution is made with proportions of 1: 3: 5, where 1 is cement, 3 is sand, 5 is crushed stone. The amount of water is 2 times less than the total volume of the mixture. At first glance, everything is simple. But even with such calculations, it is necessary to take into account the required reliability, on which the quality of the cement will depend. The minimum grade used for preparing concrete for the foundation is M300. For the correct choice, find out the probable load on 1 cm2 of the canvas and increase the result by 2 times. The resulting value will be the required brand.

In order to calculate the total amount of mortar for the foundation, you need:

- Multiply the length, width and thickness of the base among themselves. For example, you get 20 cubic meters.

- Knowing that the optimal volume of cement powder per 1 cubic meter is 380 kg, you need 20 m3 x 380 x 1.3 = 9880 kg.

2. For the construction of walls.

The proportions of the mortar per masonry depend on the expected loads. For example, the strength of the mixture for a load-bearing wall should be higher than for an interior partition. On average, this ratio is 1: 4, where one bag of Portland cement equals four bags of sand. It is not difficult to calculate the consumption of cement for the construction of walls. For 1 cubic meter of a solid brick wall, about 0.2-0.3 cubic meters, that is, 100 kg of pure cement powder, goes away.

How to calculate the consumption of Portland cement per 1 m3?

It is better to calculate the components in parts (proportions). For example, in the 1: 5 formula, the first number means the amount of cement. It should be understood that with the increasing complexity of construction work, it is not the proportions that change, but the brand of Portland cement. The unified standard states that a cubic meter of masonry "takes" 8 bags of cement and 32 bags of sand (50 kg each). That is, the ratio of the components is 1: 4.

You can find out how much cement and sand is needed per cube of concrete on your own or using the already prepared data:

| Concrete grade | Ratio C (M400): P: U, kg | Concrete volume of 10 kg, cube |

| M100 | 1 : 4,5 : 7 | 79 |

| M150 | 1 : 3,4 : 5,7 | 65 |

| M200 | 1 : 2,9 : 4,9 | 54 |

| M250 | 1 : 2,1 : 3,9 | 43 |

| M300 | 1 : 1,8 : 3,7 | 41 |

| M400 | 1 : 1,2 : 2,8 | 31 |

| M450 | 1 : 1,2 : 2,6 | 29 |

Ratio of proportions:

| Concrete | Portland cement, kg | Water, l | Sand, kg | Crushed stone, kg |

| B15 | 316,7 | 190 | 773 | 1000,5 |

| B20 | 363,6 | 190 | 728 | 1006,2 |

| B25 | 417,7 | 190 | 685 | 1004 |

A few recommendations:

1. Do not knead a lot of solution at a time.Small portions will help you achieve the correct result with the least amount of waste.

2. The quality of the mixture will be higher if you use different fractions of crushed stone.

3. The grain size of the sand should be in the range of 1.1-3.5 mm.

Consumption of glue for foam blocks / gas blocks per 1 m3 / m2

- use of specially designed tools when working. The fact is that improvisation is not entirely appropriate in this matter;

- the qualification of the master. Everything is quite simple here: the higher the level of skill, the more optimal the consumption of the adhesive will be in the process of work;

- block geometry. If they are NOT the same size in the batch, then the consumption of glue in this case will increase significantly.

- the thickness of the layer applied to the working surface. Naturally, there is no need to specifically measure this indicator, but, nevertheless, it should not exceed 3 mm. Of course, if this figure is exceeded, nothing terrible will happen, but this will significantly increase the material consumption. And 2-3 mm will be quite enough for reliable adhesion of the elements to each other.

The consumption rate of glue per 1 m2 is approximately 1.5–1.6 kg of dry powder with an applied thickness of 1 mm, therefore, 15–30 kg will be consumed per 1 m³. As we can see, the figures are approximate, as to name the exact figure, how much is needed glue per cube foam block is almost impossible. But we will allow ourselves to average the indicators - and name a certain weight - 25 kg. This is the weight that one bag of adhesive has. Knowing this, it will be easy for mothers to calculate how much glue is needed for the construction of masonry. And for more convenience, we present to your attention a small list below:

- for 1 m² - ≈1.5 kg;

- for 1 m³ - ≈25 kg (one bag).

25 (kg / m³) × 55 (m³) = 1375 (kg of dry adhesive).

1375 (kg) ÷ 25 (kg / m³) = 55 (pcs).

Therefore, we need 55 kraft bags. Although, if we proceed from the calculation that one package will go per 1 m³, there is no particular practical sense in these calculations. But they are given purely for example.

And if the blocks have not quite the correct geometry, then in this case the flow rate will have to be increased. Moreover, - to increase it seriously enough - almost twice.

With this data, it will not be difficult to calculate the cost of the glue. For example, one bag costs 300 ₽ or 150 ₴. Then:

300 (₽) × 55 (pcs) = 16 500.00 (₽).

150 (₴) × 55 (pcs) = 8 250.00 (₴).

What does it depend on?

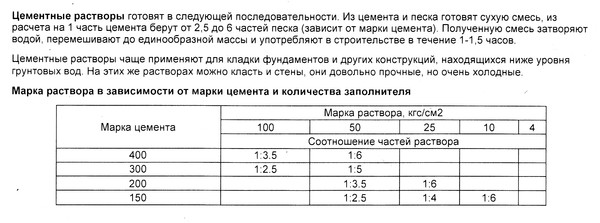

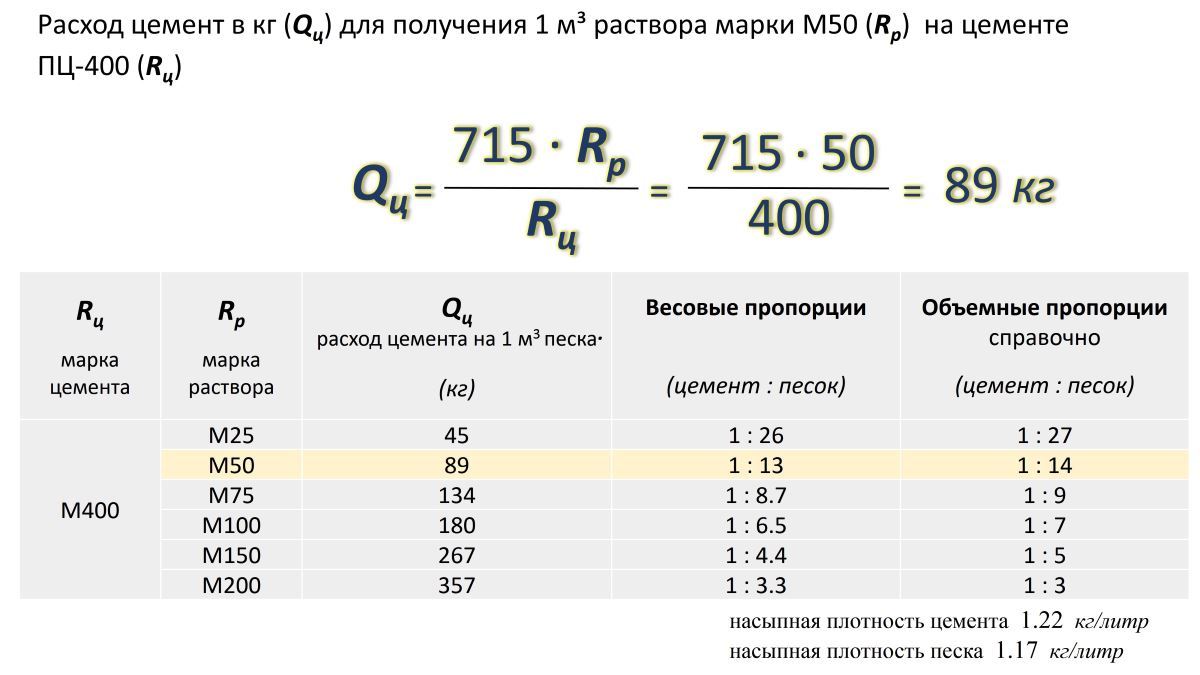

The mechanical strength of the cement slurry can be in gradations such as 2, 4, 10 and 25. Guided by tables and standards, it is possible to reduce the consumption of such valuable material as cement without compromising the strength of the structure. Typically, for construction work, for example, cement grade 400 is used for screed. The most common mortars are M25 and M50. To prepare M25, a sand to cement ratio of 5: 1 is required. To make a M50 substance, a 4: 1 ratio is required. Such a composition dries within three days with a layer thickness of 1 cm. Sometimes arbolite or PVA glue is added, then the coating is also obtained stronger.

Attention should be paid to the consumption of cement when it is required to prepare one cube of concrete. The important indicators by which the quality of the solution is determined include:

The important indicators by which the quality of the solution is determined include:

- density;

- viscosity;

- setting time.

In order for the mixture to be of high quality, it should be good stirred. The proportions of the consumption of sand and cement must be observed. In a solution of the M600 brand, the presence of cement in a ratio of 1: 3 is necessary. If cement of the M400 brand is present in the work, then the ratio is 1: 2.

It should be borne in mind that when calculating the amount of cement to obtain the required volume, it should be multiplied by a factor of 1.35, because there is an addition of water and various additives. One cubic meter of mortar will require about 68 bags of cement weighing 50 kg. The most popular brands of cement for foundation construction are M200, M250 and M300. The foundation requires a mortar in which the optimal compression ratio will be present.

If the cement grade is M100, then the following density will be present per cube:

- М100 –175 kg / m³;

- М150 - 205 kg / m³;

- M200 - 245 kg / m³;

- М250 - 310 kg / m³.

For plastering work, one square meter with a layer thickness of 1 cm will require about 2 mm of cement. With such a layer thickness, the material hardens well, without deforming or cracking.

To lay cinder blocks, the following ratios are required:

- М150 - 220 kg / m³;

- M200 - 180 kg / m³;

- M300 - 125 kg / m³;

- М400 - 95 kg / m³.

When decorating the facade, special pigments and semi-additives are often used, as well as salt, soap solution, which improve the quality of materials. When preparing the mixture, first the dry substance is thoroughly mixed, only then the liquid is added. The mixture, as a rule, is prepared in small quantities, because it has the ability to set quickly. To make the M150 and M200 brands, the proportions of cement and sand are 1: 4. If you need a solution of the M400 brand, then such a composition has a ratio of 1: 3.