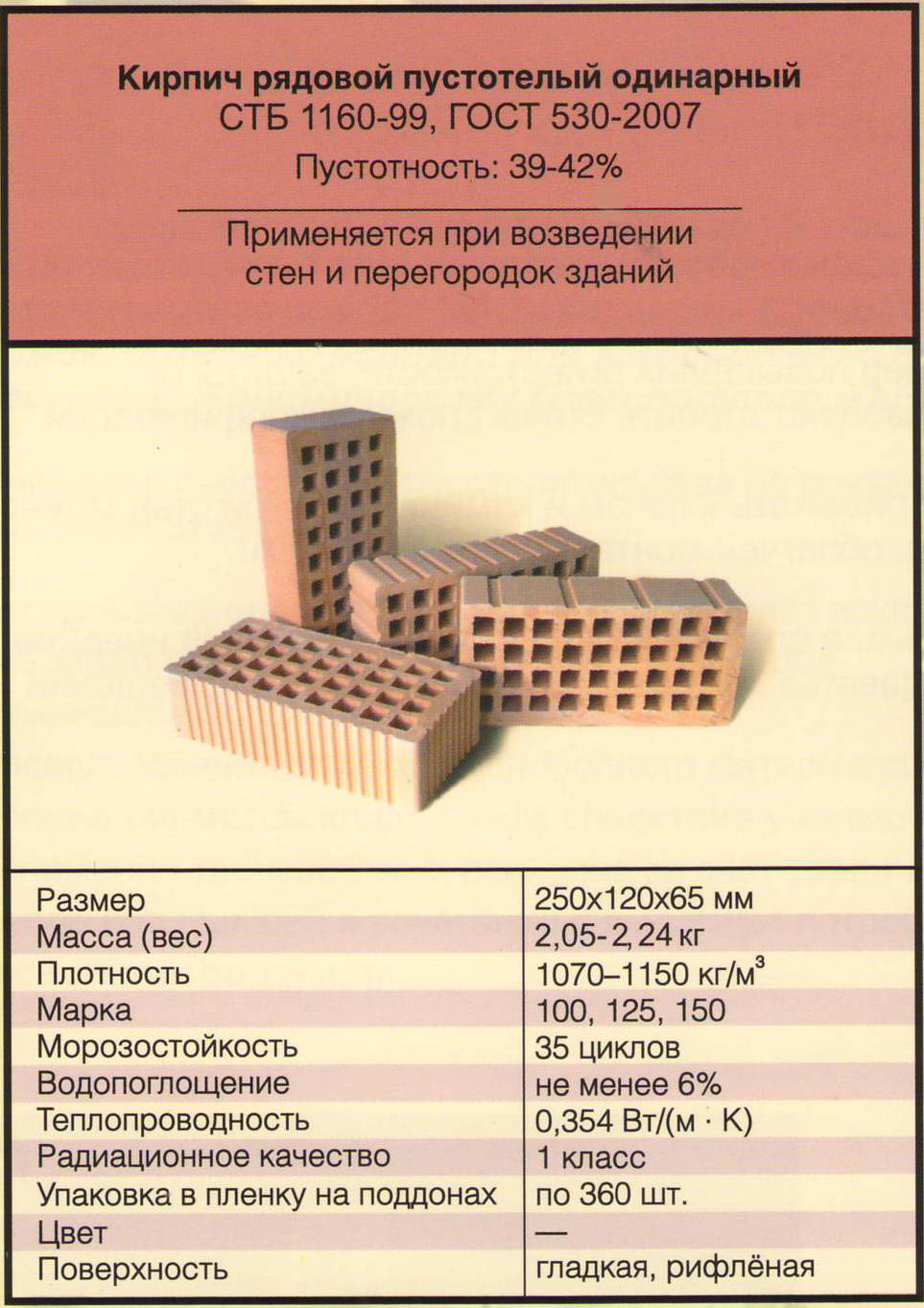

Specifications

The standard defines strength grades, frost resistance and density class. Strength grades represent the load that a material can bear. It is easy to decipher this value. The number that follows the letter "M" is the number of kilograms per square centimeter that the material can withstand without destruction. Example: M150 means that ceramic bricks of this batch will withstand a load of 150 kg / cm².

| Strength grades | Ceramic bricks | M100, M125, M150, M175, M200, M250, M300 |

| Ceramic stone | M300, M400, M500, M600, M800, M1000 | |

| Clinker bricks | M25, M35, M50, M75, M100, M125, M150, M175, M200, M250, M300; | |

| Brick and stone with horizontal voids | M25, M35, M50, M75, M100 | |

| Frost resistance | F25, F35, F50, F75, F100, F200, F300. |

Strength and frost resistance grades for ceramic stone and bricks are indicated.

Frost resistance is indicated by the letter F and a number. The figure shows the number of freeze / thaw cycles that do not change characteristics and appearance. For example F50 - 50 frost and defrost cycles. For internal partitions in heated buildings, frost resistance can be taken low - a positive temperature will still be maintained.

Thermal conductivity and coefficient of thermal resistance

The density class corresponds to the average density of the material, but the energy efficiency of the material also depends on the density. The lower the density, the better the thermal insulation properties. But it will not be possible to significantly reduce the density for external walls. They must carry a certain level of stress. Therefore, in recent years, a brick house has been made with insulation.

The ratio of the average density of the product and the density class

How to work with the last two tables? The density class is indicated in the marking. By this characteristic, you can find out the mass of a ceramic brick cube. It is listed in the first table. The second table helps to compare the density of the material and the coefficient of thermal conductivity of masonry from it. For example, the density class of ceramic bricks is specified as 1.0. This means that the cube should weigh 810-1000 kg, and the masonry on a minimum layer of glue after drying will have a thermal conductivity coefficient of 0.20-0.24 W / (m * ° C).

Groups of ceramic bricks and blocks according to the thermal characteristics of masonry (with a minimum amount of mortar)

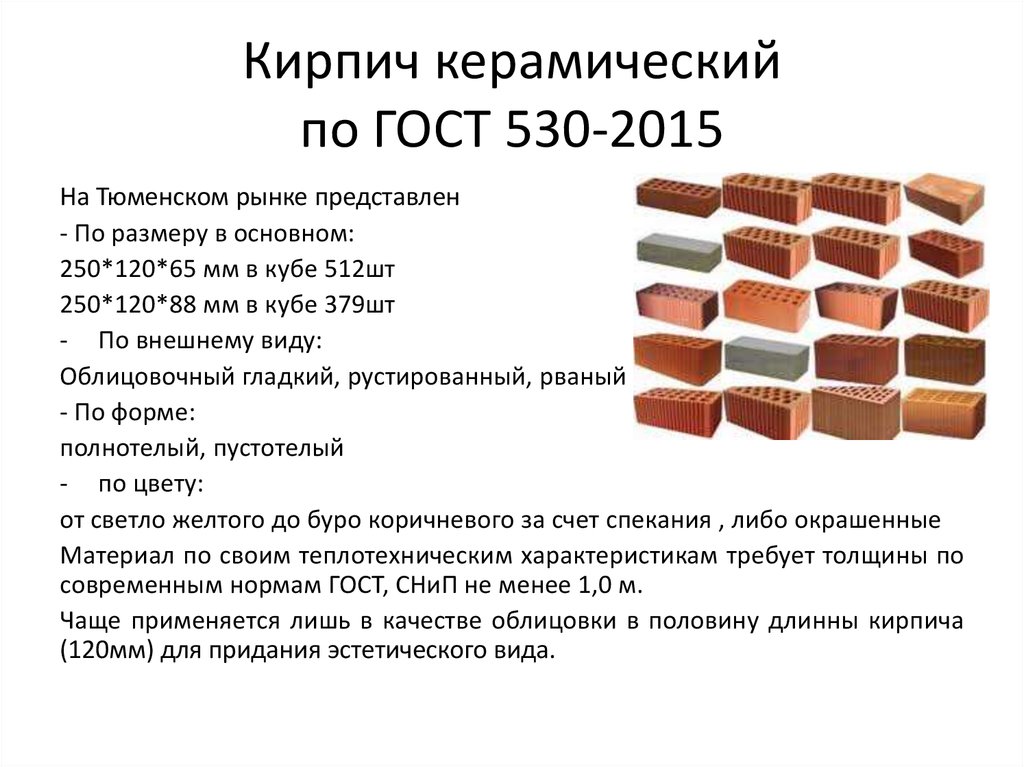

It is worth saying that according to modern standards, none of the types of bricks gives the necessary thermal resistance. Unless the thickness of the wall will be more than a meter.

Masonry made of ceramic bricks of one and a half or two bricks does not meet modern requirements for thermal conductivity of external walls

In this case, a hollow brick or a building ceramic block wins, since they have the best thermal conductivity characteristics. The wall will be a couple of tens of centimeters already - not 147 cm, for example, but only 105. So, in any case, it is worth considering additional insulation of the outer walls.

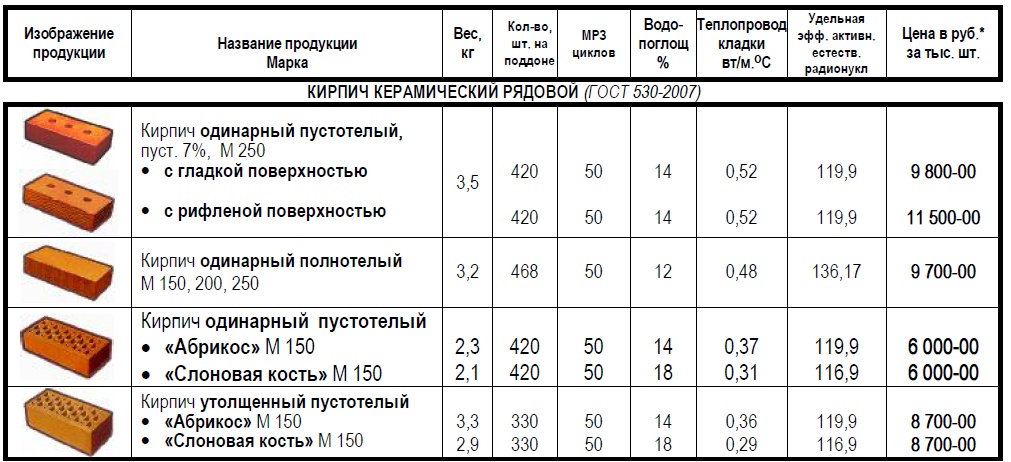

Ceramic brick weight

The weight of ceramic bricks depends on the density and the presence / number of voids. The exact figure is recognized in the accompanying documents, and then, the spread within one batch is up to 10%.

The characteristics indicate the weight of different types of bricks: masonry, finishing, with and without voids

Using the old terminology, the approximate weight of ceramic bricks will be as follows:

- Single (type 1 NF, size 250 * 120 * 65 mm):

- corpulent (private, masonry, construction) 3.3-3.6 kg / piece;

- worker (private, masonry) hollow - 2.3-2.5 kg / piece;

- facing (front, finishing) hollow - 1.32-1.6 kg / pc.

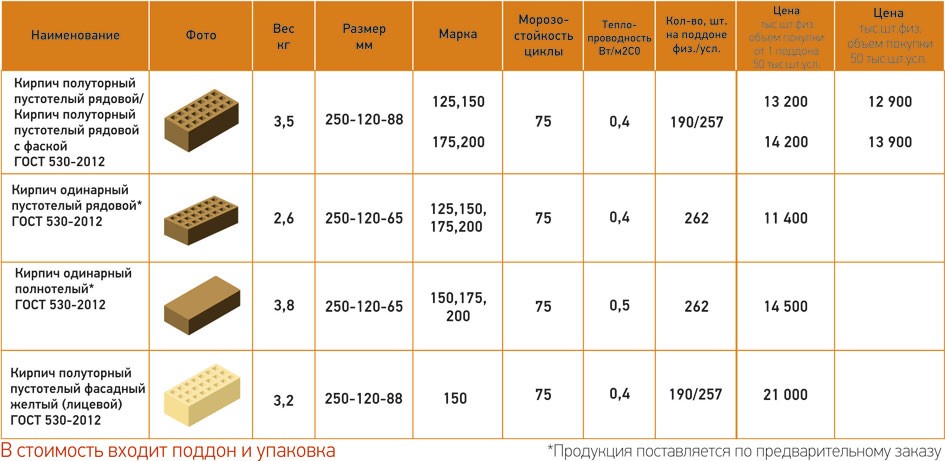

- One and a half has a mass (type 1.4 NF, dimensions 250 * 120 * 88 mm):

- full-bodied private - 4.0-4.3 kg / piece;

- hollow private - 3.0-3.3 kg / piece;

- facial hollow - 2.7-3.2 kg / pc.

- Double weighs (1.8 NF 288 * 138 * 88 mm.):

- ordinary corpulent - 6.6-7.2 kg / piece;

- ordinary hollow - 4.6-5.0 kg / pc.

Comparison of the characteristics of ceramic bricks - hollow, different density, solid

We will give an approximate weight, since the density and number of voids for each plant can differ significantly. The number of voids is not regulated, so the finishing materials can be lightweight.

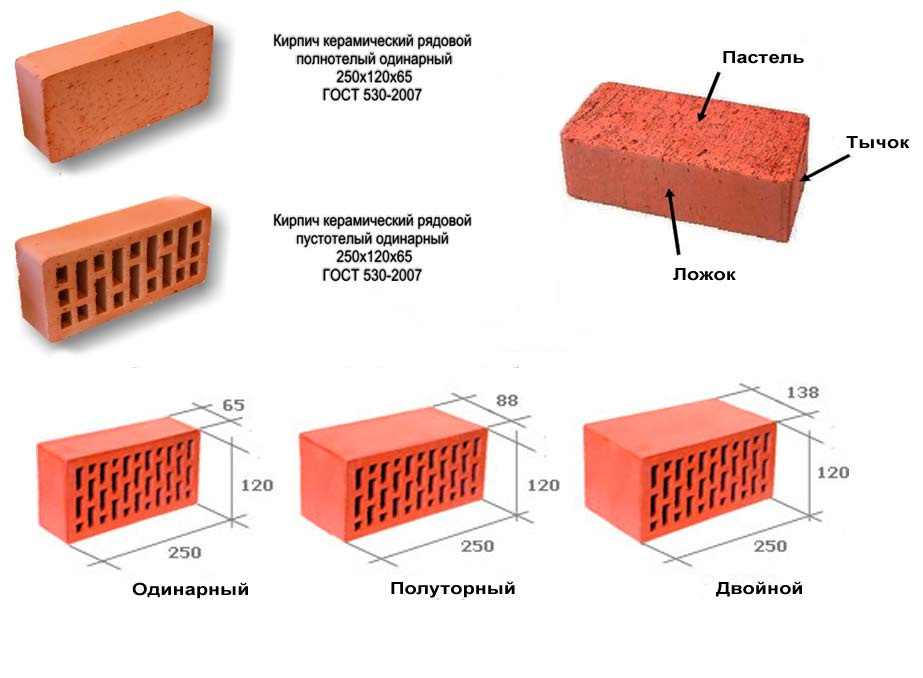

Dimensions and weight according to GOST

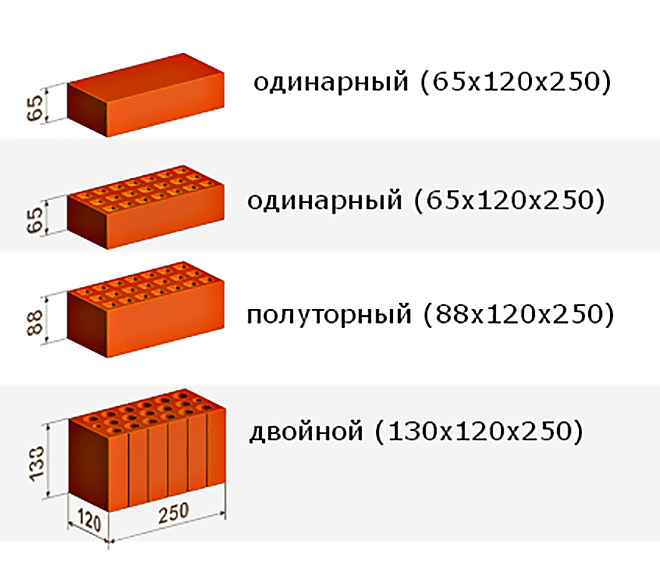

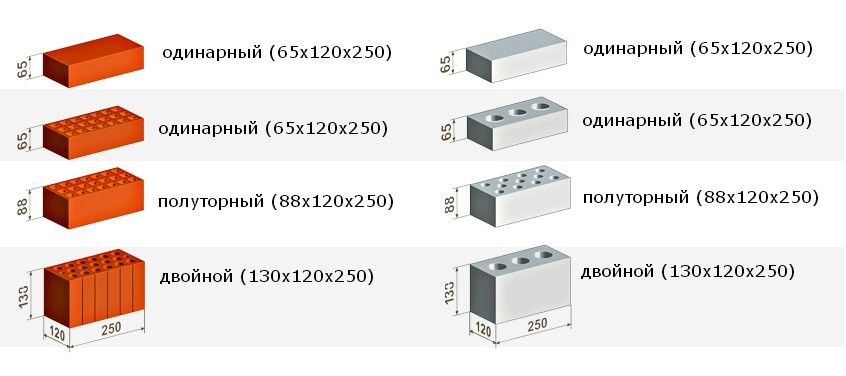

Standard sizes of single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of the red brick.

Manufacturing products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

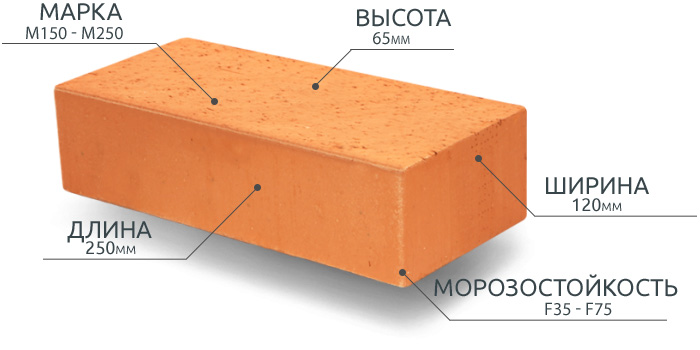

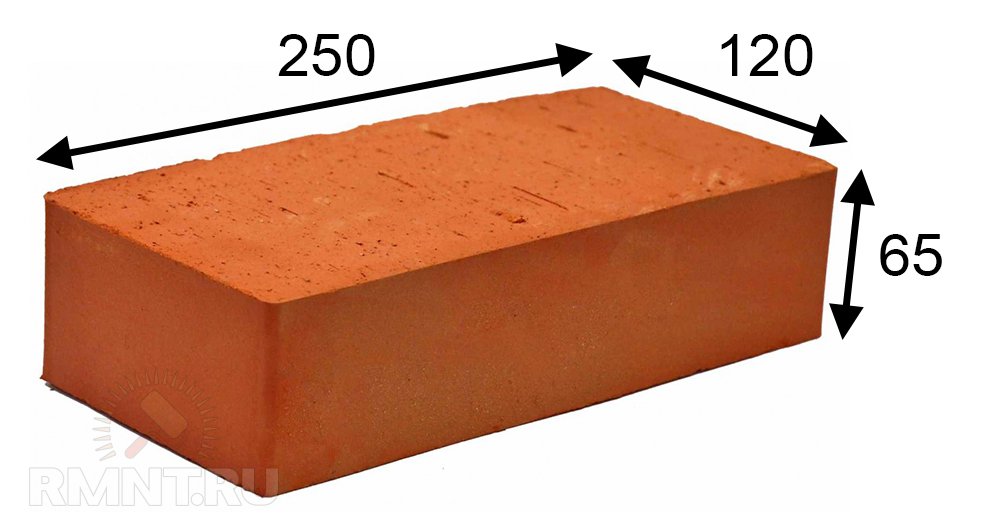

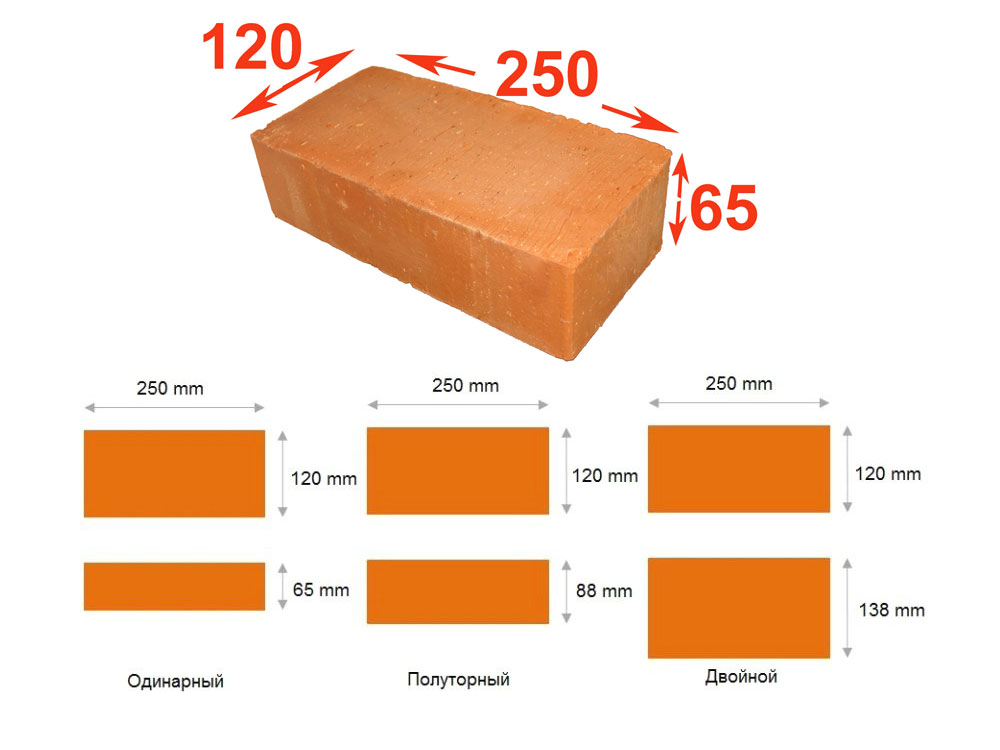

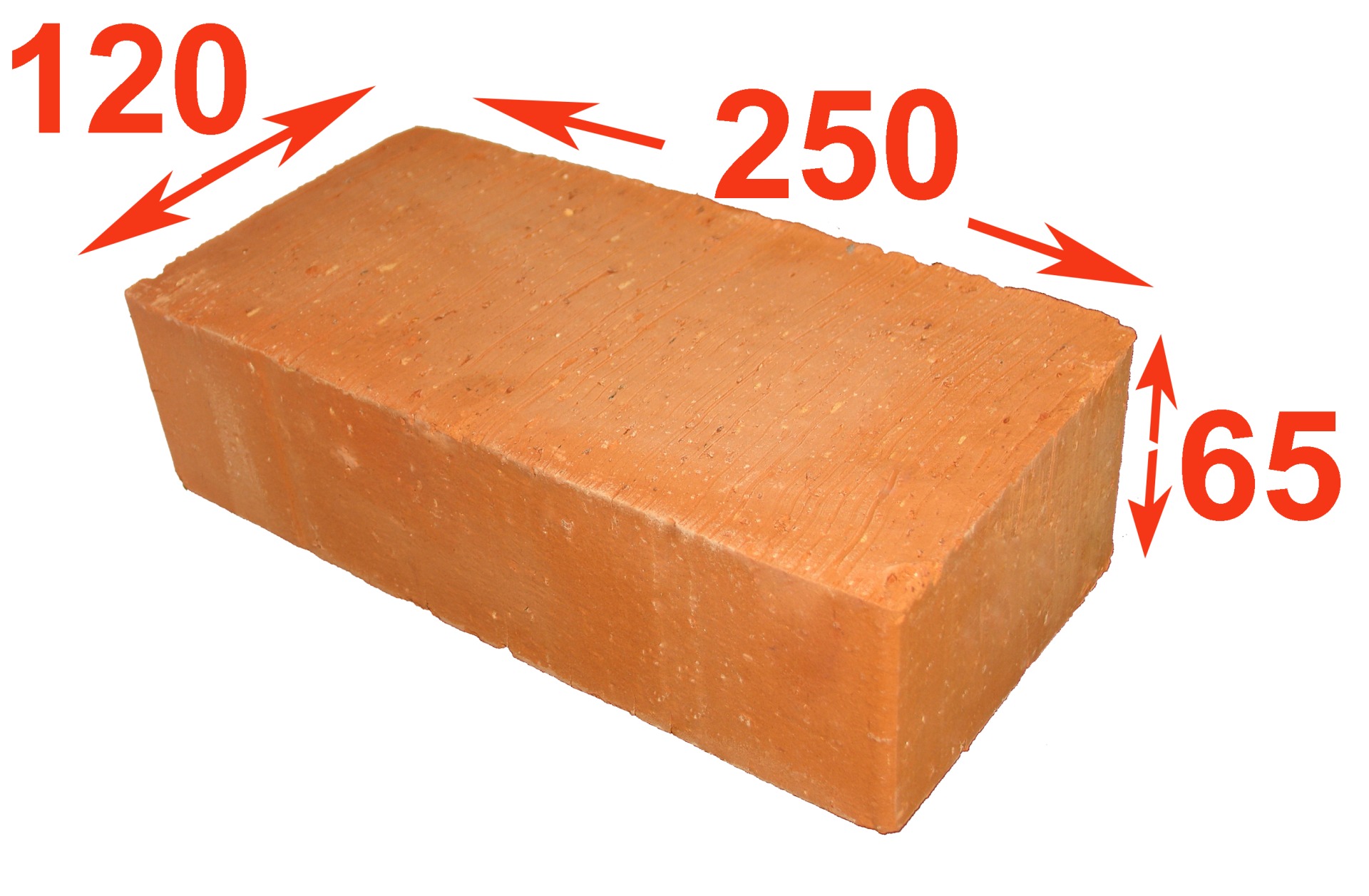

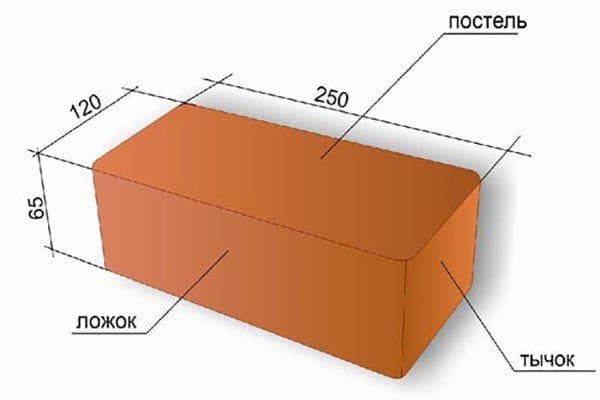

Standard sizes of red brick in normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

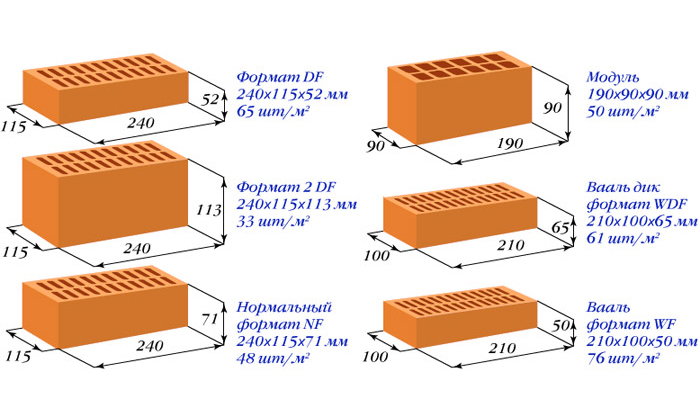

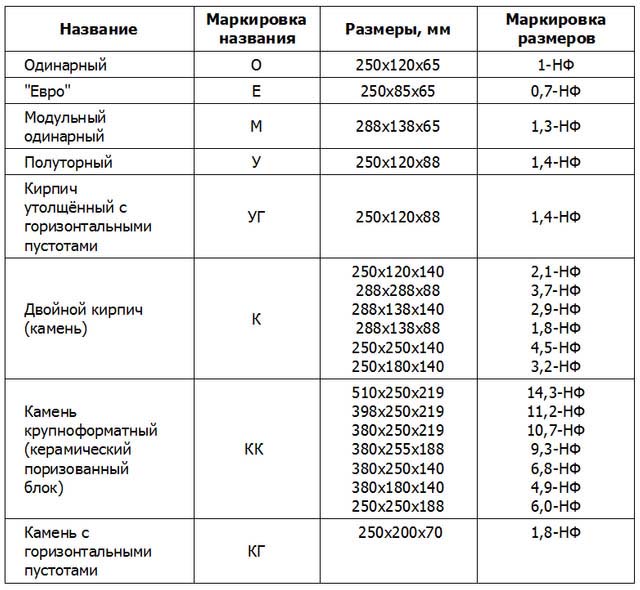

It is the dimensions of single elements provided for by GOST that are a kind of reference point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number indicates its proportions of the ratio with a single one.

So, the size of one and a half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

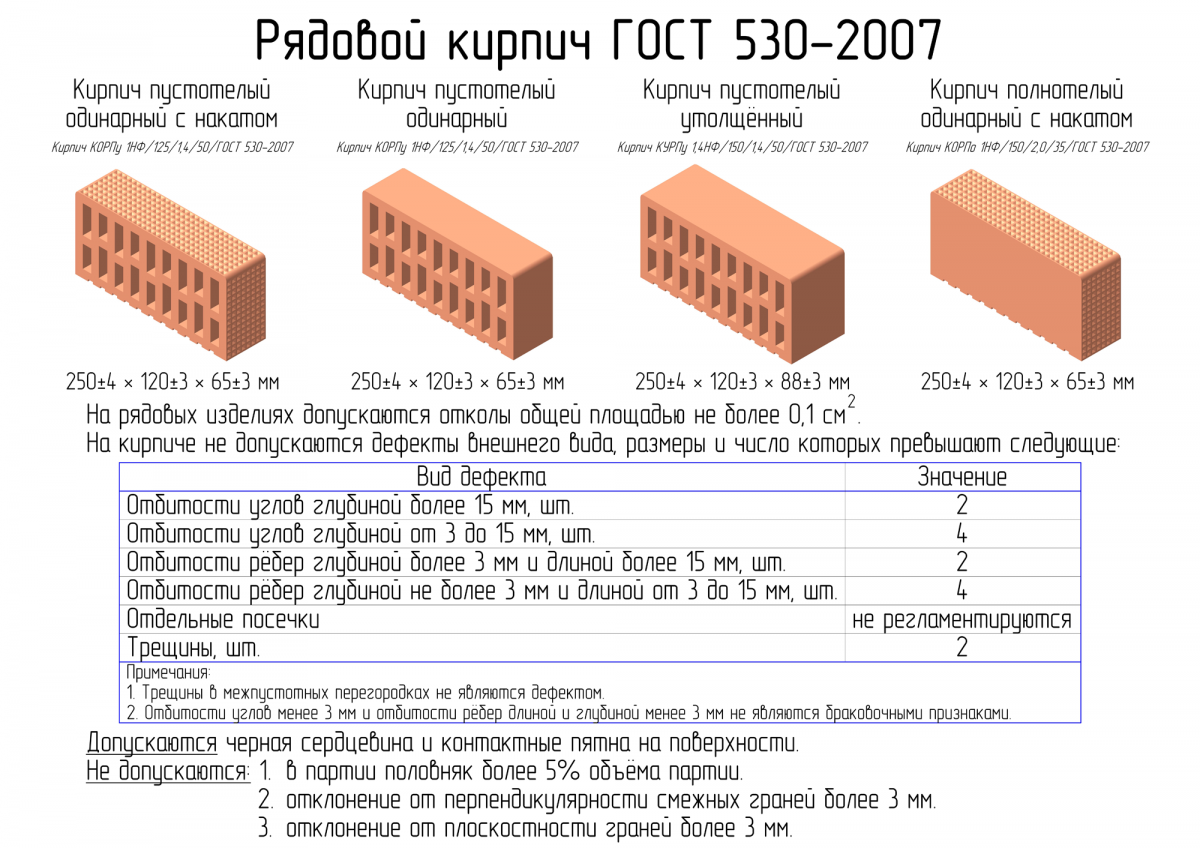

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information on how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

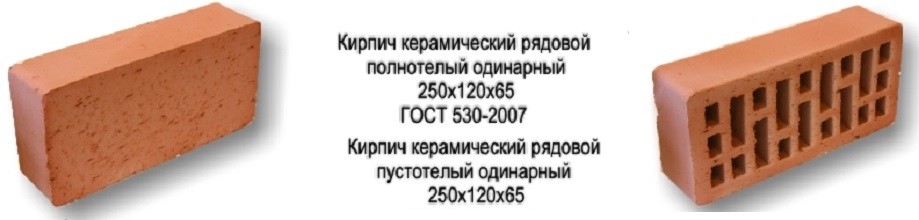

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

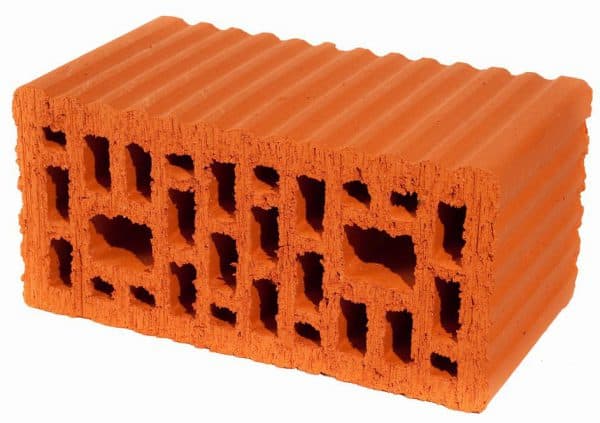

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick. It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

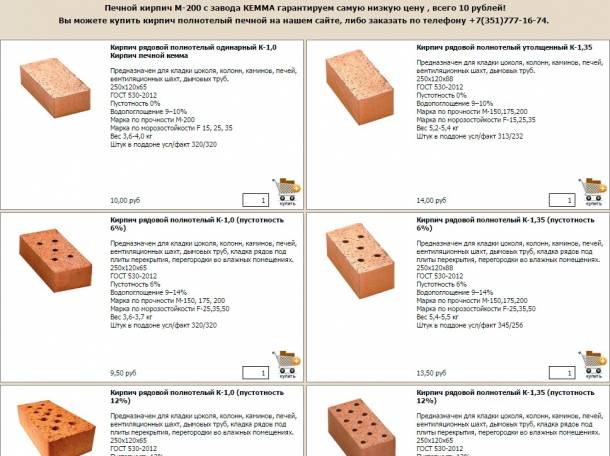

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.

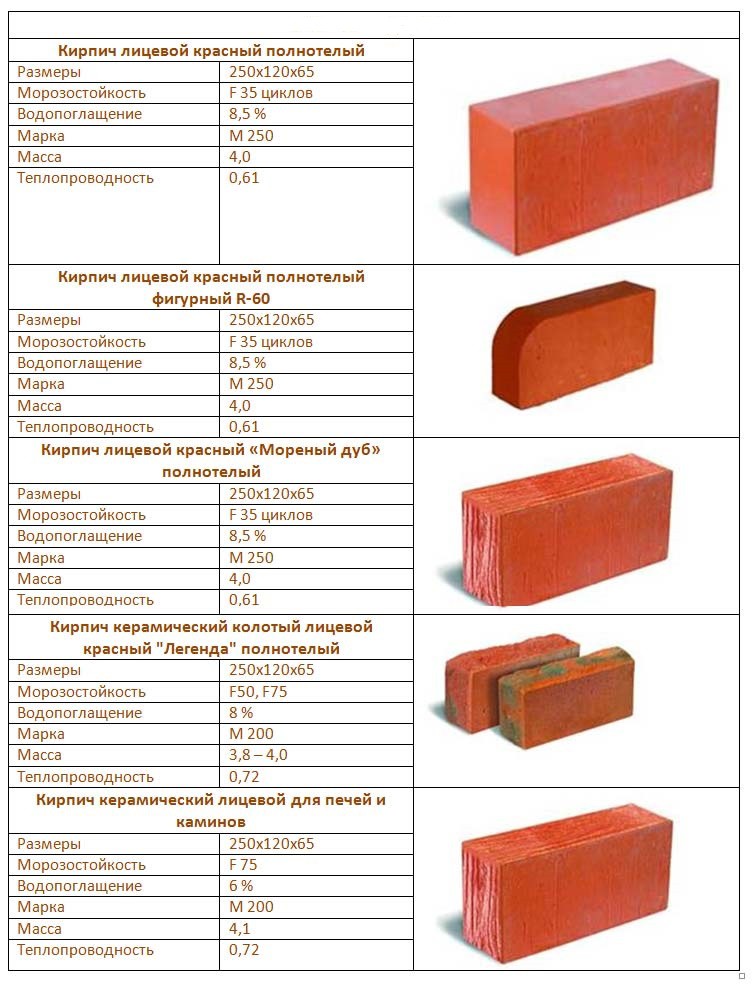

Varieties of finishing bricks

There are the following types of bricks on the building materials market:

- white (silicate);

- ceramic;

- clinker;

- hard pressing brick.

Each of them has its own pros and cons.

Silicate

Such products are often used for outdoor decoration, because the cost of the material is one of the most affordable. The manufacturing technique consists in the fact that a solution of lime, quartz sand and special components is dry pressed with a gradual increase in temperature.

The advantages of silicate bricks are as follows.

- Frost resistance. Brick is able to withstand a huge number of freezing and thawing cycles.

- Security. The structure, methods, techniques and manufacturing sequence do not affect environmental friendliness, as a result of which the products do not have a negative impact on health.

- Availability. It is the most inexpensive material available.

- Optimum strength. The resulting surface is able to withstand all sorts of weather influences, provided that the masonry is correct.

Let us also mention the disadvantages.

- Decent weight. Due to this, the load on the foundation increases, as a result of this, in order to cover the surface with silicate bricks, the structure must be thoroughly strengthened.

- Little visual appeal. The material has no texture, and even the dye does not give the desired result.

- Thermal conductivity. This characteristic of this product is high, as a result of which, under difficult natural and climatic conditions, additional insulation is required.

Ceramic

This product is the main competitor of the above, therefore, the question often arises which of the bricks is better: ceramic or white (silicate). Of course, making ceramics is more difficult, the difficulty lies in choosing the right raw materials. Only high quality clay with small impurities of other components is used for the manufacture. Since the color of the material is often red, the final product turns out to be just that color, but other varieties also come across.

If required, the feedstock can be colored. The production technique is that the mass is first molded, then sent to a highly heated furnace. Actually, the quality level of the product depends on the correct preparation of the mixture and its firing.

If the product has burnt zones, then it was overexposed at high temperatures, the brick will be brittle. With insufficient temperature and lack of firing time, the product comes out faded, has high moisture absorption, there is no ringing on impact.

The advantages are as follows.

- External appearance. Ceramic bricks can vary in color, size and configuration. This contributes to the implementation of various design tasks.

- Life time. The durability of the surface realized from these products is calculated for more than one decade.

- Sound and heat insulation.The product perfectly retains heat, protects against the penetration of extraneous noise and cold.

Hard pressing (hyper-pressed)

Such a decorative product has a surface that is more close to natural stone. For production, a fraction of natural materials, cement, shell rock and minerals-pigments are used. The mixture is pressed and exposed to high temperatures.

Facing bricks of hard pressing have many advantages: strength and long service life, the coating perfectly tolerates a large number of temperature cycles. But due to the considerable mass and high cost, the product is not in great demand.

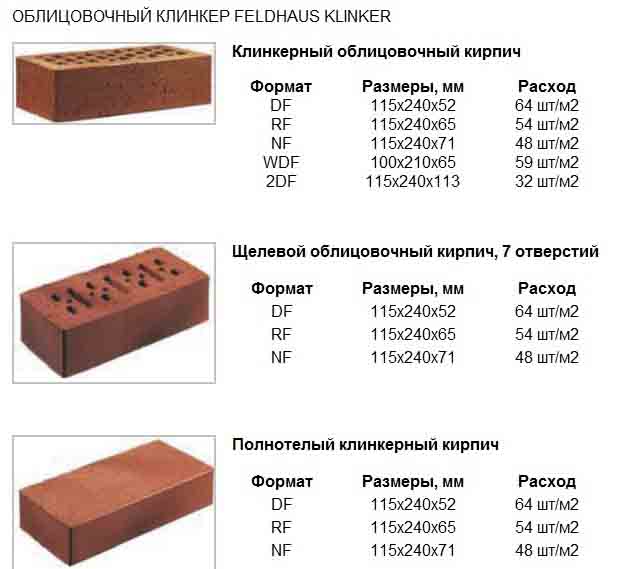

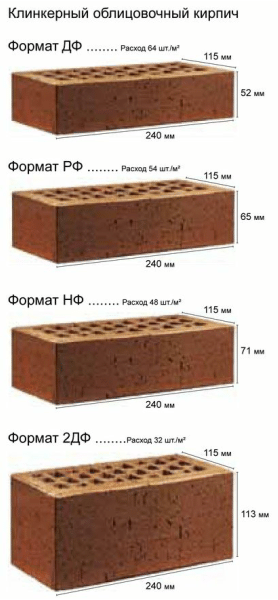

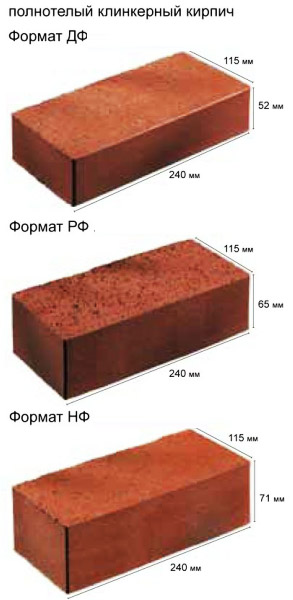

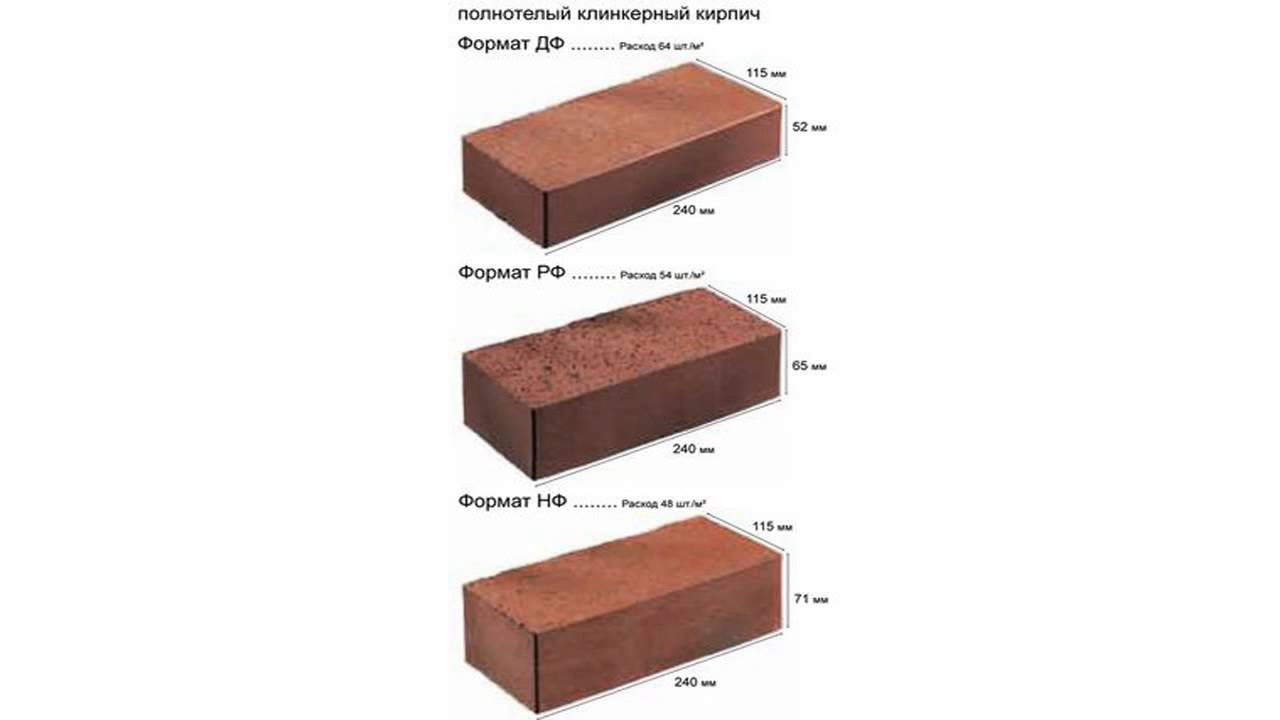

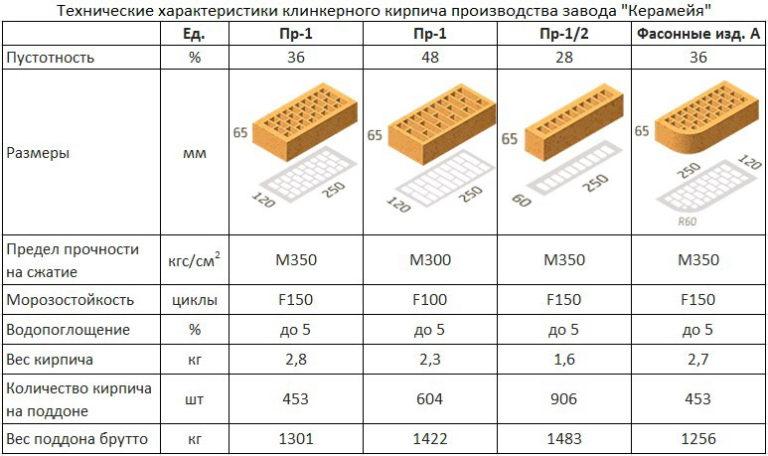

Clinker

It is somewhat similar to ceramics, but a more refractory type of clay is used for its manufacture, and firing is carried out at extremely high temperatures. Thanks to this, the product acquires excellent protective and decorative properties. But this also affects the final price: it increases greatly.

Advantages and disadvantages

Solid brick is a very popular building material that is used in a wide variety of jobs. Its popularity is due to its many benefits.

- Today on sale you can find a full-bodied product of various sizes. Thanks to this fact, consumers have the opportunity to produce structures of various shapes.

- Well-chosen products have an attractive appearance. They may vary in color and texture. For example, textured cladding with an imitation of a marble surface looks very interesting and effective on different buildings. With the help of these materials, it will be possible to give the construction a special style and high cost.

- Such materials boast high strength: they are not so easy to damage or break. In addition, it is permissible to build both internal and external walls from solid bricks - both of these structures are reliable and strong.

- Solid bricks have a specific heat capacity. Buildings in which the walls are made of these building materials remain quite warm and comfortable in winter, and in summer they have a slight coolness.

- Full-bodied products are easier to lay. To carry out such work, there is no need for special knowledge, skills and rich experience. Even a beginner can cope with laying full-bodied parts if he follows the instructions.

- Another important advantage of solid bricks is its environmental friendliness: this material is safe for both people and the environment. It contains no hazardous and harmful substances that can harm health.

- The high sound insulation of solid bricks should also be noted. Houses built with these materials remain quiet - the excess noise from the street is almost invisible in them.

- Such products are presented in the widest range. Buyers have the opportunity to purchase varieties of bricks for any construction work, from simple to very complex.

- These products also boast durability - they serve for quite a long time without losing their attractive appearance. Brick houses remain aesthetic for many years if they are made correctly and from high-quality raw materials.

- Due to its structure, solid brick is quite strong in compression and bending.

- Since there are practically no pores in such bricks, they absorb destructive moisture to a minimum.

- Solid products are resistant to low temperatures. This quality is especially relevant in Russia.

However, not everything is so rosy. Solid bricks also have a number of disadvantages that you need to be aware of before purchasing such materials.

- Walls made of solid bricks must be additionally insulated. For this, different materials are used. This stage of construction work cannot be neglected.

- Such building materials are heavy, so it is not so easy to work with them, and the transportation of such products can cost a lot.

- Solid bricks are much more expensive than hollow bricks, because they require a larger amount of the main component - clay.

- If you choose a solid brick of the wrong brand, then it can begin to crumble.

- Such products are very easily damaged during transportation.

- Defects such as efflorescence often appear on solid ceramic bricks. Outwardly, they are whitish stains that spoil the appearance of the material and the structure as a whole.

As you can see, this building material has much more advantages than disadvantages. Much depends on the point of sale from which the brick was purchased. In stores with a not very good reputation, you can stumble upon low-quality products passed off as first-class. Many problems can arise with such materials in the future.

Types

As mentioned above, according to its structure, the briquette in question is produced on the market:

corpulent;

Corpulent

hollow.

Hollow

In the first option, there are no voids. The briquette in question is not famous for its thermal features, but it is optimal for foundation work, as well as for the construction of load-bearing structures.

Foundation

The M 150 also stands out for its insignificant level of sound isolation. The hollow analogue, which has voids in its structure, is significantly lower in weight. It perfectly retains heat in the room, so it is used for the construction of load-bearing structures and partitions between rooms.

Interior partition

Thanks to its improved soundproofing properties, the briquette is ideal for the construction of partitions between rooms and apartments. If you have purchased the M 150 cladding type, it can be used for wall decoration.

A briquette of 150 marks is:

facing imported or domestic;

Facing

ordinary construction.

Private construction

To ensure optimal adhesion, the manufacturer provided this material with special edges that have a relief structure.

Relief structure

If ordinary briquettes are used for the construction of supporting structures, they are additionally processed - either they are covered with a layer of plaster, or a special paint coating is applied.

Therefore, such a briquette, according to its external characteristics, is as simple as possible, its front part is never processed. In addition, a briquette can be produced in a non-uniform shade and its distorted shape is allowed by GOST.

Facing

Facade cladding bricks with appropriate markings have found their widespread use in the construction of various objects. This became available due to the fact that different companies supply the market with a variety of shade variations, as well as briquettes of numerous textures.

Facade

The cladding analogue is used for real estate decoration - thanks to it, the object acquires ideal external characteristics. Facing bricks decorate the front side of the building, fences, openings on staircases, underground passages and even arches. Here is its size.

Private

Single corpulent building brick, marked m 150, the price of which depends on the density, can be sold from 10-20 rubles.

In addition to density indicators, the cost of a product is also influenced by its quality and the manufacturing company. Therefore, when purchasing the basis for the construction of objects, you should not look for cheap options.

In the future, this may lead to a series of unpleasant events, which will find their expression in the premature deformation of real estate. The material considered in the article is universal and can be used for all types of structures.

The surface of a solid briquette is often smooth, but embossed counterparts can also be found on the market.The latter are designed to improve the adhesion of the product to each other.

This characteristic is very important, especially if, in addition to its mass, an additional load will act on the building.

Characteristics of a briquette of 150 brands.

dimensions: 25x12x6.5cm;

Single

- weight: from three kilograms;

- strength index: 150;

- resistance to subzero temperatures: from 50;

- moisture absorption: eight percent or more;

- shade: can be anything from ivory to red. Here is the size of a red solid brick;

- surface: it can be as smooth as possible, and with the presence of corrugations.

If you want to build a brick object, choose only high quality material and never give preference to cheapness.

Before you start laying, carry out something like an analysis: why are you building the building, what functions it will perform, what role is assigned to this or that element, whether the building will come into contact with aggressive environmental factors.

Other components of real estate can be created from cheaper grades of briquettes, thus you will reduce construction costs and the structure will not be overloaded.

For more information about an ordinary solid building brick, see the video:

Product design features

A solid single brick after laying requires additional finishing or plastering of the base with other materials, since it does not have an ideal surface. The grade and strength are usually indicated on the stone, and stones of the M100 or M150 brand are used for the construction of buildings of 1–2 floors. If the building is more than 3 floors, then ordinary brick laying is not performed.

It is produced in the form of rectangular products and happens:

- hollow;

- corpulent.

These types of products differ in thickness, size, resistance to low temperatures, strength, texture and weight.

The strength of such a product is indicated by the letter M with numerical values, and frost resistance by the letter F with a numerical value.

- Strength. For example, a stone of the M50 brand is usually used for laying partitions, or it is used for low structures that are not heavily loaded. Brick of the M100 brand can be used for the construction of the main walls. Products of the M175 brand are used for the construction of foundations.

- Water absorption. Water absorption is also considered important, which indicates the ability of the product to absorb moisture. This value is determined as a percentage and indicates the amount of moisture that a brick can absorb in percentage. The tests are usually carried out in a laboratory setting where the brick is placed in water for 48 hours. Standard brick has a water absorption of 15%.

- Frost resistance. It determines the ability of the product to withstand freeze / defrost cycles and this indicator is also affected by the level of water absorption. The less moisture the brick absorbs, the greater its resistance to low temperatures. Under standard construction conditions, it is recommended to use brick grade F25, and for load-bearing foundations - F35.

- Thermal conductivity. This is also an important indicator that can fluctuate depending on the type of brick. For a standard product, the thermal conductivity is 0.45-0.8 W / M. To ensure good thermal insulation of the building when using this type of stone, it is recommended to lay out walls up to one meter thick. But this is rarely resorted to, and therefore an additional layer of thermal insulation is usually used for the base.

Dimensions (edit)

Experienced builders know exactly the size of a red full-bodied brick, this is important when calculating the estimate, as well as determining the joint, planning the foundation, etc., the size can be viewed visually in the photo. Today the stone is divided into standard and non-standard

Standard refers to the usual single brick, which can be found in most areas of construction.

Today, the stone is divided into standard and non-standard.Standard refers to the usual single brick, which can be found in most areas of construction.

The size of ordinary solid red brick is strictly regulated by GOST, which excludes significant defects or deviations from various manufacturers.

This option is the most convenient and popular today, as it allows you to lay even wide masonry panels and walls without any problems.

Standard

If you delve into the dimensions a little, it becomes obvious that its dimensions are almost 2 times smaller in each of the following parameters.

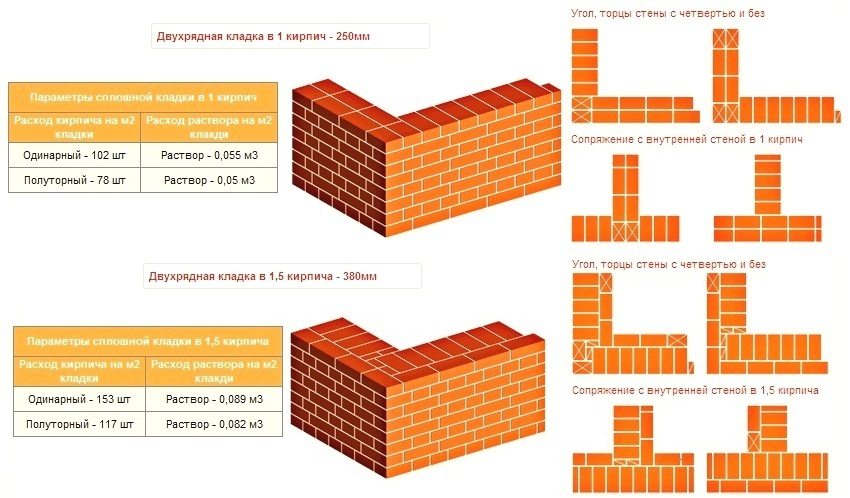

Due to the fact that the width is almost 2 times less than the length, it is possible to make cross-laying when the brick is laid perpendicular to the previous layer. This approach is actively used in construction and helps to increase the quality characteristics of the structure.

The alternation occurs at a certain frequency, it can be after 1 row or after 3 rows, it is already determined by the contractor on the spot.

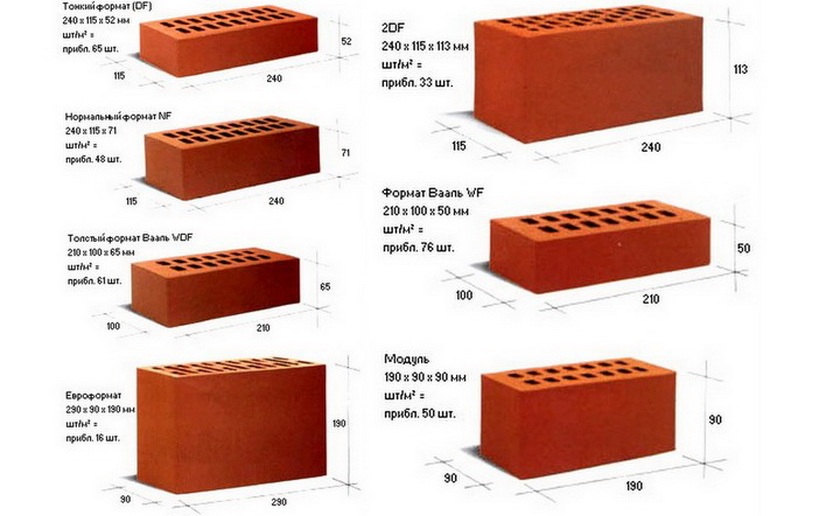

This is done to ensure maximum masonry convenience in specific industries. Such a specific stone is called one and a half. Its basic characteristics, that is, the length and width remain the same, recall 250x120 mm, but the thickness increases slightly.

For one and a half red brick, the dimensions will be 250x120x88 mm, that is, the thickness of the stone is 23 mm larger than that of a standard single brick.

One and a half

There is another brick, it is even more thickened in cross-section in thickness, such a stone is called double.

Double

The size of the brick, in addition to the popular and well-known varieties in our area, may correspond to other standards. Today the euro brick is gradually entering the market, slowly but surely. Its main difference is its small width, namely 2 times smaller than the standard one.

Its dimensions are 250x60x65 mm. It is used infrequently for the construction of houses, since it is associated with high expenditures of man-hours, but it is often produced as a facing, it makes it possible to lighten the structure. It is noteworthy that the euro standard is rarely used in Europe itself.

Euro

Uncommon, but some manufacturers can make other types of bricks, mostly made to order. Such uncharacteristic dimensions are rarely used, only for projects that require certain complex types of work.

In most cases, decorative types of bricks have distinctive characteristics.

Facade

Until now, there are craftsmen who prepare red bricks by hand, this is mainly done with the aim of giving them a specific aged look. Today there are very few workshops left; there are none at all on the territory of Russia.

Sizes can vary significantly depending on the type and production process, it is worth checking individually. The scope of application in most cases is limited to restoration work.

Technical characteristics of solid bricks

Let us now consider the positive parameters of red and silicate bricks, as well as their disadvantages. To do this, we will compile a comparative table of materials.

Solid brick, characteristics:

Parameters of ceramic brick, silicate brickStrength, kg / cm2 M75, M100, M125, M 150, M200, M250, M300.M150, M200 Density, kg / m3 1600-1900 1600-2000 Thermal conductivity, W / m * K0.5-0.60.7-0.9 Frost resistance.F25 , F35, F50, F75 F35, F50, F75 Heat resistance. Up to 1000 degrees up to 800 degrees Water absorption,% 9–128–15 Weight of 1 solid brick, kg 3.93.7

Let's take a closer look at the characteristics of a solid brick, as well as analyze what each parameter means:

Strength.

The ability of a material to withstand certain loads without collapsing. The letter "M" denotes the brand of brick, and the numbers next to it - the amount of pressure for compression, tension and bending. In other words, the higher the number, the more pressure the brick can withstand, the stronger it is.

Brick multi-storey house

For small one-story buildings, it is permissible to use brick M100, M125, for taller buildings, you need to take the M150 and higher grade. M75 is usually used for the construction of fences and other lightweight construction forms.

Density.

With an increase in density, other parameters of the material decrease.

The higher this indicator, the worse the heat and sound insulation properties of the material. If we take, for comparison, solid and hollow bricks, the use of which is almost the same, then due to the presence of voids in the body of the latter, the thermal conductivity and sound permeability of the material will significantly decrease.

This factor is directly proportional to strength: the higher the density of a solid brick, the more durable the structure will be, but other parameters will deteriorate. For comparison, the density of hollow bricks is 1200-1500 kg / m3.

Thermal conductivity.

The ability of a material to retain and transfer heat at different temperatures. The lower this indicator, the less heat will penetrate through the walls, and the more comfortable living in such a building will be. Accordingly, heating costs will decrease.

Well masonry walls

It is possible to reduce the thermal conductivity of walls by using various types of masonry, for example, using the "well" method. This is when the outer and inner planes of the walls are laid out of solid bricks, and a gap is left in the middle, a "well", the width of a brick. The quarry is laid in the interval (hollow and chipped bricks, various types of insulation).

Frost resistance.

The property of a material to withstand many freeze-thaw cycles without changing technical parameters. It is designated by the letter "F", the numbers next to it indicate the number of these same cycles. The higher this indicator, the more durable the structure will be.

Frost resistance of bricks

The frost resistance characteristics of solid bricks, regardless of the type, are the same, but experts advise using ceramic bricks in cold regions. In central areas, it is recommended to use bricks with a grade of at least F35, and in cold areas with an even higher grade.

Heat or fire resistance.

Brick is practically not subject to destruction even after prolonged contact with open fire, and of course, it is completely non-flammable, completely fireproof. Fireplaces and stoves are made of special heat-resistant red bricks, the service life of which reaches 30 years without repair.

Refractory bricks for fireplaces and stoves

But temperatures above 800 degrees act destructively on silicate bricks, therefore the instruction does not recommend using it for laying stoves and the inside of chimneys.

Moisture absorption.

This is a value that shows how much moisture a given material is able to accept and retain. The higher the percentage, the lower the frost resistance of the brick, the greater the risk of material destruction. The most acceptable moisture absorption is 6–12%.

Moisture absorption of bricks

The weight of a single solid silicate brick differs little from the weight of a ceramic brick. Therefore, their densities are almost the same, and, accordingly, the strength indicators are almost at the same level.

Brick weight

By the way, it is rather problematic to say exactly how much a solid brick weighs, here we took the average figure. Samples weighing from 3.2 to 4 kg can be found from different manufacturers.

Separately, it must be said about the cost of materials. The price of silicate bricks is 30 - 40 percent lower than that of ceramic. This is due to lower labor and energy costs in its manufacture, as well as the comparative cheapness of raw materials.

Brick house

Product dimensions

Ordinary ceramic bricks have the following standard sizes:

- normal format (single) - 250 × 120 × 65, these dimensions are designated 1 NF;

- one and a half or a bar with horizontal voids (b) - 250 × 120 × 88, designation - 1.4 NF;

- the dimensions of a double product or stone are 250 × 120 × 140. Designation - 2.1 NF.

Where, the length of the bed is a = 250 mm, the width of the bed is b = 120 mm, and the height is different for each type of material: c = 65; 88; 140.

The given dimensions of the products show that one and a half and double bricks differ from the standard single one by 1.5 and 2 times. This should be taken into account when making calculations for the purchase of materials, if there is a need for construction.

Production of ceramic bricks. Clay serves as the material for it. It is crushed, mixed with water and formed into adobe (briquettes with a certain size). The briquettes are dried under awnings in the open air. Dried adobe can be an independent building material. It is used in single-storey construction for the manufacture of partitions. The adobe house is highly ecological and warm.

Production of ceramic bricks. Clay serves as the material for it. It is crushed, mixed with water and formed into adobe (briquettes with a certain size). The briquettes are dried under awnings in the open air. Dried adobe can be an independent building material. It is used in single-storey construction for the manufacture of partitions. The adobe house is highly ecological and warm.

The dried briquettes are stacked in a certain way in kilns, where they are fired to a red color.

Brick production is organized in the vicinity of clay deposits. Uniformity of raw materials is of great importance

Therefore, special attention is paid to the mixing process of all components. The quality and size of products are highly dependent on the mineral composition of the clay and the correct conduct of the firing process.

Nowadays, the production of other innovative materials has been established, for example, building aerated concrete, but brick does not lose its popularity.

Ordinary and front bricks

Depending on the scope of use, ceramic bricks are divided into two types:

- private, he is a construction or ordinary;

- front, or facing, or front.

Building bricks are used to create foundations, load-bearing walls and partitions. Small chips are allowed on it, but the geometry of the samples must be accurate. After the construction of the wall and partitions, ordinary brick requires cladding. The material is usually made corpulent, but hollow samples are also found - they are used to create non-bearing partitions. The size can be single, one and a half, double, etc., we will talk about this separately.

Face brick is more interesting in terms of variety. It is used to decorate the facade, it can be used in interior decoration. As a rule, these are hollow bricks, which weigh less and have improved thermal insulation qualities. The facing brick must have precise geometry and uniform color. As for the shade, the natural color of ceramic bricks is quite beautiful and noble, so you don't even need to look in the direction of tinted samples. If you want something original and extravagant, then you can find colored bricks. Coloring is carried out in bulk by adding pigment, so that the original shade will remain for a long time.

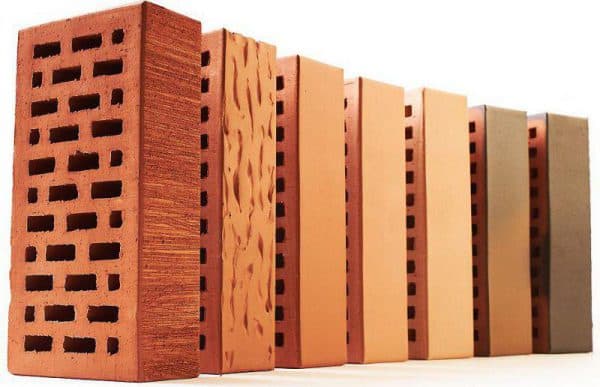

Facing bricks differ not only in color, but also in the type of surface. In its simplest form, it will be perfectly smooth, possibly with chamfers. This is a traditional and proven option. If you wish, you can move away from the classics and choose one of the following surface types:

- embossed. At the required end of the still unfired brick, a volumetric pattern is formed using a stencil. After processing in the oven, the pattern remains, while the strength of the brick does not change at all;

- engobed. An engobe, a layer of ceramics with an admixture of metal oxides, which are responsible for creating a certain shade, is applied to a dried, but still unfired brick. In the furnace, under the influence of high temperatures, the engobe is fused with the clay brick mass. As a result, a solid, durable product comes out with an interesting shade. Engobe is sometimes applied only to a part of the end, forming a spectacular color transition;

- glazed. If glaze is applied instead of engobe, then in the end you can get a brick with a smooth shiny surface, which has not only excellent aesthetic qualities, but also additionally protects the material from moisture.

Facing bricks are produced not only in the standard parallelepiped shape - figured bricks are presented in a wide range. It can have rounded corners, notches and waves, there are wedge-shaped, trapezoidal and many other patterns, the shape of which is difficult to describe. These elements are necessary for the effective design of window and door openings, corners and floors of the house.