Applications

The simple design of the spring cotter pins allows them to be used in many industries. They are used in aviation, mechanical engineering and shipbuilding. Due to their high reliability and uncomplicated design, cotter pins are used everywhere. For example, when connecting lever systems, in the manufacture of belts for lifting mechanisms. However, the lateral impact on the cotter pin should not be high: its structure is unreliable. For this, steel pins are used, since they can withstand high mechanical loads.

Unlike connecting threaded parts, cotter pins are a more rational solution, they even serve as a backup fastener for threaded ones, provided there is a hole for the cotter pin. You can use the mounts even in handicrafts at home. Some compounds in the manufacture of toys are made precisely with their use.

How to make a spring cotter pin with your own hands, see below.

Materials (edit)

Taking into account the design features, purpose and scope of the described clamps, it can be concluded that the materials from which they are made must meet certain standards. Now on the market there are split pins, including those made of copper, brass and aluminum alloys. It is worth noting that such options are much less common. In this case, the most common material is mild structural steel and stainless steel.

For example, spring-type clamps (plugs) are in most cases made of carbon and stainless steel grades. They are zinc-plated for effective corrosion protection. Its thickness ranges from 6 to 12 microns

It is important to take into account that in accordance with GOST 397-79, the surfaces of hardware products should not have cracks, chips and other damage, due to which the permissible roughness standards will be exceeded

According to current standards, the following material and coating options are recommended for the manufacture of cotter pins.

- Low-carbon steel (carbon content in the composition is not more than 0.2%) with a zinc, cadmium, oxide or phosphate protective layer.

- Corrosion-resistant steel grades with an oxide coating created by acidic solutions.

- Nickel-plated brass, grade L63.

- Alloy AMTs with an oxide coating filled in a solution of potassium dichromate.

As mentioned above, in addition to low-carbon steels, even non-ferrous metals and their compounds can be used. So, when making cotter pins from wire, the absence of coating on the ends of the "legs" is allowed. In addition, in some cases, it may be absent on the inner surfaces of the branches, namely, at the points of contact.

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

- Spring washer - connections will never spin spontaneously!

2 DIN 11024 - German standard for needle spring hardware

There is no separate Gosstandart for IS in Russia.Such fasteners are produced according to international requirements ISO 7072 or according to their German counterpart - DIN 11024. This standard, which is actively used in almost all European countries, divides IS into two types.

Spring cotter dimensions

Spring cotter dimensions

Depending on the purpose for which the hardware product is used, a specific form of its execution is chosen. The second type of fastener is usually chosen when it is required to eliminate the risk of self-loosening of the fixing nuts. Basic parameters of type 1 IS according to DIN 11024:

- diameter (outer) - 9–56 mm;

- hole section - 2.5–8 mm.

Cotter pins of the second type have slightly different dimensions:

- diameter - 9–45 mm;

- hole section - 2.5–9 mm.

State standards

The shape of the cotter pins meets a number of standards. This not only makes it easy to find the correct shape, but also ensures that fasteners of the same quality and standard dimensions are obtained. The following standards are available and are currently in use.

- GOST 397-79 corresponds to ISO 1234 - German standard DIN 94.

- ISO 7072 - DIN 11024.

There are also a number of specially shaped cotter pins designed for special requirements that are not related to standards. For example, as shown in the pictures, cotter pins, wire or hairpins, round, guide springs.

For standardized, the following types of markings are used:

- Standard (adjustable, folding) - DIN 94;

- Spring (needle) - spring clip DIN 11024;

- Quick release with ring (foldable rail, foldable plug (DIN 11023)).

Applications

Split pins are used to protect loose bolted or screwed connections from axial displacement.

Spring loaders have found use in high-load bolted connections such as construction machines, cranes or bicycle disc brakes. In this case, the components are fastened with a spring-loaded connector, so that it would not be lost, for example, using a chain. Spring mounts are by no means suitable for power transmission.

Often in mechanical engineering and automotive industry, cotter pins are used as plugs and locking fasteners. But in everyday life, we can meet them at every step, for example, in the gym, the components of the strength bench are fixed with cotter pins.

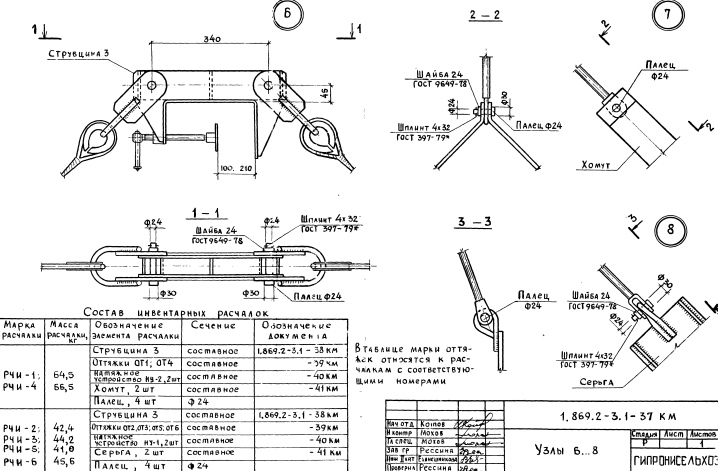

The figure shows how to attach the bucket. To prevent the bucket from being pushed out of the holder, the check serves as a safety catch. In this case, in contrast to the adjustable one, the cotter pin with a ring can serve an unlimited number of cycles.

Thus, it is possible to roughly outline the areas of application of cotter pins:

- Motor transport, motorcycles, bicycles, boats;

- Mechanical engineering, metal structures, construction of trailers;

- Industry, crafts, agriculture;

- Fuses for all kinds of parts such as screws, pins, bolts, etc.

Any kind of power transmission should be avoided when using cotter pins.

How to install?

Regardless of the type and design features, the described devices are used in order to fasten axles, shafts and threaded connections under relatively low loads. In principle, the process of installing the clips is as simple as possible. However, there are certain rules and features. Adjustable and spring cotter pins can be installed in two ways - parallel or perpendicular to the axis of attachment of parts.

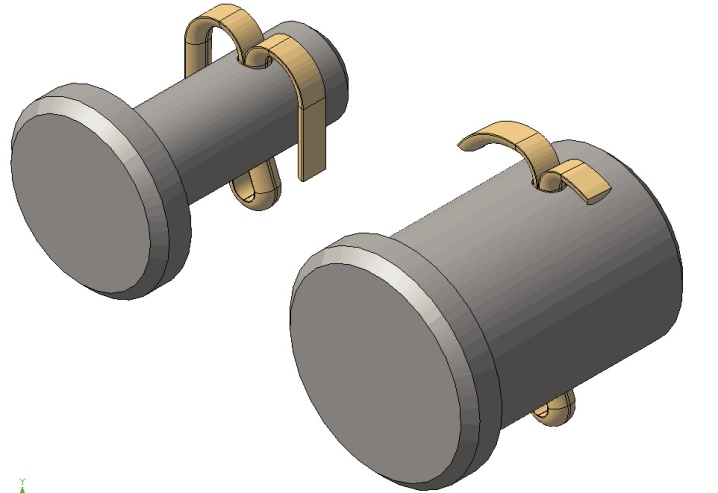

The needle-shaped (straight) part of the spring cotter pin goes through the hole, and its wavy branch is pressed against the outside of the part. Typically, these types of fasteners are used only once. An alternative in this case can be ring, quick-detachable models that are reusable.

Dismantling the clips, as well as their installation, should not cause any significant difficulties. Most often, it is enough to simply pull out the cotter pin or knock it out using a nozzle of the appropriate size.As a last resort, the fastener can be carefully drilled out by picking up a drill.

How to tighten the cotter pins correctly, see below.

Varieties

The needle cotter pin is used to connect and fix detachable structures, provides quick assembly and disassembly of component parts. The upper end is made in a zigzag manner, reminiscent of the letter R. This feature makes it possible to grip the upper part of the leg of the part from the outside: it is automatically snapped in several places at once. And the straight part, inserted into the hole, remains fixed, motionless. Thus, there is a double-sided fastening of the pin, nut or bolt.

A quick-release cotter pin with a ring (cotter pin) has a fixed rod that is inserted into the screw hole. The attached ring with free movement is thrown over the end of the fastening element from above for additional fixation, it is a folding plug. Unlike the previous types, this mount has a great advantage, as it is used many times. This is an important factor when assembling and disassembling structures for instant fastening. The convenience of just this shape, reminiscent of a check, is that when removing the cotter pin, you just need to raise the ring and, pulling on it, pull out the cotter pin.

The spring cotter pin is a little more complicated in design, there are two types: with a double loop in place of the lug and a single one. The double reversible eye is springy during operation, providing additional reliability and maneuverability in fastening parts. The upper end is made in a zigzag pattern.

Feature and purpose

The difference between spring devices and other locking elements, such as a locknut, is that the fastening of the cotter pins does not loosen over time, even in the presence of strong vibration. The hardware product has a low cost and can be reused. The direct purpose of the spring cotter pin is to ensure safe fastening of the part, as it were, control fixation.

The standard or turnover (spring cotter pin) lug is used to attach any structure, such as connecting links. This element is designed to provide speed and maneuverability during operation.

In the spring version, there is a significant difference from the standard sample - additional fastening strength due to the action of the spring. The cotter pin is an elastic product for quick installation, insertion into the part for locking, for example, to prevent self-loosening of nuts and bolts: during operation and vibration, you can lose the part and harm the entire process of the mechanism. The size of the mount directly depends on the diameter of the part. If the dimensions do not match, it will be impossible to fix. Sometimes you have to drill a hole in the mounting screw to install the cotter pin.

What is it and what is it for?

Cotter pins, as a type of fastener, are standard hardware products. They are widely used in a wide variety of designs, devices and installations. It should be noted that their main task is to securely fix the axles and nuts. Splitting works according to the principle of a quick-lock mechanism. These hardware, used for fastening individual parts of walk-behind tractors, snow blowers augers and even for assembling furniture, are very easy to install and dismantle.

Externally, a cotter pin is a small wire rod that has been bent in half. It has a semicircular cross-section and fits into an appropriately sized round hole. The latter can be done in an axle, shaft, bolt or nut. In the place where the cotter pin is bent, there is a small eyelet that prevents it from slipping. After installing the fastening element, its ends, which have different lengths, are spread in different directions and bent.

Considering the features and performance of this type of fastening device, it is necessary to pay attention to their difference from the pins.First of all, the latter are made in the form of a rod having a cylindrical or conical shape

By and large, a pin is a nail that does not have a head. In the overwhelming majority of cases, such latches are inserted into holes passing through all the connected elements of a structure or mechanism. So, the pin in the form of a cylinder of increased diameter is pressed into the bore with force, which provides a reliable frictional connection due to the elasticity of the material.

Pins are used in situations where strict fixing of structural elements in relation to each other is required under light loads. Often, in this case, additional transversely placed cotter pins are installed, which ensure a reliable connection and prevent the pins from falling out during vibration.

In practice, two types of devices under consideration are most often used - spring and extension. Moreover, the latter are the most common due to their reliability, simplicity of design and the possibility of self-production. The spring cotter pin in the form of a zigzag is a little folding in operation, but at the same time it is not less reliable.

These hardware have proven their effectiveness in situations where it is required to protect loose screw or bolted connections from axial displacement under external influences. At the same time, spring models are more relevant for increased loads. In this case, we are talking about units of construction equipment, including lifting mechanisms, as well as brake systems for bicycles. Typically, spring cotter pins are additionally secured to prevent slipping and loss.

In mechanical engineering, the described devices are widely used as plugs and retaining fasteners. However, they can be found in everyday life, almost at every step. Gym equipment is a prime example. Another type of cotter pins, namely, quick-release ones, are widely used in the agricultural sector.

Taking into account all of the above, it is possible to conditionally determine the scope of application of cotter pins of different types. And in this case we are talking about the following areas.

- Cars, motor vehicles, watercraft and bicycle equipment.

- Mechanical engineering.

- Manufacture of metal structures.

- Agriculture.

- Crafts.

It is important to take into account that the installation of cotter pins does not provide for the transfer of energy. The list of modern hardware products includes a sufficient number of elements, such as, for example, lock nuts

However, even the highest quality ones weaken over time and under the influence of vibration. Prevention of such phenomena is the main task of the cotter pin. However, it is worth considering the applied force, which, at peak loads, can destroy the entire structure.

1 Cotter pin - to secure and protect the connection from vibration

The needle cotter pin (ISH) is made in the form of a semicircular, round or flat rod, which is bent in half. At the end of such a hardware, there may be a so-called eyelet - a drop-shaped loop. In addition, the industry produces cotter pins in the form of the letter T, but they are used much less often than the standard fasteners described in this article. Ish is produced from ductile and relatively soft metals. These include: aluminum, brass, stainless steel, bronze rolled products.

Spring cotter pin

Spring cotter pin

In cases where the hardware is planned to be used for shearing, it is made of bronze, brass and aluminum alloys. In other situations, it is recommended to use stainless steel fasteners, since they can be inserted and removed without the slightest difficulty. The scheme for using IS is very simple. It is necessary to fold two parts of the same structure (attach several parts to each other), drill holes in them with the required dimensions and connect them together with a cotter pin. After installing such a spring hardware, its curved part is snapped in (automatically).As a result, you will get a reliable connection.

The fasteners under consideration are used in various fields of construction and mechanical engineering. Most often, they are used to mount special bushings on smooth shafts. In such situations, cotter pins prevent self-unscrewing of the fixing elements (nuts and bolts). Also, ISh are indispensable for fixing rolling bearings and any other elements on the wheel axles of various vehicles and any other elements that experience vibration and small constant physical. load.

Classification

Cotter pins are classified according to government standards for their design and dimensions.

Adjustable (extension) or standard

The general purpose cotter pin is standardized according to the Russian GOST 397-79 (analogue of the German DIN 94 standard).

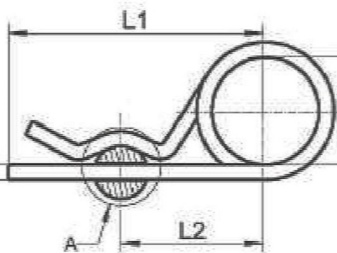

Usually it is in the form of a wire with a semicircular cross-section. The legs of different lengths are pressed against each other, so that on one side a circular cross-section with a standardized diameter is formed, and on the other side, an approximately annular, also standardized, head. It serves to limit the planting depth and fix the fastener itself.

For fixing, the cotter pin is inserted through the standard hole in the fastened parts. The ends of the legs are divorced, their different lengths simplify this process. In addition, the head is needed to remove a worn mount using, for example, pliers or a thin, strong rod.

Standard cotter pins cannot be reused after unlocking as their safety functions are no longer guaranteed.

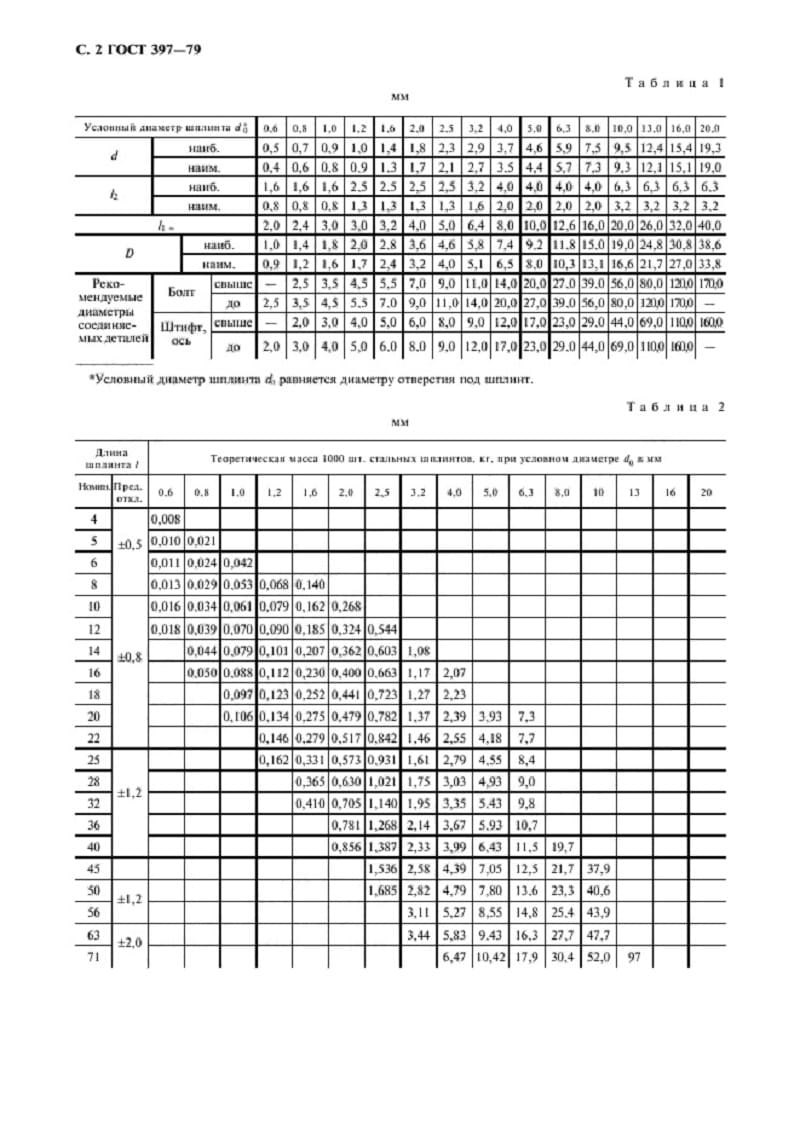

The design, dimensions and marking of cotter pins in accordance with GOST are shown in the drawing and in tables 1 and 2.

The diameter of the adjustable cotter pin is understood as the diameter of the hole in the fixed parts that can be used. The length is measured from the head to the end of the short stem. The shape of the ends of the legs is different - pointed or cut at a certain angle.

Usually the following mounts go on sale:

- according to DIN 94 - with a nominal diameter from 1 to 13 mm, a length from 4 to 200 mm, a head size from 1.6 to 24.8 mm.

- according to GOST 397-79 - with nominal diameter from 0.6 to 20 mm, length from 4 to 280 mm, head size from 1.6 to 24.8 mm.

Spring loaded

The spring cotter pin differs in its principle of action from the extension pin. It locks the parts into place by snapping in, thanks to the elastic (spring) effect of its own material. Its shape resembles the letter "R". They are produced according to the international standard ISO 7072 (analogous to the German standard DIN 11024).

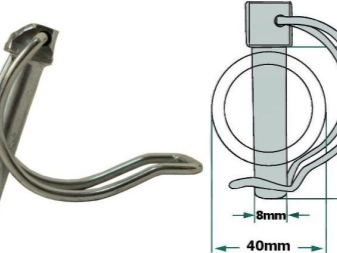

Picture of spring cotter pins and fastening method

Fasteners are carried out as follows. A straight leg, resembling a needle, is inserted into a hole of the required size, curved - snaps into place on the top of the part at several points. The result is a springy effect.

Due to their needle-shaped stem, spring mounts are often additionally referred to as needle spring mounts.

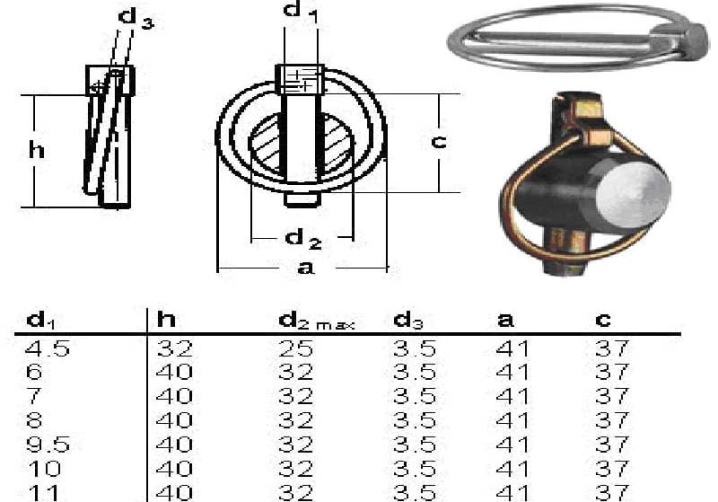

Needle pins come in E and D shapes, depending on the type of round part - in D it is reinforced with an additional turn.

The drawings and the table show the view and dimensions of the Form D fastener.

| Axle or shaft | d3 | d4 | l1 | l2 | l3 | h | r1 | r2 | The weight | |

| Hole diameter d1 | Outside diameter d2 | |||||||||

| 2,5 | from 9 to 11.2 | 2,25 | 20 | 42 | 24 | 5,5 | 2,5 | 5,6 | 4 | 0,59 |

| 3,2 | from 11.2 to 14 | 2,8 | 20 | 48 | 26 | 7 | 3 | 7 | 5 | 0,99 |

| 4 | from 14 to 20 | 3,6 | 20 | 64 | 32 | 10 | 4,5 | 10 | 6,5 | 1,89 |

| 5 | from 20 to 26 | 4,5 | 25 | 80 | 39 | 12,5 | 7 | 13 | 8 | 3,54 |

| 6,3 | from 26 to 34 | 5,6 | 25 | 97 | 45 | 16 | 9 | 17 | 10 | 6,18 |

| 7 | from 34 to 45 | 6,3 | 30 | 125 | 56 | 21 | 12,5 | 22,5 | 11,5 | 9,7 |

| 8 | from 45 to 56 | 7 | 30 | 150 | 63 | 25,5 | 17,5 | 28 | 12,5 | 13,4 |

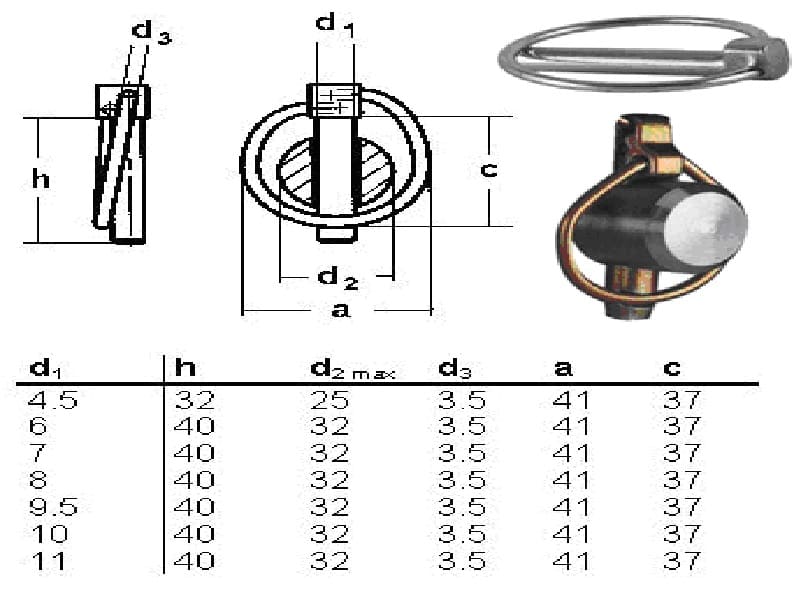

Also in the figures and in the table are given the type and dimensions of the fastener form E.

| d | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 |

| L | 50 | 60 | 60 | 85 | 105 | 105 | 110 |

| D | 10 | 18 | 20 | 24 | 30 | 30 | 28 |

| B | 25 | 28 | 30 | 40 | 50 | 50 | 55 |

| Hole diameter | 2.5 | 3.5 | 4.5 | 6.0 | 7.0 | 8.0 | 9.0 |

| External diameter | 9-14 | 10-16 | 16-20 | 20-28 | 28-40 | 28-45 | 30-45 |

Quick release with ring

The cotter pins of the German standard DIN 11023 are equipped with a special ring, which makes their use much more convenient in case of repeated use of the part. Unlike previous types of fasteners, which are recommended to be used once, quick-release cotter pins (checks) can be used for an almost unlimited number of assembly and disassembly cycles of various types of connections

This is important when parts are subject to special requirements and safety aspects. For example, for straight shafts and pipes, many types of agricultural machinery

The drawings and the table show the type and dimensions of the cotter pin.