1 Knitting wire - where and why is it used?

Reinforcing wire is used in the field of individual and industrial construction for the manufacture of frames used to reinforce reinforced concrete structures. By means of a knitting wire, the adjacent reinforcement bars are connected at the point where they overlap.

The material can be used when assembling the following types of frames:

- foundation (strip, monolithic, columnar);

- floors (basement and interfloor);

- floor screeds.

The most common wire for reinforcement in monolithic construction. In the industrial production of reinforced concrete products - piles, floor slabs, reinforced concrete blocks, their frames, in order to save time, are joined by means of spot welding.

Wire reinforcement

The connection of reinforced cages by means of knitting wire has two important advantages in comparison with welding technology. Firstly, this is the absence of weak points in the frame with increased susceptibility to corrosion, which are welded seams. During operation, the seams come into contact with moisture penetrating through the micropores of the concrete structure, the reinforcement rusts and the frame loses its original strength.

Also, many engineers point out that the wire frame is elastic, which increases the overall strength and resistance of the concrete structure to deformation. Whereas a rigid welded frame is not capable of handling severe bending loads that can cause cracks in concrete.

1.1 How to calculate material consumption?

According to the provisions of SNiP, the norm knitting wire consumption when assembling the reinforcement cage, it is 30 cm per joint or 4 kg per ton of reinforcement. To find out how much material you need to use, you need to determine the number of reinforcement coupling points in the frame and calculate the total consumption.

As an example, we give the calculation of the wire consumption for the reinforcement of the tape-type foundation. We use the conditional size of the foundation 5 * 6 m, it will have 2 belts of longitudinal reinforcement - upper and lower, 3 rods in each, connected by vertical and transverse jumpers with a step of 40 cm.

Knitting with an automatic pistol

Flow rate determination algorithm:

- We calculate the frame perimeter: 5 * 6 = 30 meters.

- Determine the number of jumpers based on a step of 40 cm: 30 / 0.4 = 75 pcs.

- Each jumper will have 6 joining points (3 rods on each belt), we determine the number of connections: 75 * 6 = 450 pcs.

- We calculate the consumption of knitting wire: 450 * 0.3 = 135 m.

In total, to connect the frame rods, we need to use 135 meters of material. In a similar way, having determined the number of connections and multiplying them by the standard consumption, it is possible to calculate the total consumption of wire for assembling the reinforcement cage of any configuration.

Wire types - characteristics

According to the standard, the wire is divided into the following types:

- VR1 - cold drawn (GOST 6727-80). It is used, for the most part, for stress-free reinforcement - the manufacture of frames, the production of meshes, etc. It is also called ordinary reinforcing wire.

- ВР2 - cold drawn carbon steel wire (GOST 7348-81). They are used in reinforcing and strengthening reinforced concrete structures (it is also called high-strength reinforcing wire).

- Spring wire made of carbon steel (GOST 9389-75). It is used, respectively, for the manufacture of springs that are twisted in a cold state, without hardening.

- Corrugated barbed wire (monobasic) (GOST 285-69).

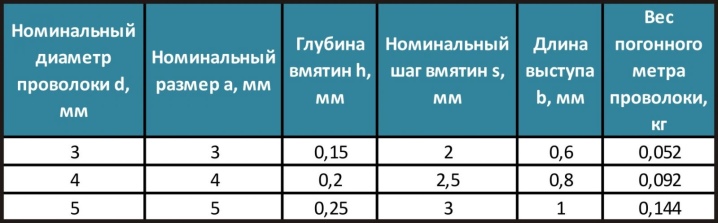

| Wire diameter, mm | 3 | 4 | 5 | ||

| Groove depth, h, mm | 0,15 | 0,2 | 0,25 | ||

| Maximum deviation in groove depth, mm | 0,05 | -0,02 | |||

| Groove pitch, mm | 2 | 2,5 | 3 | ||

| Maximum step deviation, mm | 0,02 | ||||

| Projection, mm | 0,6 | 0,8 | 1 | ||

| Maximum protrusion deviation, mm | ±0,02 | ||||

| Steel | 1kp | 2kp | 3kp | 2kp | 3kp |

| Breaking force, kg | 400 | 720 | 1085 | ||

| Relative elasticity,%, not less than | 2 | 2,5 | 3 | ||

| Linear density, kg | 0,052 | 0,092 | 0,144 |

How to calculate the expense?

Calculation of the amount of reinforcing wire helps to understand how much material needs to be purchased to complete the work and how much it will cost. For bulk purchases, the cost of the material is usually indicated per ton, although the maximum weight of a coil with wire rod is 1500 kg.

The norm of knitting wire, which will be required to carry out a certain set of works, is calculated based on the thickness of the frame reinforcement and the number of nodal joints of the structure. Usually, when joining two rods, you will need to use a piece of knitting material, the length of which is at least 25 cm, and if you need to connect 2 rods, then the consumption rate will be 50 cm per 1 docking node.

To simplify the counting task, you can refine the number of docking points and multiply the resulting number by 0.5. It is recommended to increase the finished result by about twice (sometimes it is enough and one and a half times) in order to have a margin in case of unforeseen situations. The consumption of knitting material is different, it can be determined empirically, focusing on the method of performing knitting technology. To more accurately calculate the wire consumption per 1 cu. m of reinforcement, you will need to have a diagram of the location of the docking nodes. This calculation method is rather complicated, but judging by the standards developed by the masters in practice, it is believed that at least 20 kg of wire is needed for 1 ton of rods.

As an illustrative example, consider the following situation: it is required to build a tape type of foundation with dimensions of 6x7 m, which will have 2 reinforced belts containing 3 rods in each. All joints in the horizontal and vertical direction must be made in 30 cm increments.

First of all, we calculate the perimeter of the future frame of the foundation, for this we multiply its sides: 6x7 m, as a result we get 42 m. 3 and get 140 intersection points as a result. On each of the jumpers, 3 rods will be docked, which means that these are 6 docking nodes.

Now we multiply 140 by 6, as a result we get 840 joints of the rods. The next step is to calculate how much knitting material is required to join these 840 points. To do this, we multiply 840 by 0.5, as a result we get 420 m. To avoid a lack of material, the finished result must be increased by 1.5 times. We multiply 420 by 1.5 and we get 630 meters - this will be an indicator of the consumption of knitting wire necessary for performing frame work and making a foundation measuring 6x7 m.

The next video shows you how to prepare a knitting wire.

Dimensions and weight

The BP 1 product grade should be produced in coils weighing from 0.5 to 1.5 tons, but it is possible to produce a smaller weight - from 2 to 100 kg. Taking the averaged parameters, we can draw a conclusion on the length and weight of the product, depending on the diameter of its section:

-

3 mm - there will be approximately 19230 m in a skein, and the mass of one running meter (l. M) will be 52 g;

-

4 mm - the length of the product bay is about 11 km, the weight of 1 linear meter will be 92 g;

-

5 mm - in a wire spool - within 7 km, weight 1 line m - 144 g.

Domestic enterprises do not produce BP 1 in rods - this is unprofitable, high costs are required.

You can find out how easy it is to align the wire with your own hands from the video below.

Description

In the production of reinforced concrete products, BP 1 wire is widely used to enhance the strength of the frame. It can even replace reinforcement, therefore it is also called reinforcing wire.

Explanation of the abbreviation: "B" - drawing (production technology), "P" - corrugated, number 1 - the first class of product reliability (there are five of them).

At first, this wire was used exclusively for reinforcing concrete products, but later it began to be used for the production of fences, cables, nails, electrodes and much more. And the reason for this was the cheapness of its production and versatility. Very often, such wire is used to strengthen facades, reinforce the foundations of buildings and floors. It is used to make welded mesh for concrete products and road surfaces, as well as knitting material.

The profile of this product is ribbed, has a periodic step of protuberances and recesses. Thanks to these notches, the wire-reinforced frame more reliably engages with the concrete mortar. As a result, the finished concrete products are stronger.

According to the standards of GOST 6727-80, products of this type are made of steel, in which the carbon content is very low - a maximum of 0.25%. The cross-section of the wire can be either oval or polygonal, but most often it is round, which is most convenient to use.

According to the standard, the wire is produced with the parameters indicated in the table below (all dimensions are in mm).

|

Diameter |

Dimensional deviation of diameter |

Depth of dents |

Depth tolerances |

Distance between dents |

|

3 |

+0,03; -0,09 |

0,15 |

+0.05 and -0.02 |

2 |

|

4 |

+0,4; -0,12 |

0,20 |

2,5 |

|

|

5 |

+0,06; -0,15 |

0,25 |

3 |

There should be no defects (cracks, scratches, cavities and other damage) on the surface of the product.

Having studied the standard, you can find out that a metal product of this type is able to withstand at least four bends, as well as the amount of tensile force, which is the limiting one depending on the diameter.

What is it and where is it used?

Knitting wire belongs to a wide group of building materials made of low-carbon steel, where carbon in combination with steel contains no more than 0.25%. Steel billets in molten form are subjected to the drawing method, pulling them through a thin hole, applying high pressure for this - this is how the final product, called wire rod, is obtained. To make the wire strong and give it its basic properties, the metal is heated to a certain temperature level and subjected to high pressure treatment, after which the material undergoes a slow cooling process. This technique is called annealing - the crystal lattice of the metal changes under pressure, and then it slowly recovers, thereby reducing the stress process within the material structure.

The use of knitting steel material is most in demand in the construction industry. With the help of this material, you can knit steel reinforcing rods, creating frames from them, perform floor screed, interfloor floors. Knitting wire is a strong, but at the same time elastic element for fastening. Unlike welding fasteners, the wire does not impair the properties of the metal in the place of heating, and it does not need heating itself. This material resists various multiple deformation loads and bending.