Construction of various structures

The purpose of the mixture also determines how much Portland cement is required per 1 cubic meter of mortar. For various operations, there are formulas and standards that allow you to find out the correct ratio of components. Focusing on them, you will be sure that the work was done with high quality, and you managed to avoid unnecessary costs.

For the construction of structures that will have to experience high loads, a strong solution is needed, which, after hardening, creates a particularly strong monolith of the M300 and higher grade. But finishing like performing a horizontal screed or plaster, on the contrary, will require more mobility from the mixture, but not too high strength from M100 to M150. The production of products like a cinder block even allows the use of the M50 brand.

1. Bricklaying.

The cement-sand mixture for such works is produced without a coarse-grained aggregate - the building blocks themselves do an excellent job of it. And the task of the solution is to securely hold them together. To determine how much cement is required per cubic meter of masonry mortar, you can use the traditional volume ratio. Only one nuance should be taken into account:

Standard proportions are prepared in two versions:

- 1: 3 - binder content - 33% of the cube or 0.333 m3;

- 1: 4 - 0.25 m3 of Portland cement is required per 1 cubic meter.

It is customary to give the proportions in units of volume, but the components are purchased for them by weight. Knowing the bulk density of materials will help to convert the volume to kilograms. And the total consumption for masonry is calculated based on the fact that a cubic meter of the mixture goes to 4-5 m3 of a brick wall.

To determine how many bags of cement you need in your case per cubic meter, you can use a simple calculation. Take the ratio of CPU 1: 4, that is, the binder in a cubic meter will take a fourth part (250 l). The density of the cement is taken to be about 1.4 kg / l. Then, in a cube of volume, its weight will be equal to 1.4 · 250 = 350 kg. The standard packing of bags is 50 kg, that is, you need to buy 7 packs of building materials for each cubic meter of masonry.

2. Screed.

It is more convenient to calculate the solution for the screed for the entire volume of work at once. To do this, you only need to know the pouring area and the leveling height of the floor. Let's say you need to make a 6x6 screed with a thickness of 5 cm - this is 1.8 m3 of mortar:

- The proportion of the CPU mixture for such works is taken equal to 1: 3.

- The volume of cement, respectively, is 1.8 / 3 = 0.6 cubic meters.

- Binder consumption: 0.6 × 1400 = 840 kg or 17 bags of 50 kg.

According to building codes, M500 for a screed will require 460 kg per cubic meter, M400 - 575 kg / m3. Our calculation showed consumption at 467 kg/ m3, which corresponds to SNiP.

3. Construction of the foundation.

Approximate data for filling the foundations for buildings with concrete of different brands in SNiP can also be found. But the mortar for the foundation requires extreme accuracy in the calculations, since deviations will lead to a loss of the bearing capacity of the foundation and a decrease in the service life of the entire building.

Mixes of different brands

The grade of concrete, as well as the grade of the cement for its manufacture, is selected at the stage of building design. It all depends on the loads exerting pressure on the structure, since they will determine the required strength characteristics of concrete.

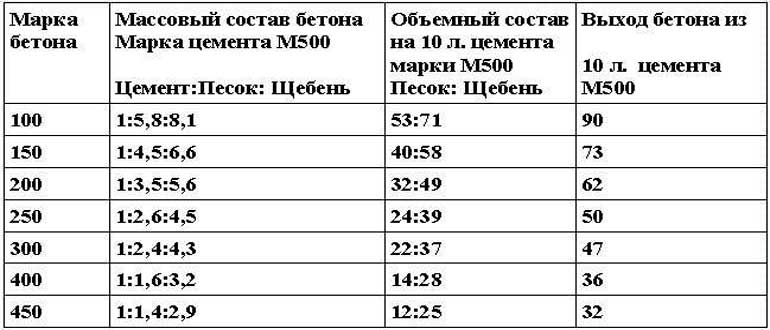

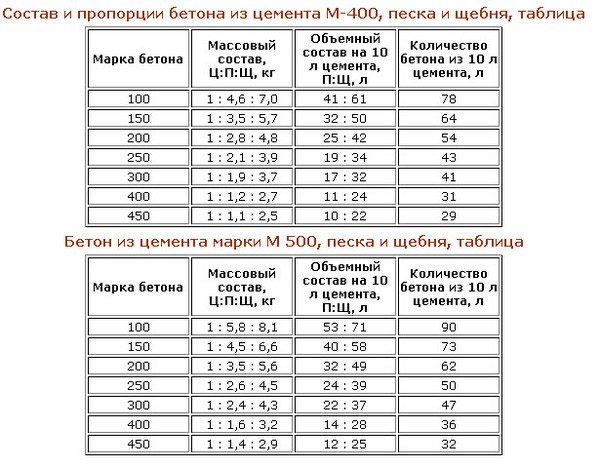

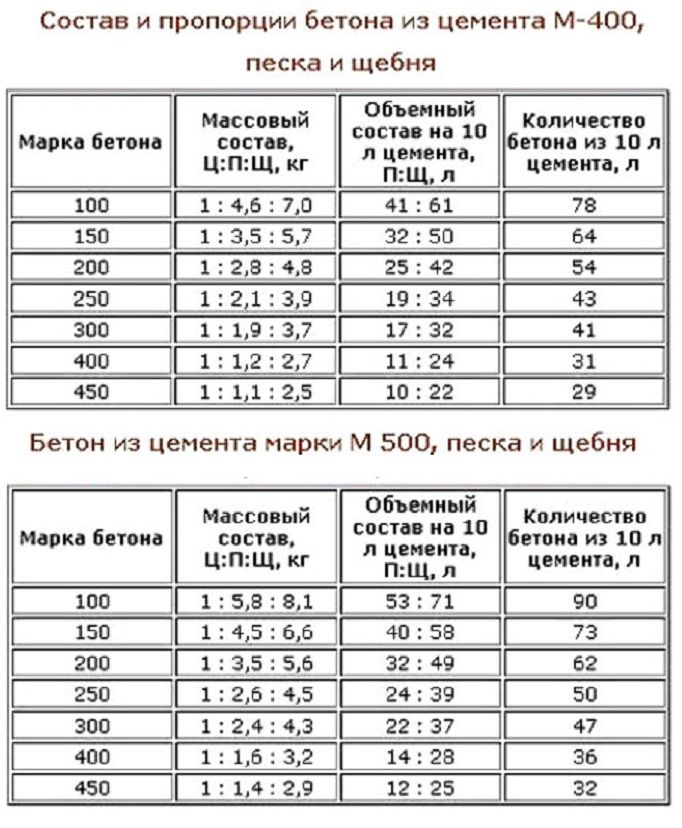

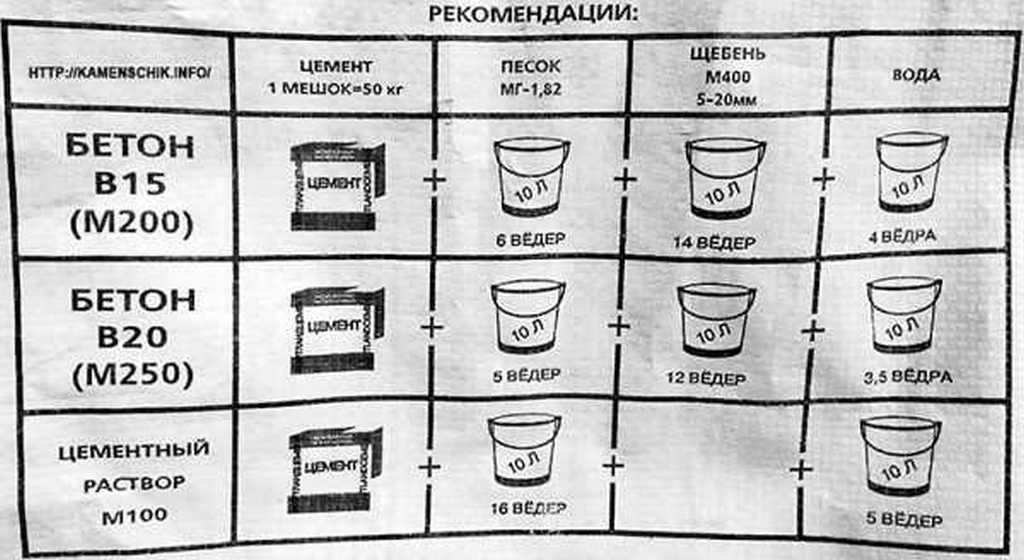

To simplify calculations, the standard proportions for solutions of different brands have already been deduced by specialists. From the table below, you can determine how many dry components are required per cubic meter:

| Concrete grade | Consumption of different brands of cement, kg per 1 m3 | ||

| M300 | M400 | M500 | |

| M50 | 310 | 230 | — |

| M100 | 390 | 300 | 250 |

| M150 | 510 | 400 | 300 |

| M200 | — | 490 | 410 |

| M300 | — | 600 | 510 |

| M400 | — | — |

Despite the strict requirements of building codes, the consumption cement for the construction of the foundation or other construction work sometimes has to be increased.This happens when one of the components is not of the best quality or simply does not correspond to the design data. The situation at the construction site is solved in the same way - cement consumption is increased:

Consumption

The quality and homogeneity of the mixture composition will depend not only on what proportions are chosen and the degree of preparation of the components, but also on the sequence in which the ingredients for the solution will be combined. If we consider private construction, then two manufacturing methods are used here - manual and mechanized (using a concrete mixer).

It is worth paying attention, if the first option is used, then the filler and the binder must be mixed exclusively in dry form, and only then can water be added

For the main grades of concrete, the consumption of cement grade 500 is as follows:

- for grade 100 concrete, which is used for preparatory work for the main pouring, 166 kilograms of cement are needed per cubic meter;

- if M200 is manufactured, which has a wide area of use, including for pouring the foundation, then 241 kilograms of cement are needed for 1 cubic meter;

- in the manufacture of grade 300, which also has a wide range of applications, but has higher qualities, it is necessary to add 319 kg of cement;

- to mix 400 grade concrete, which quickly sets and is often used for pouring structures for hydraulic engineering purposes, you need to add 417 kg of cement.

In order to obtain the appropriate grade, which will have a long period of operation, it is necessary to fully adhere to the proportion during manufacture - 1 part of cement, 2 parts of sand and 4 parts of crushed stone. In this way, high-quality, ductile and durable concrete is produced. If it deviates from the norm and the amount of cement is reduced, then the bond of all other components will not be so resistant to external influences, which may entail a temporary service life of the poured product.

To calculate how many bags are needed for work and what ratio of crushed stone, gravel and sand concrete is required for masonry, you need a table. It provides an approximate calculation of how much dropout goes, how much total mass goes, and what the result will be. Such calculations are very important, especially for expanded clay concrete blocks.

In principle, the consumption of cement per 1 m³ depends on the brand that they want to receive in the end. And the brand itself depends on the area of use, for what purpose the concrete will be used. For household needs and structures of no more than one floor, grade 200 is used. It is also used for pouring foundations, platforms and paths. Such concrete is also used to construct concrete stairs and as a cushion for curbs. M300 concrete is mainly used for pouring monolithic structures such as walls and floor slabs.

Concrete requires water. In concrete factories, the exact proportions of water for each brand are established, since experts know with which moisture indicator the sand should be used. But for the manufacture of such a mixture on construction sites or at home, factory proportions are irrelevant, since the workers do not know how much moisture the sand and gravel contains.

In this case, water is added as the solution is stirred. Experienced experts recommend adding an incomplete bucket of water to one bucket of cement, and if this is not enough, then add a little while using the mixture.

Aggregates - crushed stone and sand

The composition of concrete is determined by those functions and characteristics of concrete that are necessary during its operation. The most common are sand and gravel. They are subject to no less stringent requirements than the quality of cement. Sometimes pebbles are used, but only if they have sharp edges, and not round ones. In the presence of broken lines, the adhesion of the aggregate to the mortar is better; as a result, the concrete has a much higher strength.

Sand

Construction sand can be river or quarry.The river is more expensive, but it is usually cleaner and has a more uniform structure. It is better to use it when drawing up concrete for pouring the foundation, screed. For masonry or plastering, it is appropriate to use cheaper quarry sand.

In addition to its origin, sand is distinguished by fractions. Large or medium-sized ones are used for construction work. Small and dusty ones are not suitable. The normal size of sand grains is from 1.5 mm to 5 mm. But optimally in solution, it should be more homogeneous, with a difference in grain size of 1-2 mm.

The sand should be clean, preferably with the same grain size

The purity of the sand is also important. It definitely should not contain any extraneous organic inclusions - roots, stones, pieces of clay, etc. Even the dust content is normalized. For example, when mixing concrete for a foundation, the amount of contamination should not exceed 5%. This is determined empirically. 300 ml of sand is poured into a half-liter container, everything is filled with water. A minute later, when the grains of sand settle, the water is drained and poured again. This is repeated until it is transparent. After that, it is determined how much sand is left. If the difference is not more than 5%, the sand is clean and can be used when mixing concrete for the foundation.

For those works where the presence of clay or lime is only a plus - when laying or plastering - there is no need to take special care of the cleanliness of the sand. There should be no organic matter and stones, and the presence of clay or lime dust will only make the solution more plastic.

Crushed stone

For responsible construction - floors and foundations - crushed crushed stone is used. It has sharp edges that adhere better to the mortar, giving the structure more strength.

Crushed stone fractions are standard:

- extra small 3-10 mm;

- small 10-12 mm;

- average 20-40 mm;

- large 40-70 mm.

In the batch, crushed stone is used in several fractions - from small to large

Several different fractions are used simultaneously in concrete. The largest fragment should not exceed 1/3 the size of the smallest element of the structure to be cast. Let us explain. If a reinforced foundation is poured, then the structural element that is taken into account is reinforcement. Find the two closest elements. The largest stone should not be more than 1/3 of this distance. In the case of filling the blind area, the smallest size is the thickness of the concrete layer. Choose crushed stone so that it is no more than a third of its thickness.

Fine crushed stone should be about 30%. The rest of the volume is divided between medium and large in an arbitrary proportion

Pay attention to the dustiness of crushed stone. Lime dust is especially undesirable.

If there is a lot of it, the crushed stone is washed, then it is dried, and only after that it is poured into concrete.

Storing placeholders

It is clear that the construction site is not the cleanest and most equipped place, and sand and rubble are often dumped directly onto the ground. In this case, when loading, it is necessary to ensure that no earth gets into the batch. Even a small amount of it will negatively affect the quality. Therefore, it is advisable to pour aggregates onto solid areas.

It is also necessary to protect them from precipitation. In concrete formulations, the amount of constituents is given in terms of dry components. Taking into account the moisture content of components is learned with experience. If you don't have one, you have to take care of the condition and cover the sand and rubble from rain and dew.

Concrete volume calculator

Calculation of the amount of cement for concrete (1m3):

- Concrete grade M100, used in the construction of small and lightweight structures that do not bear heavy loads, contains 3-4 bags of Portland cement. The amount of cement per cubic meter is 160-200 kg.

- M150 grade concrete for more durable structures should contain from 4 to 5 bags. Material consumption per cubic meter of concrete in this case is up to 220-230 kg.

- M200 concrete - serves to create foundations. Includes 240 to 285 kg of material. These are 5-6 bags.

- M300 concrete is the basis of monolithic structures, walls, floors and stairs. The rate of cement per cube of mortar is 300-335 kg. These are 6-7 bags.

Consumption of material for preparing the mixture

Consumption of material for preparing the mixture

How many kg of cement to buy

How many kg of cement to buy

Online calculators

Concrete preparation technology

The process of making ready-made concrete mix with your own hands, both in the amount of one, and 5-10 or 100 cubic meters, is practically the same. The only difference is in the installations and equipment used, which make it possible to quickly and efficiently produce concrete.

The video in this article shows how to calculate the amount and proportion of the mixture of the initial components for concrete.

How to calculate correctly

The initial mixtures of the components may have a different percentage of moisture, and excess water leads to the fact that the ratio of crushed stone, sand and cement for concrete is built incorrectly due to an increase in the weight of the components, if the calculation is carried out by weight. Therefore, it is always preferable to make calculations by volume.

This has several advantages:

- It is more convenient to calculate how much ASG and cement is needed to fill a specific structure, the volume of which can also be easily calculated.

- Violations of the ratio of components are excluded if they are waterlogged.

- Less problems in practice, as it is easier to measure the volume of a bulk substance than its weight.

What else do you need to know

The volume of crushed stone, the amount of sand and cement, as well as the correct instructions for mixing them are not the only things you need to know about when making a concrete solution.

To prepare high-quality concrete, you need to consider the following nuances:

- Water for the preparation of concrete must be taken clean, without impurities and suspensions.

- The amount of water required is determined empirically and always depends on the moisture level of the mixture components.

- The cement should be fresh or stored under suitable conditions in rooms with a low percentage of atmospheric humidity.

- The initial components must be correctly selected in terms of grain size and well cleaned of earth, soil, clay and other possible impurities.

Now, knowing how much cement in a cubic meter of concrete should be, and what requirements are imposed on the original components, you can start making concrete mortar with your own hands.

How many bags of cement to buy

To understand how many bags of cement are needed to prepare the mixture, proportions and volume are used. So, if a batch is prepared for a floor screed and a ratio of 1: 4 is used, it turns out that a quarter of a cube is needed for cement. The bulk density of the binder shows that a liter contains 1.4 kilograms.

A quarter of a cube - 250 liters. They need to be multiplied by 1.4 - you get 350 kilograms of cement. There are usually 50 kilograms in a bag - for the preparation of a cube you need 350/50 = 7 bags of 50 kg (or 14 bags of 25 kg).

The consumption of the binder is allowed to be calculated in another way. So, if the thickness of the screed is 10 centimeters, then for one square you need 0.1 cubic meter of solution. It contains 10 times less cement than a cube: 350 kg / 10 = 35 kilograms. For a screed 5 centimeters thick, you need 35/2 = 17.5 kilograms of cement.

It is worth remembering that the cement consumption rate also depends on the activity of the binder. Usually it is determined experimentally, in the process of mixing control samples, during strength testing. But this cannot be done on site, so you should focus on the shelf life of the material. The fresher the better, as over time the cement can lose up to 20% of its activity per month. Having held bags with M500 cement in the warehouse for about three months, you can already work with the M400 brand.

Concrete prepared according to the technology and with the correct cement consumption is capable of withstanding all loads, demonstrating optimal parameters and properties, guaranteeing the durability and reliability of structures.

Purchase of the required volume of powder and the necessary building materials

The Group in its activities meets all consumer and technical requirements. Having considered the calculation schemes and recommendations within the framework of the article, you may know what proportion is the cement powder in the mixture used when installing walls or pouring the base when a house is being built. Then go to the "Contacts" section to order quality building materials from the best manufacturers.

Having calculated how much powder building material is needed, leave a request or call (feedback works) to discuss the details of the purchase. Competent managers will answer any of your questions. In our activities, we fulfill our obligations, as well as unconditionally respect the rights of our clients. A detailed sitemap and product catalog will help you find out what you can get from our products for construction.

Thus, working with AlfaCem, you will not only be able to buy the best building materials, but you will also easily use professional advice on how much cement 1 cubic meter of the mixture contains, provided that it is carried out under different initial parameters. We wish you every success!

Features of the mixture

Scheme of a wall made of blocks with cladding.

So, concrete has several varieties that differ in weight. Basically, when performing monolithic operations, cement concrete is used, with an average weight of 2300-2500 kg / cubic meter.

The light variety is usually used in the form of ready-made blocks (wall).

In order to make a high-quality mortar, you can not use a sand-gravel mixture or pgs. Theoretically, the solution from the gsm, of course, will work out, but the exact ratio of sand and gravel in gsm is almost impossible to establish. As a result, there is a high risk of getting low-quality material.

Because it is completely impossible to know in advance what brand will turn out from the PGS, how much it is necessary to add the necessary ingredients there, how it will behave during the period of use.

Unscrupulous manufacturers sometimes use pgs in their manufacture, which is why you need to be extremely careful and periodically look at the site where rubble and sand are stored. You can also inspect the quality of the cement.

Comparison of the structure of foam and gas blocks

So, according to the type of astringent, they are divided into:

- Silicate.

- Made of cement.

- Polymer concrete.

- Plaster, etc.

Concrete grades and strength classes

The main characteristic of the material is its compressive strength. To classify concrete by strength, two types of rationing are used: by brands and classes.

The many-sided strength of concrete. Concrete sample during testing

The material class is designated by the letter "B" and indicates a guaranteed pressure (in MPa), which it can withstand with a probability of 95%. For example, concrete of class B20 can withstand a pressure of 20 MPA, if its value is exceeded, it collapses (in 5% of cases, it may not reach the strength declared by the manufacturer).

The concrete grade characterizes the weighted average strength of the material, which is 28 days old. It is designated by the letter "M" and numbers from 50 to 1000. The mark is measured in kgf / cm2. Concrete grade and grade are inextricably linked.

Conformity of the concrete grade to the class and their technical parameters

Factors affecting the strength of the material

In the production of concrete, it is extremely important to maintain the optimal proportions of the components used. When the content of the binder in the solution is exceeded, not only a significant increase in the price of the product occurs, but also a decrease in its shrinkage, fluidity and strength characteristics

Excess water required to bind the ingredients in the mixture also results in loss of strength. The optimal water-cement ratio varies between 0.5 ... 0.9 and depends on the grade of the material.

Permissible water-cement ratio

In addition, the following factors affect the strength of concrete.

- Aggregate type (its fraction, degree of purification and shape).

- Methods for mixing the mixture and compaction of the laid solution. Making concrete by hand provides a poorer mixing quality than a process involving a technique (concrete mixer or other types of mixers). To compact the composition, it is necessary to use vibration, for example, using a deep vibrator. Thus, excess air is removed and the strength of the finished product is increased.

- Under what conditions concrete is gaining strength.The maximum possible strength indicator is achieved by the material 28 days after production and pouring of the solution. At the same time, the ambient temperature should be within 18 ... 20 degrees, and its humidity should not be less than 90%.

Resistance of concrete to external influences

Application of material of different grades

Concrete can be used for a variety of tasks.

Table. Scopes of the material.

| Concrete grade | Scope of use |

|---|---|

| M100 | Preparation before concreting the foundation or pouring the foundations. |

| M150 | Floor screed, paths, foundations for small buildings. |

| M200 | Floor screed, concreting of foundations and blind areas, production of paths. |

| M250, M300 | Manufacturing of stair structures, fences, monolithic foundations, floor slabs (medium or light load). |

| M350 | Installation of pool bowls, foundations, floor slabs, columns. |

| M400 | Erection of bridges and structures for which special requirements are imposed. |

| M450, M500, M550 | In addition to areas where the use of material grade M 400 is allowed, this concrete can be used in the construction of metro and dams. |

| M600 | It is used where maximum resistance to aggressive environments and the highest strength are required. |

Modern building material - transparent concrete, opens up new possibilities for the construction and decoration of buildings

Determine how much cement, sand, gravel and water is in a cube of concrete.

4 June, 2013 - 12:35 Concrete is one of the most demanded materials in construction. Such popularity of concrete is explained by its excellent properties: compressive strength, ease of forming and laying, waterproofness, water resistance, low price.

For the manufacture of concrete, cement, water and so-called aggregates are used, which can be coarse (crushed stone) or fine (sand). Builders often face the question of how to mix concrete correctly. It is at this stage that it is usually required to determine how much cement is in a cube of concrete.

Today, there are a large number of concrete grades that differ in their composition, or rather, in the volume or mass ratio of its constituent components. For example, to create 1 cubic meter of 100 grade concrete, 200 kg of cement are required, to create 1 cube of 400 grade concrete, 360 kg of cement is required.

There are special tables from which you can understand not only how much cement per cube of concrete is required, but also the percentage of other concrete components in the finished composition.

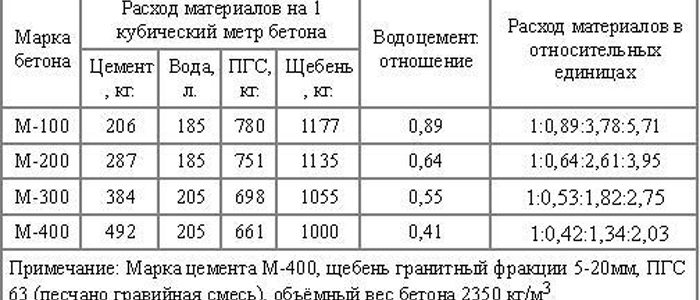

So, for example, for the most running grade 300 concrete, it is necessary to mix 382 kg of M400 cement, 705 kg of sand, 1080 kg of crushed stone and 220 liters of water. For concrete of 100 brands, you will need 214 kg of cement (M400), 870 kg of sand, 1080 kg of crushed stone and 210 liters of water.

In general terms, you can determine how much sand is in a cube of concrete, according to the following scheme:

1 volume fraction of cement in grade 100 concrete accounts for 4.1 shares of sand and 6.1 shares of crushed stone; for concrete grade 150, the ratio of cement (M400), sand and crushed stone is 1 to 3.2 and to 5.0; for concrete M200 - 1 to 2.5 and to 4.2; for М250 - 1 to 1.9 and 3.4 (cement: sand: crushed stone); for 300 1 to 1.7 and to 3, "; for 340 1 to 1.1 and to 2.4.

Table 1. Proportions of cement, sand and crushed stone by concrete grades

| Concrete grade | proportions cement: sand: crushed stone | |

| cement grade 400 | cement grade 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 : 1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

Knowing these proportions, you can not only easily find out, for example, how much rubble is in a cube of concrete, but also knead absolutely any amount of high-quality concrete without much difficulty.

Table 2. Relationships between the class and concrete grades in terms of strength.

| Brand | Class | Strength, kg / cm2 |

| M-100 | B7.5 | 98,2 |

| M-150 | AT 10 | 131,0 |

| M-150 | B12.5 | 163,7 |

| M-200 | B15 | 196,5 |

| M-250 | B20 | 261,9 |

| M-350 | B25 | 327,4 |

| M-400 | B30 | 392,9 |

| M-450 | B35 | 458,4 |

| M-500 | B40 | 532,9 |

It is important to note that the physical and mechanical properties of the concrete will depend on the grade of cement used to make concrete. So, if instead of cement M400 add cement M500, the grade of concrete will increase (say, instead of 200, it will become 350)

In order to get good concrete, you should choose crushed stone, the grade of which will exceed the grade of concrete that we want to get by 2 times.

Simple concrete mixing scheme

If for construction you do not need factory accuracy, and there is no need to strictly maintain the grade of concrete, you can use a simplified scheme: take 0.5 parts of water, 2 parts of sand and 4 parts of crushed stone for 1 part of cement. For the manufacture of 1 cubic meter of concrete, the weight fractions of the components at this ratio will be as follows: cement - 330 kg (0.25 cubic meters), water 180 l (0.18 cubic meters), sand 600 kg (0.43 cubic meters), crushed stone 1, 25 tons (0.9 cubic meters).

How much cement, sand, gravel (crushed stone) and water is needed to get a cube of concrete:

M50 concrete

- Portland cement M400 - 380 kg. (1)

- Gravel - 608 kg. (1.59)

- Sand - 645 kg. (1.69)

- Water - 210 l. (0.55)

M75 concrete

- Portland cement M300 - 175 kg. (1)

- Crushed stone - 1053 kg. (6.02)

- Sand - 945 kg. (5.4)

- Water - 210 l. (1,2)

M100 concrete

- Portland cement M300 - 214 kg. (1)

- Crushed stone - 1080 kg. (5.05)

- Sand - 870 kg. (4.07)

- Water - 210 l. (0.98)

M150 concrete

- Portland cement M400 - 235 kg. (1)

- Crushed stone - 1080 kg. (4.6)

- Sand - 855 kg. (3.64)

- Water - 210 l. (0.89)

M200 concrete

- Portland cement M400 - 286 kg. (1)

- Crushed stone - 1080 kg. (3.78)

- Sand - 795 kg. (2.78)

- Water - 210 l. (0.74)

M250 concrete

- Portland cement M400 - 332 kg. (1)

- Crushed stone - 1080 kg. (3.25)

- Sand - 750 kg. (2.26)

- Water - 215 l. (0.65)

M300 concrete

- Portland cement M400 - 382 kg. (1)

- Crushed stone - 1080 kg. (2.83)

- Sand - 705 kg. (1.85)

- Water - 220 l. (0.58)

M350 concrete

- Portland cement M400 - 428 kg. (1)

- Crushed stone - 1080 kg. (2.5)

- Sand - 660 kg. (1.54)

- Water - 220 l. (0.51)

p.s. The sequence of laying materials in a concrete mixer affects the quality of concrete.

Concrete composition

Concrete is a mixture of cement (plays the role of a binder), filler (sand, fine gravel particles or other components), additives (additives that increase frost resistance and other parameters of the finished structure) and water. The composition of such a mixture is periodically improved, more "recipes" for the preparation of better quality mixtures appear.

For example, for strip foundations some prefer to make rubble concrete. In this case, large rubble stones are used as a filler, of which at least 15% at the base. This saves on cement and creates a stylish base that does not actually need finishing. Such a foundation is not only more durable, but also much more resistant to low temperatures and the influence of groundwater. Thanks to these characteristics, such a foundation will last up to 150 years.

But, such a composition is more expensive, therefore, usually in private construction, more classic mixtures are preferred.

Standard composition

Before building a country house, fence, shed and any outbuildings, you should pay attention to the features of the components:

- Sand. Not everyone is suitable for durable concrete. It is necessary to choose exclusively cleaned sand (can be river or quarry). If there are impurities in it, then such a foundation will not last long.

- Crushed stone. This component gives strength to the mixture. As a rule, gravel is used with a fraction of 5-20 mm.

- Plasticizers. You can do without them. But, today there are many additives on the market that increase the life of the base, simplify the mixing process.

Healthy! It is recommended to use additives that increase the plasticity of the mixture if you are using a reinforcing frame.

Water. The main requirement is that it must be clean. If it is collected from a reservoir, then it is imperative to pass the liquid through a filter.

Of course, cement is also required for any foundation.

Required cement grade

The brand of cement and of the future concrete itself are designated by the symbol "M". The numbers after it define the mass load threshold. That is, if we mix cement M 200, then after the mass has solidified, such a base will be able to withstand up to 200 kg per 1 cm2 of surface. However, when it comes to concrete, Portland cement (PC) is usually used for it. It is a binder consisting of cement clinker, additives, gypsum. There are many of its brands (from M 50 to M 600).

If you plan to build a foundation, then PC 200 or 400 is usually used for such bases. Portland cement 600 is much more expensive and is usually used in the construction of industrial or other specialized facilities. Therefore, PC 200-400 is sufficient to obtain concrete of the desired grade.

Concrete: buy or do it yourself?

The composition of concrete includes:

- Portland cement or slag binder;

- Sand;

- Crushed stone, better enriched;

- Plasticizers;

- Water.

You can prepare the solution yourself, but first you should calculate the total volume - you still need to fill it continuously and evenly. One of the options for replacing factory supplies is to rent or purchase a concrete mixer.

How to calculate the amount of cement on a foundation

The amount of cement depends on the accepted concrete grade. In private housing construction, predominantly M300 or M400 concrete is used for the foundation. This strength is sufficient to ensure a reliable and durable structure.

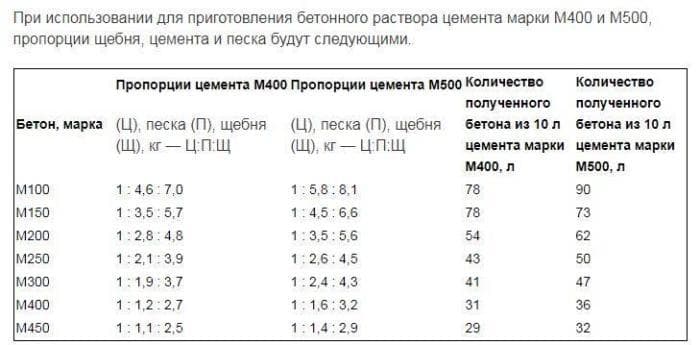

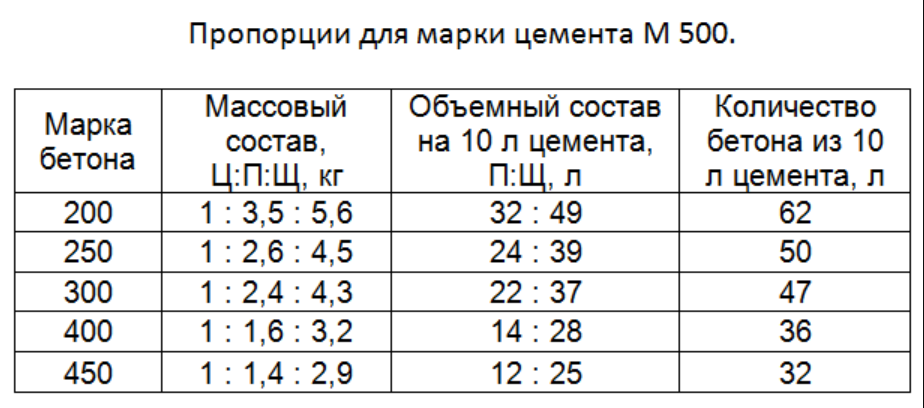

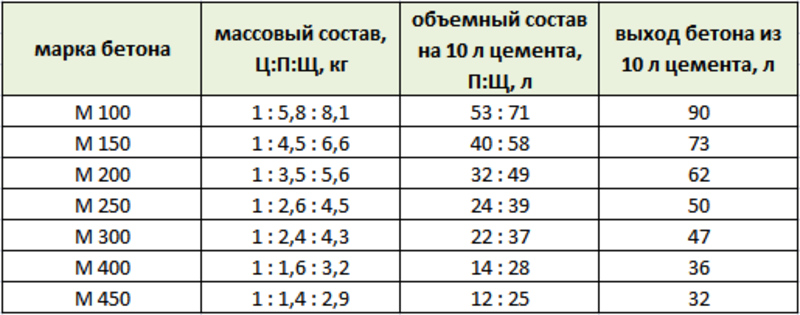

The calculation of cement for the foundation can be made according to the table of proportions:

| Concrete grade | Proportions of components C: P: U | Volumetric composition of cement per 10 liters of cement, l | How much concrete will be obtained from 10 liters of cement, l |

|---|---|---|---|

| For cement M400 | |||

| 200 | 1 : 2,8 : 4,8 | 25 : 42 | 54 |

| 250 | 1 : 2,1 : 3,9 | 19 : 34 | 43 |

| 300 | 1 : 1,9 : 3,7 | 17 : 32 | 41 |

| 400 | 1 : 1,2 : 2,7 | 11 : 24 | 31 |

| For cement М500 | |||

| 200 | 1 : 3,5 : 5,6 | 32 : 49 | 62 |

| 250 | 1 : 2,6 : 4,5 | 24 : 39 | 50 |

| 300 | 1 : 2,4 : 4,3 | 22 : 37 | 47 |

| 400 | 1 : 1,6 : 3,2 | 14 : 28 | 36 |

How much cement is needed for the foundation will be known after determining the entire volume of the supporting structure. It is worth remembering that there are 1000 liters in 1 cubic meter. Accordingly, if the calculation of the amount of concrete M300 showed 7 m3, and we had M400 cement at our disposal, we translate:

The proportionality line is 1: 1.9: 3.7 (C: P: S). The numbers are given in units of your choice (kilogram, liter). Bulk cement density - 1100 kg / m3, concrete density 1800-2100 kg / m3.

From 10 liters of cement we get 41 liters of concrete, about 24 such units are needed (1000/41). Accordingly, we multiply all the proportion values by 24. (2: 45.6: 88.8).

A simpler, but average calculation of the amount of cement per foundation is shown in the table:

| Concrete grade | Cement grade | Cement weight in kg | Number of cement bags 50 kg each |

|---|---|---|---|

| M300 | M400 | 350 | 7 |

| M500 | 300 | 6 | |

| M400 | M400 | 400 | 8 |

| M500 | 330 | 6.6 (7 points) |

In a corresponding way, it is possible not only to calculate the cement consumption, but also to determine the amount of the remaining components by multiplying the value of the cement mass by a proportional number. The amount of cement for the foundation according to the table is calculated approximately - the final value will be influenced by:

- Mass and fraction of sand and crushed stone;

- Exact weight of cement;

- Used volume of water.

How to calculate a cube of concrete on average:

| Concrete grade | Cement | Sand | Crushed stone | Water |

|---|---|---|---|---|

| M300 | 425 | 735 | 1080 | 140 |

| M400 | 483 | 695 | 1080 | 140 |

The consumption of cement for the foundation and the amount of other components should be determined by the exact formulas from the very first method, where the proportions of the components are considered. You should also take into account the margin for error and unforeseen situations - about 10-15%. It is better if the material remains than it is not enough to create the basic structure of the house. In addition, concrete and its components will be useful in the subsequent processes of erecting walls, paths, etc.

Now you can proceed to calculating the volume of concrete for the foundation. Let's consider the main types of structures separately for ease of understanding.