How much money is needed - costs and payback

Handicraft production is cheap. A small press for forming is sold for 20,000 - 30,000 rubles, but it will not be possible to achieve its capacity for the production of serious batches of goods. Especially when using a hand press. And the quality of products cannot be compared, for example, with fired ceramics.

If the plans are to open a plant for 20-60 million units / year or more, its equipment will require hundreds of millions of rubles of investment. The payback period for such an enterprise is over 7 years. But if that kind of money is already gathering dust under the pillow, the brick factory would be a good investment project.

The new production line of the mini-factory for the production of ceramic products will cost at least 2.5 million rubles. The launch of a workshop with such equipment - 3.7 million rubles.

The profitability of medium-sized production will be 24-27%. Sales in the first year reach 50% of the total capacity of the enterprise. Such workshops reach full load by 2-3 years of work, and reach full payback in 3-4 years of work.

Helpful tips for those looking to start a brick making business

When starting his own company, an entrepreneur is faced with a discrepancy between theory and practice.

To avoid mistakes at the initial stage, our expert has prepared a few tips for you:

- Open a factory near the private sector. The main buyers of bricks are the owners of residential buildings. The more dachas, cottage settlements, residential areas of low-rise buildings around, the more building materials you sell.

- Collect money from several sources: savings, bank loans, loans from relatives and friends. This will increase financial sustainability and reduce additional costs.

- If you decide to find a business partner, keep at least a 51% stake in the LLC. If your views on business do not coincide with your partner, you can continue your business activities.

- Open a business in the spring. You will start to produce products in March and sell them without leftovers at the peak of sales. This will reduce the cost of the "dead" winter season.

Is it worth investing in such a business - expert opinion

To answer this question, we turned to a professional investor, Alexander. He successfully invests his money in small businesses.

After studying the business plan, our expert became interested in the project. Alexander came to the conclusion that manufacturing Lego is a safe investment.

He highlighted several arguments in favor of such production:

- Wide sales market. The products are sold to owners of private houses, builders, repairmen, owners of construction shops, dacha associations, etc. When the situation changes in one of the niches, the products are sold in the other. At the same time, you do not have to spend additional funds on changing the recipe, packaging, etc.

- Diverse and cheap raw materials exclude supply disruptions and dumping.

- Long-term storage products do not deteriorate if the minimum storage rules are observed.

- There are no special requirements for the opening and operation of the workshop.

- Small investment, 90% of which comes from the purchase of equipment.

- A simple, almost primitive production technology that does not require special skills.

- Good prospects for expanding production.

- Fast payback of the project. A small number of businesses can boast a return on investment in just 4 months.

- Good profitability.

Lego brick release is an attractive business idea

Lego brick release is an attractive business idea

These arguments allow us to characterize the project as:

- perspective;

- profitable;

- low risk;

- inexpensive;

- well paid off;

- cost effective.

Alexander was so interested in the idea of opening a workshop that he offered to invest in it. According to the expert, such a production is a good investment of money: reliable and profitable.

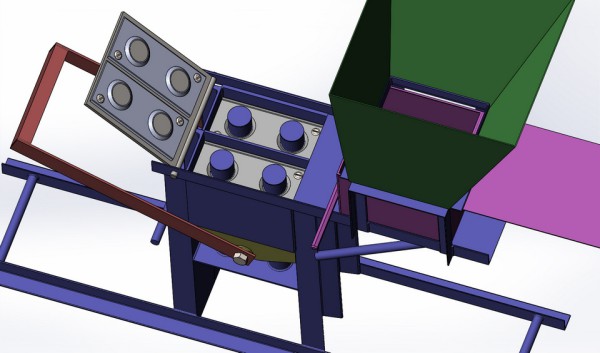

Production equipment

To start production, you will need a set of equipment that allows you to prepare raw materials and shape products. The following types of aggregates are presented on the market.

- Manual machine.

Works by the method of semi-dry hand pressing. The unit is designed for the processing of cement-clay and cement-sand mixtures under a pressure of 16 MPa, it only forms finished products. The previously prepared mixture is poured into the hopper. For its preparation, the purchase of a crusher and a mixer is required. The working cycle of the machine takes about 20 seconds. Estimated productivity of the machine - up to 1500 pieces per work shift. Not suitable for making high-strength bricks for outdoor use.

- Semi-automatic hydraulic machine.

Pressing is carried out under a pressure of 70 tons. The machine is equipped with an automatic dispenser, concrete mixer and a trailer. Its productivity is much higher - up to 250 pcs / h. or up to 2000 pcs. per shift. Designed for any shape, composition, size and purpose. The only inconvenience is the laborious removal of the finished product.

- Automatic machine.

Fully automatic line, producing up to 400 items per hour and up to 3600 per shift. The full production cycle is 8 seconds. The equipment is equipped with electronics that optimize the control process. Automatic lines make it possible to produce a wide range of products due to a simple replacement of dies and the use of raw materials of different composition.

Equipment

Among the mechanisms there is a large selection for any purpose and possibilities - you can purchase manual, automatic or semi-automatic devices. Their differences lie in the amount of electricity consumed, power and performance. Fully automated lines are mini-factories equipped with the necessary fixtures and fittings, and ready to work immediately after installation.

Estimated prices for main and auxiliary equipment are shown in the table:

|

Name |

Specifications |

Price per unit, thousand rubles |

|

Mechanical press (manual) |

productivity - 110 units / hour, effort - 10 tons |

27–84 |

|

Hydraulic hyper press |

productivity - up to 170 pcs / hour, effort - 20 tons |

135–254 |

|

productivity - up to 350 pcs / hour, effort - up to 30 tons |

from 320 |

|

|

Automatic line (mini-plant) |

productivity up to 600 units / hour |

440–1200 |

|

productivity from 750 units / hour |

1600–2500 |

|

|

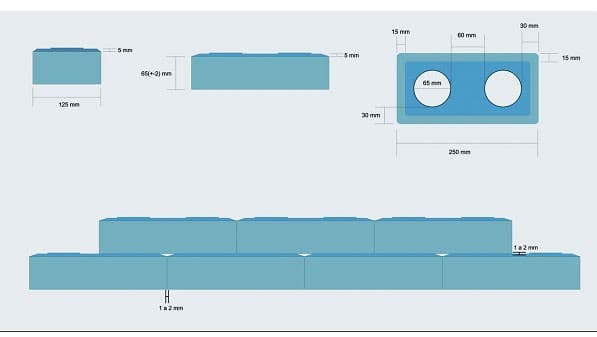

Matrix |

250 x 125 x 65-90 mm |

6,5 |

|

Forced type concrete mixer |

from 250 l |

from 125 |

Depending on the selected main equipment, you may additionally need: conveyor belts, a screen, a hammer crusher, metering bins and storage bins, auto-stackers, containers for cement and water, shovels, pallets, bunker cleaning devices.

Thus, to equip a workshop with equipment, a small business will spend about 100-250 thousand rubles, a medium-sized one - 300-1200 thousand rubles, and a large one from 1500 thousand rubles or more.

Saving

There is a way to save money on construction.

You can not buy ready-made bricks, but buy equipment for their production. You will need to buy a machine and raw materials. As a result, you will have your own production of Lego bricks, and since there are practically no competitors now, the prospects in this business are very good.

Even if at the end of construction the equipment for the Lego brick is not needed in the future, it can be rented or sold.

Raw material proportions

Proportions of raw materials for lego bricks:

- screening of limestone rocks (85-92%);

- astringent components (for example, Portland cement) - 8-15%;

- pigment for coloring colored concrete.

- water

There are 500 bricks in one cube; for production, about 1600 kg of screenings and 220 kg of cement are needed.

Machine tools

The dimensions of the machine allow for work in the garage.Its main functions are:

- dosing of raw materials;

- crushing and mixing of raw materials;

- pressing, forming a product

- steaming the product.

The approximate cost of one brick is 4 rubles. One person can produce about 2000 bricks in an 8-hour working day. But it is imperative to take into account the time for technological breaks and rest of the employee.

The brick formation time is from 4 to 12 seconds, depending on the quality of the raw materials used (the size of the fractions: the finer, the better). It takes about 3 seconds to remove a brick.

On average, taking into account technological breaks, the time for loading raw materials, it is possible to make 4-5 bricks per minute.

The machines can be either electric or manual. You can see how the machine looks like in the next photo.

Registration

Lego bricks are great building materials. It is very easy to set up its production. You will also need to purchase equipment.

But registration is the most important thing in this case. You can register your business as an individual entrepreneur or LLC

This type of activity as an individual entrepreneur is best suited for a small business. This is exactly what the production of Lego bricks will be like. The company must be registered with the tax office. For the registration procedure, you will need to pay 800 rubles.

You can pay taxes according to one of two schemes:

- From the proceeds. The rate is 15 percent.

- From income. In this case, the tax rate will be 6 percent.

Of course, this may only be suitable for small-scale sales of goods. In the event that the business will focus on large clients, then it is best to register as an LLC.

Premises

Since you do not need very large areas for equipment for making Lego bricks, it is also possible to try to create this business at home - even an ordinary garage is enough for you.

At first, even 15 square meters will be enough for you. This area is enough for you both for storing finished products and for machine tools. In order to reduce logistics costs several times, you can transport the equipment to the client's construction site and make bricks there. If you have created a small factory for the production of Lego bricks, you will need to competently equip the room, engage in lighting and equip a high-quality ventilation system. Due to the small area, and maintaining the conditions inside it, and you will not need to work in large investments. monthly maximum expenses will be approximately no more than 30 thousand rubles.

Equipment

At the very start of your business, you only need one machine for making Lego bricks yourself - in just one shift (8 hours) you can make about 2000 products on it. You can also purchase equipment, both domestic and foreign. In some cases, the kit will include a matrix, but basically, you need to buy it separately.

What to look for when choosing a machine?

The quality of the manufactured products will also depend on the competent choice of equipment. As a result, the amount of your income will depend on the given circumstance.

The main characteristics of the machine:

- Matrix wall thickness - from 20mm.

- The force of pressure on the workpiece - in order to obtain a high-quality brick, it must necessarily be 35 tons.

- Hardness of steel.

- The ability to customize the geometry of the product - depth, size, filling of raw materials.

The volume of production per shift - in addition to the work of the machine, this will also be influenced by the speed of preparation of the workplace and the rest of the workers.

Matrix type

Depending on the range of products you make, you can use the types of matrix for brick production:

- Single.

- Fitting - bricks will be obtained with side couplings.

- Rail-like - you can carry out communications within the material.

Raw materials

The technology for making Lego bricks is slightly different from the production of ordinary ceramic bricks. Primary distinguish raw material used. The basis of the Lego brick component, which occupies up to 95% of the total mass of the product, is limestone screening. The remaining ten percent is water, binder cement and cola. For 1 cubic meter of finished stone, you will need about 1600 kg of the main component and 220 kg of cement. The cost of raw materials is not very high, the cost of 1 unit of production in this case will be approximately 4 rubles. You can sell each of them 3-4 times more expensive on average. If you deduct all of your expenses, you have a 60 percent return. In some cases, clay can still be added to give the material special properties. Of course, you will have to bake finished products with clay in the composition in order for them to be durable.

Financial part

To calculate costs, we use approximate calculated data:

- staff - 2 employees;

- working hours - 20 days a month for 8 hours;

- payroll fund - 40 thousand rubles. per month;

- electricity for production - 1600 kW / h;

- purchased equipment - 600,000 rubles.

Price for material and resources:

- cement M500 - 5 rubles / kg;

- dropout - 0.6 rubles / kg;

- electricity - 3.76 rubles.

The information provided in the article is only a brief introduction to the essence of business. If you decide to move on to implementation, then you need to download a professional brick factory business plan with detailed calculations: DOWNLOAD

Profit calculation: 1600 bricks can be produced in one shift, 32000 bricks in a month. The cost of the finished product is approximately 12 rubles. Income with one hundred percent sales of products will amount to 448,000 rubles.

For the production of one Lego kripich approximately 350 gr. cement (1.6 rubles), 3 kg. dropouts (1.8 rubles), plasticizer and dye - 0.3 rubles, as well as 1.25 rubles. directed to wages and 0.2 rubles. for electricity. Other expenses (taxes, transport) - 0.75 rubles. The cost of one brick will be 6 rubles.

Net profit per month: (12 - 6) * 32,000 = 192,000 rubles.

Thus, the payback period of the project will be about four months.

Equipment

This is followed by the stage of implementing a business project, at which it is necessary to form a material base, which is represented by one machine and matrices.

Approach the choice of the machine carefully, you can purchase both an electric and a manual machine.

All the necessary equipment can be easily found on the Internet, where there is a fairly large selection, so everyone can choose the right machine for their volume of activity.

The equipment is of domestic and foreign production, and differs in quality, functionality and cost.

The types of Lego bricks and what you should pay attention to during production were discussed by us in another article.

How to implement lego-cyprichi

Your sales success depends on the quality of your ads. This process also requires spending money, but the dependence here is directly proportional: the more money is invested in an event, the more people will learn about your production.

You can promote your products in the following ways:

- use elements of outdoor advertising: message boards, billboards, city lights, etc.;

- open your own online store;

- place ads, as well as publications in construction newspapers and magazines;

- attend construction exhibitions and seminars.

This is the price of promoting your production and building a customer base.

Sales of bricks

Lego brick is profitable to produce. And this is all because its cost price is excellent. The most basic in developing a strategy for the development of your business is a competent definition of your future clients, i.e. try to find a market for your product.In addition to all this, those buyers whom you can find should be interested in the products sold, since everyone knows about the simplest ceramics, but not about Lego bricks. Because this product is new, and you will need to tell in detail about its main advantages.

You can sell the finished product in three ways:

- Selling goods to hardware stores.

- Open your own outlet.

- Sell over the Internet.

In any case, your main buyers will be wholesalers, large and small stores and individuals. What clientele you choose will determine the required production volumes, as well as the choice of the form of your organization. The main advantages of making Lego bricks is that if the number of buyers increases, your business can expand without much difficulty and expense. This means that you can buy additional machines and hire more employees.

Based on this, all financial investments in the business will not be very large. But he will be able to pay off with a competent approach in a couple, three months. In the event that you want to understand better the procedure for the production of Lego bricks, we have posted a video for you.

Watch the related video: Lego Brick Making.

Potential risks

Any organization is at risk. We will not only talk about possible threats to the enterprise, but with the help of our expert, we will give advice on how to overcome them.

And he who is forewarned is armed!

| № | Risk factor | Threat Council |

| 1 | Low sales |

|

| 2 | Breakdown or loss of equipment |

|

| 3 | Lack of funds |

|

| 4 | Damage to finished products |

|

You have already noticed that among the listed risks there is no mention of problems with raw materials. The equipment can be easily switched from one type of source material to another. The rise in prices for raw materials, interruptions in their supply, deterioration in the quality of the supplier - all these changes are easily overcome with the release of Lego.

Sales and distribution

This type of bricks is quite in demand in the private and public sector. If you intend to create a business in the production of Lego bricks, then very carefully work out the distribution channels, analyze the prices of competitors and draw up your business plan.

Sales channels:

- It is possible to sell manufactured goods via the Internet, as well as by creating your own store.

- Try promoting your product in a store that specializes in building materials. Just prepare a presentation in advance that will convince the store management that it will be profitable for them to sell your Lego brick.

- You can also sell bricks directly to construction firms.

- The most difficult thing is to create your own outlet. But in this case, it will not be superfluous to create a whole showroom.

- An excellent option would be to work on order.

By developing your business, you will be able to expand its production: increasing the customer base, purchasing additional equipment and increasing the output of goods.

Laying technology

Despite the fact that laying Lego bricks does not require any special skills and tools, there are several rules and recommendations, the observance of which will allow you to achieve high quality of laying and the strength of the building.

As with any laying, special attention should be paid to laying the first row. Since mistakes made at this stage will inevitably affect the quality of the entire building, laying the first row must be done with special attention, controlling the location of each block using a building level

Particular attention should be paid to bandaging the corners.

As a binding component when laying Lego bricks, not cement mortar is used, but a special glue, which can be purchased at a construction supermarket. To increase the rigidity of the masonry, reinforcing rods are installed in the cylindrical holes.

Instead of applying the adhesive, the through cavities can be poured with concrete. This method significantly increases the strength and rigidity of the structure, but reduces the heat and sound insulation characteristics of the material. In addition, when filling cavities with concrete, the possibility of laying communications is excluded.

To increase the rigidity of the structure, the masonry is reinforced with metal wire every 3 - 4 rows.

It is possible to increase the thermal insulation properties of the walls by laying "Lego" bricks in two rows, leaving a gap of 15 - 20 mm between them, which is subsequently filled with expanded clay or mineral insulation. This method of masonry can significantly increase the heat and sound insulation of the building.

Compliance with these simple rules will allow you to independently build a durable and comfortable house with minimal costs.

DIY brick lego machine

You can make your own lego brick making machine. Before starting work, it is necessary to prepare certain materials that will become the basis for the machine. These include:

- channel;

- sheet steel;

- metal corner;

- a pipe for creating a handle and a piston;

- bolts and nuts.

You will also need a tool. At the very least, a grinder and a welding machine will come in handy. The legs of the cylinder must be made from sections of the channel, the length of which is approximately 1 m. The width of the cylinder will correspond to the length of the brick to be produced. Two metal rectangles must be welded between the posts in the upper part, which will form a cross-section.

Homemade Lego Brick Making Machine

Homemade Lego Brick Making Machine

A channel is applied to the resulting structure, the length of which is approximately 0.7 m. It must be placed with the ribs up. It should be welded on one side, and under the protruding part, fasten it with supports. After that, a hole is cut out above the cylinder, corresponding to its perimeter. The hopper will be welded from sheet metal

It is important that its width and length fully correspond to the dimensions of the final form. The hopper is mounted on 4 legs, the basis of which will be metal strips welded to the protruding part of the channel

We make the piston from a metal sheet. Two pipes must pass through this rectangle.

We make a handle from trimming pipes and metal strips, with which the lid will open and close. The handle is secured with long bolts. The corner is needed to make the base for the machine. A homemade machine will make it possible to independently make two types of bricks. It can be either Lego with holes or corpulent. It is not worth making a matrix. It is much wiser to purchase a ready-made one.

Lego brick is actively spreading on the market today, but consumer confidence in it is low due to little operating experience. It is difficult to say how long a house made of this material will stand, since its active use began relatively recently.Today there are a number of reviews from builders who used machines to make this brick.

Many emphasize that this is quite simple, but at the same time, some emphasize the low thermal insulation qualities of bricks.

A number of manufacturers emphasize the quick return on investment of the production line. In some reviews, values are indicated in 6-7 months due to the organization of work for large-scale and projects that require a large number of bricks for construction. The line can be assembled at a cost of about 700 thousand rubles. It should be noted that the organization of work from the point of view of legislation also affects the payback period.

It is important to understand what types of taxation exist for an LLC. so that you do not have to give all the profit to government agencies

For a successful sale, it is recommended to use a large warehouse, since it is a solid stock of the product that attracts a large buyer. Many builders do not risk using Lego bricks to create houses, but they willingly buy it for the construction of fences.

Business organization

Any undertaking involves analytical and preparatory activities, such as:

- analysis of consumer demand and the study of competing firms;

- study of the intricacies of production technology;

- preliminary calculations of the cost part;

- legalization of activities;

- search and rental of premises;

- choice of equipment;

- establishing relationships with suppliers of raw materials;

- hiring workers;

- search for ways to sell products.

When the plan is developed and the analytical work is done, the first practical step is to legalize the business.

Legalization of activities

With small volumes of brick production, it is enough to register as an individual entrepreneur (IE). The choice is justified:

- simplicity of design. From the documents you will need: an application (form P21001), passport and TIN, a receipt for payment of the state duty;

- an affordable state fee of 800 rubles;

- moderate tax collections under a simplified taxation system - 15% of profit or 6% of revenue is deducted. The transition to the simplified tax system is carried out on an application that is submitted immediately during registration or within 30 days after it.

The procedure takes about 5 working days.

For a larger-scale business, register an LLC. In this case, the state fee will be 4000 rubles. A limited liability company provides more opportunities for expanding production and profitable cooperation with legal entities.

The most suitable OKVED code is 23.61, which allows the manufacture of products from concrete, cement and gypsum. As additional (in case of rapid development), add codes: 23.32 for fired and unbaked clay products and 47.52.72 for brick retail in specialty stores.

Premises for workshop and warehouse

Using mini-installations, you can start your own business in the garage. To work on several presses with good performance, a workshop with a total area of 100-200 m2 is suitable, the rental cost of which will cost from 30 to 50 thousand rubles per month.

The room must meet a number of requirements:

- availability and working condition of communications (water supply, sewerage, electricity, heating);

- supplied voltage of 380 V;

- good lighting and ventilation;

- convenient access roads;

- closed warehouses for raw materials and finished products.

Staff

On mini-installations, all manipulations take place with the participation of manual labor. So, you will need one worker for operations with the press, the second for preparing the mixture and loading it into the bunker, the third for loading and unloading.

The general management, provision of raw materials and the sale of goods will fall on the shoulders of the business organizer.

For small volumes, it makes no sense to hire an accountant on an ongoing basis, it is enough to use his services during the reporting periods.

With the expansion of production, the number of employees will also increase. It would be advisable to consider the issue of hiring a full-time driver and sales manager. And, of course, to gradually update the technological park, giving preference to fully or partially automated mechanisms.

What is good about such a brick

Buying a new apartment is becoming an unattainable luxury for many. The small funds that can be postponed are spent by private traders on the improvement of the existing dacha or backyard economy. Gazebos, fences are being erected, baths and outdoor barbecue ovens are being built.

All this requires an inexpensive, strong and aesthetic building material, and Lego is perfect for these purposes. It has good strength, climatic resistance and flawless appearance.

The low cost of the product consists of several components:

- Low cost of equipment. The technology does not require the installation of kilns, autoclaves, etc.

- The lightness of the final product. This modification of the hollow brick weighs less than the classic models, so its transportation is less expensive.

- Low raw material price. Construction material is produced from sand, dolomite, mining waste and recycled materials.

- Minimum advertising costs. Customers recommend these building materials to neighbors and friends. After 1-1.5 years of selling Lego, word of mouth is driving more buyers than ads in the local newspaper.

The main characteristics of Lego:

- durable - cuts under high pressure;

- smooth - a flat surface easily competes with facing modifications;

- easy to use - a person will lay out the masonry even without building experience, the elements are joined end-to-end, forming a flat wall;

- lightweight, which significantly reduces labor costs during production, reduces the consumption of fuels and lubricants.

In short, such a good building material, and even cheap, has every chance to continue to break sales records.

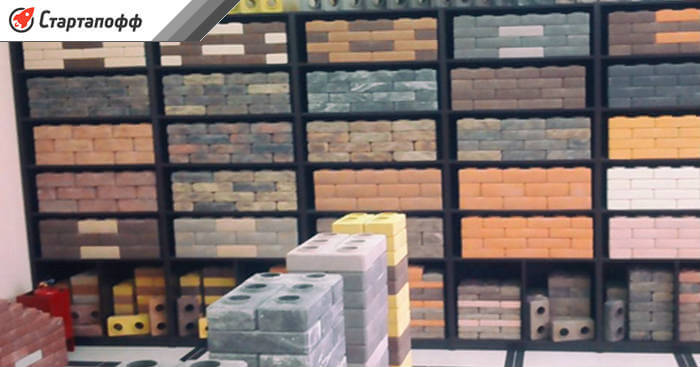

The production technology allows you to produce products of any color

The production technology allows you to produce products of any color

Production technology

Smart bricks are made on special machines with a hydraulic press, working according to the hyper-pressing method. The whole process can be conditionally divided into the following stages:

- sorting and screening of raw materials;

- blending - dosing and mixing of components;

- molding and pressing.

The initial stage is the preparation of the working mixture. The components are mixed and ground until smooth. The finer the grinding, the higher the strength characteristics of the finished product. Further, the prepared mixture from the hopper goes to molding. A strictly measured amount of raw materials is poured into the dispenser and poured onto the matrix.

The size and shape of the future product depends on the parameters of the matrix. They are standard and allow the production of bricks, the weight, size, density and configuration of which fully comply with the requirements of GOST. In addition to the typical die 250 x 120 x 65mm, ½ options and fittings are used for the production of corner and end pieces.

Under high pressure (from 30 tons), the raw material is pressed and sintered without exposure to high temperatures. The cold welding method ensures strong sintering of all components. The finished products are removed from the tray and stacked on a pallet. To gain the desired strength, they need to mature for 20 to 30 days.

Product range and its features

Bricks, so reminiscent of Lego bricks, have a number of unique characteristics:

- round holes, adapted to be pushed on top of each other, do not allow displacement. And at the same time they make it possible to lay communications (wires, pipes) through them;

- light weight, facilitating the transportation and labor of builders;

- a large selection of colors;

- absolutely smooth surfaces, which allows the products to be used both for construction and for cladding;

- due to the smoothness and lack of displacement during laying, they form a perfectly flat surface that does not require additional leveling;

- high strength, corresponding to the brand of brick M-150, which makes it possible to use it in the construction of partitions and load-bearing walls;

- standard sizes of Lego bricks, in mm: length - 250, width - 125 and height from 65 to 90;

- methods of fixing the masonry: using a special glue, or by pouring cement into the holes, which is convenient and economically beneficial. The classic way of laying will not work here.

The variety of the assortment is achieved thanks to the variety of colors and variations with the block heights.