Application of one-piece profiles for polycarbonate

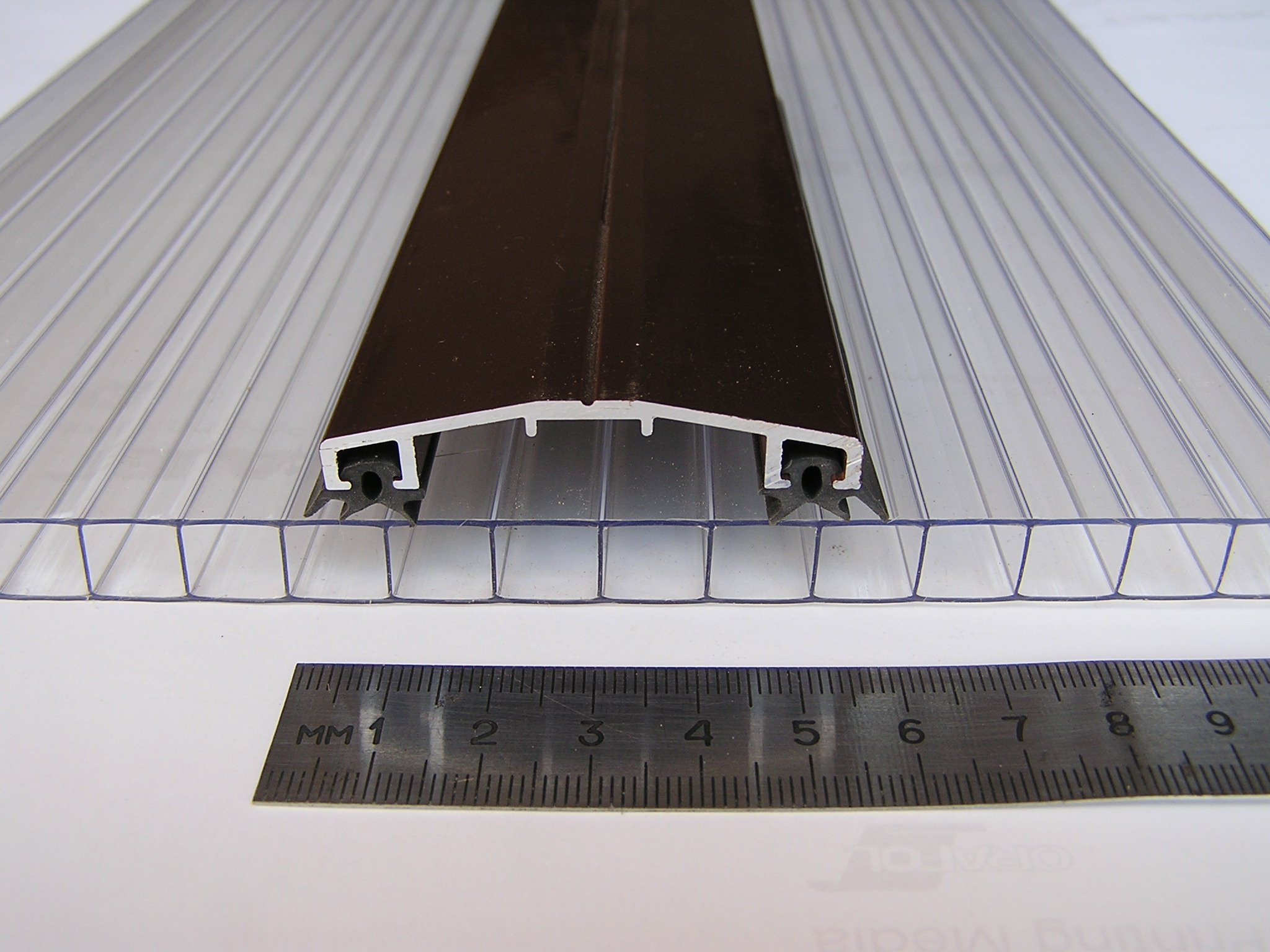

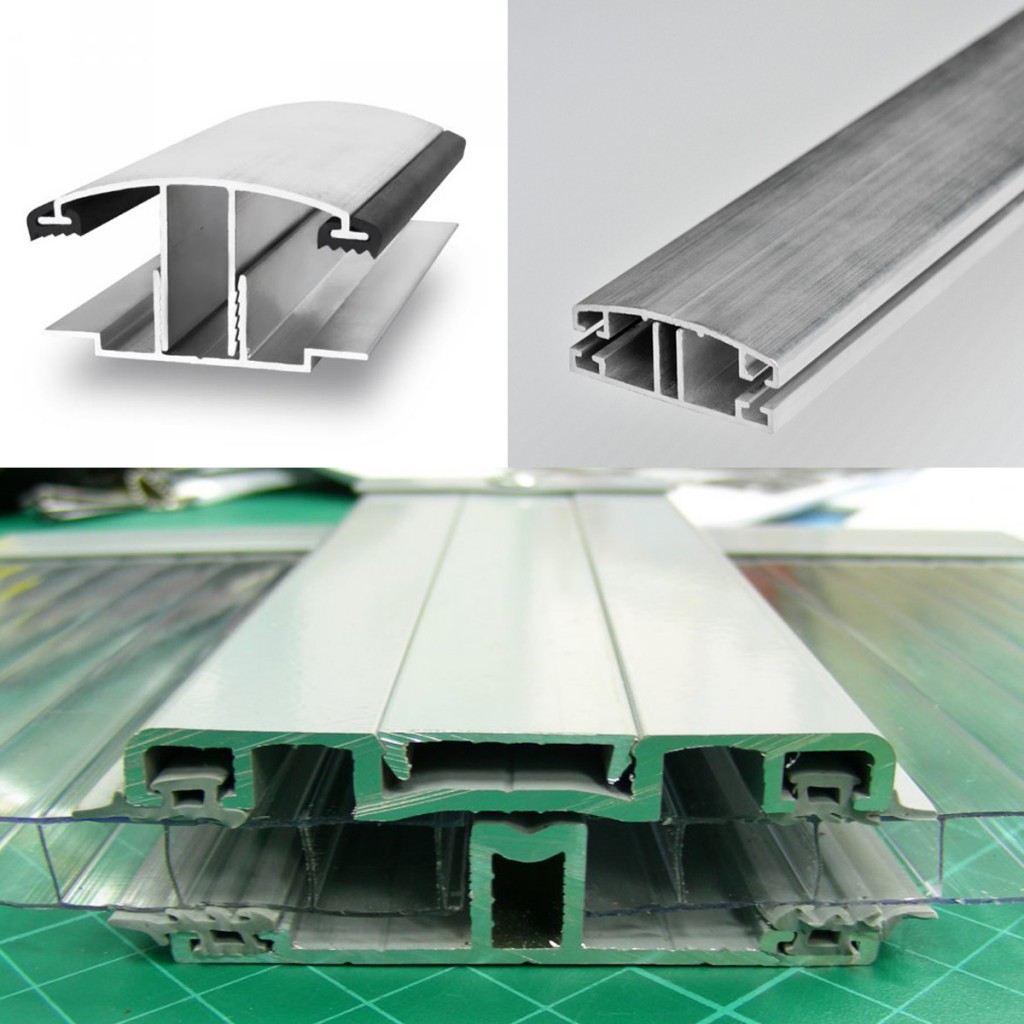

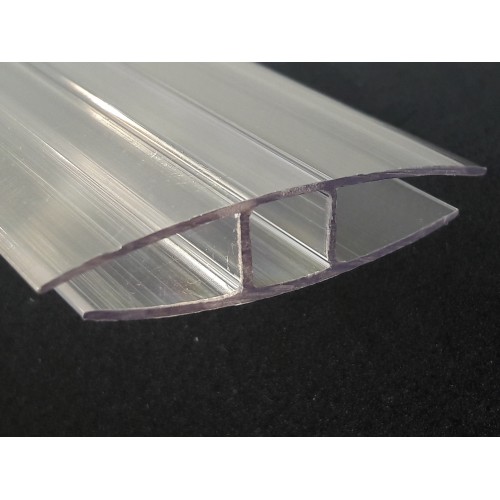

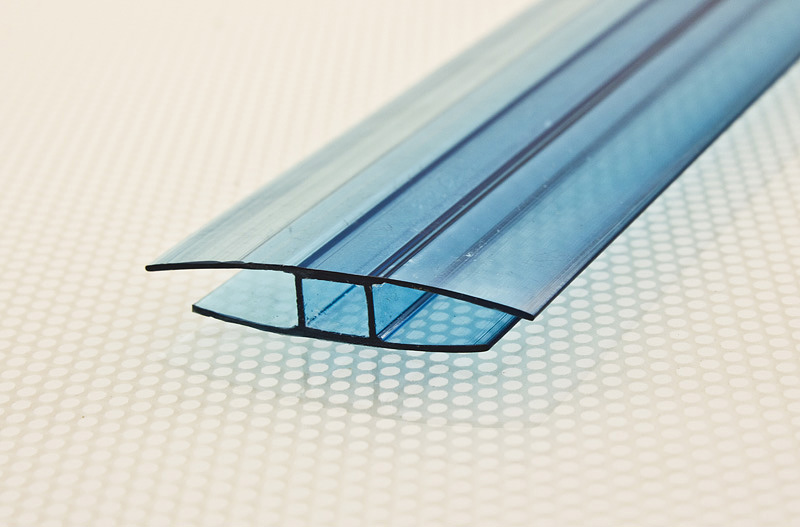

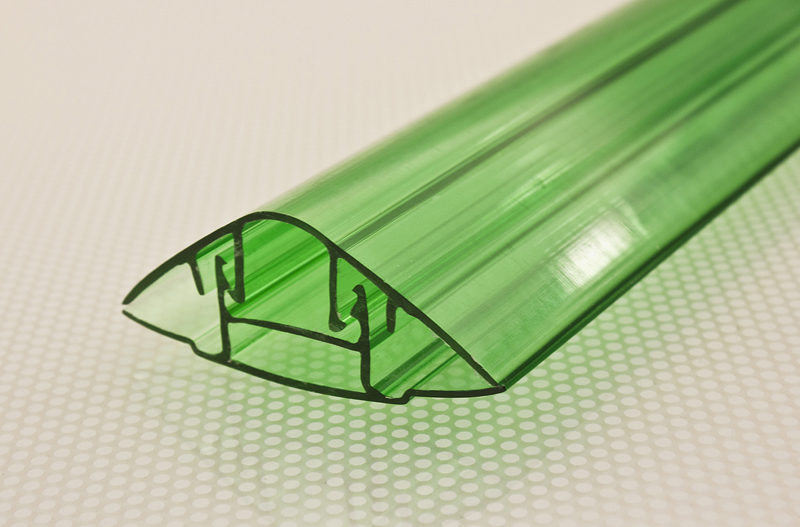

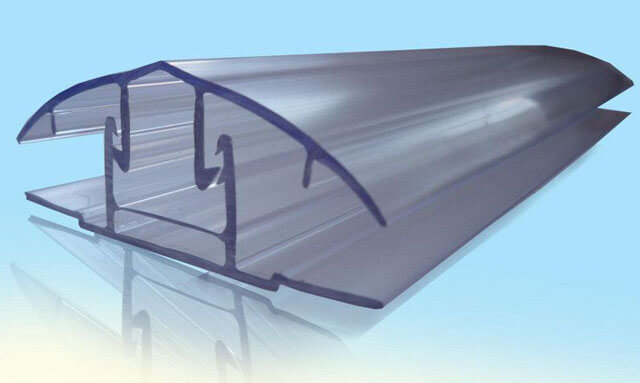

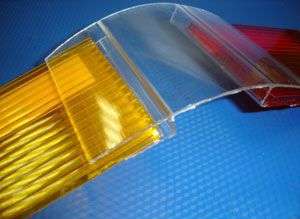

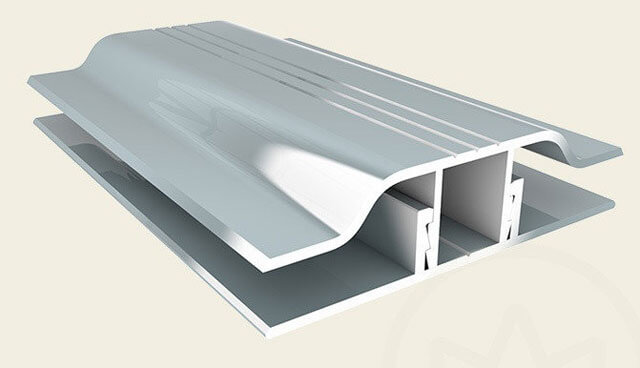

One-piece profiles are less expensive, but joining polycarbonate with their use has some difficulties, especially in windy weather. The installation itself is quite simple: first, the N-shaped profile for polycarbonate is unclenched, and then the sheet is fed into it. As a rule, it goes into the groove with difficulty, therefore, to install it, the sides are often removed with a screwdriver or a similar tool, and then the panel is slowly pushed into place. This method is complex, so it is used only where free space is limited.

However, there is an easier way to install one-piece panels. Before installation, the edges of the elements to be installed are lubricated with some kind of dishwashing detergent. As a result, the sheet will slip freely into the groove, and the remnants of the substance will simply dry out and will not disturb the sealing of the joint.

In any case, regardless of the installation method, the panels installed using permanent connectors should not reach the base of the groove - at this point a small gap must be left, which will allow the material to expand freely under the influence of temperature.

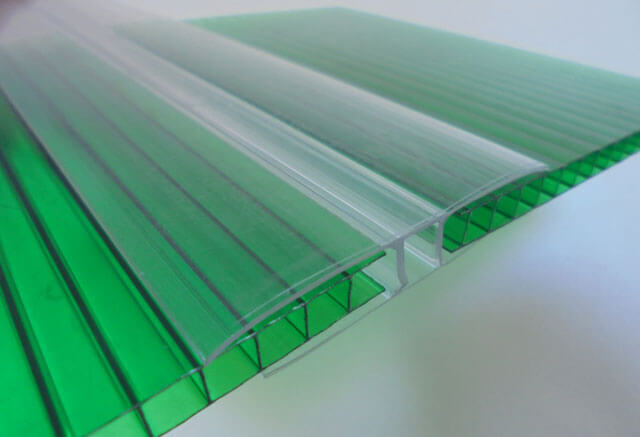

In addition, when using the one-piece polycarbonate joint profile, make sure that all panels are of the same thickness. The dimensions of the docking profile for polycarbonate were originally designed for the very specific dimensions of the sheets to be mounted. Too thin products will not allow to achieve a tight connection, and too thick products will not be able to enter the groove.

How to join polycarbonate on a canopy by gluing

The undoubted advantage of profile mounts for polycarbonate is their reliability, durability, and ease of installation. However, such joints on the roof surface are simply impossible to miss. In some situations, it is required to do the joining of the material in such a way that there are no visible joints. For such purposes, a special composition is used that allows you to glue polycarbonate panels together. As a rule, such glue can be purchased in the same place as the base material. In order to obtain a particularly strong bond, polycarbonate can be glued with a silicone-based compound.

Please note that it is possible to obtain a reliable connection of polycarbonate sheets by gluing using solvents based on methylene chloride, ethyl chloride or their mixtures. The use of such compounds for gluing polycarbonate allows you to give the structure a beautiful appearance.

In addition, no moisture from the outside can simply seep into such seams, since the connection is very tight.

In conclusion, it is worth noting that the positive characteristics of polycarbonate, among which are resistance to mechanical and chemical stress, low weight and ease of installation, strength, as well as protection from ultraviolet radiation, make it very popular in the building materials market. A high-quality and reliable connection of the panels will allow the use of polycarbonate for a long time.

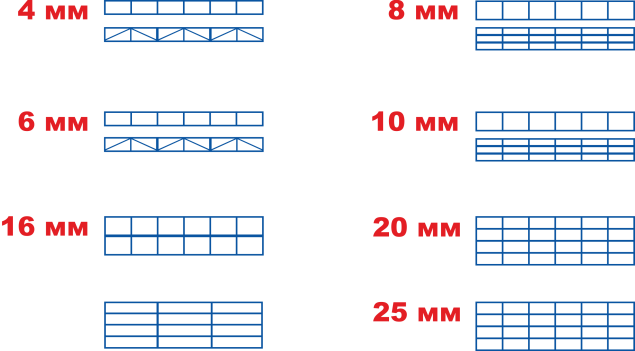

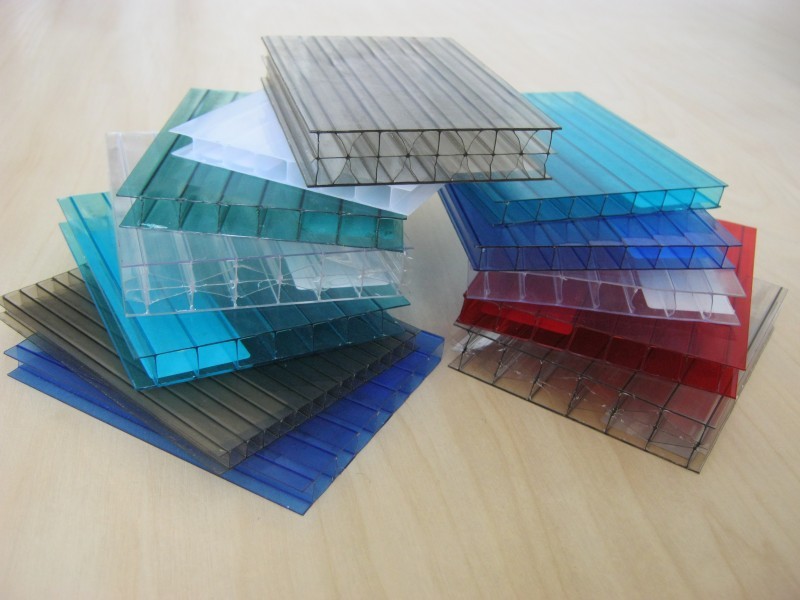

Choosing the thickness of polycarbonate for the greenhouse

For arched typical greenhouses, the thinnest polycarbonate with a thickness of 4 mm is usually used. However, this thickness may not be enough for good thermal insulation of heated greenhouses. For such structures, you should choose polycarbonate with a two-chamber structure with a thickness of 16 mm - this way you can provide excellent thermal insulation of the greenhouse and reduce heating costs. In regions with significant snow load, it is recommended to choose reinforced polycarbonate with a thickness of 6 mm, and for capital heated greenhouses - a two-chamber 25 mm thick. This type of polycarbonate has additional stiffening ribs inside the honeycomb.

Choosing the thickness of polycarbonate sheets

In areas with excessive sun exposure, plants require shading. In this case, it is advisable to choose colored polycarbonate for roof slopes: it transmits less sunlight and corrects the color component. So, for growing greenery and seedlings, the blue and blue spectrum is useful, and for successful fruiting, the red one. The saturation of colored polycarbonate should be moderate, and the light transmittance should be at least 65%.

Choice of polycarbonate color

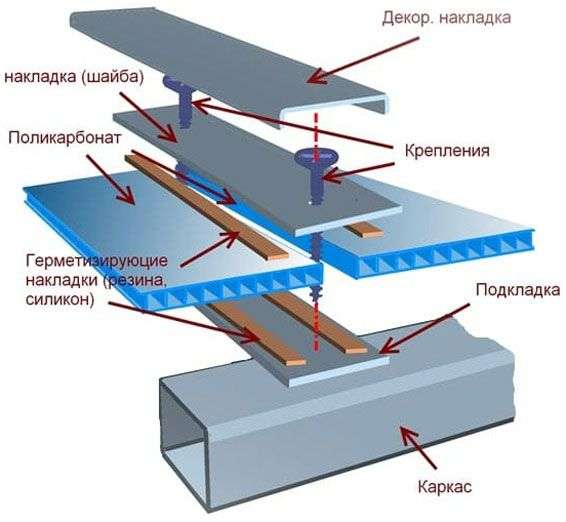

Accessories and fasteners

Specialists in the installation of greenhouses and other polycarbonate structures recommend using special self-tapping screws with thermal washers, as well as a sealing tape. These elements allow you to isolate the attachment point and exclude the penetration of moisture and dirt into them, as well as prevent the destruction of polycarbonate.

Thermal washers

Thermoshabs are designed to seal the attachment point and are of several types:

- polycarbonate;

- polypropylene;

- metal.

All thermal washers are equipped with a polymer sealing gasket, due to its compression and sealing occurs.

Thermal washer for attaching polycarbonate

Thermal washers made of polycarbonate

The most practical and durable washers for fixing cellular polycarbonate. A prefabricated polycarbonate thermal washer, it consists of a plastic washer with a fixing leg, a polymer O-ring, a stainless self-tapping screw and a cover. Thermal washers are selected for the thickness of the polycarbonate. Due to the different lengths of the legs, compression of the polycarbonate is excluded, and the self-tapping screw can be screwed in until it stops.

To install polycarbonate, you must first mark and drill holes in it with a diameter of 2-3 mm larger than the diameter of the leg. The step between the fasteners is 35-50 cm, the indent from the edge of the sheet is at least 4 cm. The washer is inserted into the hole until it stops, the seal is leveled and the self-tapping screw is tightened. The head of the self-tapping screw is closed with a lid to protect it from moisture and for an aesthetic appearance.

Fastening polycarbonate with self-tapping screws and thermal washers

Advantages of polycarbonate thermowells:

- tightness provided by a sealing washer;

- durability and resistance to UV radiation;

- aesthetics and a large selection of shades;

- several standard sizes suitable for any thickness of polycarbonate.

The disadvantages include a longer installation, since it is necessary to pre-drill the holes.

Thermal washers made of polypropylene

Universal thermal washers made of polypropylene have the shape of a truncated cone, when tightening the self-tapping screw, they are compressed, and the joint is sealed. The composition of the material for universal thermal washers includes a UV stabilizer, so that they do not deteriorate under the influence of the sun for 4-5 years.

Universal thermal washer

Correct fastening of self-tapping screws

Metal thermal washers

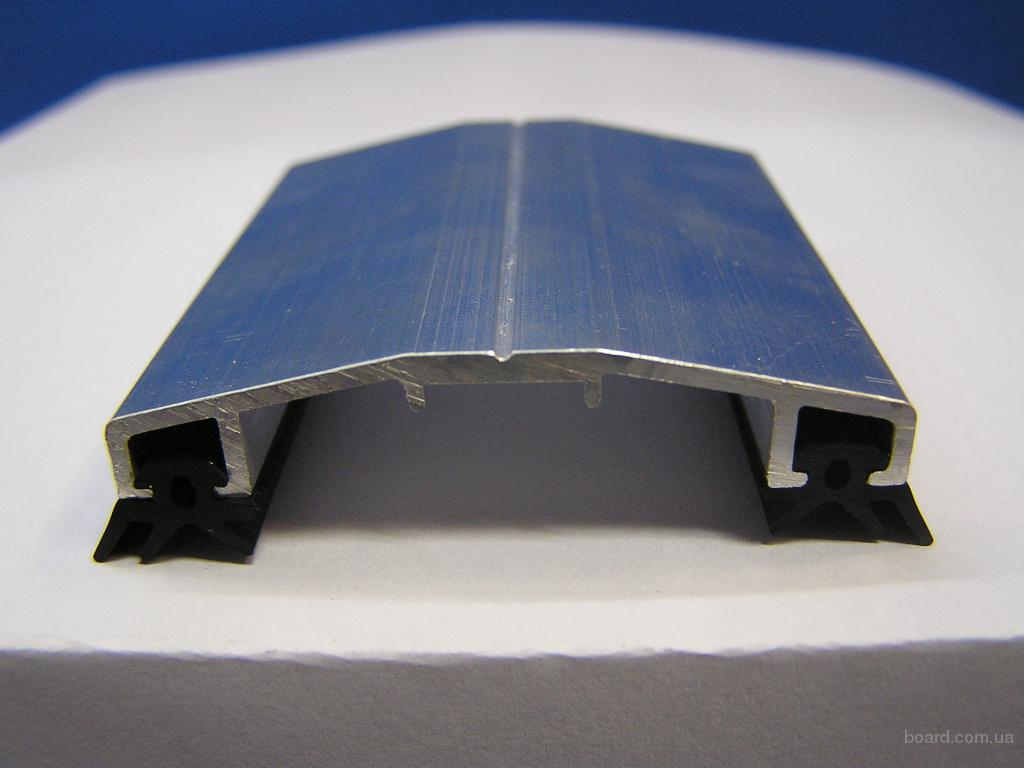

They are distinguished by their strength and durability, they are not subject to corrosion. The washers are equipped with a rubber or polyurethane gasket to ensure the tightness of the connection. Metal washers are often used in conjunction with an aluminum connecting profile. The fixing step is 30-40 cm.

Metal thermal washer

Aluminum sealing tape

There are two types of sealing tape: solid and perforated. One-piece tape is used to completely seal the internal cavities of the polycarbonate. The upper cut of the sheets is glued with it. Perforated for protection from dust and dirt and insects. She glue the bottom edge of the sheets.

Sealing tape

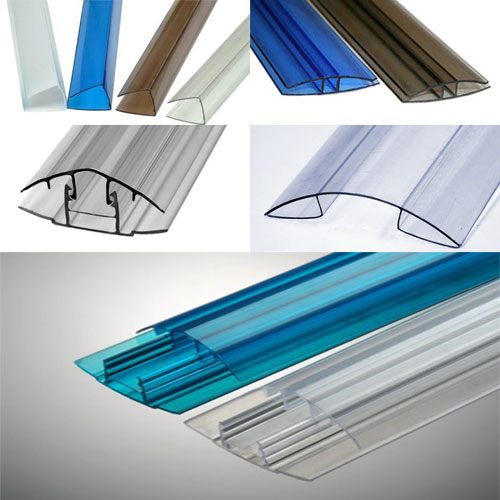

Materials (edit)

Polycarbonate profiles are made from plastic and metal. PVC fasteners are more popular due to their flexibility, durability and variety of colors. For the manufacture of metal profiles, aluminum is used, such profiles are more rigid, they increase the bearing capacity of the entire structure. They are almost always equipped with rubber seals.

In addition to profiles, it is necessary to be able to correctly select additional materials and accessories that increase reliability and make the structure the most durable. Thermal washers - point-type fasteners for all types of polycarbonate.

Polycarbonate thermal washers have a number of advantages over simple polypropylene fasteners: transparency and shade are combined with a carbonate sheet, increased service life and increased strength, the ratio of the coefficient of expansion due to heat is similar to the expansion of the sheets. Polypropylene thermal washers have less durability, shorter service life, and are opaque. But due to their low cost, they are very popular.

Thermal washers made of metal are made of stainless steel. They are used for monolithic polycarbonate. The package includes a rubber seal, which is used to ensure the reliability of fixation and the tightness of the fastening. Aluminum tape is a material used during bonding of carbonate sheets. It provides complete isolation and sealing of the sections and joints.

Installation features

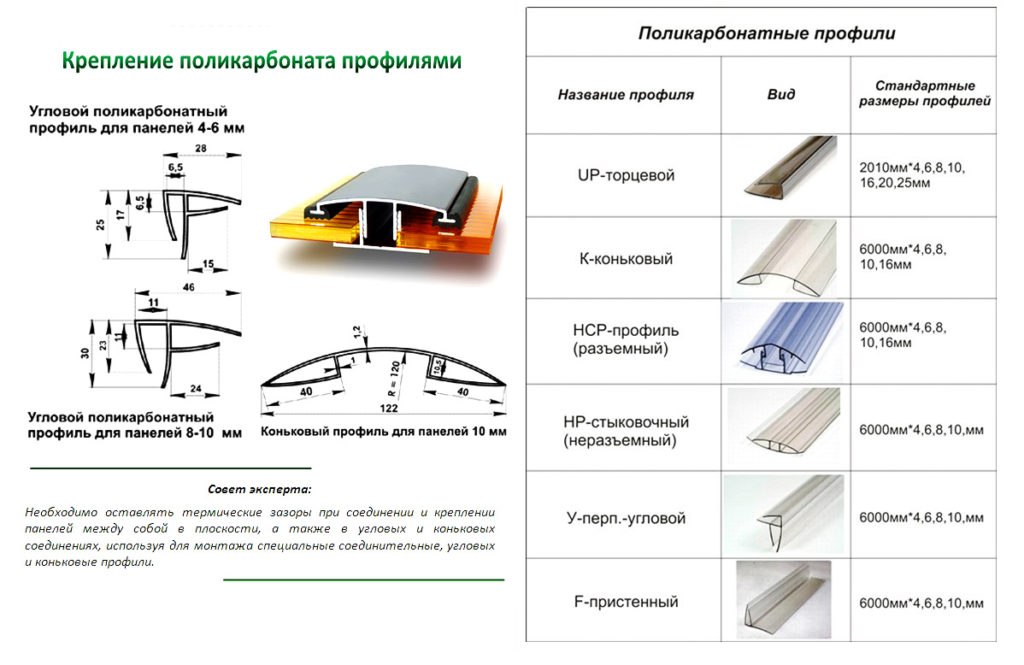

In order for the junction of the profile and the canvas to be reliable and durable, the edges of the polycarbonate must be cut off. The base of the connecting strip must be fixed to the frame with special screws, the distance between which is 30-40cm. Aluminum profiles minimize the use of load-bearing structures due to their rigidity. For polycarbonate 8 mm, the width of the sheet is 60 cm, for 10-16 mm, the width of the web is 70 cm.The distance between the bearing components can be from 6 to 8 m.

The ends of polycarbonate in a vertical or inclined structure are closed with perforated tape from the top side. In arch-type buildings, the tape must be attached on both sides.

For information on how to attach the polycarbonate connecting profile to the arch, see the next video.

Polycarbonate installation rules

Correct installation of polycarbonate is an important stage in the installation of a greenhouse, greenhouse or gazebo made of this material. In this case, it is necessary to observe the technology described in Table 1.

Table 1. Step-by-step instructions for installing polycarbonate.

Stages, illustrations

Description of actions

Polycarbonate preparation

Polycarbonate sheets are placed on a flat, smooth surface, excluding the appearance of scratches and damage. Remove the protective film from both sides from the polycarbonate. Be sure to mark the outside with a marker - it has a protective layer that protects polycarbonate from UV radiation. You can identify it by the applied logo or drawing.

Cut polycarbonate

To cover the ends of the greenhouse, polycarbonate must be cut according to a template. It is most convenient to use a fully assembled end wall - it is applied to the sheet so that the internal stiffeners are located along the vertical axis, and outlined with a marker. Cut polycarbonate with a jigsaw with a metal or plastic file, a circular saw with fine teeth or a hand hacksaw. Thin 4mm polycarbonate can be cut with a sharp cutting knife.

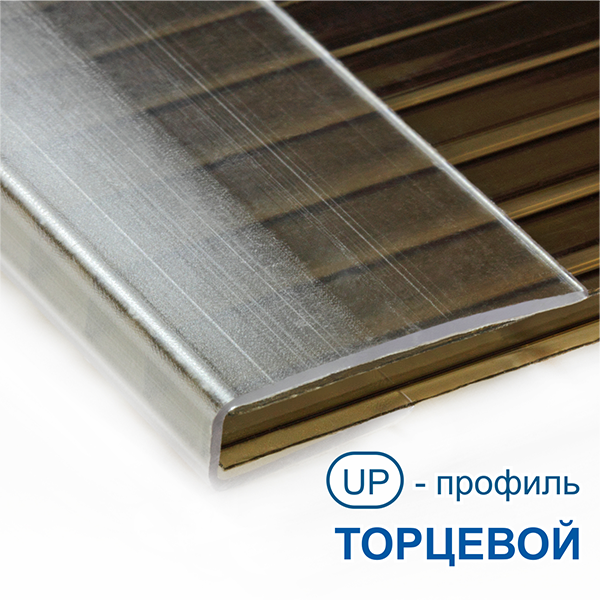

Fastening the end profile

All cross sections of polycarbonate are finished with an end profile. In this case, the upper cut is pre-glued with an aluminum sealing tape, and the lower one - with a perforated one. The profile is put on over the tape, pulling it tightly. It is recommended to pre-drill holes with a diameter of 3 mm in the lower end profile in 30 mm increments to drain the condensate.

Correct arrangement of sheets on the slopes of the greenhouse

Polycarbonate sheets can only be bent in one direction so that the honeycomb channels and stiffeners are positioned along the arch. With a transverse arrangement, creases are possible, as well as stagnation of condensate

As a result, the light transmission of the greenhouse will sharply decrease.

In addition, it is important to ensure that the UV protective layer is facing outward. Choice of connecting profiles

Connecting profiles are used to join sheets on the side walls and roof of the greenhouse

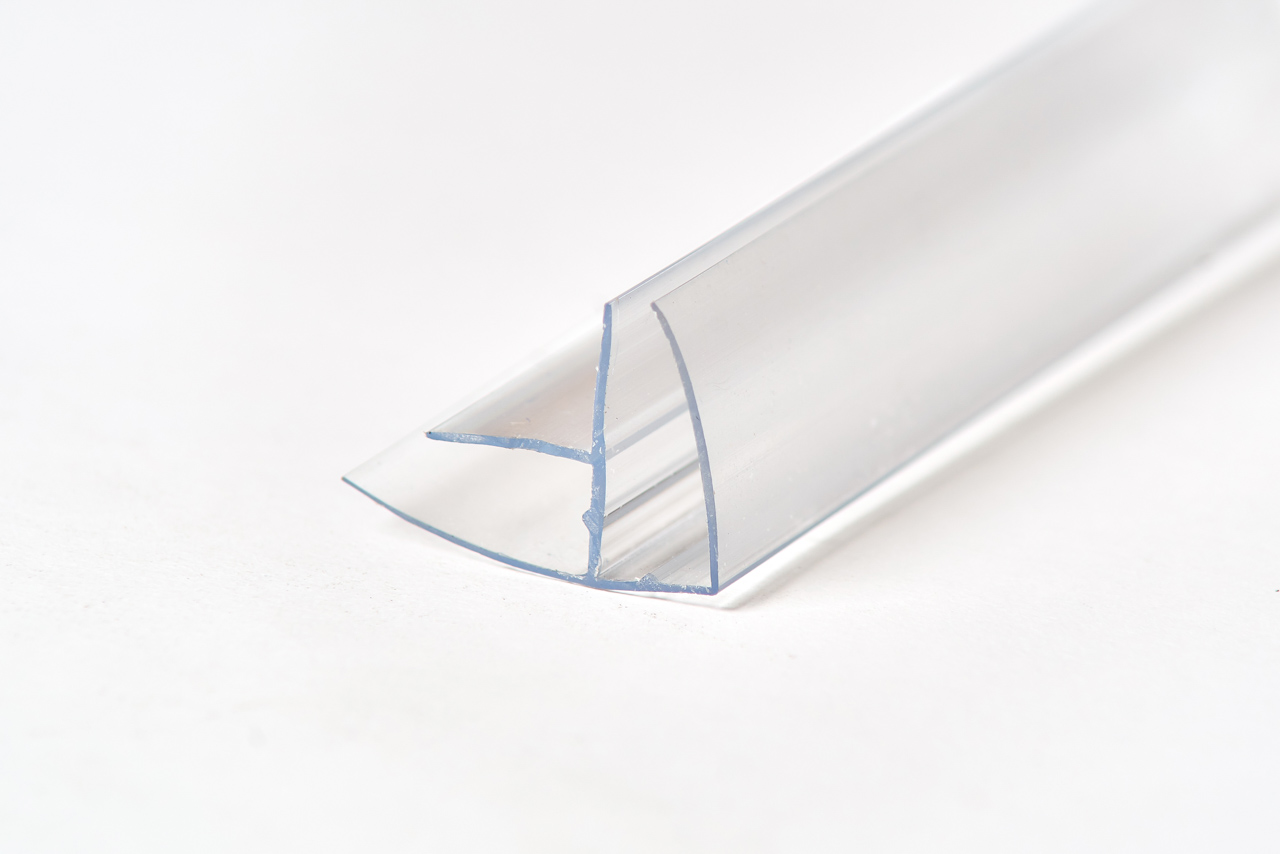

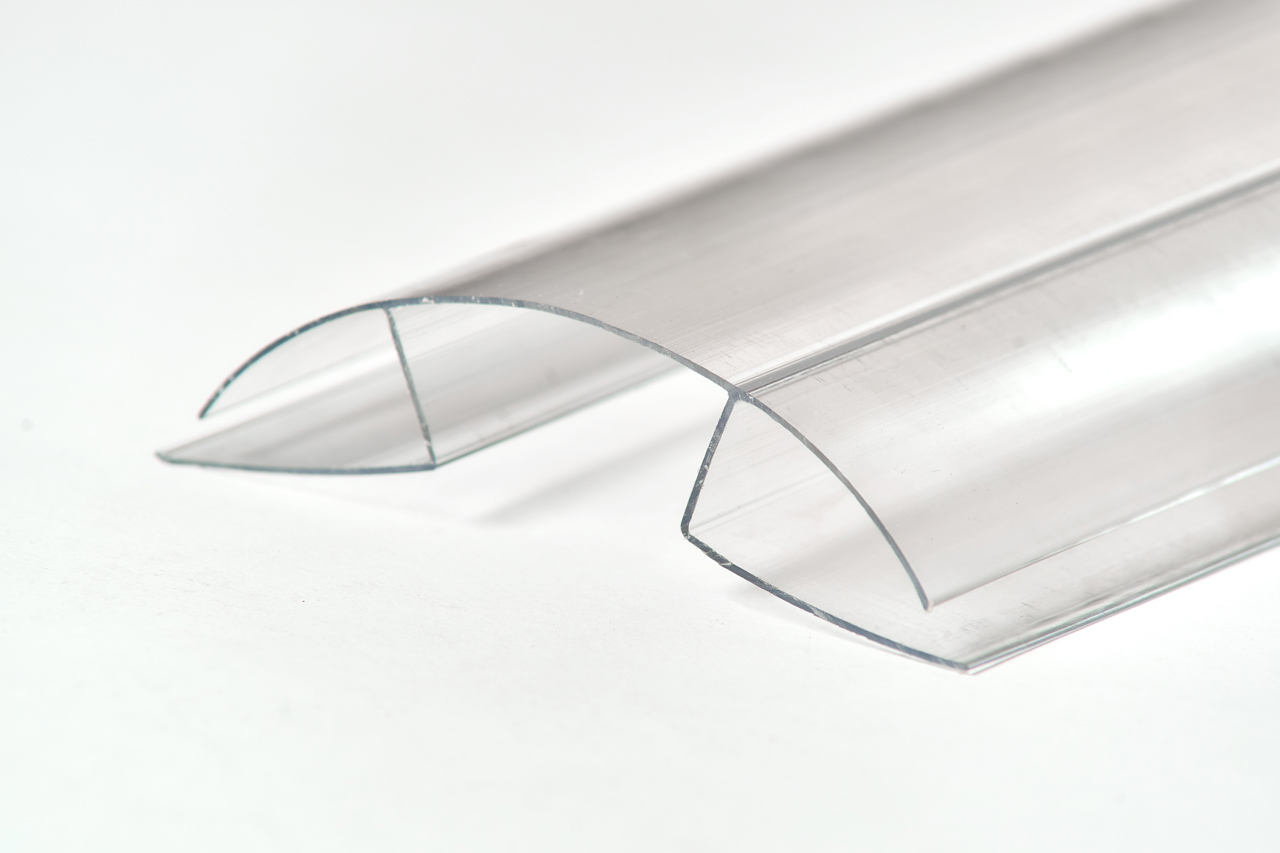

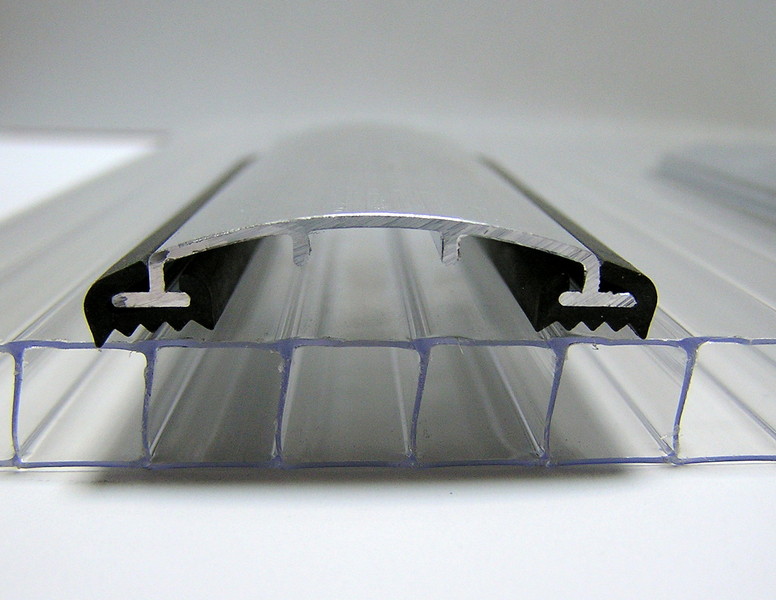

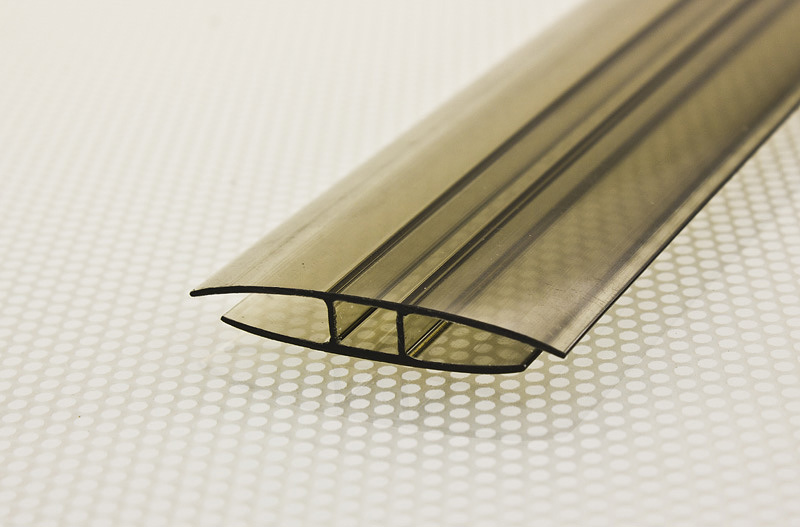

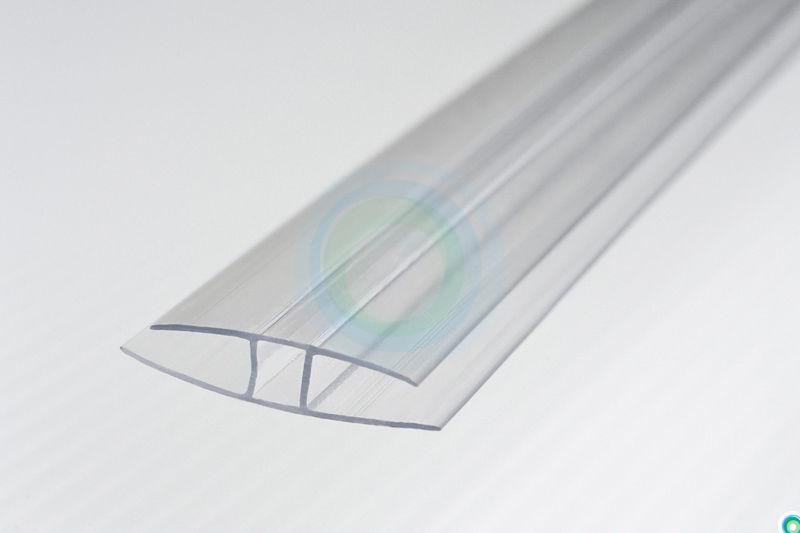

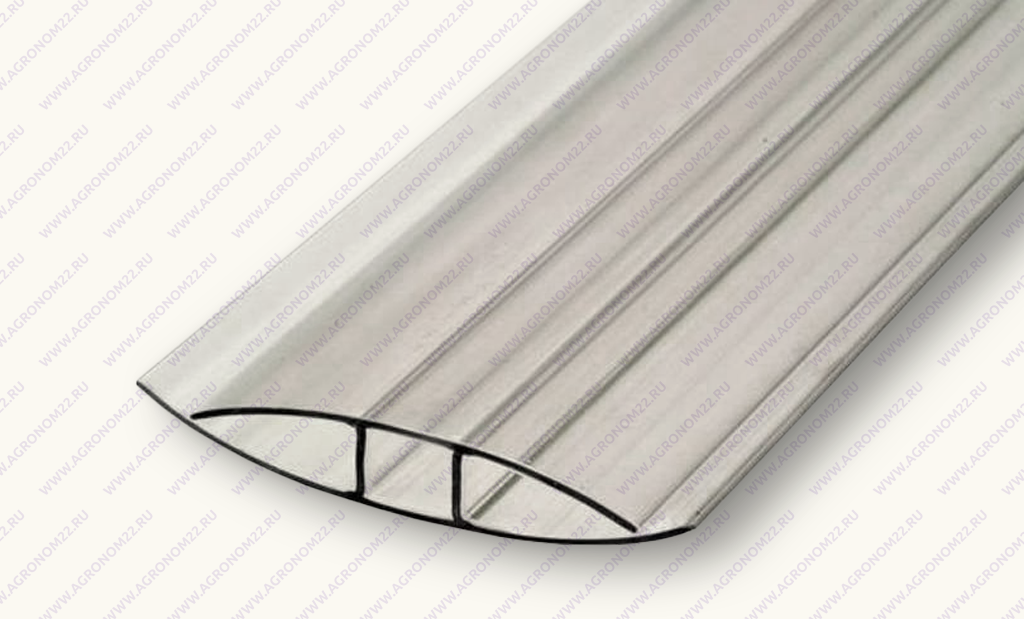

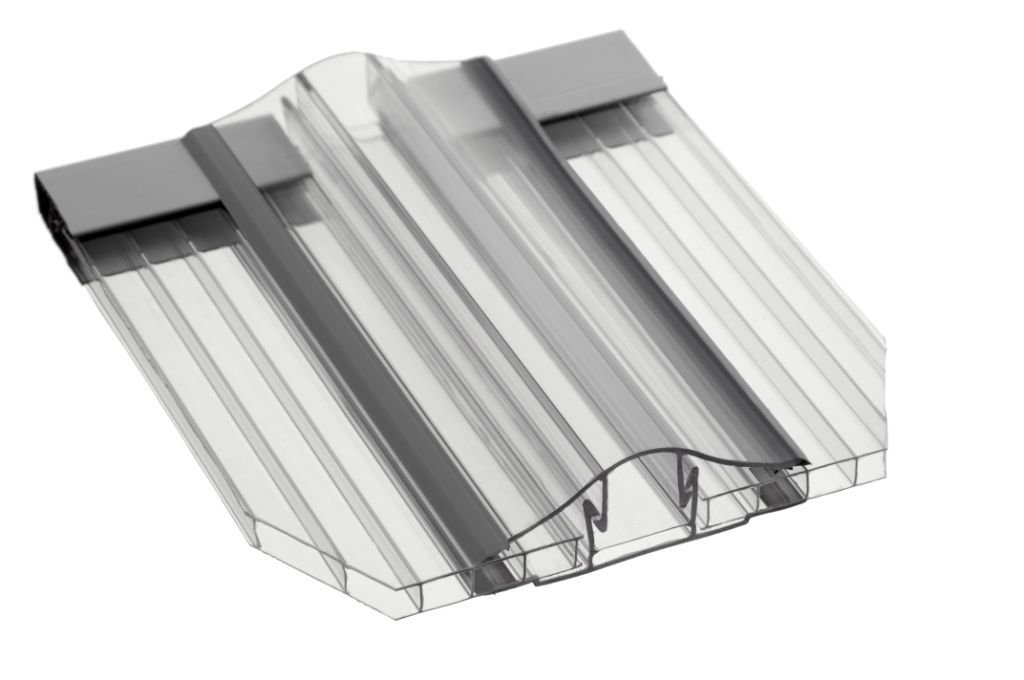

For polycarbonate up to 10 mm thick, one-piece HP polycarbonate profile is usually used

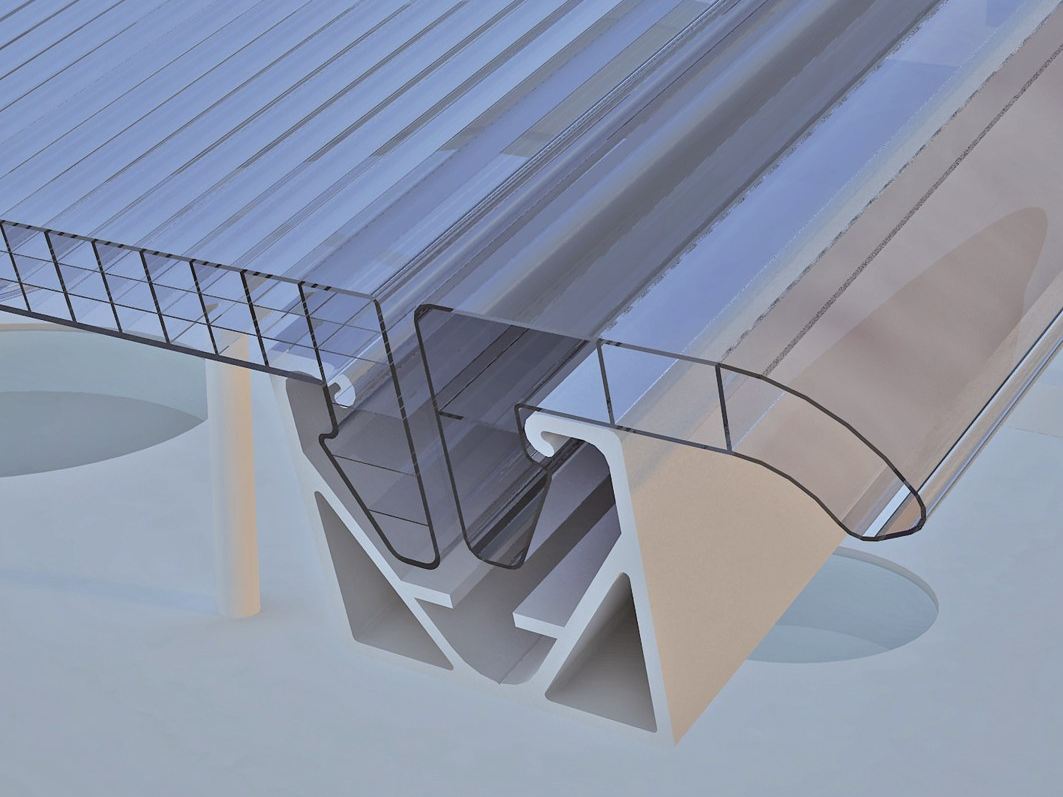

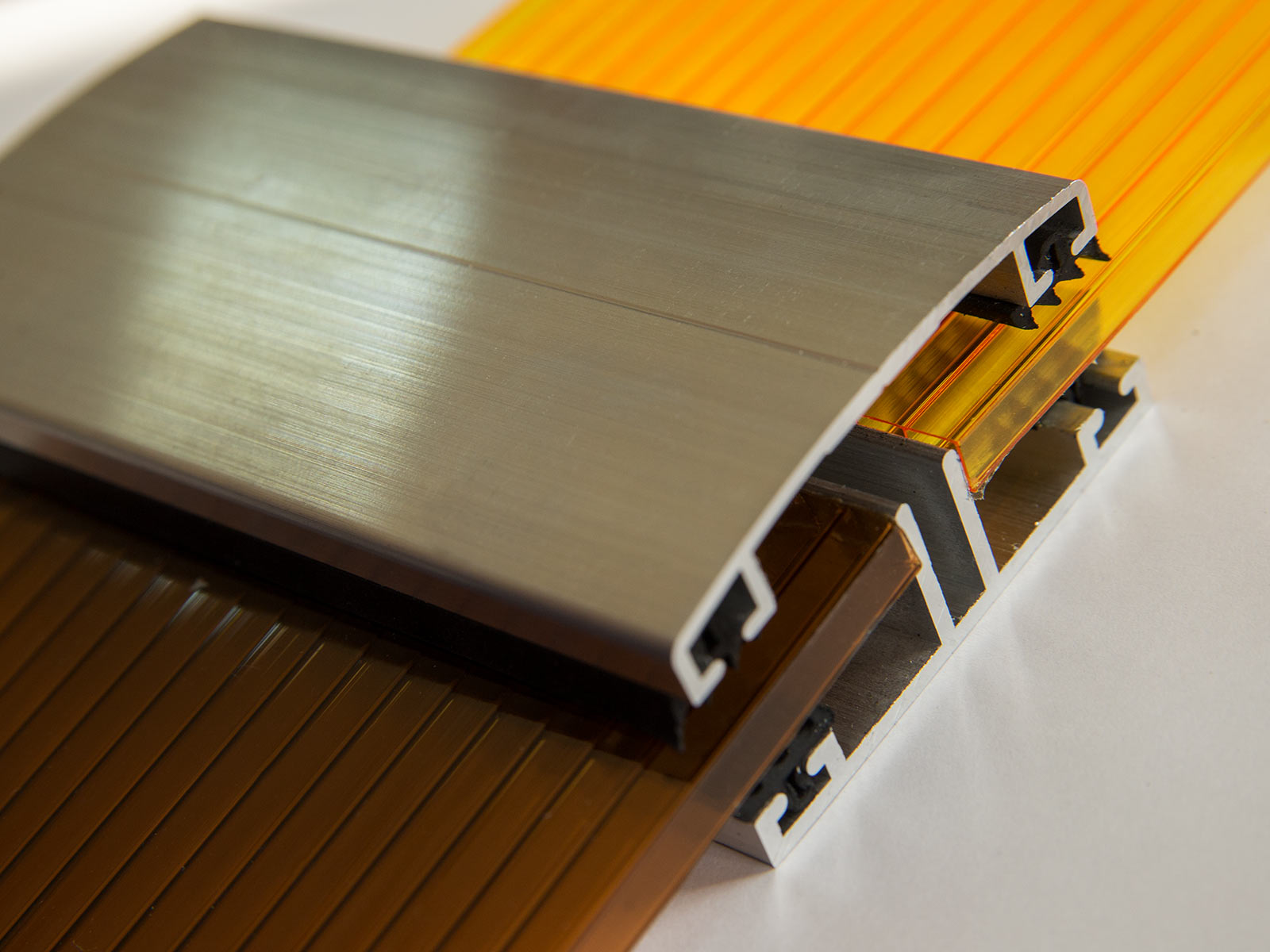

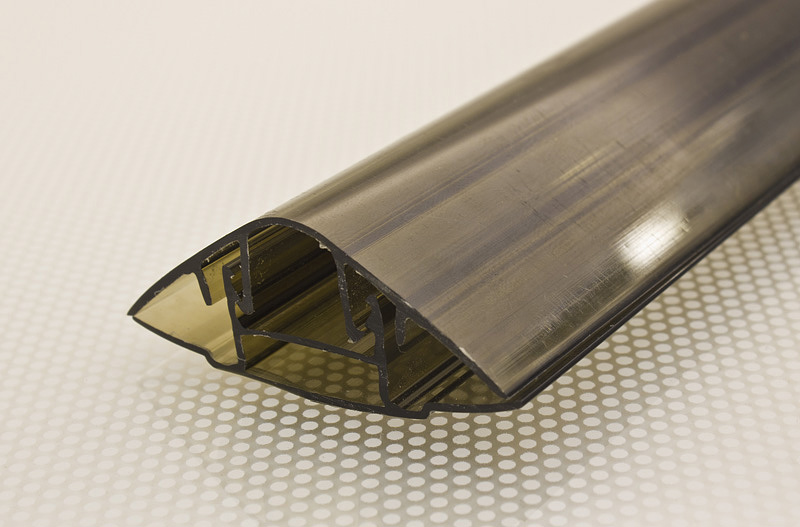

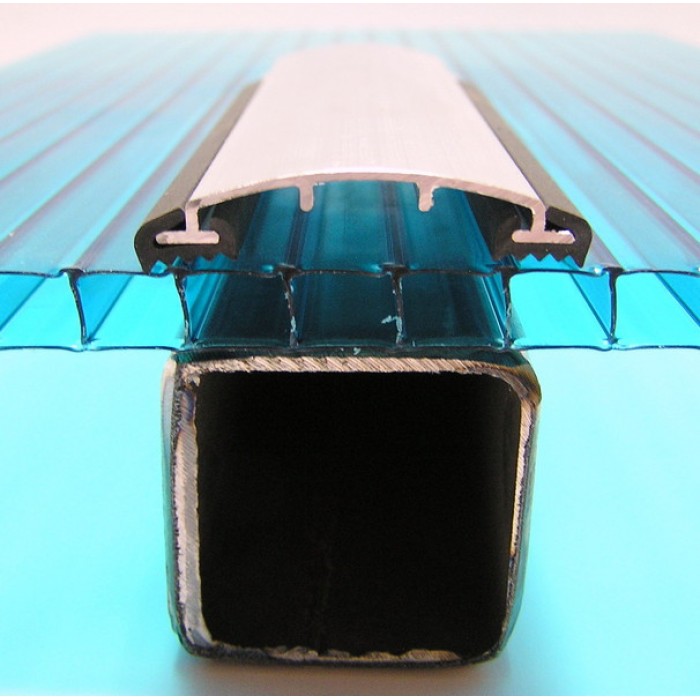

For winter use greenhouses with a polycarbonate thickness of 16 mm or more, a split HCP profile made of polycarbonate or aluminum is used. The length of the profile is 6 m, which corresponds to the length of the polycarbonate sheets.

Installation of polycarbonate on an arched surface

Polycarbonate sheets are applied to the arched surface and the bottom edges are trimmed if necessary. The latter are glued with a perforated aluminum tape and the end profile is fixed. The sheets are thrown over the greenhouse arch and inserted into the grooves of the one-piece connecting profile. The profile is fixed with self-tapping screws and thermal washers to the frame.

Installation of polycarbonate on the walls and roof of a gable greenhouse

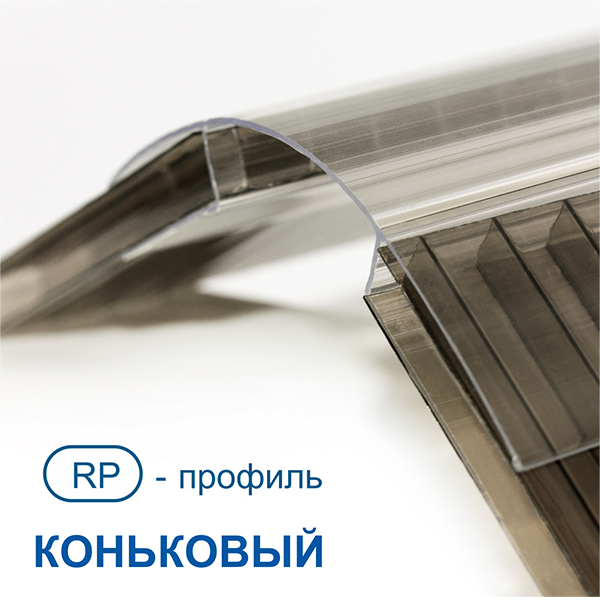

On the walls and roof of a gable or single-slope greenhouse, polycarbonate is attached in the same way as on the ends: cut to size, insulate the end cuts and connect the sheets using connecting profiles. On the ridge of the roof, a ridge connecting RP profile is used: sheets of polycarbonate, pre-glued with a sealing tape, are inserted into the grooves on both sides, and the profile itself is attached to the ridge beam of the frame.

Processing the corners of a gable greenhouse

At the corners of the greenhouse, a corner FR profile is used. It is put on the end wall so that the free profile shelf goes behind the frame post. The wall is fixed through the profile to the frame. A side wall made of polycarbonate is brought into a free groove, fastened with self-tapping screws with a thermal washer with a step of 30 cm.

Docking polycarbonate to the main wall

This type of fastening is used in wall greenhouses or buildings with a permanent vestibule. A wall-mounted FP profile is used for mating. It is attached through a rigid gasket or wooden rail to the wall, after which a polycarbonate sheet, previously sealed with an aluminum tape, is inserted into the profile groove.

Video - Correct installation of polycarbonate on the greenhouse

Correct installation of polycarbonate will help to give the greenhouse an aesthetic appearance and protect it from moisture, dust and debris. The use of profiles for cellular polycarbonate is a guarantee of a long service life of your greenhouse.

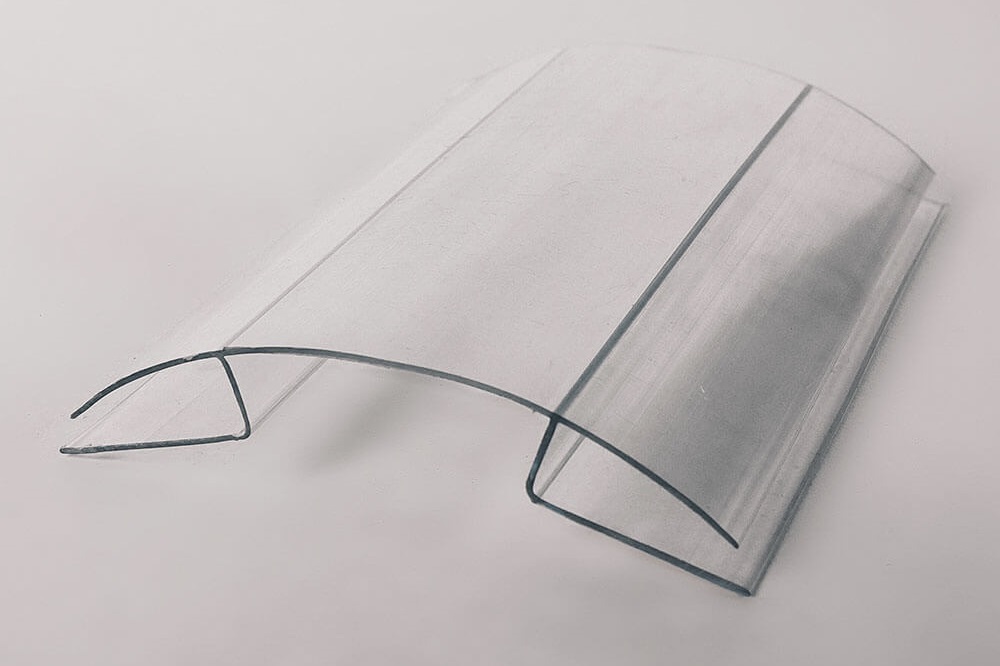

Semicircle

If the sheets to be joined are also curved, such as in the roof of an arched greenhouse, it is better not to use any profile fasteners. Here they do not justify themselves. After a year and a half from the load, the joints loosen and cracks form.

In this case, you just need to overlap the sheets, grease the inside with glue or sealant, and carefully attach the polycarbonate to the frame with self-tapping screws.

Sometimes a ridge profile is used for this option. Before installing this profile, make sure that the gripping of its "wings" securely holds the panels and matches their thermal expansion.

The advantages of polycarbonate

Firstly, polycarbonate is transparent, so it can replace glass. It is much lighter than glass, and its strength is 50 times higher, which makes it much easier to stop installation.

Polycarbonate is practically not afraid of all kinds of chemicals, which increases its durability and maintains a presentable appearance for a long time. The important properties of cellular polycarbonate include the fact that it can be used as an excellent protective agent against exposure to ultraviolet radiation. The resistance of this material to high temperatures is so great that it can be used in regions with any climate. And thanks to the special structure and shape of the sheets, polycarbonate becomes an excellent heat and sound insulation, as well as moisture-proof material.

This is interesting: How to cut polycarbonate at home: explaining the essence

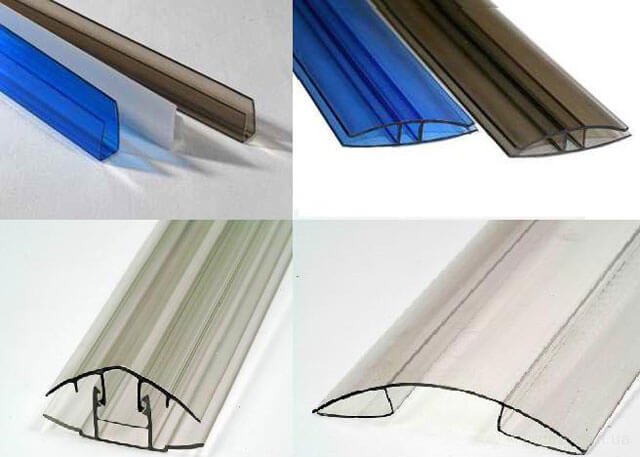

Linear profiles of split and one-piece type

Docking of polycarbonate sheets is carried out by linear profiles, which are divided into split and one-piece. When working with a non-detachable profile, polycarbonate is inserted into the grooves, after which the through fastening of the fastening system and panels is carried out with self-tapping screws. It is desirable that self-tapping screws equipped with special gaskets or thermal and moisture-proof washers are used.

The process of how to connect polycarbonate sheets to each other using split-type profiles is more complicated. Before joining the polycarbonate on the canopy, the base of the profile joint is fixed to the even wooden slats using screws. After that, the prepared polycarbonate panels are placed in special recesses, and then both halves of the profile are fastened together. A polycarbonate lock serves for these purposes. After all the manipulations, the bases of the profile fastening can be unscrewed from the strip, since the connection is complete. To give the polycarbonate canopy a finished look, a special outer profile is used.

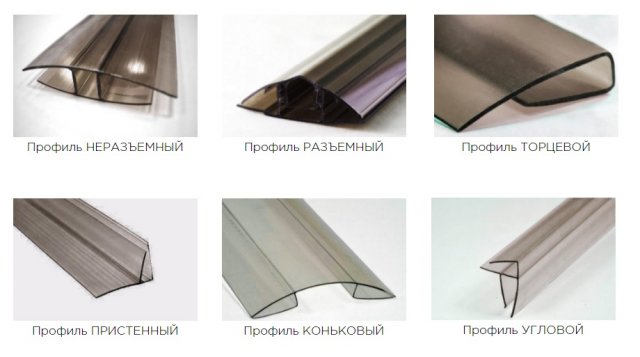

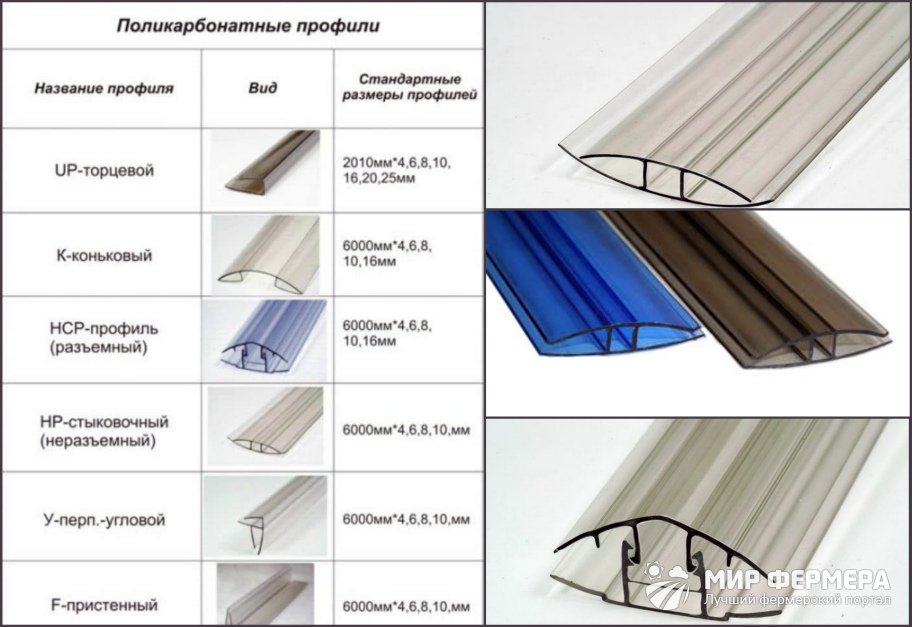

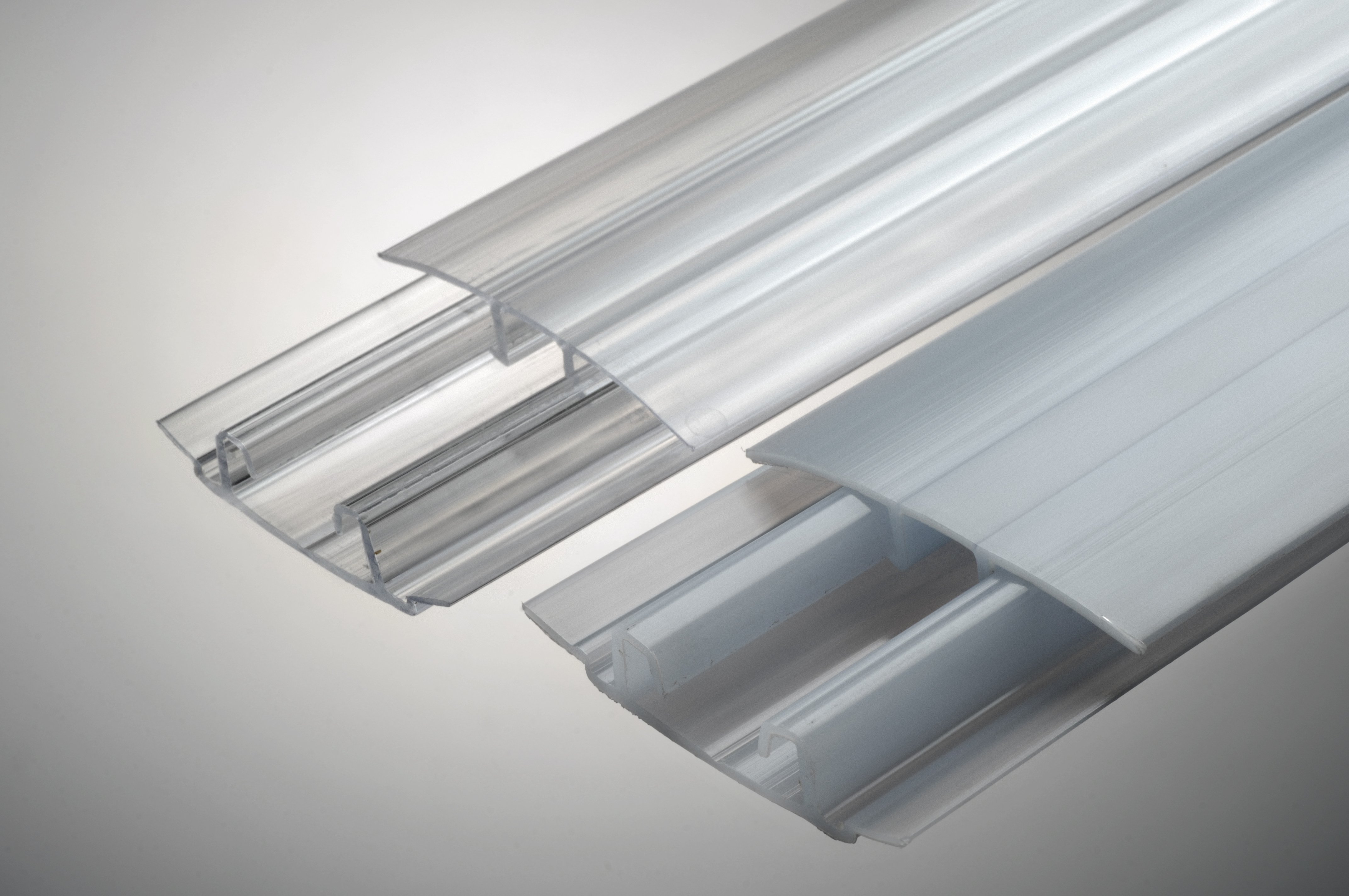

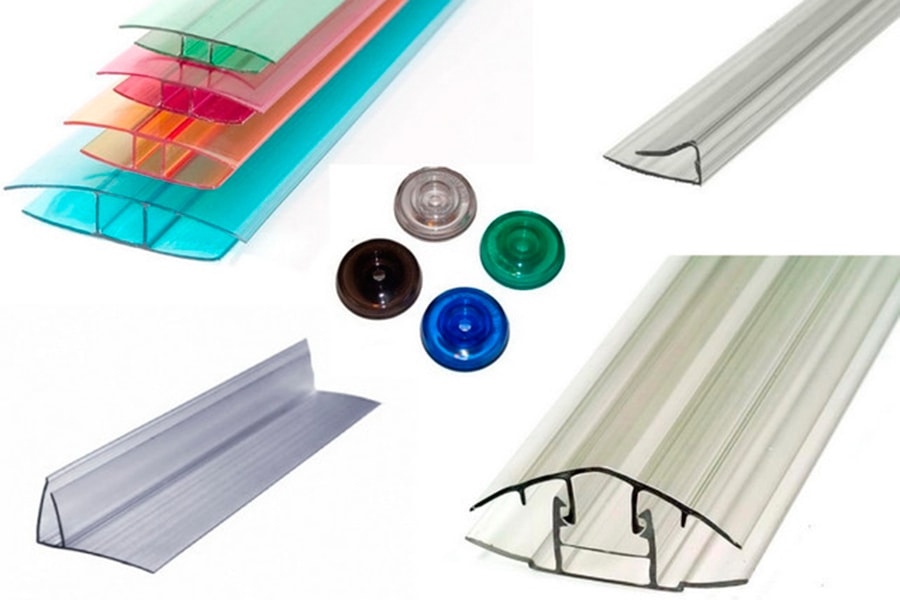

Classification of connecting profiles

There are the following types of profiles for polycarbonate, which are classified depending on the configuration:

- One-piece;

- Detachable;

- End.

Considering the classification in more detail, the following types of profiles can be distinguished:

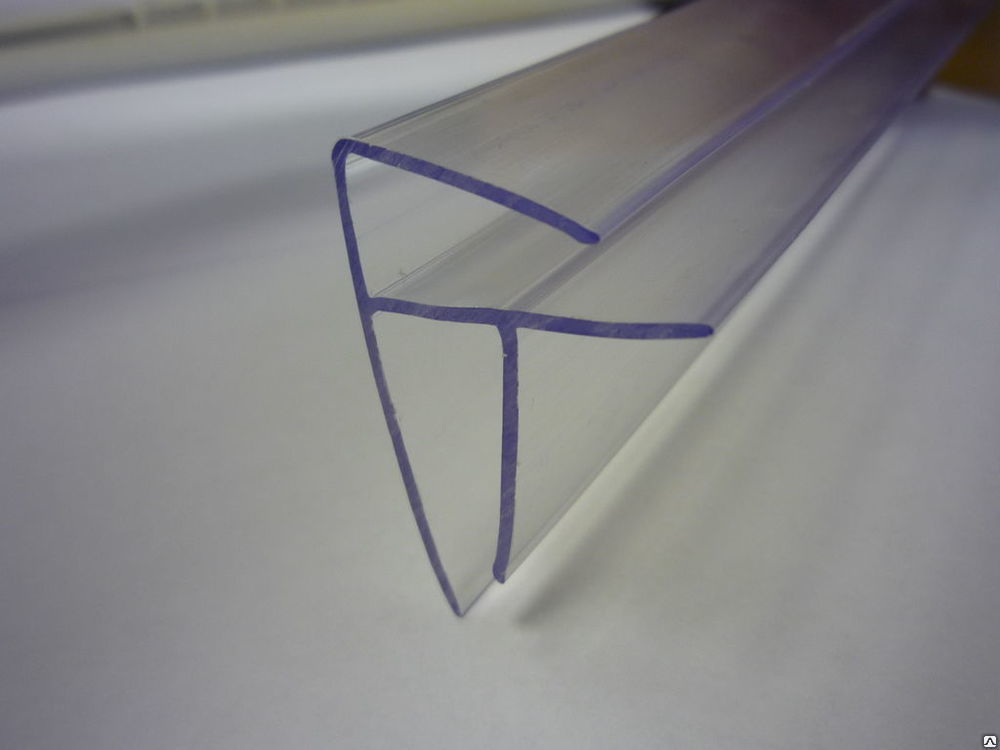

- Connecting one-piece profiles (HP) are produced in one piece, so they must be selected so that the color matches the base material;

- Connecting detachable profiles (НСР) consist of a cover and a base;

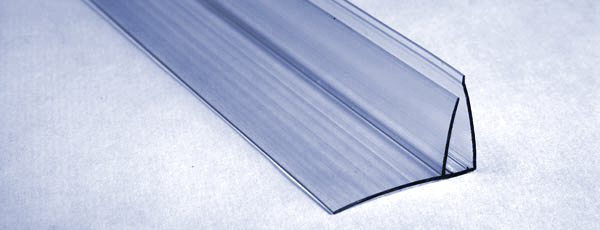

- End profiles are used to cover the end parts of the structure;

- Ridge connecting profiles are necessary to create a floating fastening of arched structures;

- Solid corner profiles are used to join two sheets at right angles (the configuration of these profiles allows you to combine sheets of different thicknesses);

- Wall connection profiles allow you to fix polycarbonate sheets to the wall and protect the ends directed towards the wall.

Profile for connecting polycarbonate, in addition to thermoplastic, can also be made of aluminum. The result is one of the highest quality joint systems with many advantages.

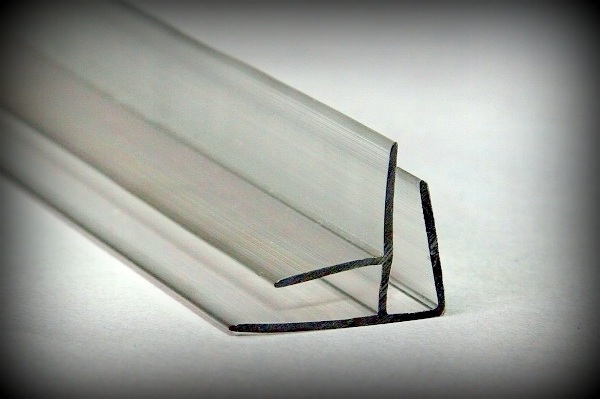

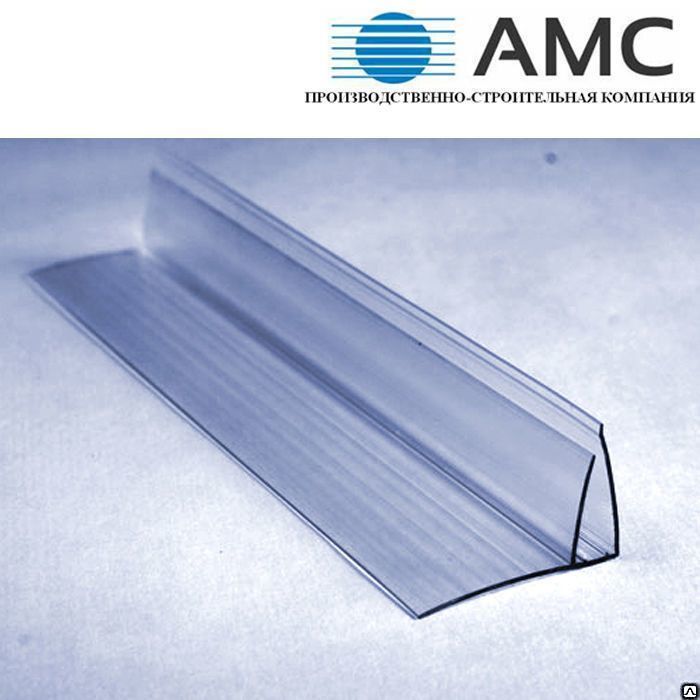

Using end profiles

For sheet caps, polycarbonate end profiles of two types are used - L-shaped and F-shaped. The first option visually resembles guides for plastic sheets. This kind of connecting profile is used exclusively for cellular thermoplastic, preventing moisture and dirt from entering the pores of the panels. The second option also resembles guides of the corresponding shape.

The scope of application of the plugs is determined by the individual design features:

- For the assembly of greenhouses, L-shaped plugs are most often used, which allow protecting the edges of the sheets buried in the ground;

- When arranging roofs, you can use any type of plugs, selecting it depending on specific tasks.

The role of plugs in maintaining the integrity of the structure is very important if honeycomb sheets are used to create it. The moisture that gets into the inner cavity of the honeycomb sheets begins to turn into steam over time, due to which the transparency of the polycarbonate is significantly reduced. If you do not close the polycarbonate profile with plugs, then in the future it will be almost impossible to remove water from the internal cavities of the sheets. In addition, it is desirable to seal such profiles hermetically using a micropore film.