The foundation for a house made of foam blocks

The foundation is the foundation of the entire building and its design must be based on accurate calculations. Mistakes in the construction of the foundation can cause the destruction of the entire building, which will be irreversible. If the roof can be re-assembled, then the base of the house cannot be remodeled.

And therefore, the construction of a house from an aerated block should begin with an important stage of calculations and design of the foundation.

Aerated concrete is a light material and does not require a good reason. One aerated block wall weighs 2-3 times less than a brick. At the same time, the base must be reliable, since aerated concrete is very fragile and the slightest shrinkage of the base can cause cracks in the walls.

Choosing the type of foundation

The main criteria and factors that are taken into account when choosing the type of foundation for a house made of aerated concrete with their own hands: the total mass of the building, the load from wind and snow, the level of groundwater, the bearing capacity and composition of the soil, the presence / absence of a basement, climatic features, the relief of the entire territory, surrounding buildings and their location in relation to the future home.

For a house made of aerated concrete, choose the following types of base: tape, pile, slab. According to the method of installation, the foundation can be monolithic or prefabricated. Pile types are with a buried, ground, hanging grillage. The strip foundation can be made in the form of a beam, which is laid below / above the level of seasonal soil freezing. A monolithic slab also involves laying the sole at different depths.

Soil studies must be performed before starting the construction of a house from aerated concrete with your own hands or by a developer. The soil can vary greatly not only by region, but even within the same territory.

The type of foundation is chosen, taking into account the characteristics of the soil and it is better that all calculations are performed by a professional. It is quite difficult to calculate everything on your own.

When you can choose the type of base yourself:

- On the territory, a dense homogeneous soil was noted, which is determined by the excavation of pits in the corners of the future building to a depth greater than the depth of the foundation by 50 centimeters.

- If the soil water level is low - from 3 meters.

- When marshy plants are not seen around - if there are any, situations of interstratal water release or flooding are possible.

- In the presence of a flat construction site, excluding height differences.

- When there is an opportunity to equip drainage, designed to effectively drain melt / rainwater.

- If there are no cracks in the neighboring buildings and houses, subsidence of the base.

In all other cases, before building a house from aerated concrete, geological surveys must be carried out, all the characteristics of the soil are determined, and various options for creating a foundation are considered. It is better to leave the execution of the task to the design organization or to an individual specialist.

Shallow tape foundation

This type of foundation demonstrates optimal load-bearing capacity in order to absorb the load from the roof and other elements. A shallow foundation is not afraid of frost heaving, relatively inexpensive, easy to install.

How to build a shallow foundation:

- Marking the boundaries of the future foundation using pegs and cords, checking the geometry with a tape measure and optical instruments.

- Installation of strips at the corners and at the intersections of walls made of 2 posts and a board nailed between them. Here the position of the axes of the structure is noted.

- Digging a trench up to 70-100 centimeters deep with preliminary removal of a fertile soil layer up to 30 centimeters thick.Backfilling of crushed stone and sand cushions to the bottom of the trench, the layer should be with a total height of 30-50 centimeters. Next, layer-by-layer compaction is performed.

- Installation of removable formwork made of wooden panels, or assembly of a permanent structure made of expanded polystyrene. The structure should rise above the ground by a maximum of 30 centimeters, the optimal strip width is 30-40 centimeters. A layer of waterproofing is laid inside with an overlap on the formwork.

- Assembly of the reinforcing cage from rods with a cross section of 12 millimeters in the amount of 4-6 pieces. Fastening a sleeve from pipe scraps, where communications will be laid.

- Pouring the formwork with at least M200 concrete, high-quality layer-by-layer compaction with a mechanical or hand tool.

- Dismantling of the formwork after concrete curing - after 28 days.

With the laying of the foundation, it is advisable to arrange in parallel drainage, which will protect the house from the influence of moisture

It is important to perform heat / waterproofing work, to mount a temporary blind area. All this will prevent the foundation from collapsing under the influence of heaving.

The foundation for a house made of foam blocks

The foundation is the basis of the entire structure. The mistakes that were made during its construction are then difficult or almost impossible to correct. Aerated concrete is a fairly light material. The wall from it weighs 2-3 times less than from brick or expanded clay concrete. But the foundation for the house must be laid in accordance with all the rules of building science.

Choosing the type of foundation

The main criteria when choosing the type of foundation for a private house:

- building weight;

- load from snow and wind;

- composition and bearing capacity of the soil;

- soil water level;

- the presence of a basement;

- climatic zone;

- site relief;

- surrounding buildings.

The bases for the construction of a private house differ in design. Basic types:

- pile;

- tape;

- slab.

According to the method of installation, they can be prefabricated or monolithic. In turn, pile foundations are performed with a hanging, ground or buried grillage. Belt - in the form of a beam, laid below or above the level of seasonal soil freezing. The bottom of the slab can also lie at different depths.

Soil conditions can be different not only in different areas, but also within the same site. Optimally, if the type of foundation is provided house construction project taking into account all factors.

The developer can make an independent decision in the case of:

- On the site there are dense homogeneous soils. This is found out when digging pits in the corners of the proposed structure with a depth exceeding the foundation by 30-50 cm.

- Low - from 3 m - groundwater level.

- Moisture-loving marsh plants do not grow around. Their presence indicates possible flooding or the release of interstratal waters.

- The construction site was chosen flat, without elevation differences.

- There is a possibility of a drainage device for the removal of rain and melt water.

- In neighboring houses and outbuildings, cracks, subsidence of foundations are not found.

In other cases, before starting construction, it is necessary to carry out engineering surveys, during which the characteristics of the soil are determined. The final decision is made after considering possible options for the construction of foundations. It is better to do this together with the design organization.

Shallow tape foundation

The shallow strip foundation - abbreviated as MZLF - has sufficient bearing capacity to take the load from aerated concrete walls, is not afraid of frost heaving forces, is not expensive and is easy to install. This is one of the most common types of foundations when building a house from gas silicate blocks.

The sequence of work with the device MZLF:

- They mark out the contours of the future foundation with pegs with a cord, control the geometry with optical instruments or a tape measure.

- In the corners and intersections of the walls, castoffs of two posts and boards nailed between them are installed.The position of the axes of the building is marked on it.

- A pit is dug with a depth of 70-100 cm, after removing and removing a layer of fertile soil 30 cm thick.

- Crushed stone and sand with a total height of 30-50 cm are poured into the bottom of the trench, tamped in layers.

- Install removable formwork made of wooden panels or fixed formwork made of expanded polystyrene. The width of the strip should be 30-40 cm, the top of the structure should be at least 30 cm above the ground.

- A waterproofing material is placed inside with an overlap on the surface of the formwork.

- Reinforcement cages are mounted from rods with a diameter of 12 mm. Depending on the load, the number varies from 4 to 6.

- Install sleeves from pipe scraps for laying communications.

- Concrete of a grade not lower than M 200 is poured, layer by layer compacted with manual or mechanical rammers.

- After gaining strength, after 28 days, the removable formwork is dismantled.

What you need to know before building

What to do before building a house

What to do before building a house

If this is your first time building your house, you need to know that the first thing to do is to do the paperwork. After all, no one will give you just to build a house on the site. First, you need to obtain a building permit in order for it to be approved by the authorities in your area. Therefore, you need to prepare the necessary documents, including a plan for future construction.

Not everyone can make drawings at home, because this requires special education. Therefore, you can turn to specialists who, for a certain amount, will be able to transfer your dream house to paper. Another option is to surf the Internet in search of a home project. In this case, be careful, because you do not know who made them and if they were right.

Such a plan must necessarily have:

- foundation;

- floors with cuts;

- roof truss structure and calculation of the roof surface;

- door and window openings.

Another important point before starting construction is to purchase material. To avoid additional financial costs, you need to buy as many blocks as you need. But how to calculate gas blocks for a house so as to avoid a shortage and excess of material? Here you need to take into account the size of the house itself and the aerated concrete blocks. The first step is to find out the area of the walls.

All dimensions must be indicated in the house plan. For example, one wall is 12 m long and the other 10 m. There will be two such walls. All of them need to be added:

12 + 12 + 10 + 10 = 44 m

It turns out that along the perimeter we have a length of 44 m. But, the house also has a height, so it must be multiplied by the perimeter. Suppose the height of the house is 4 m.Then it turns out:

44 × 4 = 176 m2

In total, the area of the walls of your house is 176 m2. Based on this data, you need to calculate the number of blocks that are sold in cubic meters. To do this, the thickness of the block (0.3) must be multiplied by the area:

176 × 0.3 = 52.8 m3

So, to lay out the outer box of the house, you will need 53 m3 of gas blocks. For interior walls, the calculation is the same. Please note that it is undesirable to take close to the material, it is better to throw 10% on top so that you have enough blocks during construction.

It is imperative to store aerated concrete in a dry place where it does not pick up moisture. Cover it under a canopy to avoid atmospheric precipitation

It is important to provide a level surface for stacking the blocks. Then the material will be stored correctly without losing its qualities.

Foundations. Why do walls crack in spring?

The light weight of a gas block house can help save on the width of the foundations, but that's all! The deepening of the foundation, its reinforcement must be carried out in accordance with all the rules.

The most common problem associated with foundations is the appearance of cracks in the walls after the first winter. You can often come across the misconception that cracks appear due to the low weight of the blocks, as a result of which the house "floats", as it were. Even more erroneous is the recommendation to be sure to pour a foundation slab under such houses.In conditions of frost heaving, the heaving forces will be the greater, the larger the contact area of the soil with the underground part of the building. With a significant rise in the level of groundwater, the Archimedean force will be proportional to the volume of the part of the building immersed in the ground. In both cases, a slab foundation will do nothing.

The main nuance of building a foundation for building a house from an aerated block is its insulation. A properly reinforced, sufficiently deep foundation is not a guarantee of the absence of cracks in the walls after the very first winter. Especially with a basement.

Let's consider a real case with a specific example.

The cracks in the corner of the building are not high from the floor.

Cracks in the corner of the building at the level of the first floor ceiling.

The crack in the corner of the building is the middle of the floor.

The walls were built from high quality aerated concrete blocks. The foundation is tape, reinforced. There is a basement. Before the onset of cold weather, the house was covered with a roof, windows and doors were installed.

Factors influencing the appearance of cracks

The reasons for the appearance of cracks were:

- The construction was carried out on frosty soils. Despite the sufficient depth of the foundations (below the freezing depth), due to the lack of heating through the basement, the house froze through and through. The outer contour, obviously, froze through at a different speed than the inner space. As a result, the uneven heaving created dangerous internal stresses in the walls.

- Reinforcement was not provided in the gas-block masonry.

- A monolithic belt for overlapping with reinforced concrete slabs does not encircle the building around the perimeter. Monolithic reinforced concrete is poured only in the places where the slabs are supported, which is why it does not perform the function of a belt.

As you can see from the above list of factors, it is highly undesirable to leave a newly built house for the winter without insulation or heating. The boundary depth of soil freezing is due to the presence of molten magma in the center of the globe. The upper (freezing) layer of the soil is a kind of jacket, deeper than which the cold cannot penetrate due to the presence of heat in the center of the planet. Sampling of soil under the basement opens the way for freezing to an even greater depth.

The method for solving this problem is obvious - if the building is not put into operation before the onset of cold weather, the foundation (especially its basement part) must be carefully insulated

This is critical for heaving soils. Insulation can be done by backfilling with expanded clay gravel or blast-furnace slag, spreading mineral wool mats or straw, etc.

It is highly undesirable to backfill the pit sinuses (trenches) with ordinary soil. Preference should be given not only to non-heaving materials, but also to warmer ones.

Perlite sand is ideal. In the absence of an opportunity to purchase it, you can limit yourself to the usual. In this case, the negative heaving effect on the underground part of the basement walls will be completely excluded.

The appearance of cracks not in winter, at the height of frosts, but in spring, is associated with a sufficiently high stability of the soil in a frozen state. During thawing, the soil is reconsolidated, forming shrinkage. The result of these processes is shown in the above photos.

Construction technology

Construction from aerated concrete blocks

Construction from aerated concrete blocks

The technology of building houses from aerated concrete blocks began to be used in Europe, from where it came to us. For many years, aerated concrete has been a popular material that has proven itself well due to its properties. For many decades, such houses have been in most of the countries of Canada, Asia and Europe.

Many people with no construction experience know the technological procedure for performing work in general terms. Let's take a closer look at what needs to be done to build a building:

Arrangement of the foundation.Due to the fact that aerated concrete is a relatively light material, it is not necessary to make a reinforced foundation, it all depends on the number of storeys, the location of groundwater and the type of soil at the construction site. Basically, a strip or monolithic foundation is chosen from a gas block for a house. Work on its device can last 3 weeks or more.

Please note that the porosity of the material promotes increased water absorption, therefore, it is imperative to carry out waterproofing work, paying special attention to them.

Wall masonry. It is much easier to erect walls from a gas block than from brick

Since the blocks are large and even, it can be done very quickly. The main thing is to choose masonry and strictly adhere to the scheme.

If the house will have two or more floors, it is important to strengthen the walls, making the structure reliable and durable. For this, reinforced belts are used, then the perimeter of the house will be additionally strengthened.

To lay the walls, use a solution or special glue, which is applied with a special tool or a comb-type spatula

Thanks to it, you can achieve an even technological millimeter layer. To level the blocks, a rubber hammer is used, which is tapped on top of the block. This will not damage the block and will ensure an even masonry. It should be noted that the walls of the aerated block after construction practically do not shrink. It turns out that finishing work can be done immediately, due to which the construction juice will significantly decrease.

Overlapping a house is an important part of building. For an aerated concrete house, they can be monolithic, made of wood, concrete slabs, or combined.

Another important step is the construction of the roof. You immediately need to calculate the roof surface, purchase the material and make the roof truss system, as well as sheathe it with roofing material.

Glazing of finished box windows. A double-glazed window should be chosen to provide sound and thermal insulation.

After that, you need to carry out interior decoration: lay engineering communications, such as sewerage, water supply, heating, electricity, equip the base of the floor, erect internal partitions, prepare the surface of the walls for finishing and complete it.

Final finishing of the facade. At this stage, the overhangs of the eaves to the roof are sutured, and a water drainage system is installed. Well, the walls are being finished directly. Thanks to it, you can achieve the following goals: to level the surface, hiding irregularities, to protect the material from mechanical damage and moisture ingress, to give the house a beautiful aesthetic appearance.

The last stage is landscape design. You can decorate the site, plant trees, build a fence, and make decor.

So, theoretically you are already prepared, you can move on to practice to learn how to build a house with your own hands.

Advantages and disadvantages of the material

Projects of houses from gas blocks are presented in the network and design and architectural bureaus in a large number and it will not be difficult to find something suitable. But first, it is worth studying the features of the material itself, which, along with a lot of pluses, has some minuses. To eliminate their negative impact on the operation of the house and take into account all the nuances, you will have to think about certain activities.

The main advantages of blocks:

- Heat retention - the house does not need to be additionally insulated, and during operation, you can save up to 40% on heating costs due to the high characteristics of the blocks themselves and thin seams (no cold bridges).

- The possibility of building a cottage in cold areas - they are frost-resistant.

- Safety - the blocks practically do not burn, do not emit toxins and harmful substances into the air, as they are made from environmentally friendly components.

- The foundation for a building may not be very strong (also a cost saving item), since the structure is lightweight.

- Installation - cheap and quick due to the low weight of geometrically ideal blocks, the walls are laid in the shortest possible time, there is no need to attract special equipment, even one person can build.

- Material processing is easy - aerated concrete is well cut, sawn, drilled, so the project of a country house can be of any shape, configuration, complexity of implementation.

- Low material cost - along with many advantages, aerated concrete is much cheaper than brick and wood.

- The ideal geometry of the blocks, exact dimensions - these factors greatly facilitate the process of calculations and design, installation of walls, and reduce the cost of interior and exterior decoration.

- High level of strength - especially when it comes to autoclaved aerated concrete, from which 1-2-storey houses and cottages can be erected.

- Vapor permeability - will "breathe", the room will create an optimal microclimate.

One aerated concrete block can replace 12-15 standard-sized bricks, while it weighs up to 25 kilograms (the exact weight depends on the density and grade of the material), which simplifies the construction of a house at all stages - from loading / unloading material to finishing.

Disadvantages of the gas block, which must be taken into account in the calculations and design:

- High water absorption is around 85%, which is a lot. The structure of the material is such that it easily and quickly absorbs water, then accumulates it and breaks down. Therefore, even at the planning stage, it is necessary to choose vapor-permeable, but reliably moisture-proof materials for interior / exterior decoration.

- Unaesthetic appearance - here we are also talking about finishing, since without it, in their natural form, gas-block houses look ugly. If a brick or wood from the outside can be left in its original form, then aerated concrete cannot.

- Brittleness - the possibility of cracking under bending load. Therefore, it is possible to build a house only on a foundation reinforced with reinforcement, which has stood and will definitely not shrink.

Formwork and reinforcement laying

Formwork device

Formwork device

Shields need to be assembled from boards, plywood or other wooden materials. You can connect the elements together with self-tapping screws or nails. If you live in areas with a harsh climate, raise the formwork 40-50 cm above the ground level so that the walls under the snow do not freeze through. And when the climate is not so harsh, the base can be made up to 30 cm. Then pull the line around the perimeter so that it corresponds to the level of concrete pouring into the foundation.

This stage includes not only the formwork device, but also the necessary communications. After all, if you do not do this in advance, holes for the sewer or water supply will need to be made in the finished foundation.

To strengthen the foundation, you need to place a reinforcing mesh in it. It will be placed in the formwork. To make such a frame, you will need Ø14 mm reinforcement rods and flexible steel wire. The rods need to be tied into a mesh with wire. When making cells, it is not necessary to adhere to certain sizes. On average, these are cells 20 × 20 cm in size equal to the size of the trench.

Now everything is ready for pouring concrete.

Recommendations for the purchase of finishing materials

In order for the interior decoration of aerated concrete walls to be beautiful and aesthetic, of high quality and durable, it is necessary to choose the right finishing materials. It is quite easy to decide on the type of finish - the choice is huge, each type of finish has its own advantages and disadvantages, which must first be studied.

The main task is to find materials that will ideally interact with aerated concrete, improving and preserving the advantages of the material and minimizing the effect of its disadvantages on the comfort in the operation of the building.It is not worth saving on materials, since the result will depend on their quality.

Even if the optimal type of finishing is selected and all work is performed correctly, due to the low quality of materials, all efforts can be reduced to zero - the finishing will not last long and will not fulfill its functions.

It is better to purchase materials only from trusted suppliers who have all the documents and give a guarantee for the goods. All goods must exactly correspond to the task at hand, meet the necessary requirements and have certain characteristics. Also, masters recommend giving preference to one manufacturer when choosing several items to be sure that the components of the funds do not react and do not lead to surprises.

Application area

Due to inexpensive production and excellent characteristics, there are more and more companies on the aerated concrete market - many companies offer high-quality material that is in consistently high demand. The area of application of aerated concrete is quite extensive - it is used for housing objects of various types, commercial and industrial buildings, and various structures.

Scopes of aerated concrete:

- Wall masonry - standard blocks are used in the construction of load-bearing walls in buildings up to 3 floors, as well as for the construction of internal partitions in construction sites of any height. Wall blocks are made in different sizes, with special protrusions and depressions that create a thermal lock.

- - projects of small-storey residential and industrial buildings are being implemented, which are not expected to be exposed to too high a load.

- Fences - in household plots, they are often built from aerated concrete, with the obligatory arrangement of a concrete foundation (it is forbidden to put blocks directly on the ground).

- Construction of a bath - aerated concrete blocks are simply ideal for these purposes due to the minimum combustibility and maximum heat saving.

- Creation of monolithic structures - the material is poured into the formwork for the implementation of certain tasks.

- Thermal insulation - often aerated concrete is used for insulation, choosing minimally dense blocks (they are not very strong) of a low grade.

Interior decoration

A gas-block house requires high-quality interior decoration. Fortunately, today in the stores of building and finishing materials there are a lot of reliable and durable decorative coatings that can be applied to the gas block without causing any harm to it. Finishing materials must necessarily comply with the requirements specified in GOST and SNiP.

To decorate the ceiling in such a block house, you can use the following methods:

- cover the base with plaster, and then paint or install sheets of plasterboard;

- using drywall to build various multi-level structures with built-in lamps.

Plasterboard is attached to the ceiling base on a pre-prepared frame. Plastering in this case is not required, but insulation can be provided.

As for the walls, here, before applying the topcoat, you first need to make a high-quality leveling. It is imperative that the wall ceilings be covered with a primer and a reinforcing mesh should be laid. This is due to the fact that the adhesion characteristics of aerated concrete will not allow the finishing materials to be firmly connected together without unnecessary impact.

Prepared wall surfaces can be painted, wallpapered or finished with decorative plaster. It is permissible to cover some areas with a spectacular decorative stone or other similar material.

You can focus on corners, window openings, or highlight certain functional areas

Materials such as laminate, parquet or linoleum are most often laid on the floor.In the kitchen, in the bathroom and in the hallway, porcelain stoneware or ceramic tiles are mainly installed. Before laying decorative flooring materials, wooden logs are first installed. After that, the floor is insulated and covered with a board.

If you want to diversify the interior a little, then you can turn to the beautiful arched structures. Most often they are made from plasterboard sheets. This material can be processed without problems, therefore it is used inside a wide variety of premises. With the help of drywall, you can place a structure of almost any shape and configuration in your home.

The dignity of the gas block

Advantages of the gas block

Advantages of the gas block

Aerated concrete is an excellent alternative to brick, as it is distinguished by its good thermal insulation properties, reliability, strength and durability. This material has already won the respect of most builders and developers, as it has many advantages. What are they?

It is for these characteristics that gas blocks are gaining more and more popularity:

- Aerated concrete has a low thermal conductivity, so buildings made of it have much better thermophysical characteristics than houses made of brick, concrete or wood.

- The porous structure of aerated concrete endows the walls with high air and vapor permeability. Houses built from gas blocks have constant regulation of air humidity and circulation of air exchange, due to which a good microclimate is created, the same as in natural wooden houses.

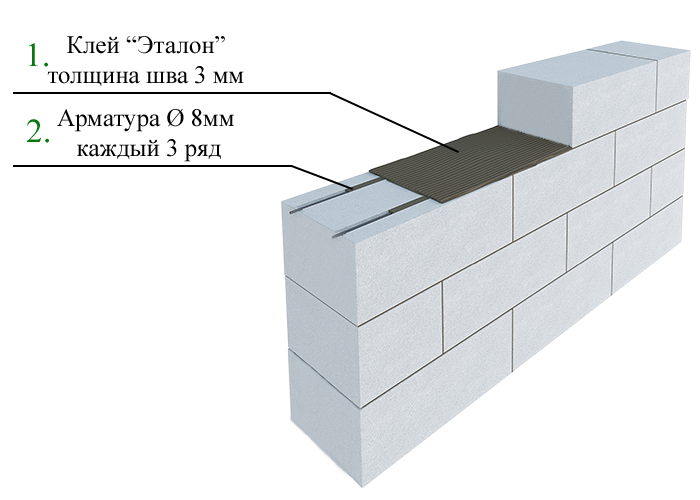

- Aerated blocks are made to exact dimensions with minimal tolerances and a smooth surface, therefore, when laying walls, you can use special glue, which will speed up the construction process and prevent the formation of cold bridges during operation. Also, the process is accelerated due to the large block sizes.

- Aerated concrete is a fire-resistant and ecological material.

- The material has a porous structure, due to which the weight of the blocks and, accordingly, the load on the foundation is not the same as that of other building materials. This allows you to reduce the cost of installing the foundation.

- Due to its high strength, aerated concrete does not break, does not crumble and retains its original appearance.

- According to many experts, aerated concrete building can serve for more than 30 years.

- Aerated concrete has a high absorbent surface, which allows it to adhere well to plaster and other materials.

Such advantages allow you to use the material to build your own home.