How to use?

It is necessary to use a tight-fitting fastener only for its intended purpose and if such a fastener is necessary. The first step is to choose the right fasteners, taking into account:

- its technical parameters and main characteristics;

- the amount of load that the product will withstand;

- manufacturer and cost.

And the presence of marking is also important. This is brief but complete information about the product.

Its presence indicates that the fasteners were made in accordance with the requirements, passed all laboratory tests, after which they received a quality certificate.

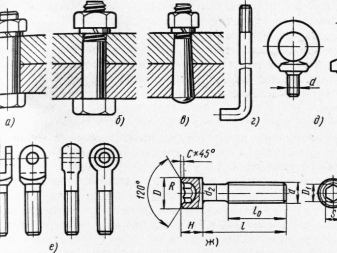

Mounting the bolt is quite simple and does not take much time. The base of the bolt is simply placed in the hole that was designed with a screwdriver, and then, using a special wrench or tool (it depends on the type of bolt), it is screwed, connecting the structural parts.

How to make a tight-fitting bolt with your own hands, see below.

Fitting bolt

Fitting bolt has the same function as the pin, but also serves as a fastener.

Fitting bolts made of steel 35, swing bolts: - of steel st. Round nuts are made of st.

|

Power locating pins. |

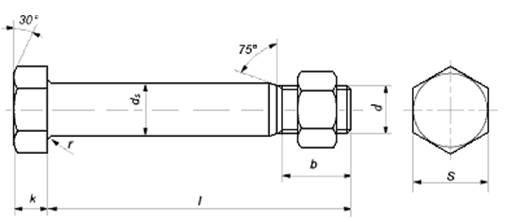

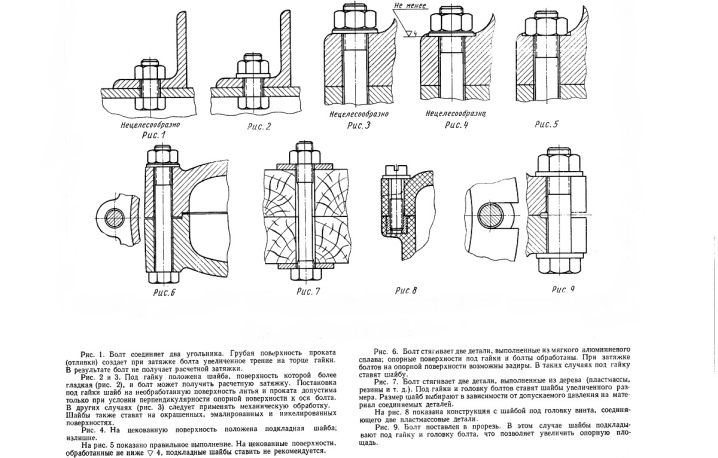

Cylindrical fit bolts (Fig. 168, /, II) allow to tighten the parts to be joined. This compares favorably with power locating pins.

|

Power locating pins | Methods for fixing power locating pins. |

Cylindrical fit bolts (fig. 168 7 77) allow to tie the parts to be joined. This compares favorably with power locating pins.

|

Connection of the inner ring of the turbojet compressor guide vanes. |

Usage fit bolts for centering parts to be pulled together avoids additional alignment measures. To do this, it is necessary to technologically ensure the centering of the parts during the machining of the bolt holes. So, for example, when drilling and reaming holes for tight-fitting bolts, the discs of a drum-type compressor are based in conductors along specially made central holes or protrusions. During disassembly and subsequent assemblies, the alignment will be strictly guaranteed by the prize bolts.

Loads on tight bolts it is possible to accurately determine when they are caused by centrifugal forces: in compound rotors, in couplings, in bolted structures of marine gearboxes.

|

Flange shapes. |

Holes for tight bolts are processed jointly or along the jig with subsequent joint deployment for landing T or I. To ensure the assembly of the flanges in the position at which the joint processing was carried out, control pins are installed or one of the holes is positioned at an angle that differs from the angle of the other holes.

|

The disc of the last stage of the axial compressor 2 is mounted on the cylindrical shank of the rear trunnion 4 and is tightened with a nut 1. The protrusions on the disc, entering the grooves of the flange of the rear trunnion, provide centering when a significant gap appears along the main seating surface. The torque from the rear pivot flange to the disk is transmitted through six shaped protrusions 3 evenly spaced around the circumference, one of the side planes of which is located strictly radially, and six grooves with parallel side planes on the rear pivot flange. Simultaneous adherence of parts on six contact surfaces T is monitored by paint. | The torque from the rear trunnion 4 of the axial compressor to the drum 1 is transmitted by means of four rectangular keys 3, fixed to the drum disk by pins 2. Shoulders on the keys are used to axially fix the trunnions on the drum.The circumferential force from the keys to the drum disk is transmitted through the shear pins b. The trunnion is centered on the drum disk along a cylindrical belt. To prevent centering misalignment, the cylindrical protrusion of the disc, subject to large tensile deformations from centrifugal forces, enters the journal bore. A similar connection is made at node I. |

Holes for tight bolts holes are made according to the system of holes, as a rule, of the second accuracy class and according to the 6-7th class of cleanliness.

|

Straight bolts to tie up several parts | Positioning sleeve. |

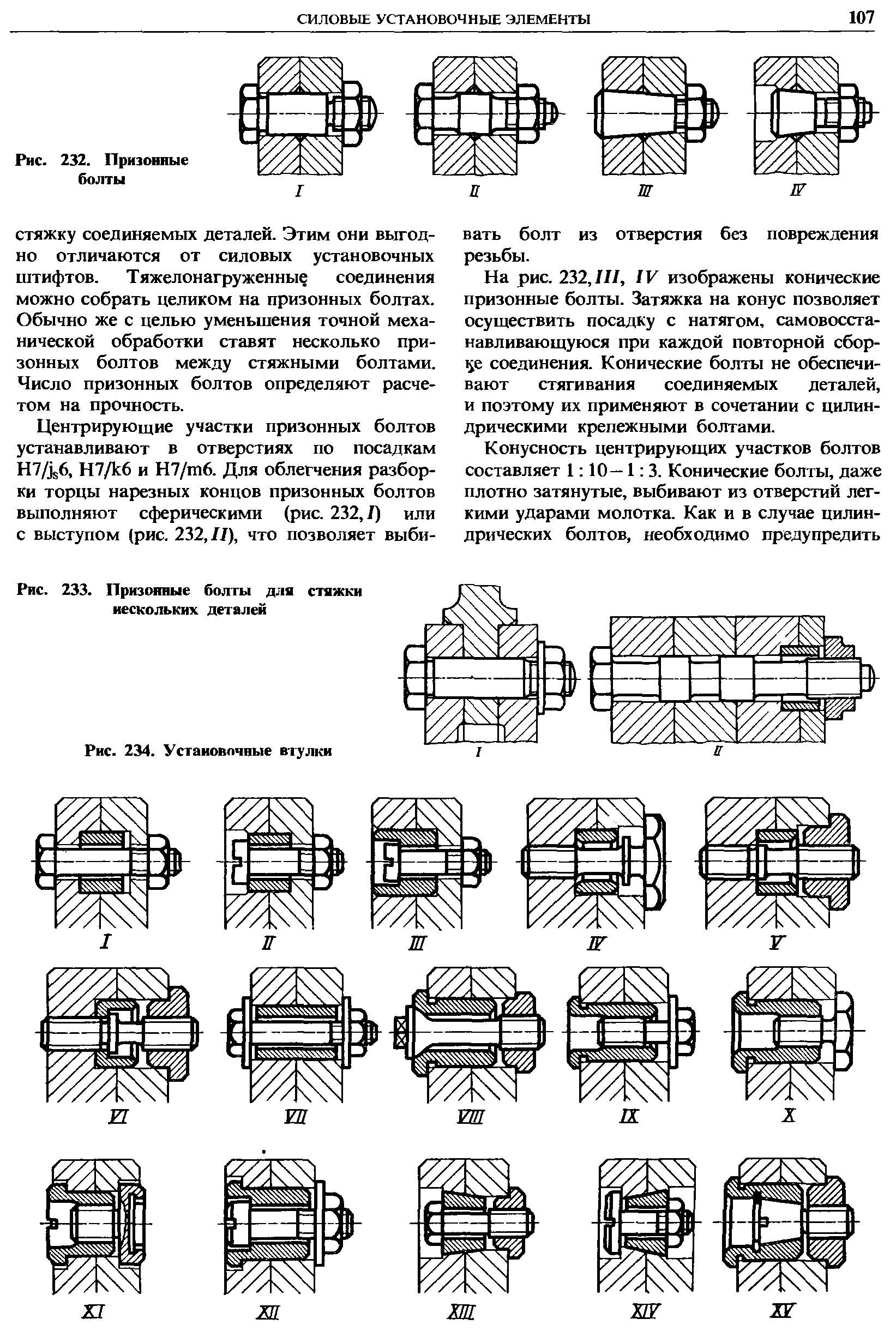

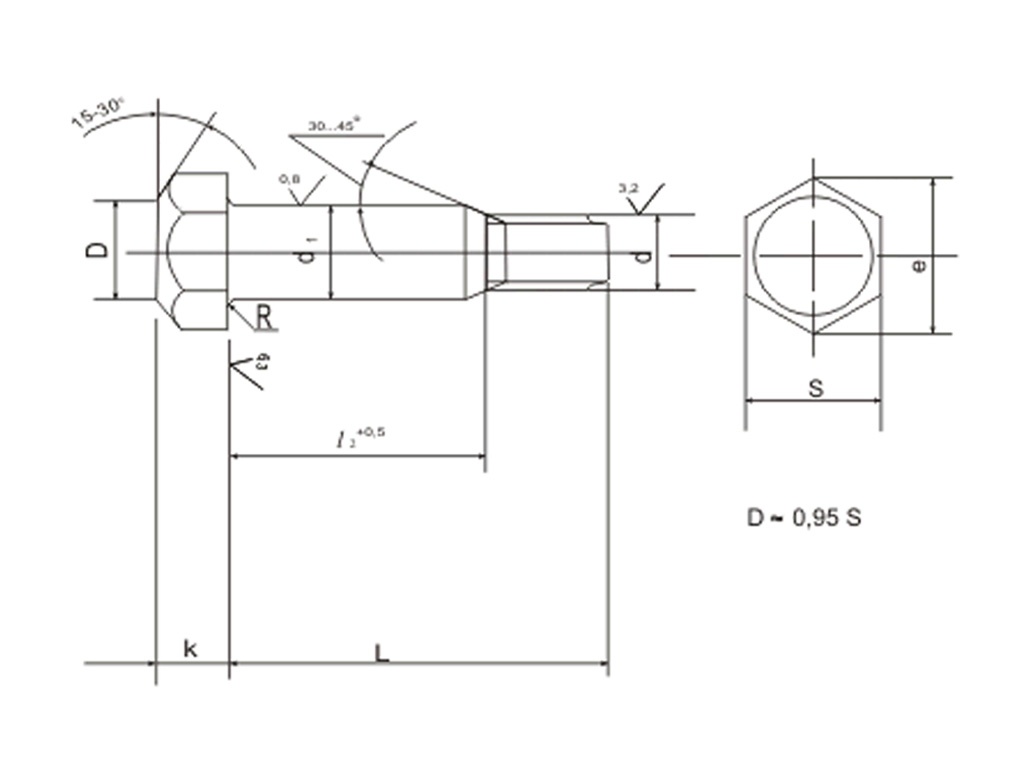

Centering plots fit bolts are installed in the holes on a tight, tense or tight fit. To facilitate disassembly, the ends of the threaded ends of the close-fitting bolts are made spherical (Fig. 168 /) with a protrusion (Fig. 168 1 /), which allows knocking the bolt out of the hole without damaging the thread.

Applications

Despite the fact that the bolt itself is quite compact and its dimensions are small, it is very strong. That is why it has found wide application both in manufacturing industries and in everyday life.

Fasteners are used both in the process of installation work and in construction:

- during the construction of the metal frame of the building;

- for fastening metal trusses, consoles, hinges, flanges, beams;

- in the process of installing facade panels;

- during the construction of the roof, to secure all its individual elements;

- when installing cover and floor panels;

- during the creation of new equipment.

Today, this fastener is widely used in industries such as mechanical engineering, shipbuilding, metallurgy, and the oil industry.

Fitting bolt

To the hub flange of the ChTZ cutter fit bolts a base ring is attached, which has open grooves at the end, into which 20 knives are inserted, slightly pressed against the base surface by wedges and fixed with screws. The knives have different lengths and profile angles, which makes it possible to form so-called cutting sections from two or three knives and thus ensure cutting of the metal of the cavities of the teeth being cut according to a preselected pattern. Thanks to this design, the cutter runs more smoothly, ensures chip width separation and a uniform finishing allowance.

|

Carter. a - upper half. b - lower half. |

Both halves of the crankcase are centered by four fit bolts and fastened with stitching pins.

Fix the half-couplings on the couplings fit bolts, collect the oil line and the nozzle. A probe is used to check the meshing clearances, which must correspond to the drawings. Disconnect the oil lines, the pump housing from the gearbox, unscrew the mounting bolts and tapered pins, and remove the front cover / with oiled paper gasket. Then take out the drive and driven gears. Inspect gears, bushings, cover and casing of the cam-type coupling pump. The support sleeves of the gears must be free from scoring and other damage. The rollers of 10 gears are ground, if necessary, with a sandpaper moistened with oil.

The position of the bearing housings must be fixed fit bolts or planks.

|

Deployment with mechanized special sweeps. |

It is very difficult to deploy precise holes for tight bolts according to the 2nd - 3rd class of accuracy with surface roughness according to the 6th - 7th class, located in a hard-to-reach place. Of interest is the reaming of the holes with special mechanized reamers. In fig. 285, and the design of the sweep itself is given.

In fig. 168 777, IV depicted tapered fit bolts... Tapered tightening allows for a very tight fit, self-healing with every reassembly of the joint.

Fixed connections are most often carried out using fit bolts or pins. The first of them are at the same time a fastening element, the second - only a latch. Both types of prisons perform well their functions; they require almost no manual labor during manufacture and installation.

The body is connected to the cover with studs and two fit boltsinstalled in holes e, and centering the body and cover.

In fig. 168 71 /, IV depicted tapered fit bolts... Tapered tightening allows for a very tight fit, self-healing with every reassembly of the joint.

Secure flywheel attachment is ensured by a sufficient number of fit bolts.

When it is necessary to obtain the exact dimensions of the drilled hole for installation fit bolts or control pins, the holes are reamed with special cylindrical and conical reamers. The reamer in the chuck is fixed with a tapered or cylindrical shank with a square at the end. When manually reaming the holes, a knob is put on the square.

In fig. 169 7, II examples of application are given fit bolts for screeding several parts.

In fig. 169 /, II examples of application are given fit bolts for screeding several parts.

What it is?

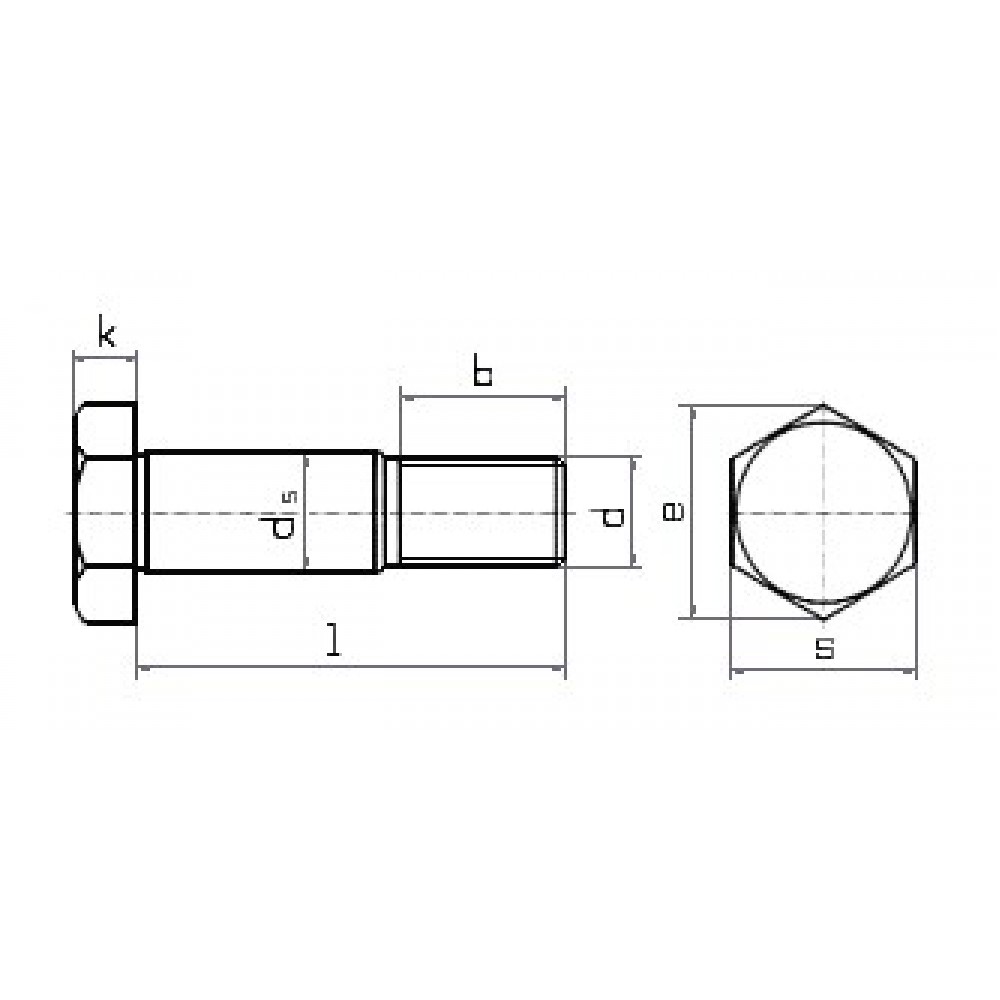

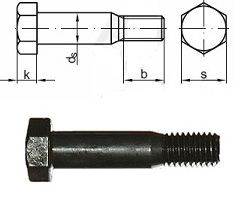

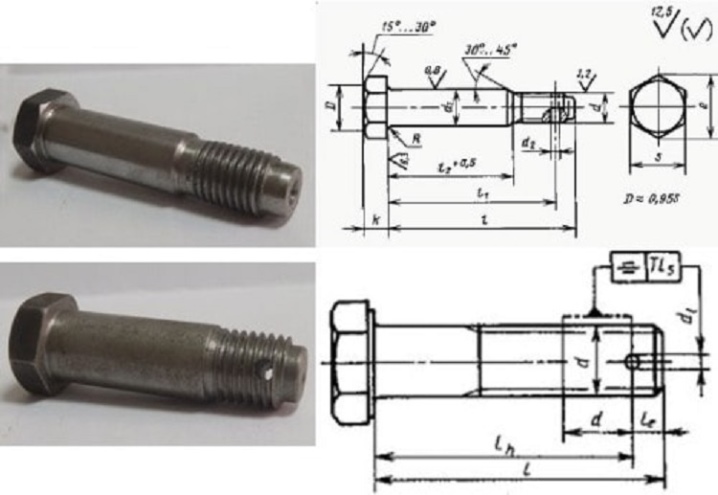

A fitting bolt, or, as it is also called, a precision bolt, is a special fastener that, due to its excellent physical and technical characteristics, creates a very strong and reliable connection between individual structural parts.

The product is widely used. This is due to a number of features and advantages that are inherent in such fasteners.

- For the manufacture of the bolt, only high-quality steel grades 35X, 40X, 45X are used. Its choice depends on the purpose of the product, on what materials it will hold together, what kind of load it will need to withstand.

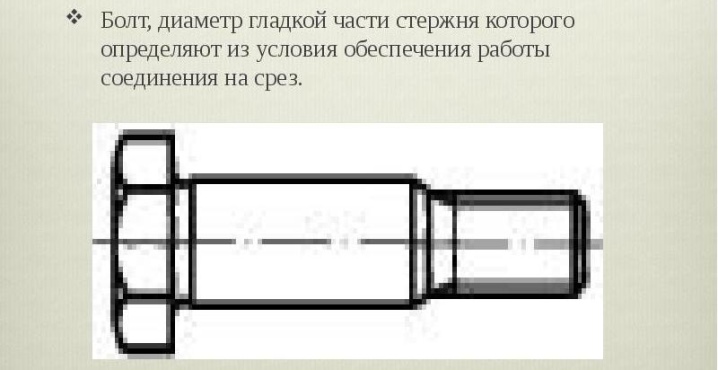

- During the installation process, the fasteners are placed in the hole, thereby creating a gap-free connection.

- The use of fit bolts with a turned, ground thread, which is characterized by strength class A, guarantees a strong and reliable connection of parts to each other.

- Each product, before receiving a quality certificate, necessarily goes through a hardening stage, due to which its properties and parameters are enhanced.

The main advantage of the close-fitting bolt is its ability to withstand very high loads: static, cylindrical and even shock.

Such fasteners are manufactured in accordance with the standards specified in GOST 7817-80 “Bolts with a reduced hexagonal head of strength class A for screwdriver holes. Design and dimensions ".