Self-made template

In hardware stores, you can buy almost any model. But some craftsmen prefer to assemble almost everything with their own hands. The first step is to determine the main parameters of the masonry seam - height and width.

To make a quality template, you need to prepare tools and materials:

- pencil, ruler, level;

- hammer, screwdriver, screwdriver;

- electric drill;

- fasteners;

- plywood sheet (laminated chipboard) up to 25 mm thick, or a plastic box, aluminum or steel profile;

- steel corners.

The best material is plastic because it is easy to cut and handle. In a plastic container, you will have to remove only part of the bottom and fix additional stops. Aluminum parts are fastened with self-tapping screws or rivets. For a steel structure, a welding machine is required. A wooden template can be assembled in a few hours, but its reliability cannot be guaranteed with frequent use.

The device itself consists of several elements. It:

- Frame. Its internal width should be the same as the width of the building material. The requirement for it is a snug fit to the brick. The transverse and longitudinal elements of the frame can be either rigid or sliding.

- Boards. Their task is to limit the width and height if the main frame parts are not thick enough. They are needed to accommodate additional elements.

- Stops. These parts are used to securely fix the structure on a number of bricks or on the side of the masonry.

- Auxiliary tools that simplify the work (for example, instrumentation) are used if necessary.

Even the simplest device will correctly dose the amount of solution if used carefully. But in order for the tool to last longer, it is better to protect the plastic or wood by treating the surfaces with wear-resistant parquet varnish.

Tools to make the work of a bricklayer easier

Before buying a bricklaying tool, remember that it must be made of durable and reliable material that is resistant to aggressive media, for example: concrete, lime, cement and other mixtures and mortars. It is advisable to know the conditions in which the installation will be carried out, and the type of installation. The construction of a brick structure is not complete without the use of the following tools.

Bricklaying tools

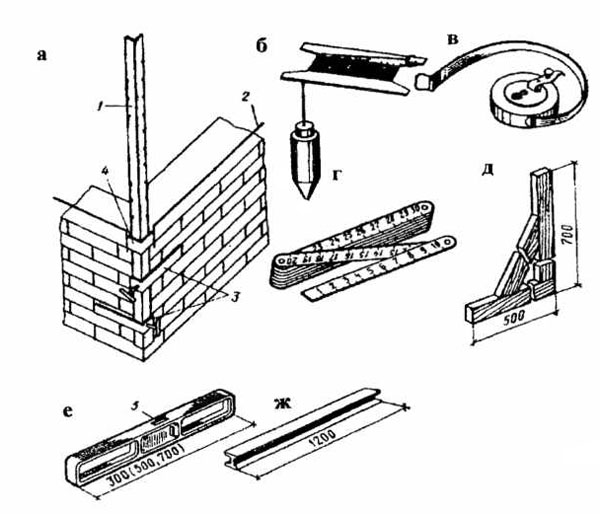

- A level is a measuring device with the help of which the geometry of the rows and the verticality of walls, openings, corners are controlled. The design is a robust body filled with an anti-freeze liquid, inside of which there are air bubbles that allow you to determine the evenness of the masonry.

- A trowel, or a trowel, which looks like a steel smooth spatula equipped with a wooden handle, is necessary for leveling the mortar, filling vertical joints, removing excess mixture.

- Decorative processing of seams, giving them the desired size and unique shape, is carried out under the jointing. The joining itself can be of various shapes and sizes.

- A hammer-pickaxe is a tool for cutting and laying bricks used for cutting and chopping stones, correcting errors made during the construction of a wall. The tool is designed for chipping off unnecessary parts and giving a perfect surface appearance.

- A small double-sided pickaxe will help to neatly arrange the masonry.

- The plumb line helps to identify deviations during the construction of a vertical surface, the angle of inclination of a multi-storey structure. This is the oldest and most proven device for laying bricks with your own hands.

- When laying, it is necessary to observe right angles. This is done using a square.

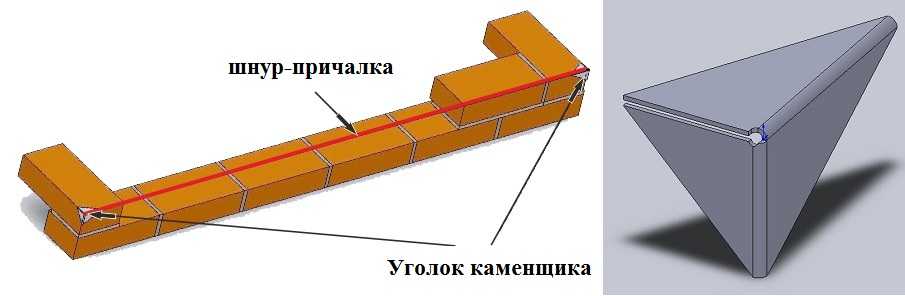

- A mooring cord is a device for laying bricks, which is a reference point for the removal of horizontal and vertical rows.

- Bucket - a shovel is indispensable for large-scale work requiring a large amount of mortar. He shovels, feeds the mixture, applies it to the brick. A shovel bucket is a metal device that applies mortar to bricks in a perfectly even layer, which has a positive effect on the quality of the masonry, the strength of the bond, and hence the increase in the service life of the entire structure.

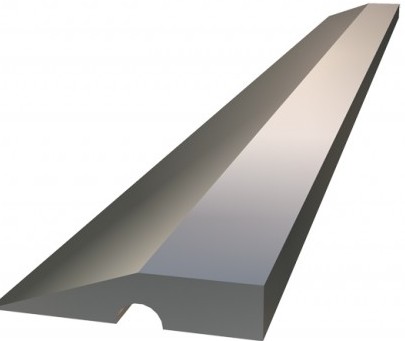

- The rule is an indispensable tool for ensuring the evenness of the front surface of the masonry. A kind of ruler, made of wood or plastic, with calibration notches, reaches 300 cm.

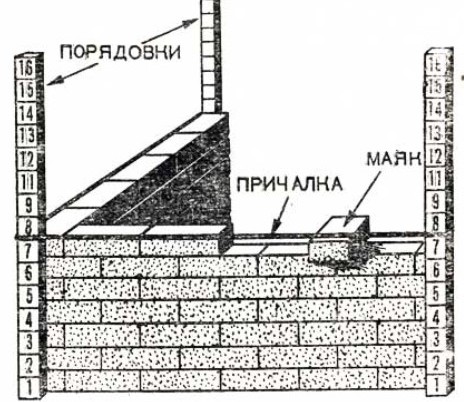

- A long corner or rail made of metal or wood is called an order. Angle or intermediate devices are used together with a mooring cord attached by means of special brackets or beacons to check the horizontal seams and the verticality of the masonry.

- Smoke and ventilation openings are cleaned of concrete protruding from the seams using a mop.

- Special construction templates allow you to accurately mark window and door openings. Builders use them during the laying of pillars, arches, vaults and more.

This is the main equipment used by bricklayers, which is automated and modified every year, making construction and restoration work easier. But many of the tools you can make yourself out of wood, plastic, or metal. At the same time, tools made according to special drawings, taking into account the requirements for the strength and quality of equipment, can be more convenient to use and durable.

Properties, sizes and types of bricks used for cladding

Material used for cladding

To decorate an interior or facade, you need to pay great attention to how to lay facing bricks. If we compare, for example, with a working solid brick

then it must have a high-quality front side of various shades and colors.

In addition to the common standard colors (yellow and red), you can choose brick and other colors. The front part can be smooth or decorative.

But the main difference between the cladding material and the simple one is the ideal dimensions, ends and right angles. The front side should not have a variety of chips and deformations.

Main assumptions in dimensional deviation, in mm:

There are simple and clinker bricks for cladding, they are also distinguished by their durability and quality. In simple, water absorption is much higher, due to the large number of pores. Double silicate brick M 150 is often used.

- ordinary - 250 X 120 X 65;

- narrow - 250 X 60 X 65;

- thickened - 250 X 120 X 88; 250 X 107 X 65; 230 X 107 X 65.

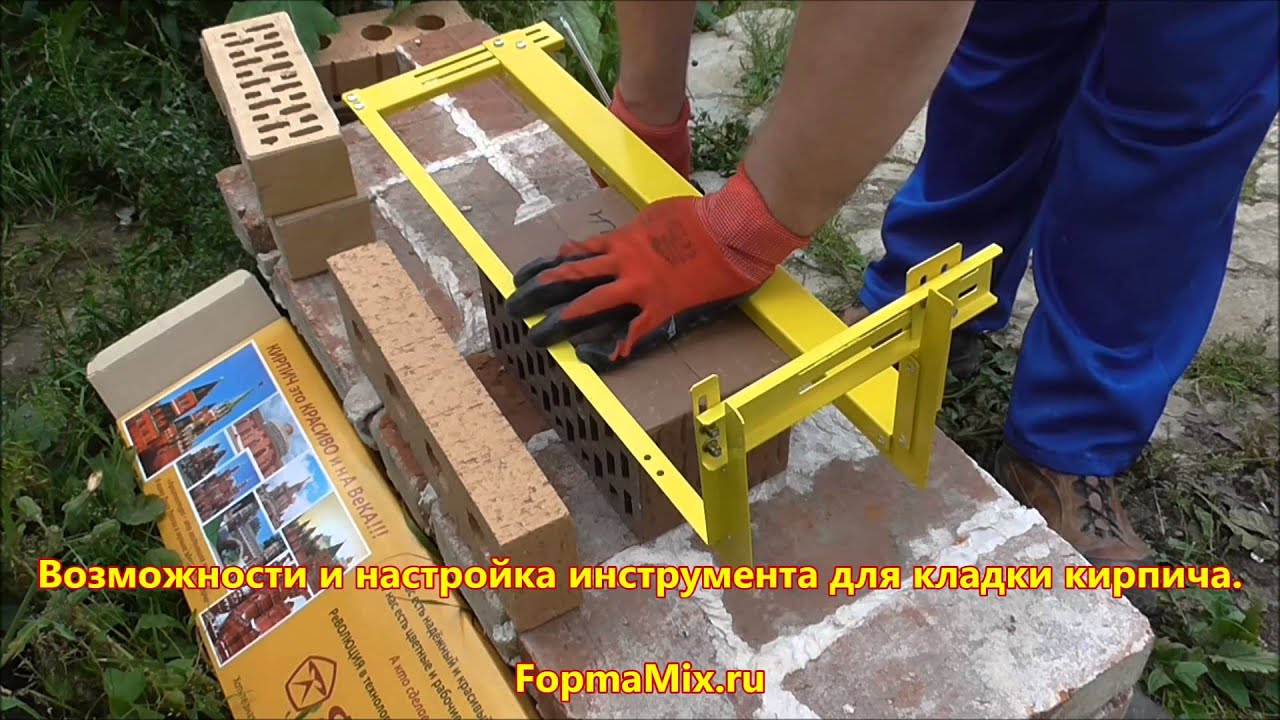

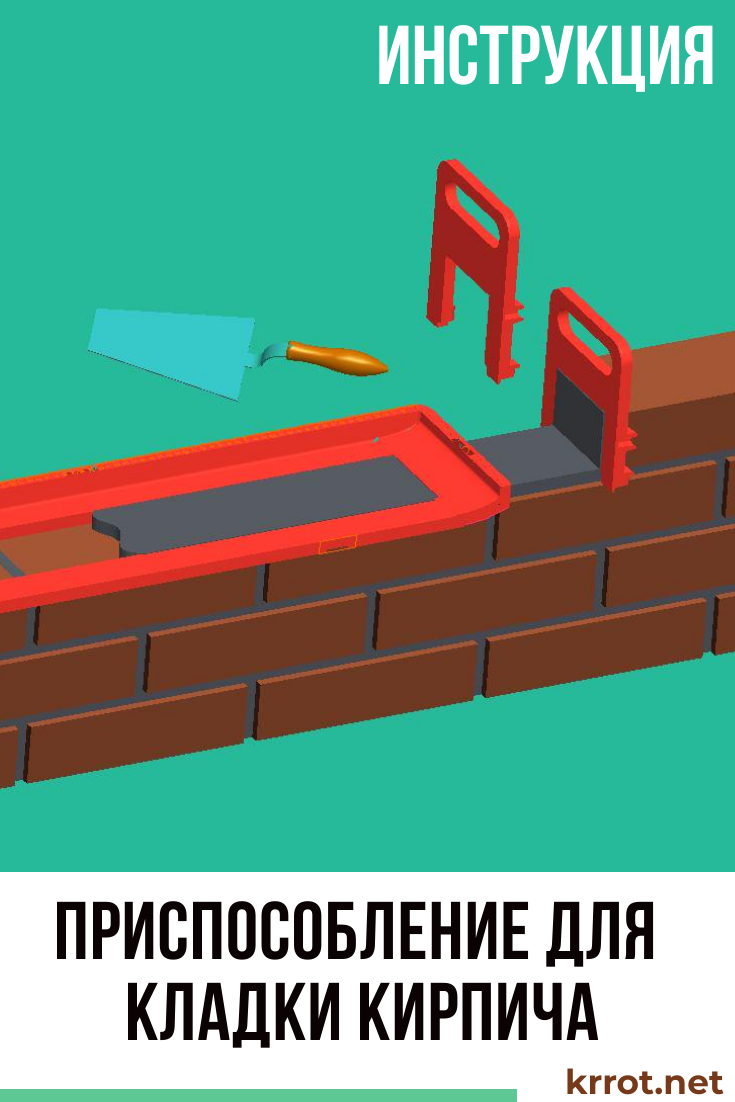

Factory products cost

When it comes to large volumes of work, it is better to buy fixtures made at the factory. Most often they are implemented in a set, for example, a set of "Brick" or "Bricklayer" includes the following elements:

- Templates for laying out the mixture on the bed;

- Trowel;

- The shape of the wall is one and a half bricks - 88 mm;

- Wall shape in one brick - 65 mm;

- Corner - allows you to check the angular parameters of the wall, the dock is attached to it;

- Operating instructions, most often in a video version.

The "Brick" set is used for laying the mixture on a horizontal row

On average, such a complex will cost about 1500-1900 rubles per set. The main advantage of such kits is high-strength plastic, which is designed for a long period of use.

The finances spent on the purchase of factory fixtures or your own time and costs for materials that are inevitable in the manual manufacture of additional fixtures are always justified by accelerating work, increasing quality and saving bonding materials.

Conductor for perfectly flat brickwork

In connection with the development of industry and the production of various building materials, so-called panels or other, lighter or cheaper material have recently been preferred to bricks. This is not to say that other materials are not able to bypass the brick in terms of properties. Probably, everything is moving towards this.But the appearance of a brick or "stone" building is always appreciated. Especially if the hand of a real master mason is visible.

You don't need to do this

But like any other type of construction work, builders without experience undertake to build a brick wall, which is called “for themselves”. Indeed, if everything is done carefully, then the difference (with small errors) between your masonry and the bricklayer's masonry will be especially visible only in the speed of work. Nevertheless, it will constantly move towards convergence with the standard.

How to pull the lace, knead the solution or how much reinforcement is needed - it's not a problem to find out. But how much mortar should be thrown under the brick so that you do not have to add, rake or knock with a mallet, deforming the previous work, the question is more serious. Of course, with experience this will happen automatically, but what about a beginner? There are two choices: learn like everyone else, or use an amazingly working device designed just for this task.

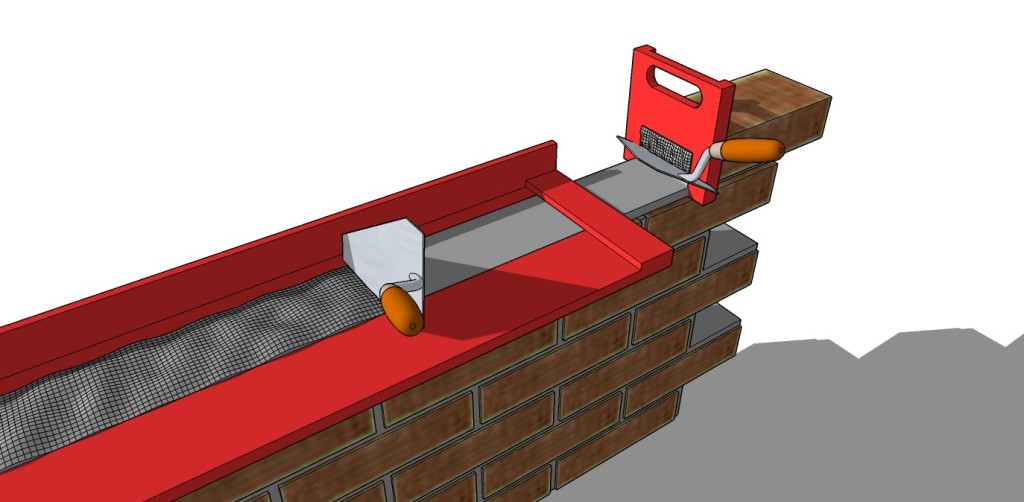

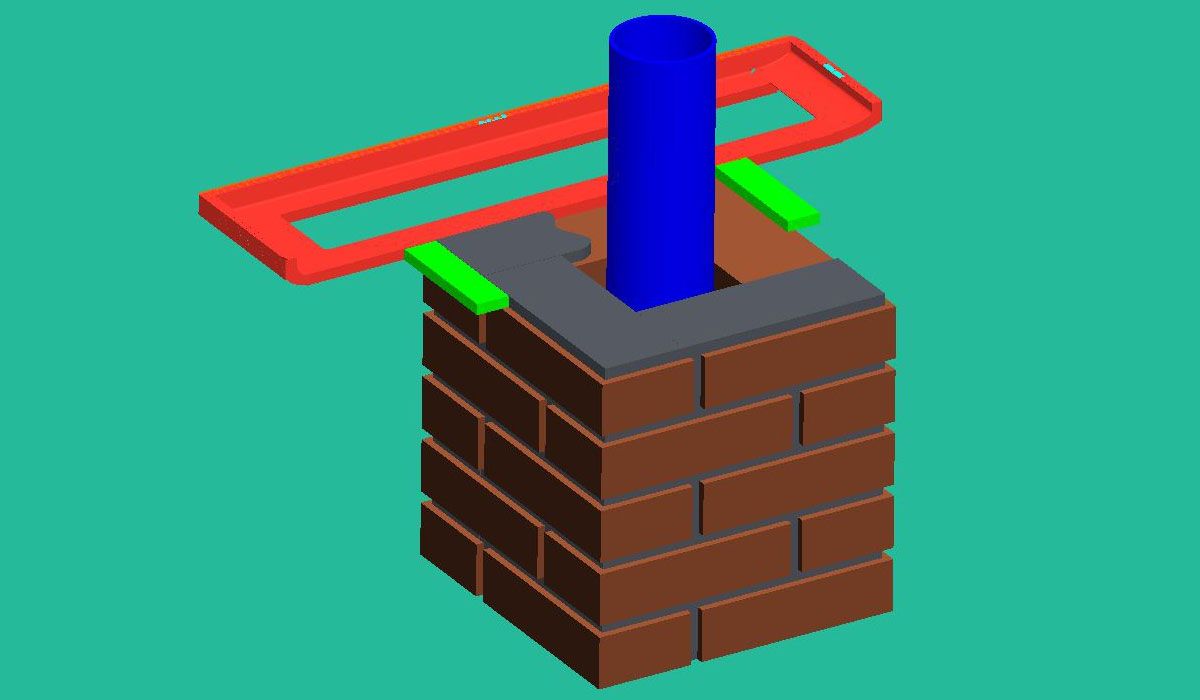

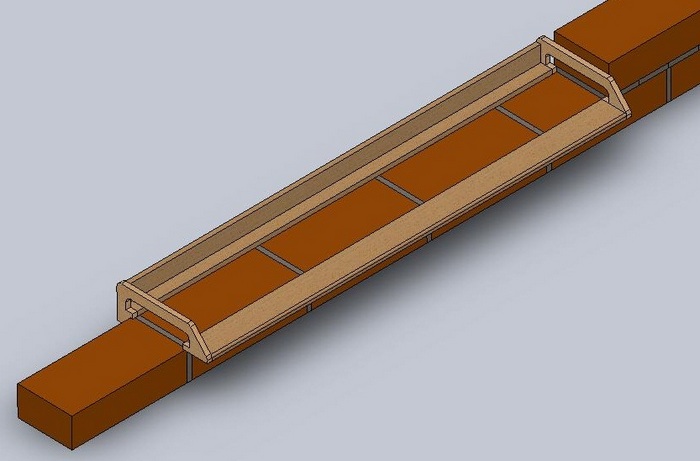

The grouting guide or template is made of a durable plastic. From itself it is a rectangular frame with provided cutouts and protrusions. In the process of work, you should install it on the laid row of bricks, throw the mortar into the recess and, leaning the trowel close to the upper part of the conductor, clean off its excess.

As a result, an interbrick layer of the same thickness is obtained throughout the entire length. It is enough just to evenly lay a brick on it and slightly press down. A similar device, only of a smaller size, is also provided for applying cement mortar to the end part of the brick. The use of such a template also allows the outer edge of the seam to be positioned at the same distance from the outer side of the wall, which looks very nice.

The price of such a pleasure is on average 1,500 rubles. Plus or minus half a thousand, depending on the company, the quality and completeness of the set.

Construction specialties are different. The most difficult to realize, respectively, are the highest paid.

The specialty of a bricklayer is one of the most difficult. Just take and start laying brickwork will not work for anyone. To do this, you need to learn, both theoretically and gain practical experience from real masters of their craft, working as an assistant for them and gradually performing simple operations at first, step by step moving on to more complex ones.

When you have gone through everything from easy to difficult, you will be entrusted with laying the brickwork. Brickwork of a multi-storey building is the height of the skill of any bricklayer.

Smooth inter-brick joints are perhaps the most difficult element of brickwork. It was always interesting how are they made? How do bricklayers manage to apply the mortar in an even layer and then lay the brick on it one line at a time?

I built a brick garage on my site. The brickwork was carried out independently. Did it for the first time. It took a hundred sweats until, at least somehow, I got used to laying a more or less even wall. About inter-brick seams on the walls of my garage, I'd better not say anything at all, as you yourself understand, everything turned out crooked.

But don't be discouraged

Recently I found a special device for bricklayers on the Internet. With its help, it is possible, even for the most inexperienced beginner, to make even inter-brick seams, both horizontal and vertical.

Such a miracle device is on sale at a well-known foreign online store.

Costs 39.99 euros. To be honest, the price is very high!

Yes, we do not need to buy it, this is a device. Make your own, completely free - from the usual corners!

The principle of operation is simple

Install the fixture on the brickwork, fill its frame with mortar, level the mortar along the frame, remove the excess. Take off the frame. Put a brick on an even strip of mortar.

Proceed in the same way with a vertical seam.

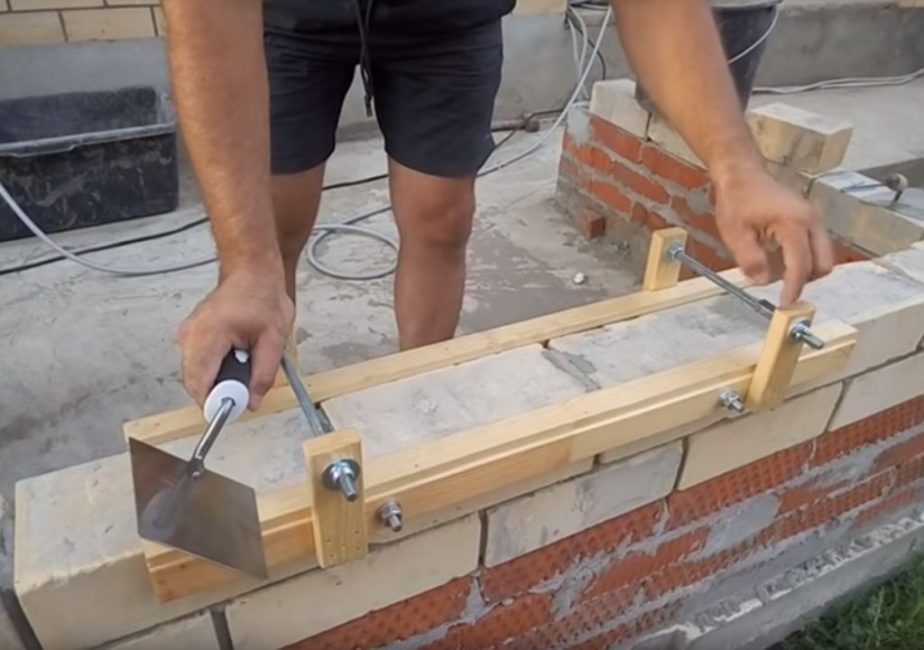

Homemade device for getting even masonry

To improve the quality of masonry work and speed up them, you can make a special masonry template

To improve the quality of masonry work and speed up them, you can make a special masonry template

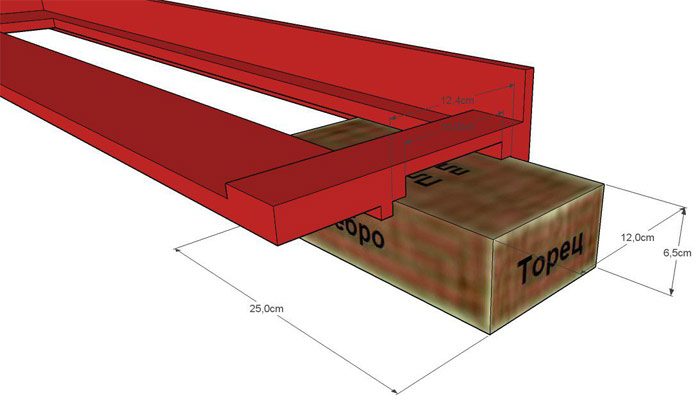

To improve the quality of masonry work and speed it up, you can make a special masonry template. Outwardly, this product resembles a wide container without a bottom. With this device, you can easily apply a perfectly even layer of mortar. As a result, the masonry process itself will be much easier.

The following characteristics of the masonry depend on the evenness of the application of the solution:

- If you lay the stone on a very thin layer of mortar, then the adhesion of the bricks will not be strong enough.

- Too thick layer of masonry mortar will lead to overspending and getting ugly uneven masonry.

- If the mortar is applied in an uneven layer, then the outside of the masonry will look sloppy due to the curved rows.

You can avoid all these disadvantages of incorrect application of the solution using a template. Outwardly, this is not just a container without a bottom, but a product with restrictions on the sides, which allow it to be firmly held on the wall. The dimensions of the template can be very different and depend on the masonry performed and the stones used.

The mortar can be put into the elongated hole in the central part of the fixture.

The mortar can be put into the elongated hole in the central part of the fixture.

The template is placed on top of a row of bricks. The solution can be put into the elongated hole in the central part of the fixture. As a result, thanks to the limiting parts of the template, the mortar layer comes out perfectly even in width and height. Moreover, the seam height will be exactly the same as specified by the dimensions of the template. After filling the niche with a solution, the template can be moved to a new place.

The template allows you to replace two tools used at once when making a masonry mortar - this is a building level and a cord. At the same time, during the construction of one building, several types of templates can be used:

- When executing the main walls of the building, templates with the specified basic parameters of the walls are used.

- To perform the facing brick layer, a different template is used with the parameters of the facing stone.

Making a template

Such a device for quickly laying bricks is easy to do with your own hands.

Such a device for quickly laying bricks is easy to do with your own hands.

Such a device for quickly laying bricks is easy to make with your own hands. It's over, you can buy the finished product in the store. Usually on it you can adjust all dimensions (seam height and seam width). But if you want to save money, you can make a template yourself.

First you need to decide on the basic geometric dimensions of the masonry joint (width and height). Here a lot depends on the stone used. Depending on the masonry technology and the material used, the dimensions of the template niche are determined.

To work you will need the following materials and tools:

- a plastic box of a suitable size or a sheet of chipboard (plywood) and strips of a suitable thickness;

- pencil, level and ruler;

- drill (hand or electric);

- fasteners (screws, nuts, screws);

- steel corners;

- screwdriver;

- screwdriver;

- hammer.

If you managed to find a plastic box of a suitable size, then the template is much easier to make from it.

Moreover, the plastic is quite strong and lightweight, which is important when performing masonry work. If you did not find the box, then you can construct a structure of the required size from chipboard sheets or plywood and slats

First, you need to make a regular box without a bottom slightly larger than the width of the brickwork.

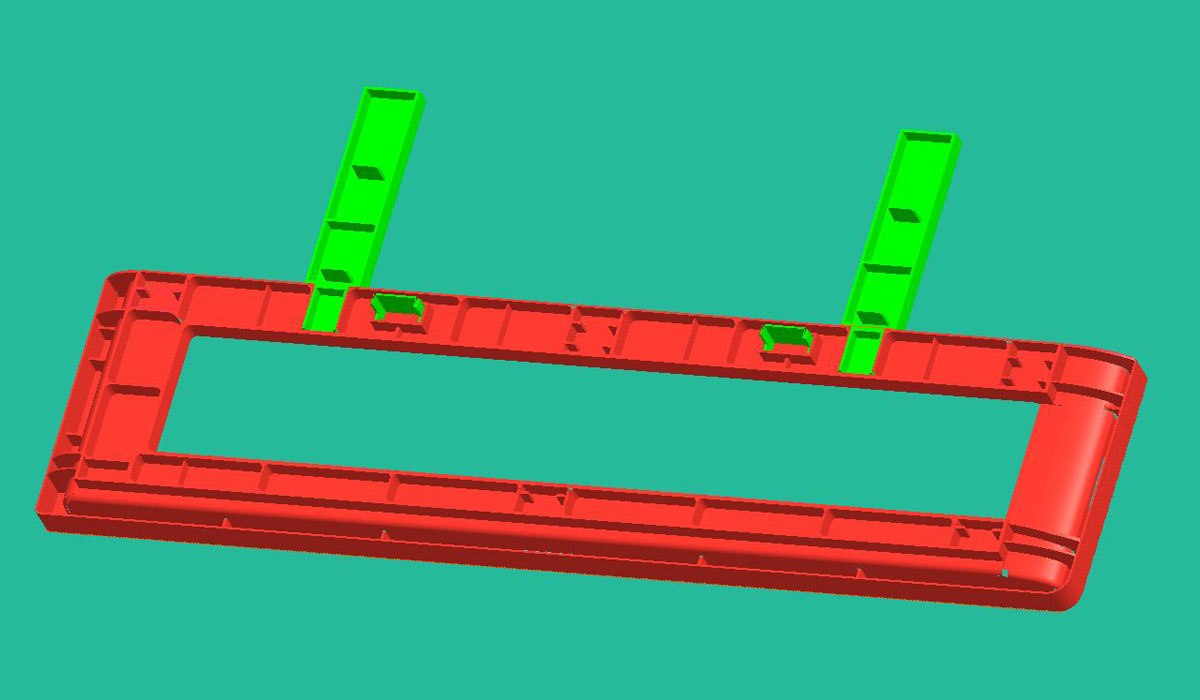

The whole structure includes the following components:

- Frame with two longitudinal wooden sides. The distance between these wooden planks should be equal to the thickness of the wall. Thanks to the protruding lower parts of the planks, it is convenient to align stones when laying, as these planks go into the lower row. This makes it much easier to maintain the verticality of the wall without a plumb line and level.

- Carrying handles.The handles make the tool easier to use.

- Crossbars. They are usually made of strip steel. This element allows you to control the linearity of the masonry.

The second name of such a template is a dispenser, since it can be used to accurately dose the amount of applied solution.

The second name of such a template is a dispenser, since it can be used to accurately dose the amount of applied solution.

The second name of such a template is a dispenser, since it can be used to accurately dose the amount of solution applied. Above, we described the device and the principle of using a horizontal dispenser. It is suitable for horizontal seams.

To form a correct and even vertical seam, a vertical dispenser is used. The principle of using an end dispenser is similar to that of a horizontal template. The only difference is that, due to the small amount of solution, it is applied using a hand trowel.

Delivery terms

Delivery by Russian post cash on delivery.

Kit price 1 350 rub.

Delivery price from 450 to 600 rubles.

It is more profitable to order several pieces, because unit shipping cost will be less.

Rating: 5/5

The fixture, as shown in the picture, includes two templates: one for a horizontal seam and one for a vertical seam. With the help of it, you can significantly simplify the process of making a high-quality seam, despite some of the difficulties described in the article about the nuances of brickwork and in the article about brick partitions.

How to use it is easy to understand from a short video.

Now more about templates.

Horizontal seam template

General view of the template

Top view: left side

Top view: right side

Bottom view: right side

General bottom view

Template for the device of a vertical seam

Back side view

Top and Bottom Views

The dimensions of the template for the device of the vertical seam are given for the laying of ordinary bricks. It is clear that for thickened bricks, the height will need to be increased to 88 mm.

Types and methods of styling

If we talk about what a brickwork is, then this is a structure made of bricks, while they are laid in a given order and connected to each other with mortar.

The classification of brickwork will depend on its complexity and where it is applied, therefore there are several groups of it:

the simplest masonry, it is used for summer cottages and houses, implies the construction of any walls, while work is carried out without architectural elements;

If the height of belts and cornices is no more than 4 bricks, they are not considered architectural elements, and this type of masonry is one of the simplest.

- simple complexity, in this case decorative parts in the form of cornices, bay windows, belts, semi-columns and other elements make up no more than 10% of the wall surface;

- medium complexity, part of the wall with architectural elements is no more than 20% of its area;

- complex, in this case decorative elements account for up to 40%;

- especially difficult when the creation of arches, domes and other elements with a complex curvilinear shape is carried out.

Depending on what materials are used during the masonry, it differs into the following types:

- From solid bricks made by plastic pressing, it is used to create walls, chimneys, underground buildings.

- Any walls of buildings are made of hollow bricks. If we compare such masonry with the one that is made of solid bricks, then its thermal conductivity will be less, which makes it possible to make the walls 20-25% thinner, and its weight is 20-30% less, which reduces the load on the foundation.

- Concrete stones are used to create foundations and underground spaces.

- Walls are made of hollow concrete stones, if they are lightweight concrete or cinder-concrete, then to protect against the effects of natural factors, such surfaces must be plastered.

- Hollow ceramic stones have a low thermal conductivity, which allows masonry to be made 50% thinner than that made of hollow bricks.

- Silicate stones are used for the construction of any walls.

- Natural stones are used for foundations, underground structures and basements.

- Natural stones with the correct shape.

The option of masonry with insulation in the photo below allows you to insulate brick walls during masonry.

Both the brick and the stone have edges: the upper and lower bed, spoons, so the lateral long sides are called, butts are the lateral short sides, there are ribs to intersect the edges.

Testing and measuring instruments

It will not be possible to cope with masonry without hand tools, but another category of "helpers" is no less important - those tools for masonry that control its correctness. The set includes an elementary rule, tape measure, level, square, plumb line.

The rule

This construction tool is a long piece of metal or wood. Its main difference from “relatives” is perfect evenness. The purpose of the rule is to identify even the smallest defects, to identify tiny depressions, bulges or other irregularities. The tool is applied to the row, then its adherence to the masonry is checked along the entire length.

The dimensions of the rule are from one meter to 2.5, usually the step is 500 mm. Professional bricklayers have a whole range of slats of various lengths, since large models are good for long walls, but they cannot be used to test the quality of work with a small area of \ u200b \ u200bthe object, as well as in hard-to-reach places.

Building level

This is a mandatory attribute of any construction, it is no less important when working with bricks. The most common type of instrument is the simplest spirit level. This is a flat bar with a built-in flask filled with alcohol. The air bubble in it shows any horizontal deflection when moved from the center.

The building level, which controls the masonry, has 3 flasks at once - vertical, horizontal and located at an angle of 45 °. The most preferable option is a laser level, which is more convenient, easy to use, and as accurate as possible. However, the disadvantage of the device for many is significant - it is its price.

Roulette, plumb line and square

The first representative does not need advertising: everyone knows about the convenience of a thin metal tape that independently rolls into a roll. The plumb line is also an elementary device - this is a load that is suspended on a thread (nylon cord). Cargo material - aluminum or other metal, rubber. The optimal shape is a cone weight. Using a plumb line, the fastest way to check the verticality of the masonry is by bringing this simplest tool to it.

Square - two metal plates connected at an angle of 90 ° The long side is also a ruler. The shorter and thicker element provides a snug fit to the building material. An alternative to a tape measure and a square can be a folding wooden ruler - 10-centimeter rulers, connected together. They can be easily folded into a triangle, and where the first links connect, there is a protractor.

Ordering and mooring

These masonry tools are used to check the correctness of the masonry. Ordering is the main one: it is a long "ruler", metal or wooden. It is installed in the corners of the future structure (house, stove, fireplace, etc.), then markings are applied, using the brick height and joint width as a standard - 65 and 12 mm (77 mm), respectively.

On this ruler, the height of the rows, lintels, openings is marked. The lowest mark should match the first row of masonry. At the level of the brick to be laid, an inelastic rope (for example, a polypropylene cable) is pulled - a mooring. Its task is to control linearity, to ensure the evenness of each row, therefore, sagging of the thread is unacceptable.

Devices to make work easier

For the speed of work, but not at the expense of quality, several interesting types of inventory have been invented. These masonry tools make it possible to achieve flawless seams at minimal cost.

- The cuvette is the first and simplest representative. She also has another name - dispenser. This is a small container with straight or beveled walls, and it does not have a bottom. The size of the cuvette is not more than one brick. Its purpose is the exact dosage of the solution. Using this design, you can quickly give the seam the desired length, thickness, width.

- Ordering dispenser. This is a cuvette with markers. Often, such auxiliary devices make it possible to adjust the length, have supporting mechanisms that facilitate their movement.

- Integrated dispenser. Such a tool has serious equipment: it includes a level and various instrumentation. With its help, you can not only level the solution, but also give curly shapes to the seams.

Any dispenser will greatly simplify the work, however, as with any device, you must first get acquainted with it, get used to work, get used to it.