Views

Today, a large assortment of polyvinyl chloride products is presented on the market. The classification of the material is carried out depending on the purpose, size, connection method, surface characteristics.

Tiled

It is possible to imitate different variations of ceramic tiles if you use PVC tile panels for a bathroom or kitchen.

Design solutions for PVC can contain combinations of plastics and ceramics or cover the entire wall surface. There are products on which the tiles are painted with different masonry options: standard, checkerboard, with inserts of individual elements.

Wall

Up to 1 cm thick, from 2.7 to 4 m long and up to 0.5 m wide, panels for walls are produced.

The choice of interior options that can be realized using PVC products is not limited.

Manufacturers offer elements of calm monochromatic colors, bright ornaments, decorated with floral designs or abstract compositions.

Wall panels with the same connections are well combined with each other, thus further increasing the design possibilities of the product.

Using additional elements (corners, connectors), it is easy to trim complex areas, slopes, corners with plastic.

Leafy

For wall decoration, there is another type of finishing material - in the form of sheets, with a length of up to 4 m, a width of 50 cm to 2.3 m. Products of this type are: thin - 1 mm or thicker - 30 mm.

A distinctive feature of such PVC panels is that the dimensions allow 1 element to cover a large area with minimal effort, which is convenient for installation.

Sheet material imitates various embossed or flat surfaces:

- slate;

- mosaic;

- tiles;

- brick;

- wood.

Lining

A stylish aesthetic appearance of the room can be created if you use a material that is made for lining.

Along with unpretentious maintenance, low wall stress, complete resistance to corrosion, and 100% moisture resistance, the buyer receives a reliable, simple structure made under polished wood.

The material is produced 48 mm thick, up to 30 cm wide and from 0.9 to 3 m long.

The most common are 2 options:

- "Polka" (with a narrow type locking system);

- "Euro lining" (with a standard size lock).

3D effect

Ceramic tiles, wood, natural stone covered with a layer of varnish can be well imitated if panels with full-color 3D printing are used.

The interior is done with the help of a composition of ornament and paintings made up of 3D drawings.

Unlimited color palette, seamless structure, good heat and sound insulation qualities, not without a few disadvantages:

- the price of some types of PVC is high;

- it is necessary to make a crate during installation, which will somewhat reduce the space of the room.

With thermal transfer

Polyvinyl chloride with thermal transfer is produced in entire collections. Technologies make it possible to apply patterns and images on a polymer film quickly and efficiently. The pattern on the surface is fixed at high temperatures.

The length of the products is from 2.7 to 6 m, the thickness is 0.8-1 cm, and the width is 25 cm.

A variety of patterns decorating plastic makes it possible to create an original design of a bathroom, kitchen, while providing at the same time waterproofing, protection from mold and rot, and the absence of cracking over time.

Laminated products

The image is glued to the front of the PVC panel so that a protective laminated layer is formed on top.It protects the pattern from damage, thereby improving the performance of the product.

The PVC product is available in up to 12 mm thick, 2 m long and 25 cm wide.

To correctly calculate the required amount of material, you need to measure the surface area, and subtract the squares for the openings for doors and windows.

Advantages and disadvantages

The demand for ceiling tiles is due to various factors. They have excellent aesthetic properties, highlighting the interior of the room, made in a variety of styles. They are used in any room, be it an entrance hall, kitchen, living room, balcony or loggia. The main advantages of the material include the following characteristics:

- low cost;

- simple installation, almost everyone can do the work, while there is no need to buy special tools, the construction tools at hand, which can be found in every house, are suitable for finishing;

- most of the raw materials used for the manufacture of products are moisture resistant, which makes it possible to install structures in a bathroom, toilet, and other rooms with high humidity;

- with the help of panels, perfectly flat surfaces are created, while under them it is easy to hide wiring, engineering communications;

- the coating allows you to mask any defects, such as cracks, irregularities, floor joints;

- if one of the elements is damaged, you can easily replace it yourself;

- many models are distinguished by high heat and sound insulation;

- most materials can be easily cleaned with standard products;

- products are characterized as safe, even made of plastic, they do not emit harmful substances;

- slabs are available in different sizes, which makes it possible to use them in rooms of various sizes;

- for manufacturing, fire-resistant components are used.

Ceiling panels also have certain disadvantages. With their help, it is impossible to create complex structures in several levels. On large areas, the coating does not look attractive enough. The quality, respectively, and the service life depend on the price. Panel finish is not resistant to mechanical damage, sunlight, some species begin to crumble after a certain time.

PVC panel ceilings: types of coatings

There are many varieties of PVC panels on the modern construction market. The panels can be made in a single color scheme, imitate the texture of various materials, and design drawings can be applied to them.

Types of panels by type of coating:

- Matte. The cost of such a panel is affordable. The panel looks like a lining, has a width of 10 cm. They look quite simple, but this is due to their low price.

- Glossy. Wide panels are covered with special paint and protective coating. The choice of colors is very large, there are also panels that imitate the look of marble or wood. Their cost increases along with the width, which reaches 25 cm. This size provides a beautiful finish with a minimum number of visible seams.

When choosing the type of coverage, it is important to think over the general appearance of the room in advance. There are many different types of plastic panels, from size and color to installation method

Before buying, it is important to check the integrity of the panels, to see if the corner is not lined

There are many different types of plastic panels, from size and color to installation method

Before buying, it is important to check the integrity of the panels, to see if the corner is not lined

# 1. What are the pros and cons of plastic panels?

The basis for the production of plastic panels is solid polyvinyl chloride, which is characterized by maximum resistance to fire. The material is made by extrusion, between two painted or varnished surfaces there is a space consisting of numerous longitudinal honeycombs formed by stiffening ribs.

The main advantages of PVC panels:

- light weight;

- moisture resistance, hygiene, antistatic, ease of care;

- environmental friendliness;

- fire resistance and resistance to temperature extremes;

- good soundproofing qualities;

- a huge selection of patterns and textures, which allows you to organize the interior in any style;

- simple installation that almost anyone can handle;

- low price.

Considering plastic panels as a material for lining the ceiling or walls, you need to be aware that it also has some disadvantages:

- low strength. It is easy to leave a scratch, dent or other kind of damage on the surface of the material;

- at first, the panels may emit a specific smell;

- the material has a limited scope and is suitable for those rooms where strength is not as important as moisture resistance, fire resistance and decorative effect.

Types of PVC panels

The following types of PVC panels can be found on sale:

- Suture plastic is the cheapest and outwardly unattractive. This is a common plastic clapboard that was widely used as a decoration in the 90s. It was installed indoors and outdoors. Today, this budget finishing option is used for commercial premises.

- A wide assortment of seamless slabs is presented in every construction hypermarket. They have a special tongue-and-groove connection that allows the elements to be joined without a visible seam. The result is a solid monolithic surface. This coating option is represented by a wide assortment of boards that differ in texture, color and size.

- Sheet plastic differs from its counterparts in impressive dimensions, allowing it to be mounted on a small area with one continuous sheet. There are different colors of this material, but it is rarely found on sale, because it is not in great demand.

How to make a ceiling from plastic panels

Installation of PVC panels is possible even for non-professionals. But you need to be attentive to each stage of the work so that the result satisfies you.

First, you need to make a drawing and calculate the consumption of materials - they should be taken with a margin.

Calculation rules:

- measure all 4 walls: opposite walls may not be the same length;

- the number of panels is determined as follows: divide the total ceiling area by the area of one panel and multiply by 1.2;

- the step with which you need to mount the ceiling profile and suspensions is 50-60 cm;

- the length of the starting profile is equal to the perimeter plus 10-15 cm;

- to calculate how much plastic profile you need, divide the length of the perimeter by 3;

- dowels must be taken with the calculation of 1 per half meter of the profile, self-tapping screws - 1 per half meter of the panel length.

All results obtained should be rounded up.

You may also need docking profiles.

You will also need to do some preparatory work:

- completely remove the old ceiling trim, if necessary, then the wiring;

- small defects like cracks need to be putty. You do not need to level the ceiling if you want to use a suspended installation method, otherwise it must be trimmed;

- treat the ceiling twice with an antifungal compound.

Then you can start making the frame:

Mark the ceiling by measuring the level around the perimeter and drawing lines on the walls. If you are making a ceiling in a bathroom with flat tiles, you can measure along the seams of the tiles.

Make note of the location of the luminaires immediately; they may require additional space. At temperatures above + 90C, the plastic does not burn, but it can deform, so it is better to purchase LED or halogen lamps.

Cut the starting profile to the length of the walls and make holes every 50 cm.

Attach it to the wall and, using the finished marks, drill holes in it at the attachment points. Before starting work, be sure to check if there is any wiring in the places of drilling.Otherwise, you run the risk of damaging the power grid or the hammer drill, or even getting an electric shock.

Insert the plastic profile into the guide. Too large a distance between the supporting profiles will cause the panels to sag, so it is optimal to measure at 40 cm.

If the profile is longer than one and a half meters, it must be fixed with metal hangers and twisted with self-tapping screws.

Then get ready to install the luminaires:

- wire to the places where you plan to install them. In this case, it is better to leave the wire with a margin of length and insulate the wiring well;

- additionally reinforce the places where the lamps will be installed with guides

Now you can mount the panels:

Attach the rail to the guide rail. You can use not a rail, but a ceiling plinth, gluing it to liquid nails. Cut the panels to fit the wall.

Insert the panel into the guide rail with one end, bend and insert the other end slightly, press lightly against the wall and screw. Mount the rest of the panels in the same way, tightly joining the previous one and making sure that they run the same along the entire length. Do not overdo it with pressing force, otherwise the panel will deform.

The last panel is trimmed to fit the actual dimensions of the remainder of the ceiling and inserted in the same way as the others. Seal gaps and joints with acrylic sealant if necessary.

Connect the power supply to the lighting fixtures.

Ready! As you can see, the installation of ceilings made of PVC panels is up to everyone.

Types of ceiling panels

There are pvc wall and ceiling panels. If a global repair is planned, then it will be very profitable to install ceilings with your own hands.

For mounting the ceiling, you need lightweight material with thin walls. What is the difference between wall panels and ceiling panels?

Walls are more durable, but there is no need for this strength. In terms of cost, this type of panel is more expensive, and heavier in weight.

Panels are distinguished by the type of connection:

- Seamless. As a result of installation, a flat, smooth surface is obtained. The joints are difficult to distinguish, a spike and a groove are visible in the side part, with the help of which the structure is assembled.

- Embossed, or rack. This type of panel outwardly resembles a lining: the same stripes, but made of plastic.

- Sheet plastic. The installation is used in few places, since it is complex. This method is suitable for finishing non-linear surfaces.

Views

Depending on the parameters, PVC lamellas come in several varieties.

Tiled

The tile material is similar in appearance to ceramic tiles. The standard dimensions of this product are 30x30 cm, 98x98 cm, 100 x 100 cm. Their thickness can be from 1 to 5 mm. Tiled panels can be used in combination with plain tile variations that imitate natural stone.

Wall

Wall slats are used to decorate wall surfaces. Thanks to the large assortment of products, it becomes possible to create an original image in the interior of the room. The width of the products varies from 15 to 50 cm, the size is 2.6 m, 2, 7 m, 3 m, the thickness is from 6 to 10 mm.

Leafy

These panels differ from the previous variations in large parameters. When working with this type of product, a large area of the working surface is covered. The standard width of the lamellas is 50-122 cm, the size is 0.9-2.44 meters, the thickness is 1-6 millimeters.

Sheet products often imitate various materials:

- wood;

- brick;

- mosaic;

- tile.

Lining

This type of plastic product has a sanded surface. Manufacturers make lining of various colors and textures. The connection of the products is carried out by means of the existing spikes, as a result of which even an inexperienced craftsman can perform the assembly. The width of the products is 10-30 cm, the size is 90 cm - 3 m, the thickness is from 4 to 8 mm.

PVC lining is made in 2 variations:

- "Euro lining" is a product of a standardized size with a wide locking structure.Width - 10 cm, width - 3 m.

- "Polka" is a product of a standardized size with a narrow locking system. Length - 3 meters, width -10 cm.

PVC wall panels also differ in the connection method:

- embossed lamellas;

- seamless plastic building materials;

- panels that are chamfered.

Seamless type finishing materials are commonly used for ceiling cladding in various premises. With a correct installation, you can achieve an effect in which the joint between the parts will be almost invisible. The seamless joining method allows you to create continuous lines and patterns when covering various surfaces.

Beveled panels are somewhat reminiscent of seamless products. The only difference is that in the first version there is a chamfer in the end part of the building material. A chamfer is a recess designed to join plastic panels into a single whole.

Embossed lamellas are commonly used for wall surfaces. In appearance, they are similar to the clapboard. Embossed products differ from the previous variations in a high coefficient of strength and wear resistance. Thanks to such technical characteristics, they have a high cost price.

3D effect

This type of product is used not only in the design of residential buildings and apartments, but also in office buildings and shops. The original drawing allows you to create a unique design in the room. Lamellas with this effect imitate natural wood, natural stones, ceramic tiles. Standard parameters: width - 25 cm, 37 cm, 50 cm, size - 2.7 m, 3 m, thickness - from 8 to 10 mm.

With thermal transfer

The manufacturing technology of this type of product is carried out in such a way that an image or a pattern is displayed on a polymer film, after which, on specialized equipment, this image is transferred to a plastic building material under the influence of high temperatures. Panels with thermal transfer are considered the most popular among homeowners, because they have a high resistance to high temperatures, and installation will not cause much difficulty even for a novice builder. The width of the panels is 25 centimeters, the size is 2.7, 3 and 6 meters, the thickness is from 8 to 10 mm.

Laminated products

The method of manufacturing laminated panels is that a film with an image and dressing is glued to the front part. Such a manufacturing method gives the finishing material additional performance characteristics; such a pattern or image is rather difficult to spoil. Laminated panels are treated with an antiseptic, which prevents small dust particles from settling on the surface of the products. The quality of panels of this type is certified by the appropriate quality certificate. Width - 25 centimeters, size - 2.7 and 3 m, thickness - from 8 to 12 mm.

Advantages and disadvantages

The use of plastic panels for ceiling decoration has a number of advantages. Let's note the main ones.

- Ceiling installation, including cutting and fixing, is straightforward. It will take a little time, and the result will please with the aesthetics of the appearance.

- You do not have to contact specialists: you can do the work yourself without unnecessary garbage and preliminary preparation of the base.

- Plastic panels are of reasonable price. Everyone can buy them: it will not hit the planned budget.

- Ceiling plastic panels are available in a wide range of colors. You can choose varieties in any color and pattern, making a choice between a variety of textures and color contrasts.

- Plastic panels can become a bright accent of any design. They fit well into the interior of classic, modern, ethnic, ecological and vintage styles.

- They are easy to transport. You can not be afraid that during transportation it will break.

- They are available to everyone. They can be bought at any hardware store, choosing according to your own taste. If you wish, you can decorate the ceiling with fragments of contrasting shades. This will bring freshness to the design and emphasize the individuality of a particular room.

- The plastic trim comes in standard sizes. The cladding allows you to make the ceiling even, without defects at a low labor cost.

- Plastic ceiling panels are easy to clean. You do not have to scrub dust, dirt and soot for a long time. The surface does not absorb dirt, it can be removed with a damp cloth or semi-dry sponge.

- The ceiling covering can withstand temperature changes. The plastic does not deform when exposed to moisture, it is protected from soot and fumes.

- If one of the elements breaks down, it can be replaced. It's easy to do, you don't have to start from scratch.

- Such a coating hides all the flaws of the base, which is not the case with whitewashing and painting.

- This facing material can be an independent ceiling decoration or its bright center. It goes well with other finishes, so you can create a unique design in the style you want.

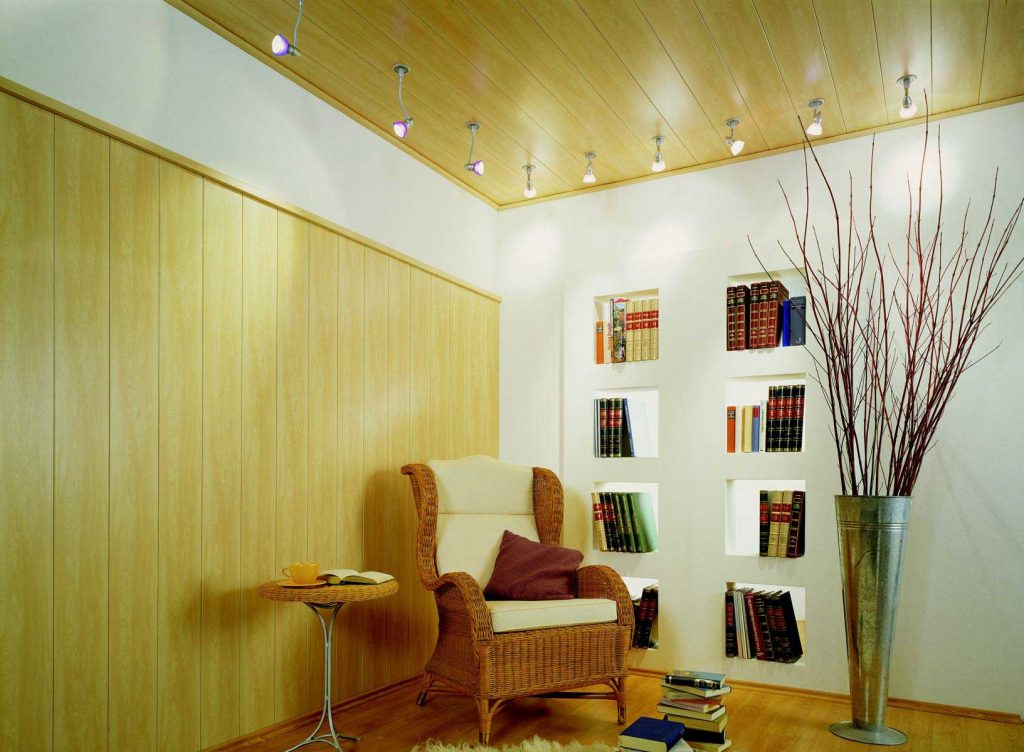

Due to its high-quality performance characteristics, it can be used in different living rooms and utility rooms. You can decorate the ceiling of the bathroom, bathroom, kitchen, dining room with such material. You can make a bright accent with its help in the interior of the living room, study, home library, decorate the ceiling of a glazed loggia or balcony.

With a thorough choice of material and texture, they will look harmonious in the interior of a city apartment or a wooden house, as well as in the country. Despite its apparent simplicity, it allows the installation of two-level ceilings. If the need arises, it can be dismantled and reinstalled. The technology allows the installation of insulation between the plastic panels and the ceiling overlap.

The use of plastic panels for the ceiling allows you to visually play up the design features of the premises. For example, they can be used to zone a space. Choosing such a decor, you can unobtrusively highlight one of the functional areas of the room.

How to make a ceiling from plastic panels. Brief installation technology

The panel ceiling requires preliminary work. The following tools and materials must be prepared:

- dowels and screws;

- screwdriver, drill;

- hacksaw for metal;

- knife for cutting plastic;

- ruler, tape measure, building level, pencil;

- metal profile or wooden slats;

- panels for decoration.

Preliminary work includes:

- Measuring the walls of the room (the lengths of the opposite walls may not match).

- Determination of the required number of panels. To do this, the total area of the ceiling is divided by the area of one panel element, and a margin of 20% is added to the resulting value.

- Determination of the length of the profile. For calculations, you need to divide the perimeter of the room by 3.

- Preparation of the main surface. At this stage, the old finish is removed, the base is cleaned, the existing wiring is removed. Then the surface is putty (careful leveling of the ceiling is not required if the construction of a suspended structure is planned), treated with antifungal agents in 2 layers.

Assembling the frame

The frame for the suspended structure is assembled as follows:

- Using a tape measure and a ruler, mark the base of the ceiling. For tiled bathrooms, markings can be carried out using tile joints.

- Places for lamps are marked.

- A starting profile is measured and cut with a hole pitch of 0.5 m. Its length should be equal to the length of the larger wall. After drilling the holes, the profile is applied to the wall, according to the marks obtained, holes are drilled for fastening, then fastening to the wall with dowels is performed.

- The remaining elements of the profiles are measured according to the size of the room.

The materials for the frame can be wood, metal and plastic. When drilling holes in the ceiling, it is advisable to first check that there is no electrical wiring in this place.

Wooden slats as a frame

For the construction of a wooden frame, you can use bars with a cross section of 50x50 mm or thick slats (if the panels have a minimum weight).

The wood should be pretreated with an antiseptic compound. The wooden frame is undesirable in bathrooms due to high humidity.

Plastic frame for ceiling profiles

The load-bearing profiles should be placed in 0.4 m increments to avoid possible sagging of the panels. The plastic profile is inserted into the guide, then the installation of the ceiling elements follows the standard scheme.

Metal profile - material for the frame

The lightest metal is aluminum. Assembling a metal frame is similar to assembling a wooden one; profiles are cut with a hacksaw for metal. The fixing of the profiles to the walls and ceiling is carried out on dowels with a pitch of 0.5 m. The metal profiles are connected to each other with galvanized self-tapping screws.

Installation of panels depending on the material of the frame

First, the first element is attached to the guide profile. The panel is inserted into the rail, first with one end, then with the other, screwed to the frame. The second rail will be mounted on the spike of the previous element, tightly adjacent to it

In this case, it is important to ensure that the pressing force during fastening is not too large, otherwise the fragile element will deform.

The last strip should be cut to match the actual dimensions of the remaining ceiling section and inserted in the same way as the previous ones. It is recommended to seal joints and resulting gaps with an acrylic-based sealant.

To improve the heat and sound insulation properties, the air gap of the frame is sometimes filled with vapor-permeable foam.

Sealing cracks

Since the panels are produced equipped with special spikes that are driven into the grooves when connected, the likelihood of cracks formation is minimized. The exception is products for lining.

However, when cladding, attention should be paid to the formation of transverse joints between the elements, as well as at the junction of the walls with the ceiling. To design such joints, you can use moldings - special decorative elements

They are selected in the same shade as the ceiling panels.

In some cases, you can choose a skirting board that matches the design of the ceiling.

Foam panels for the ceiling

For inexpensive interiors, you can choose affordable polystyrene foam or foam panels for the ceiling. The main advantages of such a decorative ceiling covering: resistance to moisture, environmental friendliness, low weight, non-susceptibility to rotting and mold formation. Such ceiling tiles are an opportunity to bring a room into a decent look quickly and inexpensively. Kindecor offers several decorative coatings, among which the expanded polystyrene model is popular:

- model name: Kindecor 32 White tile;

- price: from 23 rubles;

- characteristics: size 0.5 * 0.5 meter,

- pluses: moisture resistance, affordable price;

- cons: deformation at high temperatures, discoloration under the sun.

While it is generally accepted that styrofoam tiles are a solution for low-cost interiors, there are premium options among these products that will cost a lot. They can often be used for wall and ceiling decoration. These products include Belgian-made polyurethane products:

- model name: F30 ORAC DECOR

- price: 440 rubles per piece;

- characteristics: moisture resistance, smooth surface, square shape;

- pluses: compliance with environmental safety standards, elegant appearance;

- cons: high cost.

Selection Tips

The appearance of the panels in the store sometimes seems more attractive. Once installed, coloring can change perception and visually split the ceiling into pieces. For these other reasons, too, the choice must be solid.

Consider the main nuances that you need to pay attention to

Approaching the panels, he will pay attention to the smell. Quality material does not have it

The presence of a specific aroma indicates that this is a material containing toxins.

Visual inspection concerns shape and geometry. Pay attention to its correctness. There should be no curved edges and irregularities around the perimeter. Examine each item you are giving money for.

Reliable brands supplying quality goods to the market supplement it with documentation. Ask the seller for a certificate of quality and compliance with safety standards.

Inspect the clarity of the coating. If there is a drawing on the surface, its lines should be expressive.

Any smearing of the contours indicates a low quality of the panels.

Pay attention to color. Harsh acid paints indicate toxic constituents

They will not stay on the surface for a long time.

Bending resistance is important. A good product does not leave marks on multiple bends. If the seller is confident in the quality of the product, he will demonstrate this.

- Ask your salesperson what the panels are for. A good seller will definitely emphasize the types of plastic panels, indicating whether they are for walls or for a ceiling, indicate the type of installation technology.

- Look at the panels from the side: they should have a lot of transverse stiffeners. Notches and sharp edges are faults. In this case, it will not work to connect the locks neatly.

Having clarified the basic requirements for plastic panels, he will pay attention to the aesthetic component. Eliminate cheap gloss with a visual synthetic base

It is better to choose panels with imitation of natural materials (for example, wood, stone, marble). If panels are needed as an accent on the ceiling, start from the main interior and the purpose of the room.

Gloss and cheerful colors are appropriate for the kitchen. For the most harmonious effect, do not overload it with prints. Green, olive, sandy soft tones of colors will bring positive to the design of the ceiling.

When decorating panels in the hallway or corridor, you can use white or milky monochromatic coatings. Ivory panels will look good here. Patterns are excluded: it is undesirable to overload the space limited in footage with an abundance of variegation.

Plastic panels look great in the interior of a kitchen combined with a living room or a cooking zone and a place for a dining room. In such cases, they try to highlight the dining area with an insert of panels. Sometimes they are connected with a golden strip, adding elegance. In other cases, they put an emphasis on the texture, choosing a matte finish with an imitation, for example, of wood painted in white.

If you want to decorate the bedroom ceiling with plastic panels, try to use a matte seamless material.