Operational Features

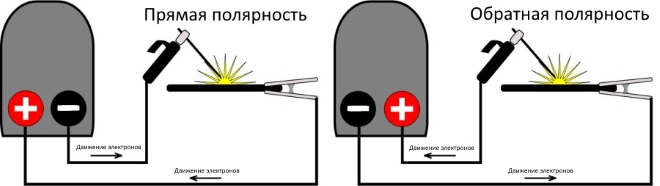

She, as already mentioned, is used to weld metals with direct polarity.

Direct polarity means that the positive contact of the welding machine is connected to the workpiece itself with a ground cable, and the negative contact to the electrode through the welding cable.

In the settings of the welding machine, the minimum feed rate and operating voltage are set. For example, using a 1.2 mm diameter, the optimal feed rate would be 2 meters per minute and the voltage would be 14 V.

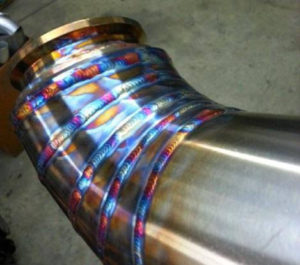

It is common for her to form a thick slag layer on the weld made. If the seam is planned to be multi-pass, then this slag must be carefully removed with a metal brush and a hammer.

In general, according to reviews, the seam, almost always, is rather rough, has large scales and nodules. In case of careless and hasty actions of the welder, lack of penetration is possible. This is virtually inevitable when working with an intermittent electric arc.

In general, according to reviews, the seam, almost always, is rather rough, has large scales and nodules. In case of careless and hasty actions of the welder, lack of penetration is possible. This is virtually inevitable when working with an intermittent electric arc.

Peculiarities

Welding with a semiautomatic device without gas allows you to achieve the required level of melting of the metal surface, while the wire diameter is from 0.8 to 2 mm. Due to the special composition of the flux, semi-automatic welding makes it possible to perform a high-quality and durable seam when joining metal workpieces of any thickness, which indicates a high efficiency of the welding method.

The process of welding metal parts without the use of a shielding gas has a number of advantages over other technologies:

- there is no need for the purchase and subsequent refueling of expensive cylinders with a gas mixture;

- no need to move heavy gas cylinders during work;

- welding flux can be selected according to the diameter and composition of its filling powder, which is convenient for welding various types of metal;

- During the welding process, it is possible to control the formation of a butt seam through the glass of the protective mask.

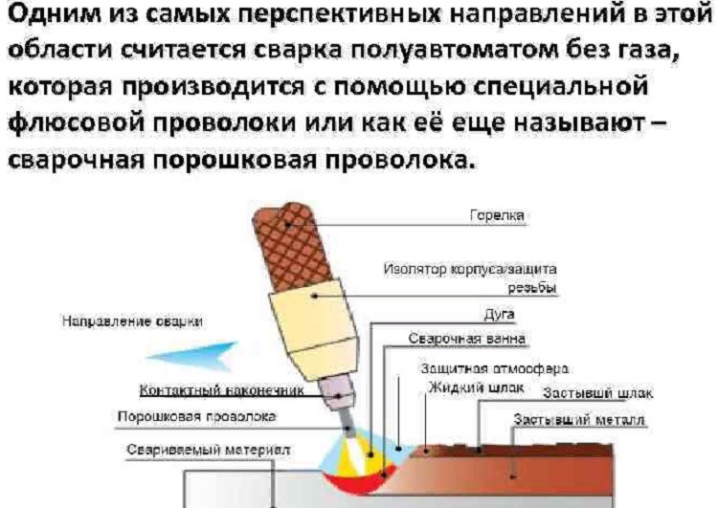

A wire with a flux placed inside it is a versatile and cost-effective substitute for gas equipment. According to its structure, the wire consists of a hollow tube made of steel material, inside such a tube is a flux in the form of a powder. Outwardly, such a powder looks like a coating that is used in the manufacture of a conventional welding electrode. During the work, the semi-automatic welding device provides a high-temperature environment in which the flux melts without residue. In the resulting weld pool, a liquid metal is formed, protected by the gas formed during the combustion of additives. This gas protects the joint of the seam from exposure to oxygen, which ensures the strength and reliability of the joint.

The use of the method of welding without gas using a semiautomatic device, in comparison with conventional types of welding performed in an active or inert gas medium, which is supplied during operation from a cylinder, has its advantages and disadvantages.

Among the advantages are the following:

- the semiautomatic welding machine is compact in size and light in weight, you do not have to purchase hoses and a gas cylinder with a reducer to perform welding;

- the compactness of the equipment allows it to be used in inaccessible areas - you can work with it at a height, as well as in narrow corridors or rooms;

- time is significantly saved for preparing equipment for operation;

- the welding process is performed quickly and accurately;

- the weld is formed under visual control, carried out through a protective mask;

- the temperature and power of the electric arc can be selected depending on the type of metals being welded;

- the wire can be selected with different types of filler.

The disadvantages of semi-automatic welding include the following points:

- the cost of wire with flux is quite high;

- welding wire has a certain degree of fragility, so it requires careful handling during operation;

- in accordance with the composition of the flux powder on the semiautomatic welding apparatus, it is necessary to correctly select the desired operating mode, which causes difficulties for beginners;

- when using a welding flux, slag is formed during the formation of the seam, which will have to be cleaned;

- the semiautomatic device has the ability to change the polarity of the connection, how to use it and for what purpose - it often raises doubts among inexperienced welders.

The cost of such work is minimal, which is especially important if you have to weld a small area

Main types of wire

Depending on the method of use and the method of protection against external influences, the wire for flux-cored welding can be gas-shielded and self-shielded.

Gas protection view

Gas-shielded wire is used when welding is carried out using semi-automatic and automatic devices for low-alloy and carbon steels.

The process involves carbon dioxide or its mixture with argon. Gas comes from outside. The filler powder can be selected to improve the welding parameters. For example, you can increase the vertical welding speed or firmly bond difficult-to-weld steel.

This technology is used when it is necessary to create overlaps, when working at joints and at the corners of structures, both for an automatic machine and for a semi-automatic machine. This technology provides consistent spray, reduced spatter, and resistance to pore and slag formation.

The material, which is used in the process of welding, has a high deposition rate, has a low level of smoke and allows high-quality seams.

Self-defense look

Self-shielding flux-cored wire is made in the form of a special "inverted" electrode (as if it were turned inside out). The use of this type of welding allows work under various temperature conditions (even extreme), with strong gusts of wind, and the like.

The main components of the core are various additives (dioxidizing, slag-forming and protective), which allows welding without the use of gas.

Self-shielded welding wire has a number of positive features, among which are:

- the ability to carry out welding work in various positions;

- due to the openness of the arc, it is possible to carefully move the weld metal;

- a special type of wire coating ensures its resistance to the pressure exerted by the rollers;

- due to the control of the chemical composition, it becomes possible to obtain a very specific slag composition.

In assembly conditions, mechanized powder welding is becoming more common. Although many people complain about the high cost of consumables, the efficiency of flux cored welding is significantly higher, just choose the right brand of wire.

Features of production

Wire production takes place in several stages in one installation.

- Cleaning the strip from dirt, oil, scale and moisture at the beginning of the machine.

- Slight longitudinal deformation of the pipe to form a semicircle.

- Filling the strip with powder.

- Connection of ends, formation of a tube with flux.

- Calibration of the connection and the profile itself. Creation of the correct circular cross-section.

In modern welding production, the most used welding strip is made of low carbon steels.

During manufacturing, the wire is not docked and is rolled to the length of the strip. There should be one whole piece on the spool.

To remove moisture and oil from the surface of PP and PS, the coil should be placed in the oven before installing it on the device. Maintain for 2 hours at a temperature of 230 - 250⁰.

Features of use

The use of a semiautomatic device during welding contributes to the rapid application of seams, because the powder type of products is fed without interruption. Since the gas hose may not always be available for work, this method allows you to weld metals in an environment of protective gases

Practically everyone will be able to cook correctly without gas, while special attention should be paid to surfacing and setting. When mechanized welding, it is imperative to take into account the current parameters, polarity, as well as the correct execution technique

There are some nuances in working with this metal device, which the master must not forget. In order to successfully lead the arc and form a seam, it is worth preparing a flat surface. When working with semiautomatic devices, this can be achieved by switching contacts in the interior of the unit.

An important point in the work is the installation of rollers that fully correspond to the diameter of the wire used. On the side of the roller there is information about the diameter range. A roller with a movable type should not be tightened tightly, since the wire is characterized by a hollow structure, and this event may entail its deformation or the occurrence of a jam in the cable channel.

In order for the wire to be fed unhindered, it will be necessary to remove the tip located at the outlet of the clamping element. Its winding is carried out after the consumable element appears from the end of this channel. The diameter of the tip must also be matched to the size of the wire, as a large hole can make it difficult to control the arc. No gas is used during this procedure, so it is not necessary to put on the nozzle. In order for the spray not to stick to the tip, it should be sprayed with a specially designed product.

Since the powder attribute of welding does not have mechanical strength and rigidity, experts recommend using a special mechanism, which ensures the continuity of the automatic feeding of the element.

In the process of welding, there is an intensive formation of slag, it must be quickly eliminated with a metal brush. Otherwise, slag can get into the working area, which will lead to the formation of defects and a decrease in mechanical strength.

Flux-cored wire can be made entirely of metal or be flux-filled to fulfill the tasks of a gas. Using this weld attribute may result in a lower quality weld than usual, but in some cases it is impossible to do without a powder additive.

Transportation of gas cylinders is not always appropriate, so the technician can use flux-cored wire, for example, at a height or in an inconvenient place. As practice shows, for home use with a small amount of work, this welding option is expensive. But in production, when using powder tubes, fast and high-quality welding can be carried out even by inexperienced specialists. It was also noticed that such welding can pay off when applying a long seam, otherwise a lot of waste is obtained.

Flux-cored wire welding is described in the following video.

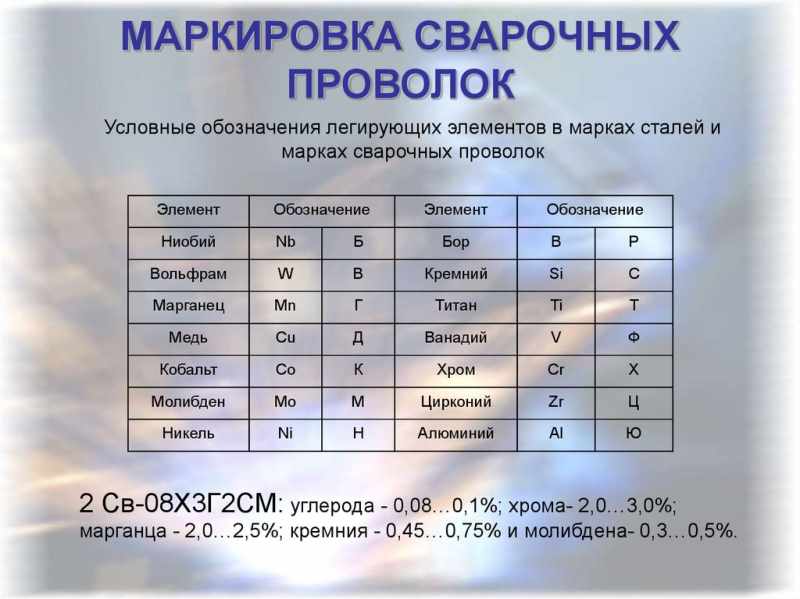

Types and marking of wire for welding

RF standards describe about 80 different grades of welded wire. However, in practice, no more than a dozen are widely used.

Welding wire marking

The remaining brands are highly specialized materials for special and rather rare applications, such as:

- manufacture of nuclear reactors, internals and nuclear power components;

- aerospace industry;

- special shipbuilding, including submarine hulls and reservations;

- equipment for the extraction, transportation and processing of oil and gas;

- shells and equipment for chemical reactors;

- other high-tech industries.

Wire designation consists of several groups of numbers and symbols:

- diameter in millimeters;

- destination:

- actually for welding "Sv";

- for surfacing - "Np".

- carbon content in hundredths of a percent;

Symbols of alloying elements

- the content of alloying additives in percent, if the content is less than 1%, then it is not indicated:

X-chrome.

N-nickel.

- M is molybdenum.

- C is silicon.

- N - nickel.

- X is chrome.

- C - zirconium.

- G - manganese.

- A is nitrogen.

- B - tungsten.

- T is titanium.

- Yu - aluminum.

- F - vanadium.

- B - niobium.

- D - copper.

- C is silicon.

- Requirements for the purity of the material.

- A - refined.

- AA - high purity.

- Smelting method.

- VI - vacuum induction.

- VD - vacuum arc.

- For the production of electrodes - letter E.

- Copper-plated - letter O.

- Link to GOST.

So, for example, from the designation you can find out that the Sv-08G2S brand contains 0.08% carbon, 2% manganese and silicon less than 1%. This filler wire is suitable for gas welding of alloy steel.

Marking brand Sv-08G2S

The world's leading welding wire manufacturers ESAB, Autrod and others use their own designation systems that comply with American or European standards. Dealers of these companies always have ready tables of correspondence of their brands to the brands stipulated by GOST.

What is needed for welding

- Power source (semiautomatic device);

- welding wire;

- shielding gas.

The welding wire must be identical to the metal to be welded. In our case, choose a stainless steel for a semiautomatic device.

Welding wire stainless steel for semiautomatic device

There are wires of Russian and foreign manufacturers on the market, which are subdivided into flux-cored and solid wires. Diameter from 0.13 to 6.0 mm. At home, diameters of 0.6 and 0.8 mm are used, and over 1.0 mm in production.

- Solid wire is used for gas-shielded and submerged-arc connections. This method eliminates the ingress of air into the welding zone, thereby improving the quality of the weld.

- Flux-cored stainless steel wire (self-shielded) - a thin-walled tube filled with flux and gas. The mixture of components allows welding products without protective gases (carbon dioxide and argon).

Semi-automatic stainless steel wire, produced with heat treatment or cold drawn. And it is subdivided into oxidized (T) and light (white, TC).

Stainless wire is available in 2 accuracy classes:

- increased accuracy (P);

- normal precision.

The wire is used with increased accuracy to improve the quality of the seam.

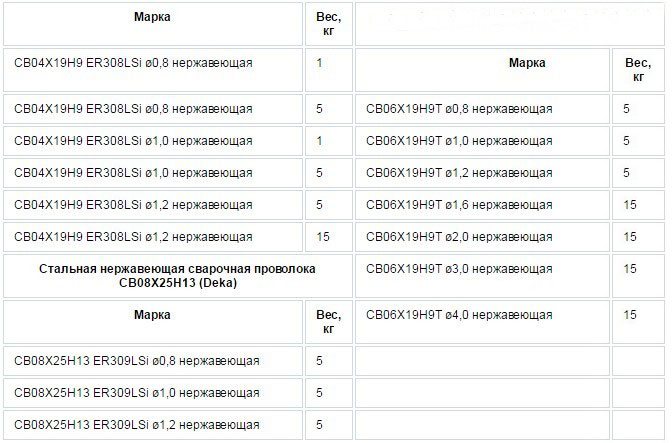

According to their chemical composition, stainless steels are divided into different grades and the wire also has different markings. The table (below) will acquaint you with the brands, diameter and weight of stainless wires:

The cost of stainless wire for a semiautomatic device

The price varies depending on the manufacturer and the region of residence of the buyer.

Average indicators:

- ER 308 LSI 0.8mm 1kg - 825 rubles;

- ER 308 LSI 0.8mm 5kg - 4237 rubles.

Video:

Gas selection

It is impossible to cook with a semiautomatic device without gas, except when using flux-cored wires. Welding of stainless steel with a semiautomatic device can be performed in an environment of carbon dioxide or a mixture of carbon dioxide and argon.

Carbon dioxide is an affordable and cheap gas for joining stainless steels. When used cleanly, the welder is faced with excessive metal spatter and a gnarled weld bead.

The percentage of carbon dioxide to argon can be adjusted using two separate cylinders.Connect the outputs from the two gearboxes using a tee taken from a domestically produced car windshield wiper. Details of a similar design in the video:

That's it, you just have to connect the selected shielding gas and wire to the device. Be aware: the conductive tip must be the same diameter as the wire.

Video: how to set up a semiautomatic device for work (for beginners).

How to weld stainless steel in carbon dioxide

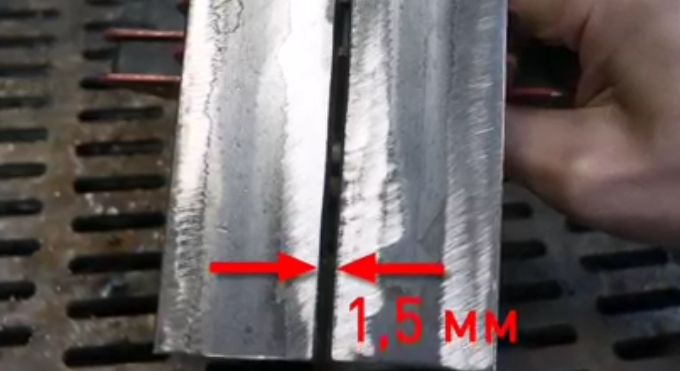

After chamfering, join the parts with the help of clamping pliers, leaving a gap between the products (at least 1.5 mm).

The gap should be along the entire length of the workpiece, it will allow the metal to be boiled to its full thickness. Connect the mass and set your settings on the semiautomatic device, depending on the design of your device and the thickness of the metal.

Simple semiautomatic devices on the front panel have 2 adjustments:

- welding voltage;

- wire feed speed.

The inductance setting changes the arc hardness, penetration depth and bead shape:

- With low inductance: cold arc - we get a thin bead with deep penetration;

- With high inductance: hot arc - wide bead with shallow penetration.

Holding the torch with a slope of 20-60 degrees (distance from the nozzle to the weld pool 10-20 mm), make a stainless steel connection with short tacks. We pulled the trigger - released it, pressed it and released it, just like that, slowly, the cut edges are filled with metal. You can cook both with an angle back (towards yourself) and with an angle forward (away from you).

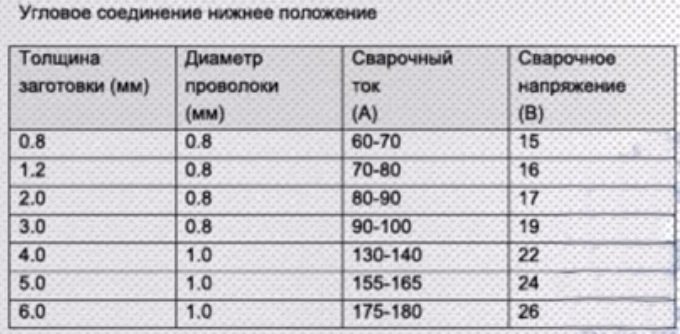

The tables (below) will help you determine the settings for the semiautomatic device:

When welding with an overlap, chamfers do not need to be cut, it is enough to clean the surface, superimpose the parts on top of each other and make the connection.

When welding, bite off the weld bead on the tip of the wire before making a new weld.

In the process of joining stainless steel with a semiautomatic device in an environment of carbon dioxide, change the wire feed speed, with such manipulations you will achieve a high-quality seam.

Video:

P.S. After reading the article, watching the tables and videos (for beginners), you will master the automatic technology of stainless steel joining - quickly. Good luck!

Welding with flux cored wire without gas

Before starting the welding process, you need to set the recommended current values on the machine. Next, you need to check the condition of the feeding sleeve (for wear) and the absence of displacement of the feeder. The feed rollers also need to be calibrated - they should not press too hard to avoid deformation and uneven feed.

The parts to be joined must be cleaned of oxide film and, with a thickness of more than 4-5 mm, bevels must be formed. After the occurrence of an electric arc, it is led from the bottom to the top of the part (if it is located vertically). The torch handle must be held at an angle to the surfaces to be welded - this stabilizes the weld pool, protects against premature spreading of metal from it.

The parts to be joined must be cleaned of oxide film and, with a thickness of more than 4-5 mm, bevels must be formed. After the occurrence of an electric arc, it is led from the bottom to the top of the part (if it is located vertically). The torch handle must be held at an angle to the surfaces to be welded - this stabilizes the weld pool, protects against premature spreading of metal from it.

It is recommended to keep the seam withdrawal speed about 15-20 mm per second. When forming a seam in several passes, you need to wait for the layer to cool and clean its surface from the slag crust - otherwise the second and subsequent seams will turn out to be of low quality due to impurities.

Activated wire

This welding consumable is similar in composition to flux-cored wire, but special additives have been added to it, which optimize the parameters in the weld pool area and prevent metal destruction during and after welding. Structurally, activated wire has a different structure than flux-cored wire. The percentage of additives is significantly less and does not exceed 6-8% of the total running weight. In this case, the additives are not poured into the cavities, but are embedded in the wire body in the form of thin channels, and the material combines the advantages of solid wire and flux-cored wire. Due to the small proportion of additives, welding with such a wire can only be carried out in an inert gas atmosphere.

The additives are readily ionizable compounds of light metals and slag-forming components that improve the situation with the stability of the working parameters of the weld pool. They increase the stability of the arc.

The following advantages of the activated wire can be formulated:

- Wide range of compatible equipment. Wire, unlike flux-cored wire, allows bends and does not require specialized feeders.

- High quality of the seam due to lower surface tension of the jointed workpieces and low hydrogen saturation.

- Reduced current consumption by protecting the weld area from excessive heat loss.

Welding wire

The main disadvantage of the activated wire is the need to use gas. This increases the complexity and cost of the operation.

Technology

With a semiautomatic welding machine, you can independently cook stainless steel, non-ferrous metals, steel, aluminum. To connect nonferrous metal blanks, you need to choose the right wire for welding. For example, a flux containing magnesium, manganese and aluminum can be used to weld aluminum parts. This wire makes it possible to connect thin metal or thick sheets

For novice welders, it is important to observe all stages of preparation and technology of the welding process

Wear protective clothing and a welding helmet before starting welding. Work can be carried out provided that there are no flammable objects within a radius of 10 m. Unauthorized people without protective equipment are not allowed into the working area.

Preparation

The welding method with a semi-automatic device without gas equipment differs from the usual welding method in that it has a different polarity: a terminal with a "plus" sign is attached to the workpiece, while a "minus" will be connected to the electrode. This polarity is explained by the fact that with its help it is possible to achieve the highest possible temperature conditions, which are necessary for melting the powder flux.

Another important stage of the preparatory work is a thorough preliminary treatment of the surfaces of the workpieces connected to each other.

To set up semi-automatic welding equipment, you will need to do the following:

- choose the indicator of the current strength set for work, according to how thick the metal will need to be connected;

- select the optimal mode of the welding wire feed speed so that it does not get damaged by tension during welding;

- transfer the device to the direct polarity of the current;

- scroll the wire forward, open the flap at the flux feed funnel, press the start button and activate the electrode;

- carry out a test welding and, if necessary, correct the parameters of the machine.

After the adjustment of the semiautomatic device is completed, the wire will freely feed into the welding area, and the welding arc is stable, you can start forming the connecting seam.

Experienced experts recommend setting the pressure rollers of the machine according to the wire thickness. If this condition is met, the flux wire will move freely through the pipeline without the risk of getting stuck in the feed channel or breaking.

Process

During the operation of the semiautomatic welding machine without the use of balloon gas, the flux creates a cloud of shielding gas during combustion. Such vapors tend to rise upward, so the welder must provide for an exhaust system or provide good ventilation of the room.

After the semiautomatic welding machine is brought into operational readiness, the movements of the electrode must be performed along the formed connecting seam. If thick sheets of metal are to be joined together, then this process is performed in several layers.Moreover, in order to avoid the appearance of cracks in the seam, you need to boil the first layer at a low electric current. A seam is formed by filling the weld pool with molten metal. After the cavity of the weld pool is completely filled, it is necessary to turn off the wire feed, stop the welding machine and turn it off from the network.

So that the work can be performed as conveniently and efficiently as possible, it is recommended to start the welding process from the upper segment of the parts to be joined, gradually going down. When the flux burns, heat energy is generated and, rising up, it makes it possible to constantly maintain the same temperature level required for melting the metal. It is recommended to tilt the handle of the electrode holder slightly upward to maintain a constant melting of the metal and form a weld pool.

The torch of the semi-automatic welding machine must move quickly and smoothly along the joint seam, while trying to prevent the appearance of sagging of molten metal. For this purpose, the wire must come to the leading edge of the weld pool.

How to cook with a semiautomatic device without gas, see below.