Positive traits

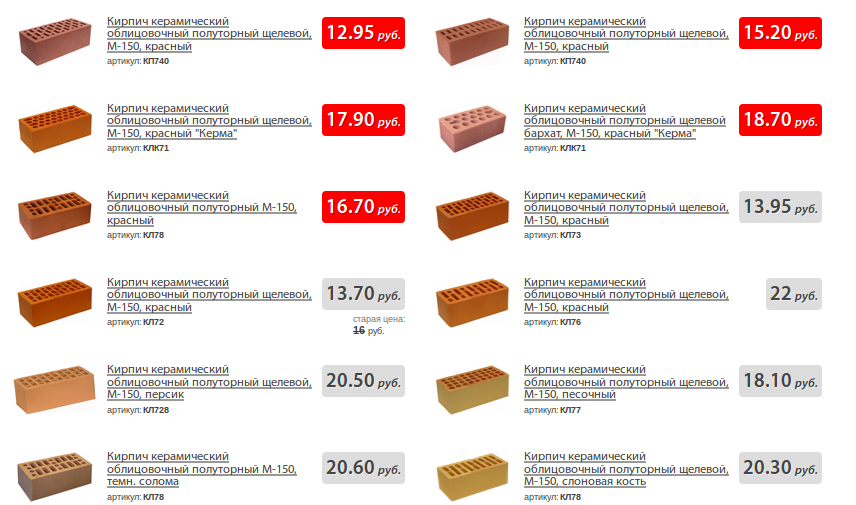

One-and-a-half facing brick is an artificially created stone, which is characterized by a corresponding demand due to some of its rather important advantages. It is they who distinguish it from other types of building materials of this type.

Builders highlight the following positive qualities:

- due to the fact that a one-and-a-half brick in its overall dimensions is slightly larger than standard products, it requires the use of a minimum volume of mortar to work with it. This allows you to save money by purchasing sand and cement for its preparation;

- due to the fact that facing bricks are mainly used to give the walls a beautiful appearance, it is distinguished by an increased level of aesthetic properties. Manufacturers are constantly trying to improve manufacturing in order to make the material more original and unique;

- due to the rather significant size of each unit of material, less labor is required from the workers to carry out the work. This significantly affects the speed of wall decoration, rather than when using artificial stones that are standard in size;

- since facing brick in most cases is directly the outer layer of any building and structure, it has increased water absorption. Precipitation practically does not penetrate into its middle, which increases the duration of its operation;

- one of the distinguishing qualities of the material is also frost resistance. Negative temperature readings can affect the facing brick, but due to the fact that water does not penetrate into it, the process of freezing and defrosting of the liquid does not occur;

- namely, this provokes the destruction of many other types of stones, which have pores through which sediments pass into them;

- in order to ensure the proper degree of its decorative effect for a long time, facing brick is also distinguished by such quality as color fastness;

- the ultraviolet light that the sun emits cannot change the shade of the material over a fairly quick period and affect the start of the process of fading of the original shade.

The above-written advantages that one-and-a-half facing bricks have provided it with the proper level of popularity and prevalence.

Weight measurement

In terms of its severity, silicate is similar to fireclay brick. Some manufacturers may add iron oxide to the raw materials for brick making, as a result of which the product will look like ordinary red brick. But when choosing, you need to be careful, since this type of stones cannot be used to decorate fireplaces or stoves. With intense heating, they will crumble and turn into powder.

It is also important to know the weight of the brick, which is determined by the type of product. Depending on the use, silicate can be as follows

Ordinary. It is used for simple masonry and has rough sides. The presence of small chips on the surface is allowed.

The weight of any body can be calculated in a certain form and perform such work yourself

Also, when calculating, it is important to take into account the presence of voids in the product and its moisture content, which affects the weight characteristics. The specific gravity of standard silicate is 1300-1900 kg per cubic meter

Correctly made preliminary calculations will make it possible to find out how much weight will affect the basement and provide a reliable foundation that will withstand all loads and at the same time will not allow the walls to crack during construction. Also, the manufacturer must always indicate the specific gravity of the finished product, which simplifies the calculations.

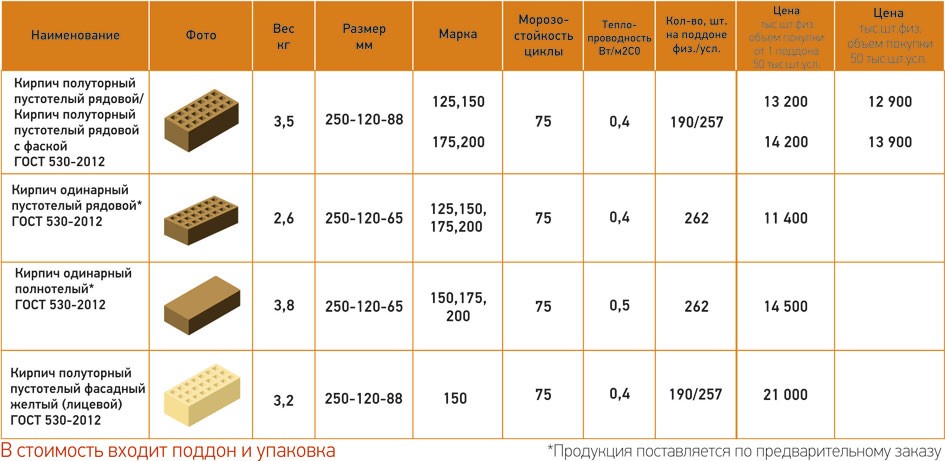

The strength of the stone is determined by the brand, which must also be taken into account when choosing. For example, grade M75 is used for the construction of structures with a height of no more than one floor. It is also assumed the possibility of constructing load-bearing walls from them with a small load. The M100 brand is suitable for constructions of objects with two or three floors. For tall buildings, a brick with a strength of M200 is used.

Any silicate brick is distinguished by fire safety, which is ensured by the absence of flammable components in it. Walls made of this material should, in any case, be additionally finished with insulation. A disadvantage of silicate is a high rate of water absorption.

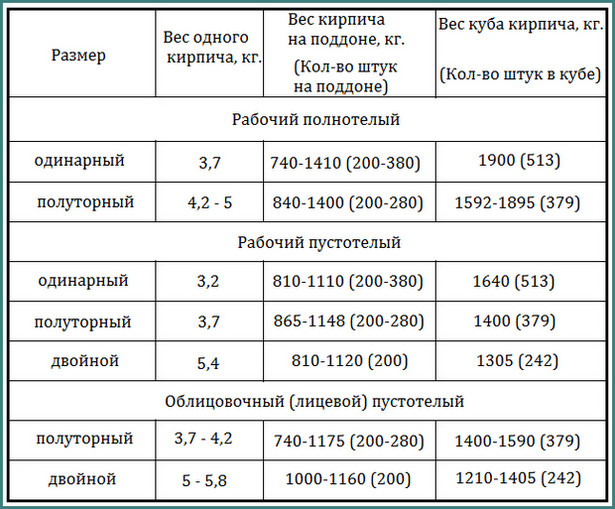

To know the weight of 1 cube of brick in the masonry, you must initially determine the number of products in it. Experts note that in the cube of masonry there are 414 single pieces, and thickened - 314. This amount is approximately, since it all depends on the thickness of the seams and the type of masonry. For example, the average joint width is one and a half cm, and therefore this value must be added when calculating the number of bricks in one cubic meter of masonry. All the data on which the calculations are made apply only to products manufactured in accordance with GOST.

- The formula for calculating the number of bricks in a cube of masonry: 100x100x 65 (88, 206).

- The formula for calculating the weight in a cube of masonry: 414 pcs. x 3-4 kg.

The bricks to the site are usually delivered in stacked pallets containing one cube of brick. This allows developers to navigate the calculations and order the required number of products. The sizes of silicate are standardized so that it is convenient to calculate their volume and number of units.

These bricks can be used for load-bearing foundations, columns, pillars and other objects, and therefore, before buying, you need to decide on the type of masonry that will be used. The choice of the product in terms of thickness and other parameters depends on this. For example, a single brick is usually used for the construction of load-bearing walls in structures. To fill the voids, you can use one and a half bricks.

Also, when choosing this material, it is necessary to take into account the ability to absorb water by it, which reduces characteristics and reduces resistance to low temperatures. Therefore, it is not recommended to use such products without additional waterproofing in basements or other places where high humidity is observed. It must be remembered that silicate does not tolerate high temperatures well, and therefore it is not recommended to use it near heating devices.

Sizes and some types

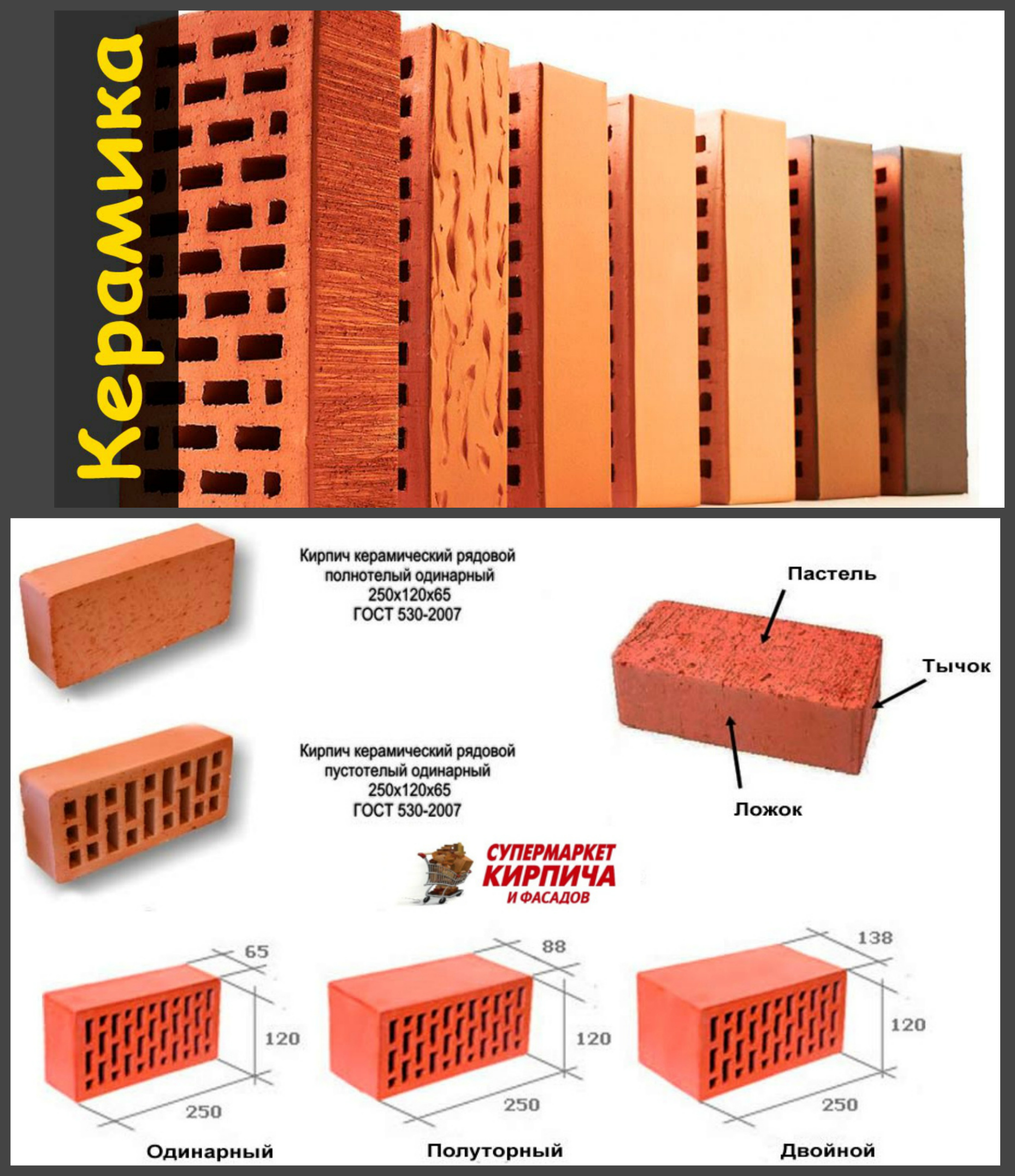

Types of bricks.

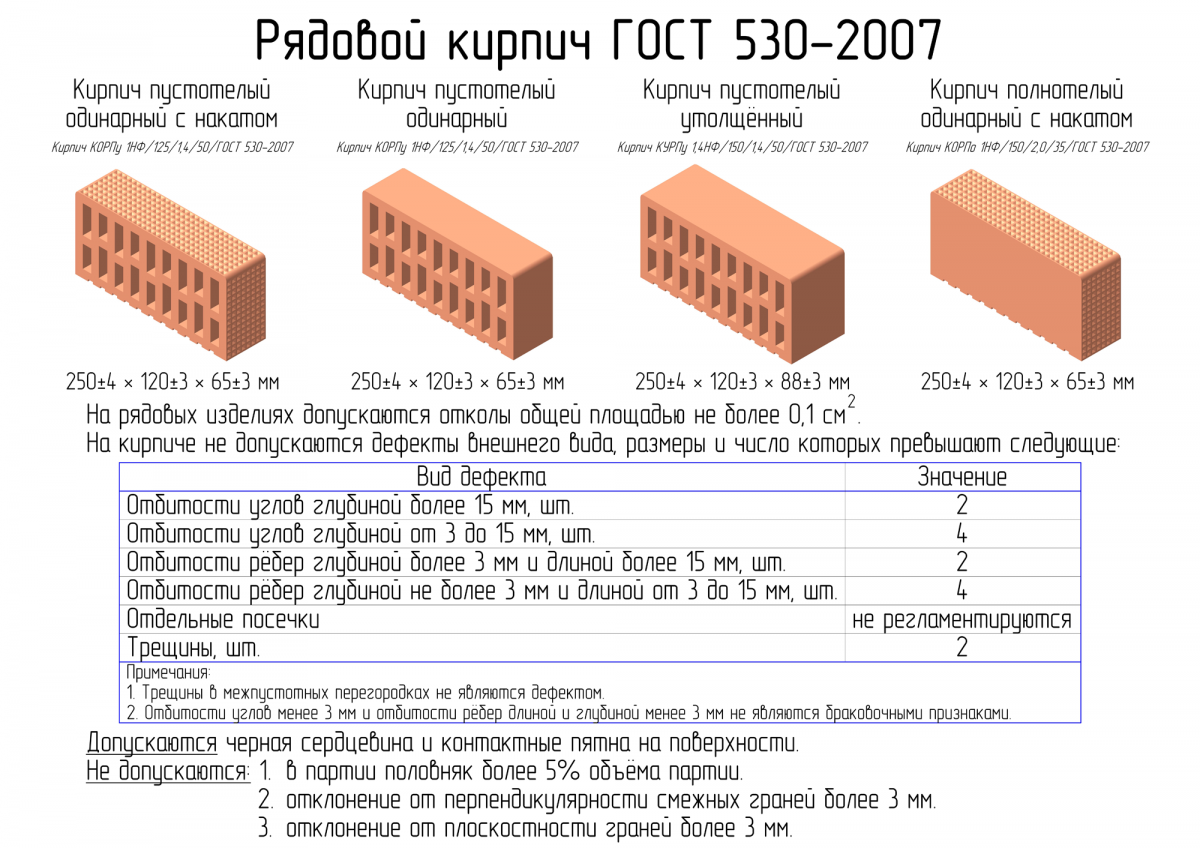

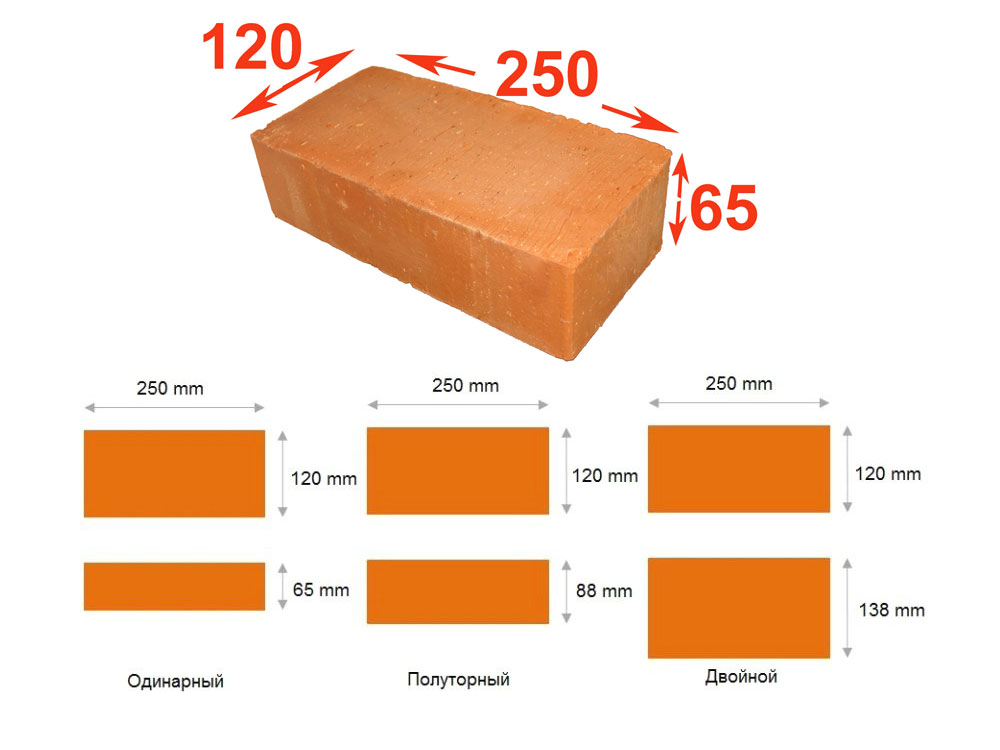

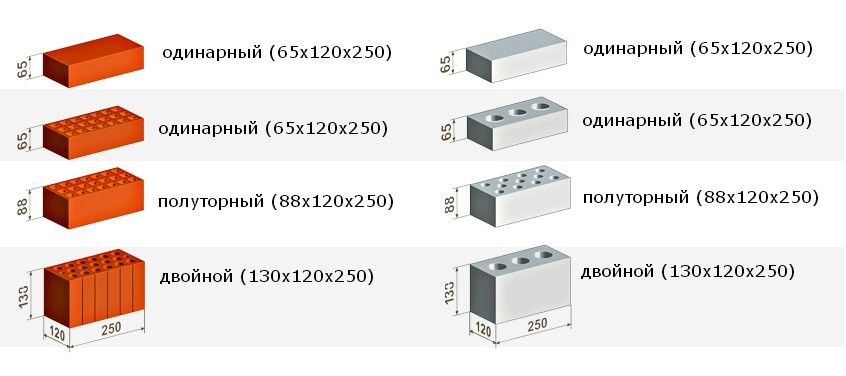

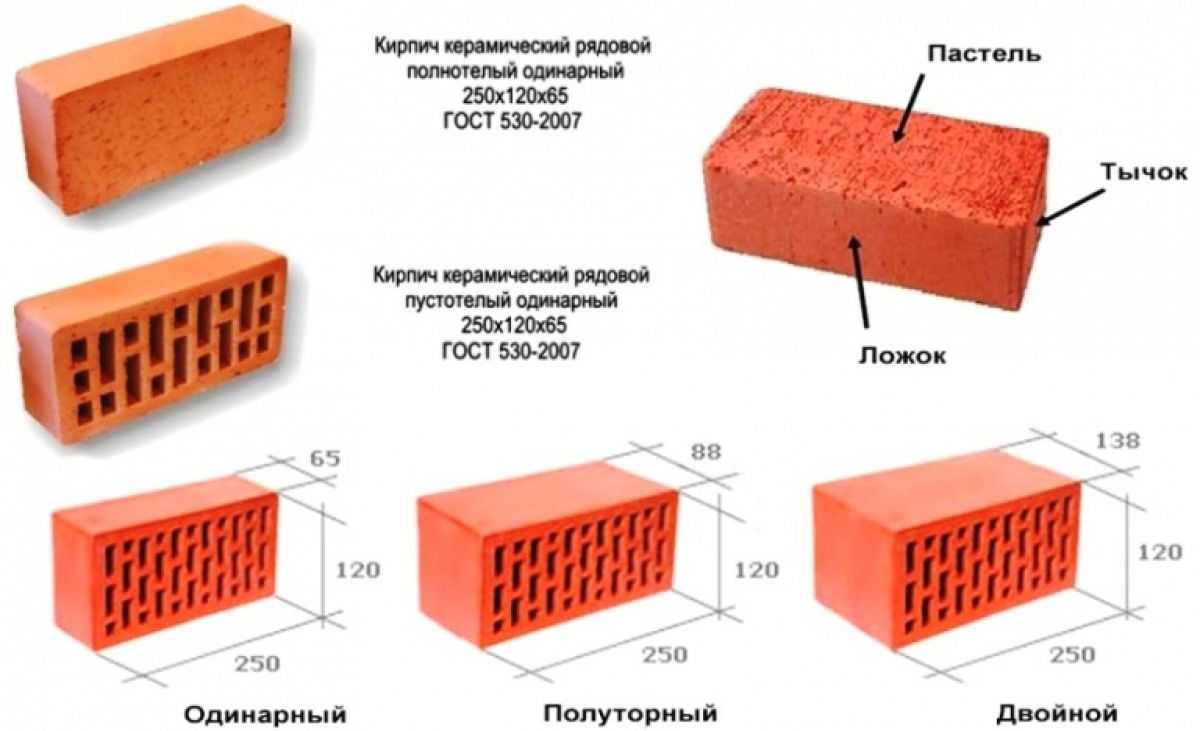

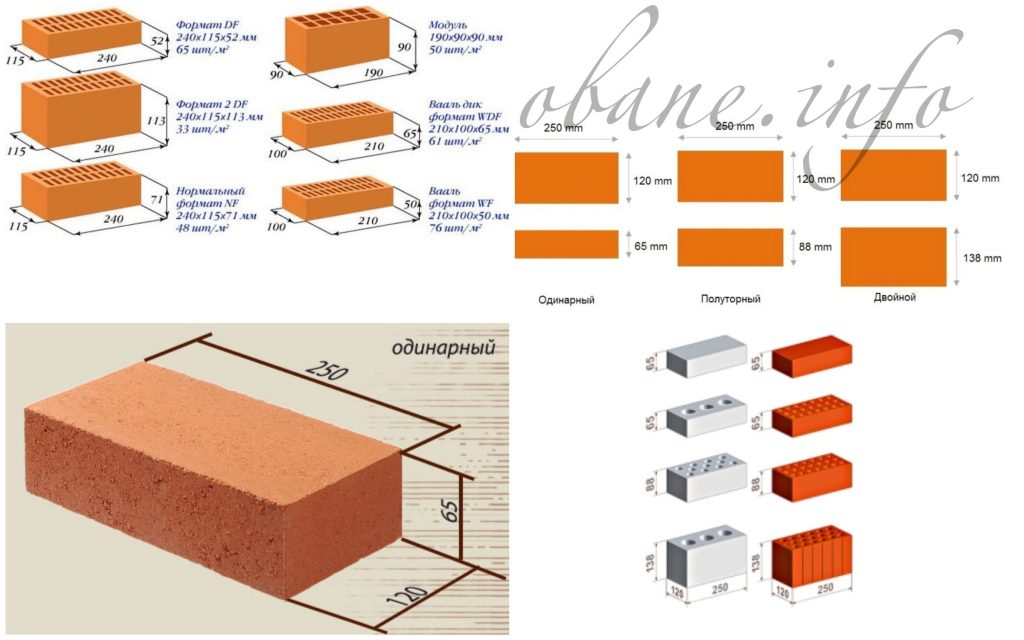

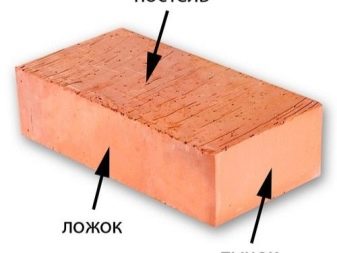

Ceramic brick is an artificial stone that has a regular shape, straight edges and a flat surface. The edge parallel to the base of the masonry (bed) is 25 by 12 cm, and the middle one (placed perpendicular to the bed) is 25 by 6.5 cm (for a single brick). The jab is the small side of the product, which measures 12 by 6.5 cm.

A solid pottery has no holes and has a voidness of 13%. Therefore, it has a higher cost than other types, which mainly depends on the energy and material used. Solid brick is used in places where it is necessary that the loads are distributed and sustained, that is, when building a basement, the foundation of a house or an industrial structure.

Experts advise using this material for laying out the outer wall. It should be borne in mind that in order to ensure the thermal conductivity established by the norms, the walls of such a brick must have a thickness of up to 2 cm.

In addition to solid and hollow ceramic bricks, a slotted brick is also produced, which has a through hole, and the shape of the hole can be different. This type, in comparison with others, is warm, and the walls of it are erected with a width of 1-1.3 cm. It is also lightweight, therefore, a large load is not created on the base under the house and the basement.

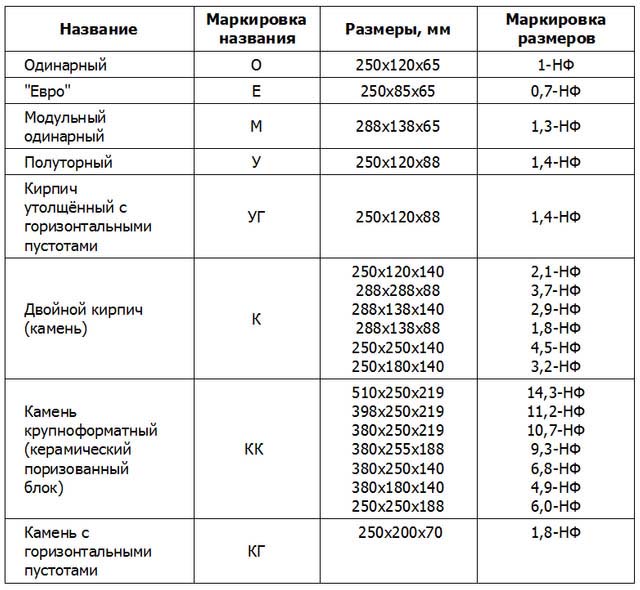

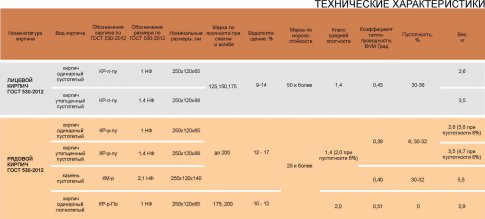

The following full-bodied products are produced:

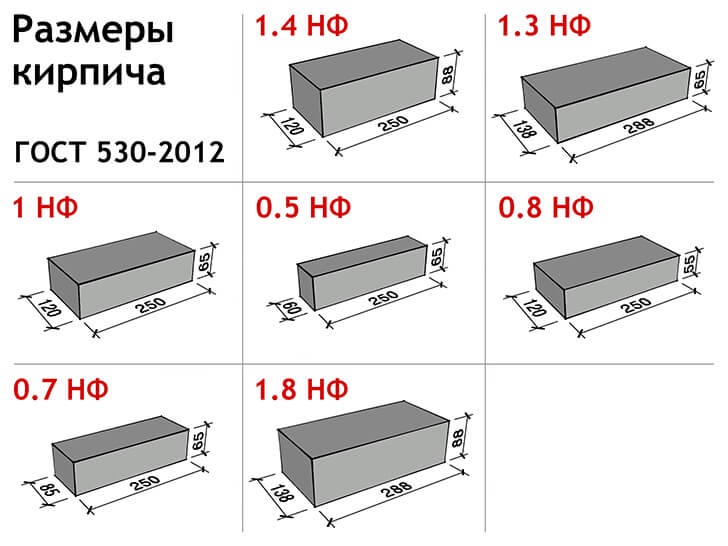

- single NF (25 X 12 X 6.5 cm);

- one and a half 1.4 NF (25 X 12 X 8.8 cm);

- double 2.1 NF (25 X 12 X 14).

Ceramic brick production technology.

Consider the methods of making ceramic bricks. There are 2 ways: plastic and press.

When using the first method, the clay should have a moisture content of 17-30%. Using special equipment (belt press), a product is squeezed out of the material, then fired. This means that the product is plastic molded.

When using the second method, a ceramic semi-dry pressed brick... This method differs from the previous one in that the clay has a low density (8 - 10%). The first method of production is most often used, since the material obtained by semi-dry pressing cannot be used in the construction of premises with a high level of humidity.

Characteristics and composition

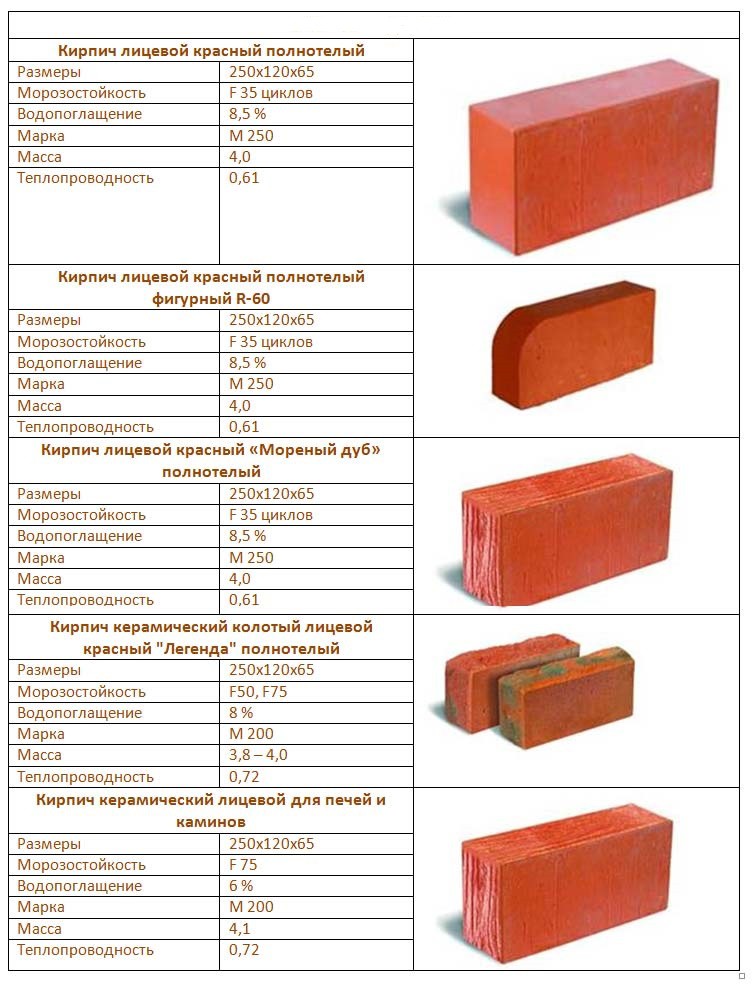

Red brick is a common building material that many users turn to. Buildings and houses of various configurations are built from it. This building material has certain characteristics that should be considered when choosing it.

Strength characteristics. Red brick is a fairly durable building material. This parameter is indicated by the letter "M" and the number

You should pay attention to these designations when selecting high-quality and suitable products. There are bricks "M" 25-100

The higher the digital marking, the more impressive load the material can withstand per 1 sq. cm.

Resistance to frost. Resistance to low temperatures is measured by the number of cycles. Each cycle consists of 2 main procedures - first, the brick is immersed in water for 8 hours, and then it is moved to the freezer for a similar time period. The level of frost resistance is determined at the moment when the building material changes some of its characteristics.

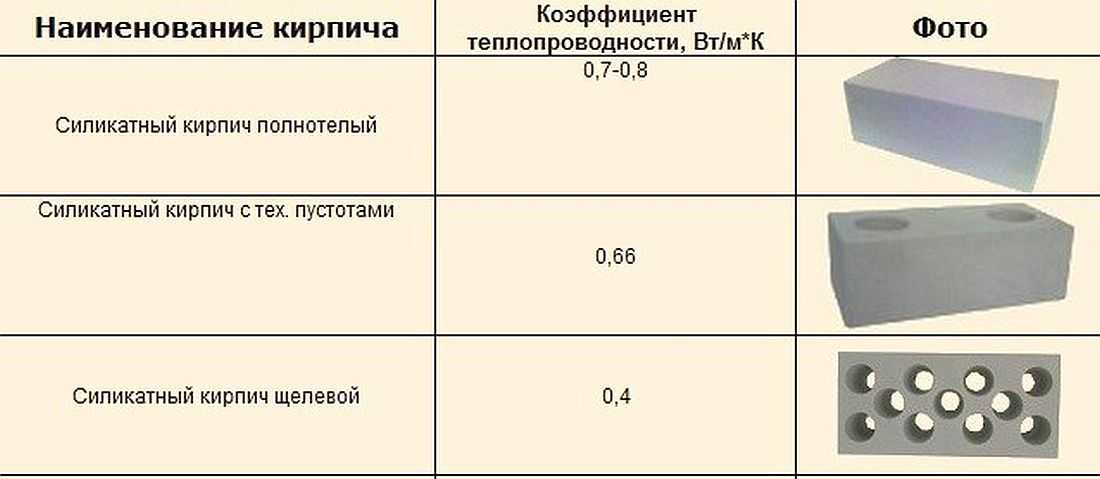

Thermal conductivity

This characteristic is no less important than the same frost resistance. The coefficient of thermal conductivity indicates the amount of heat that can pass through a wall with a thickness of 1 meter under conditions of a temperature difference of 1 degree on both sides

This indicator is measured in watts. The more significant it is, the weaker the heat-conducting properties of the building material are.

The main characteristics of this building material directly depend on the components present in its composition. It is possible to obtain a high quality product using good clay. So, the face type of brick is obtained from fine-grained clay. The best material is considered to be made from a clay composition without additional additives. In most cases, bricks are made from clay that is not suitable for preparing other pottery.

It should also be noted that in the production of red bricks, ingredients are often used, the content of which contains:

- kaolinite;

- illite;

- montmorillonite;

- quartz.

The primary properties of clay intended for the production of bricks include:

- high plasticity - the raw material should not be crumbly, if kneaded, and should also keep its shape (a little less often you can find absolutely non-plastic clay);

- binding ability - clay remains sufficiently plastic after adding auxiliary components;

- shrinkage - in this case, a change in size is meant during drying and firing;

- sintering property - here we mean the ability to harden when heated;

- fire resistance - during heating, the clay should not melt.

In many cases, in the manufacture of high-quality red bricks, not only one clay is used, but also various additives. They allow you to end up with a more reliable and attractive building material. These additives include:

- slag, ash and sand;

- coal and peat powder, sawdust;

- iron ore;

- sandstone;

- metal oxide.

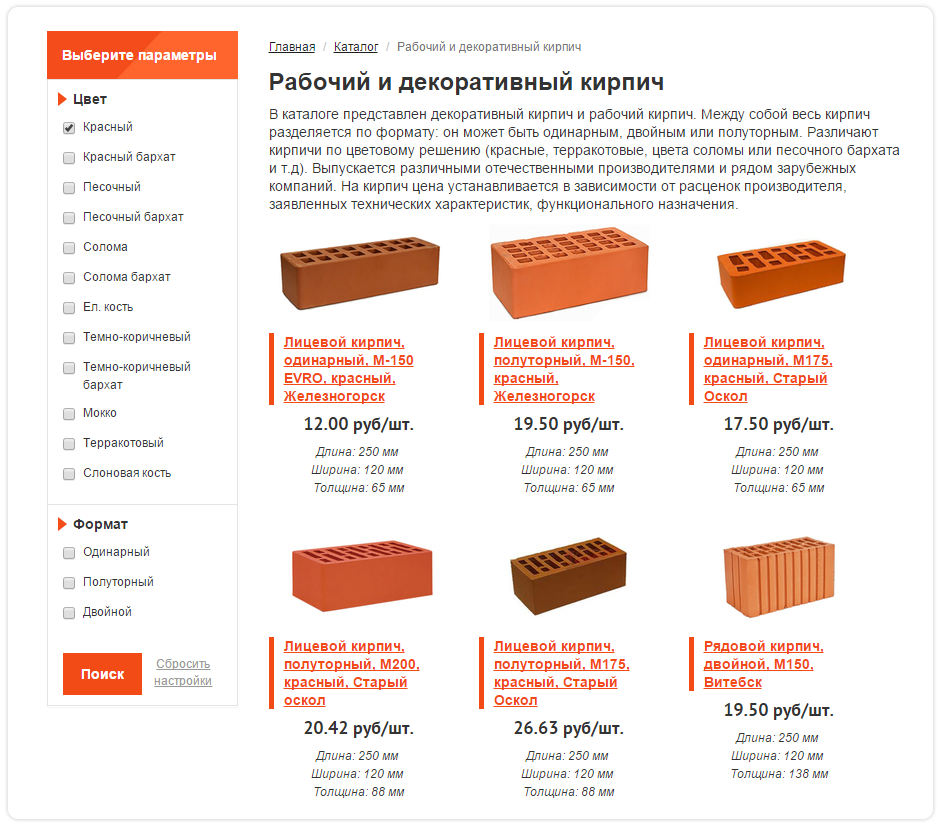

Red one and a half brick: its characteristics and manufacturing process

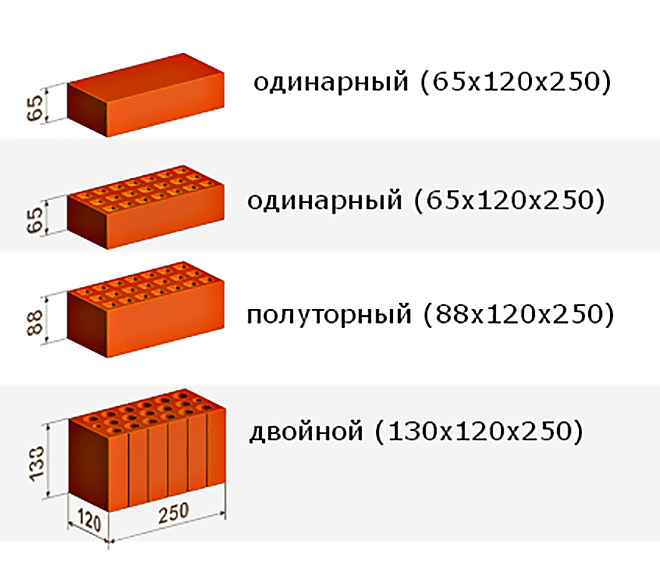

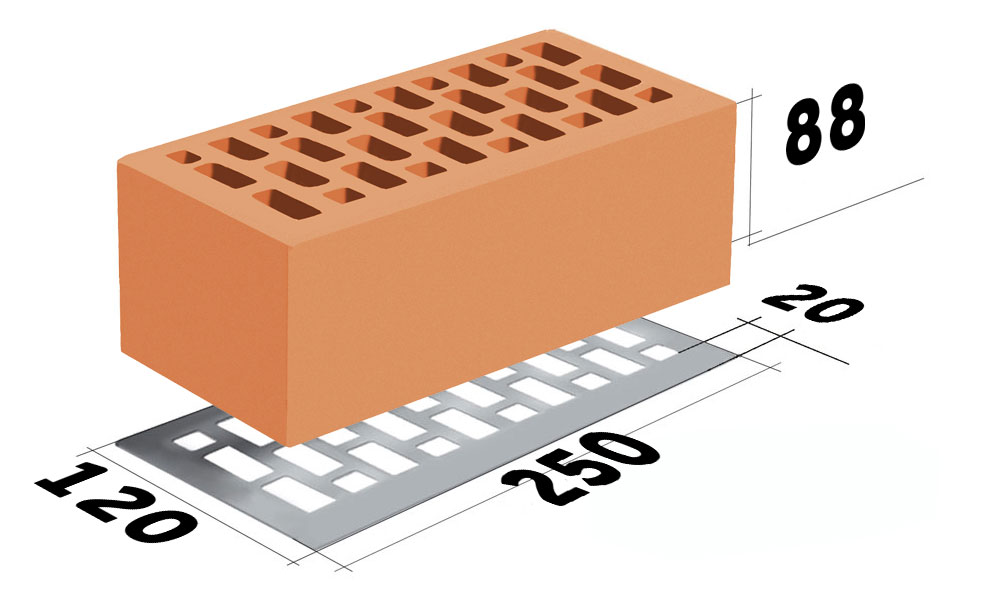

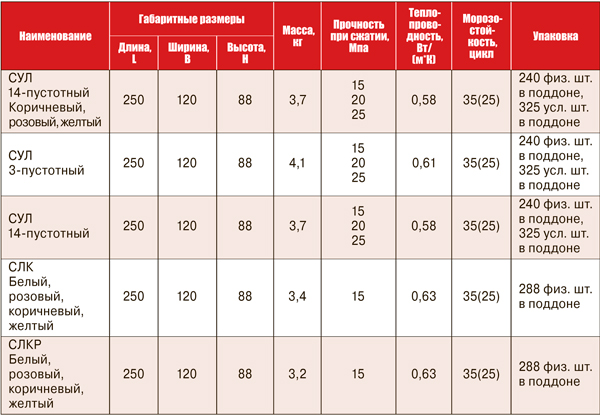

Red one-and-a-half brick is a fairly common product, which does not differ much in its cost from a single version. True, this principle is true when comparing price ratios. At the same time, one-and-a-half brick in its characteristics fully complies with all the necessary technical standards specified in the regulatory documents. These parameters completely coincide with those criteria that are inherent in ordinary red bricks. The only difference between this material and the parent specimen is its size. If the parameters of an ordinary single product are 250x120x65 mm, then in the one-and-a-half analogue they differ in the size of one indicator. One-and-a-half brick is characterized by the following parameters, showing the length, width and height of the specimen, and look as follows - 250x120x88 mm.

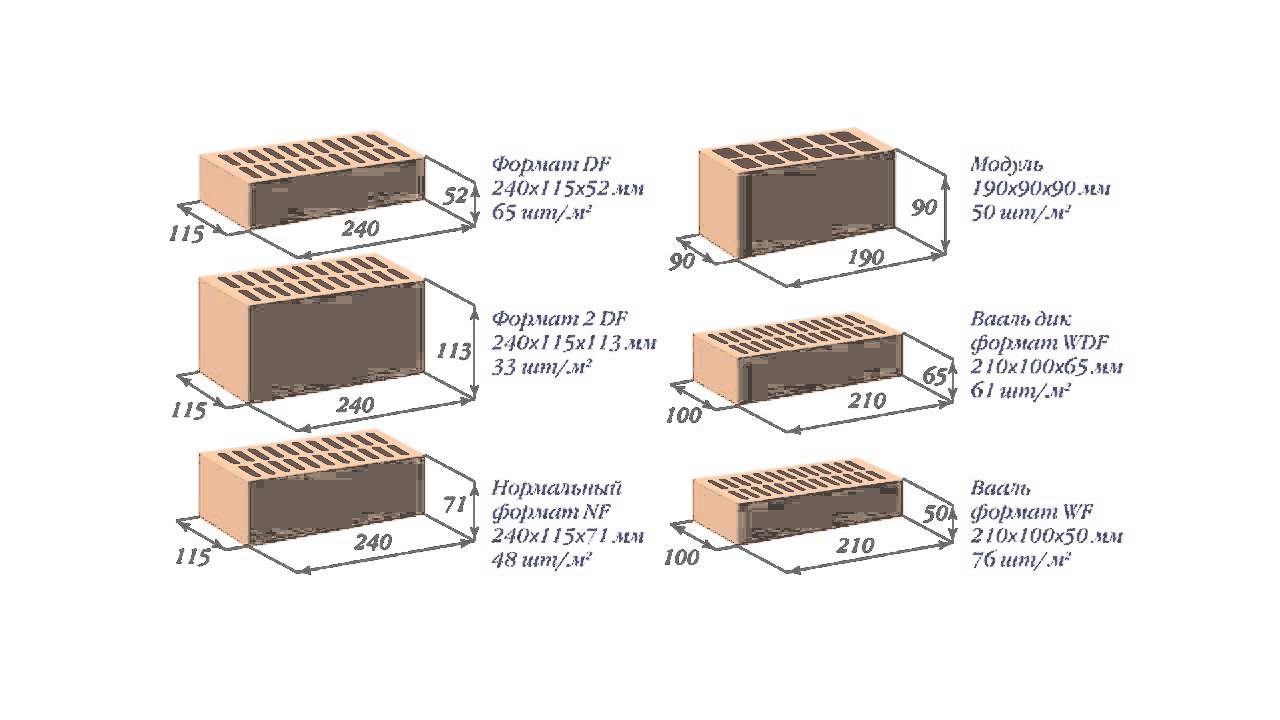

Basic brick formats.

Specifications ordinary brick and a half due to the process of its manufacture, which consists in uniform firing of clay blocks until they acquire the necessary parameters of rigidity and strength. In the process of thermal action applied to the workpieces, the top layer hardens most quickly, and the middle hardens much more slowly. This process leads to the formation of a rather porous structure of the material, containing many voids.

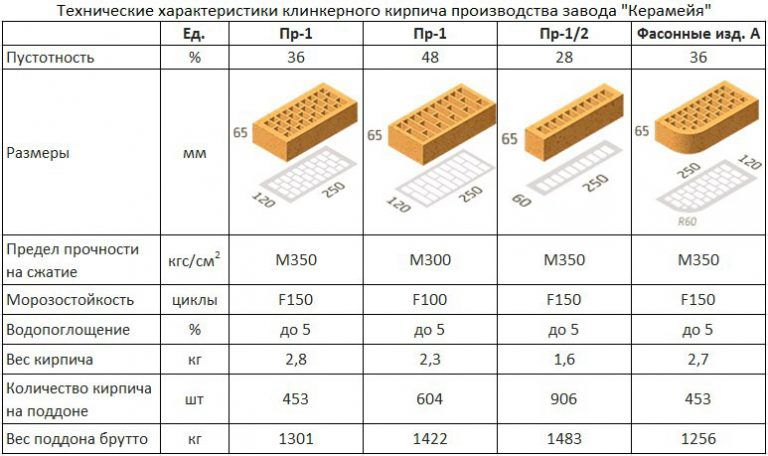

At the same time, the very name "brick one and a half" is rather a household name and can be applied to almost any similar ceramic products. Today, manufacturers of similar products produce many varieties of this material with such dimensions. These materials can be either clinker or silicate type of this material.

Dimensions as standard

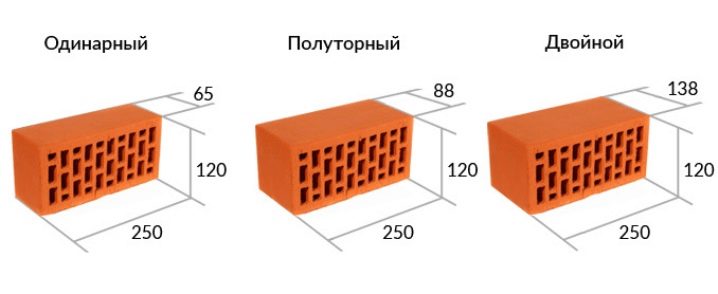

The main point in the standardization of brick sizes is the following proportions 1: 1/2: 1/4. This aspect ratio is optimal for masonry with a rotation of the transverse and longitudinal placement. In individual construction, single brick is in demand, its consumption per 1 m³ of masonry is 513 pieces.

According to the state regulations available on the territory of the Russian Federation, the size of a standard single product is equal to:

- 25 centimeters in length;

- 12 centimeters wide;

- 6.5 centimeters in height.

In addition to single bricks, the building materials market offers other types of standard sizes:

- one and a half;

- double.

One and a half building material began to be produced during the industrialization of the country in order to accelerate the pace of construction. The standard consumption of bricks is 318 pieces per 1 m³. A characteristic indicator of a one-and-a-half product is the added height; GOST defines the following standard product parameters:

- 25 centimeters in length;

- 12 centimeters wide;

- 8.8 centimeters in height.

The double brick, having the same 25 centimeters in length and 12 centimeters in width, has a height of 13.8 centimeters. Based on the considerable size, to reduce the weight of the product, double bricks are usually made hollow. It is widely practiced in various fields of construction. Height-added products are practiced for the construction of both civil and industrial facilities.

Application

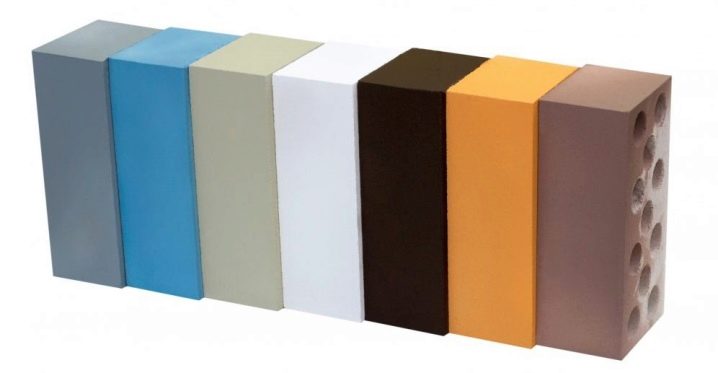

Facing brick is the most common and popular type of ceramic counterpart. It has found its application in the interior and exterior decoration of the facade of the building. It is used for the construction of load-bearing columns, the construction of fences.

Fence

Facing briquettes have found their application in the improvement of adjacent territories. They are actively used by architects and landscape designers who are not afraid to embody even the most diverse ideas.

The use of plaster has already faded into the background, because it requires increased attention and care. Otherwise, the constructed building will have an unpresentable appearance, moreover, the plaster will begin to crumble over time.

At the same time, repairs and constant maintenance of the external facade requires a lot of money. This problem can be solved easily and cheaply by using brick for the first time in real estate cladding. It is considered to be a fairly durable building material that does not require any additional maintenance.

Facade

Today, modern technologies are actively developing and red facing bricks are able to embody any decisions of architects and designers with their original projects.

But when working with bricks, and especially when it comes to facing, it is worth remembering that it is advisable to use only the material that was produced in one batch. Then all the briquettes will be not only the same color, but also the shade.

Also, always consider the main rules when laying facing bricks in order to get a predominantly good contrast between the shade of the material and the color of the mortar:

red facing brick should be combined with black mortar;

Black solution

facing bricks of brown and gray colors are harmoniously combined with snow-white mortar.

White solution

The building briquette differs significantly from the facing one. And not only here external characteristics are taken into account, technical features are also important.

Building

For facing work, hollow or porous briquettes are most often used. The use of the former is extremely rare.

In addition to improved appearance, this briquette stands out for its resistance to subzero temperatures and strength.

Glazed

In addition, it is rational to use a relief analogue. Such bricks are produced in figured and shaped, in addition, they give the facade an original and memorable look. The material considered in the article is often used for decorative purposes for interior decoration.

Shaped

In addition, it stands out for its practicality in operation - you just need to correctly choose the material from the whole variety of color palette, trust the masters. As a result, any room in this design will become nontrivially aesthetically perfect.

Hyperpressed

Due to the unique production technology, this type of material for the construction of load-bearing structures stands out not only for its aesthetic external characteristics, but also for the established dimensions. Do not forget about the high performance characteristics.

The weight of a solid brick in a classic design is 3.3-4.3 kg

It is used for buildings made of ceramic stone, in the construction of plinths of wooden houses, for bandaging foam concrete / silicate masonry, quite rarely - as the main building material. Before concrete slabs and foundations appeared, it was irreplaceable. This is due to its resistance to the action of groundwater, the possibility of using it in the layout of vaults and large-scale arches and selection for complex facade decor. However, the degree of thermal insulation of this material is quite low, which automatically increases the thickness of the walls, and, consequently, the load on the foundation.

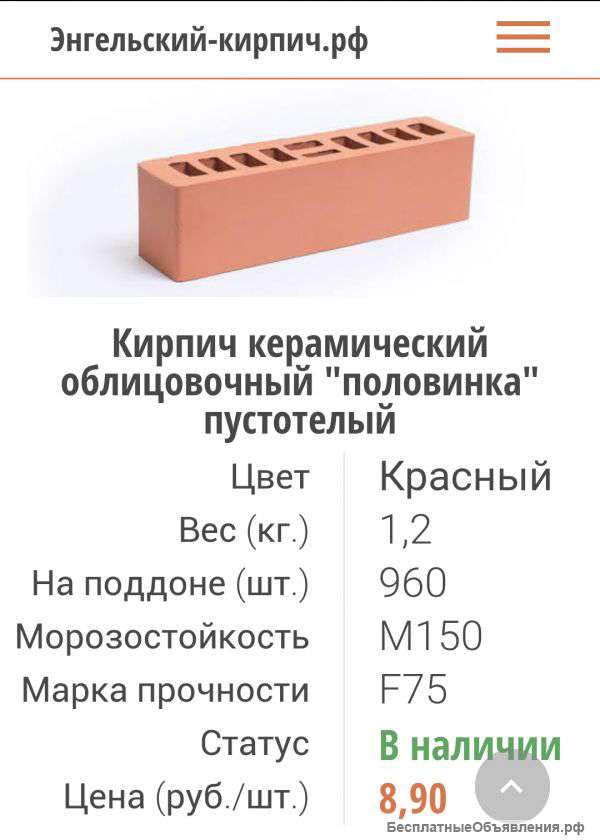

The weight of a single solid red brick averages 3.45 kg (3.3-3.6 kg), a single hollow brick - 2.4 kg, a single facing brick - 1.45 kg.

- Construction slotted (hollow) brick weighs about 2.5 kg. however, it is also losing its popularity in the construction market. Taking into account the mortar, 1 cubic meter of masonry weighs almost 1700 kg, which guarantees a significant weight of the structure and the corresponding load on the base of the house. In low-rise construction, it is much more profitable to use ceramic stone with high thermal efficiency.

- Silicate is the heaviest option.According to GOST 379-95, the weight of the silicate brick should not be more than 4.2 kg. but today many manufacturers in their work are guided by the TU, according to which even a brick weight of 5.0 kg is considered normal. The indisputable advantage of this material is its affordability. The disadvantages include fear of high temperatures and significant water absorption. The weight of a single solid white silicate brick is 3.7 kg on average. single hollow - 3.2 kg, single facing - 3.95 kg.

Porous blocks are the lightest building material. Their dimensions correspond to the thickness of the wall, however, due to their high thermal conductivity and low weight, they significantly reduce the load on the base of the house. The abundance of closed pores and through cracks in a ceramic stone explains its significant dimensions and minimal weight. 1 cubic meter of such material weighs no more than 800kg.

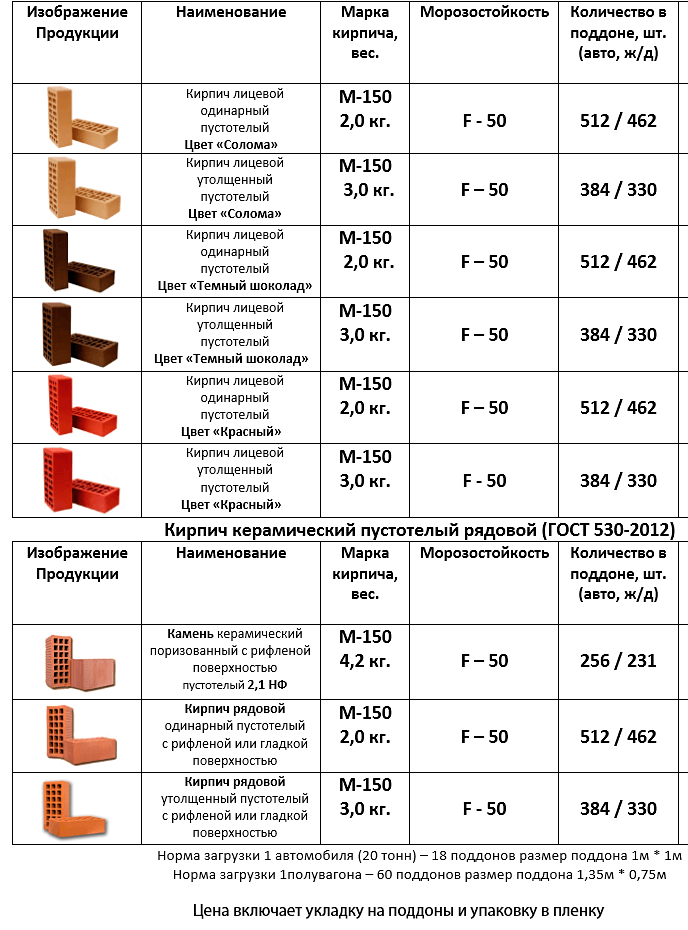

Facing ceramics. The indisputable advantages of this option include high frost resistance and durability. The weight of the facing brick is 1.6-4.3 kg. The heaviest are clinker solid stone, which is obtained from highly plastic clays by sintering into a monolith.

The clinker is characterized by high strength and durability, is not afraid of temperature extremes, and does not lose its texture and color for a long time. Considering the fact that in most cases the bed of facing stones is narrowed, the pressure on the foundation is insignificant.

What is it and what is it for?

In simple terms, a one-and-a-half brick is a regular brick block, but slightly increased in height. The need for such a material appeared in the era of total development, when the construction industry was required to build houses quickly and at minimal cost. It was then that the manufacturers slightly increased the initial parameters of the brick in length, height and width and proposed a technology for the manufacture of a modern and much more efficient material.

At first glance, it may seem that one and a half brick is not much more than usual and the savings, if any, are not particularly noticeable. This is a common misconception. On the one hand, one single brick does not differ much from a single one, however, on the general scale of construction, the savings become very tangible. Just imagine: three lorries are the same thickness as four standard blocks, which significantly reduces installation time and the amount of grout required.

There is also a certain aesthetic moment: the use of one-and-a-half blocks reduces the number of seams. In this case, only the large blocks themselves are striking, which have a very interesting texture. By the way, the modern construction industry offers both smooth and rough bricks, options with a wood-like texture are popular, and the choice of shades is quite wide.

Brick structure

In terms of structure, the material can be solid or with voids - these types have slightly different characteristics. The voids in the brick are made so that less is spent in the manufacture of raw materials - they occupy about a third of the total volume of the element. But its design is thought out in such a way as to withstand a sufficiently large load, and thanks to the presence of cavities, it has good heat retention.

Whole, that is, full-bodied, has better strength, but it is also slightly more expensive. Other, less common varieties have been developed for making lightweight masonry: porous, hollow, perforated. Strength and light weight are more in demand here.

One and a half bricks are purchased in those cases when they want to get a good result with not very large investments. It will be a great help when saving time during construction is an important factor.