Peculiarities

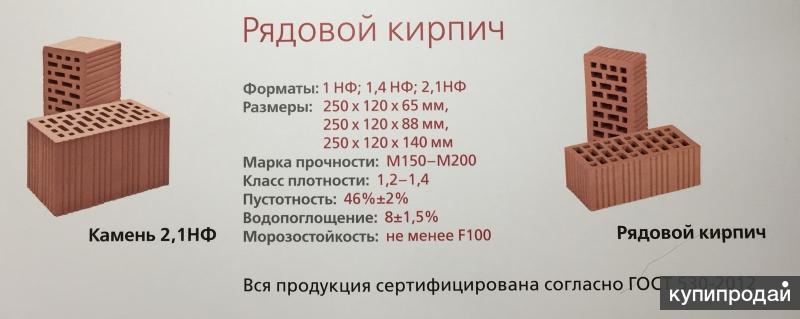

One-and-a-half brick is a certain type of building stone that is used to erect the walls of buildings.

One and a half white brick, due to the presence of several of its varieties, can be used in certain special cases, such as the need for additional protection from frost or precipitation, the need to arrange proper aesthetics, etc.

One and a half white

Some types of this material, unlike red, are able to withstand rather extreme operating conditions, as well as the variability of weather conditions.

In addition, the main role is played by those properties, as well as characteristics that the manufacturer wants to give in the future to artificial stone used for the construction of buildings.

Most often, the method of firing a clay mixture with certain types of additives is still used, but this is not the only option for producing the material.

Kiln firing

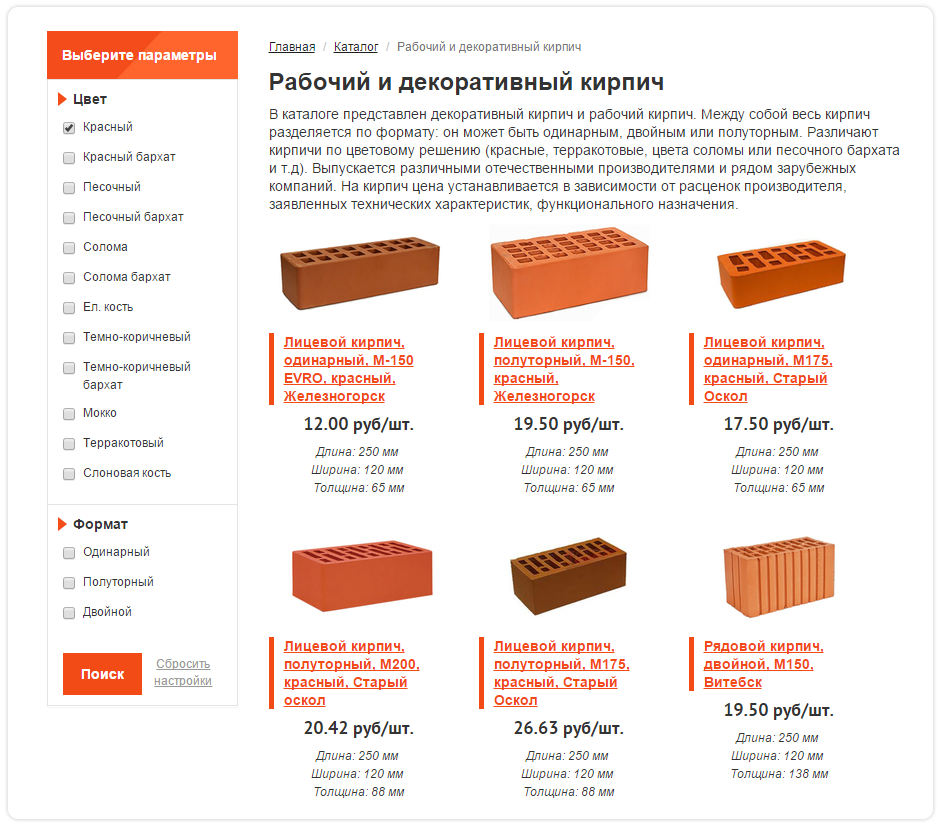

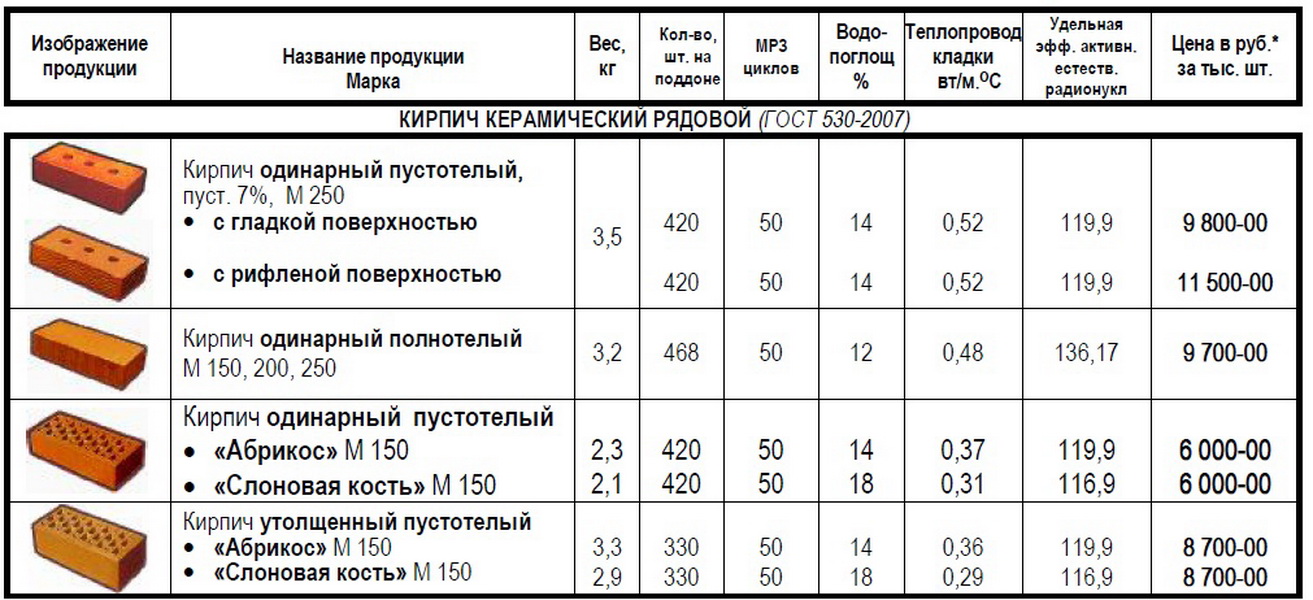

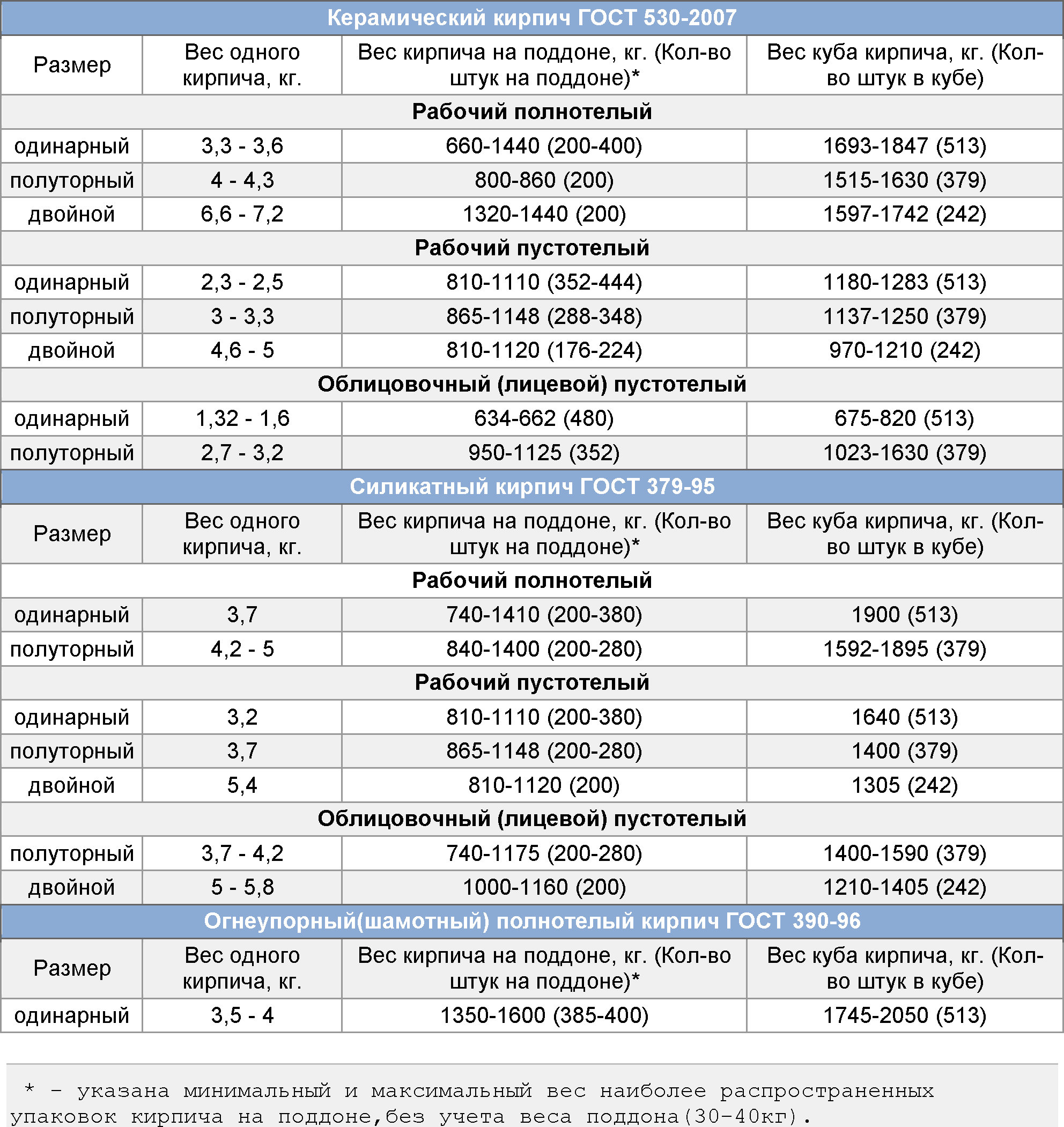

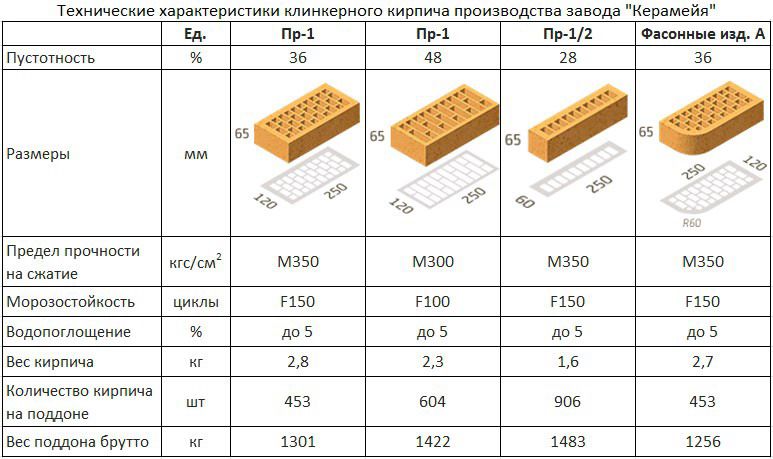

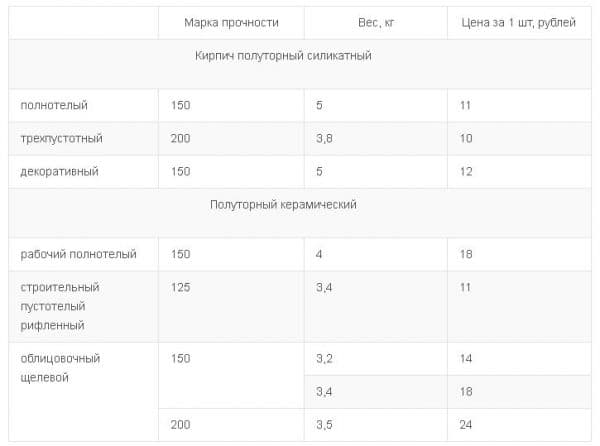

The price largely depends on the region of sale and the type of brick. The mass of one and a half brick can also be varied. This is influenced by factors such as density, as well as the presence of voids inside the product.

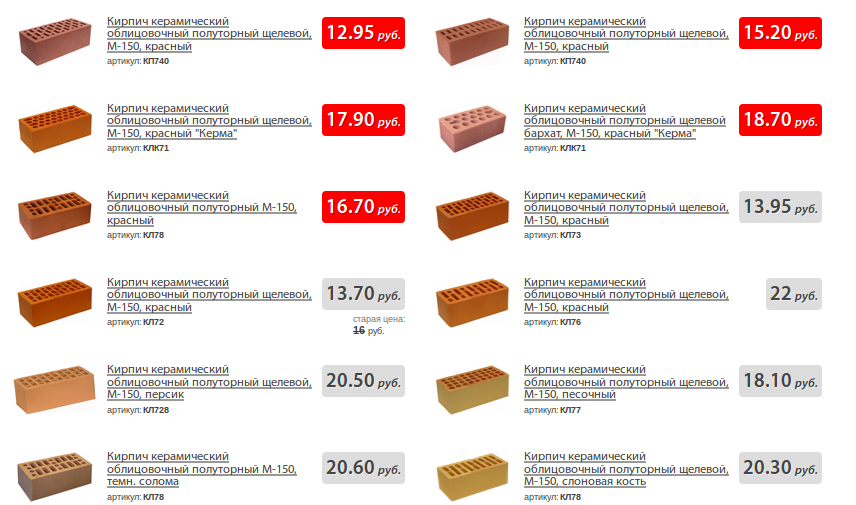

The cost of a one-and-a-half stone also depends on many factors. First of all, this concerns the availability of materials for its manufacture in the region, the volume of the order, the type of manufacture, some technical characteristics, etc.

Price

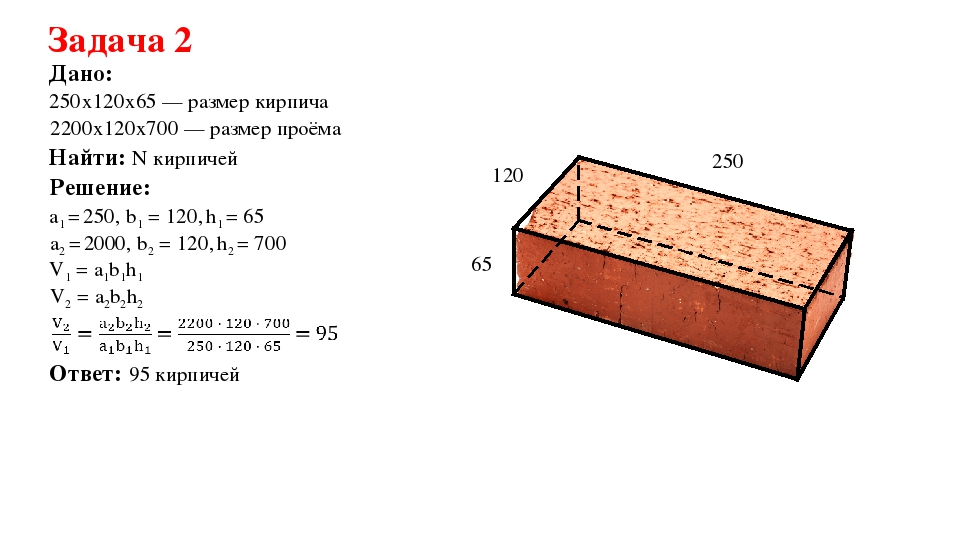

Before making a purchase, it is worthwhile to clearly calculate how much product is needed for construction.

Classic sizes and scope

The bar considered in the article is a building material that is actively used in the construction of load-bearing structures. It is used for the construction of cylindrical pillars and arched arches. The product stands out for its specific, doubled service life. As a result, the supporting structures are classified as stable. For example, the life of a foundation based on bars is not limited by anything.

But the bar stands out from other analogs with its precise, established dimensions and organic external data.

Peculiarities.

The white bar is manufactured using standard technology. For this, a silicate base is used, which is supplemented with calcium oxide, natural rounded sand and mineral additives. The main advantage of the bar is environmental friendliness.

The bar in question is distinguished by sound insulation, which makes it possible to use it for the construction of load-bearing structures. Silicate-based bars are in many ways superior to their ceramic counterparts. This is due to their positive characteristics:

- given strength, as well as resistance to subzero temperatures;

- undemanding;

- maximum stability;

- large assortment and types of shades.

But, like other materials for construction, a white bar is characterized by its disadvantages. For example, if we compare the material with a ceramic analogue, the first one stands out for the minimum level of resistance to increased thermometer readings and to water droplets.

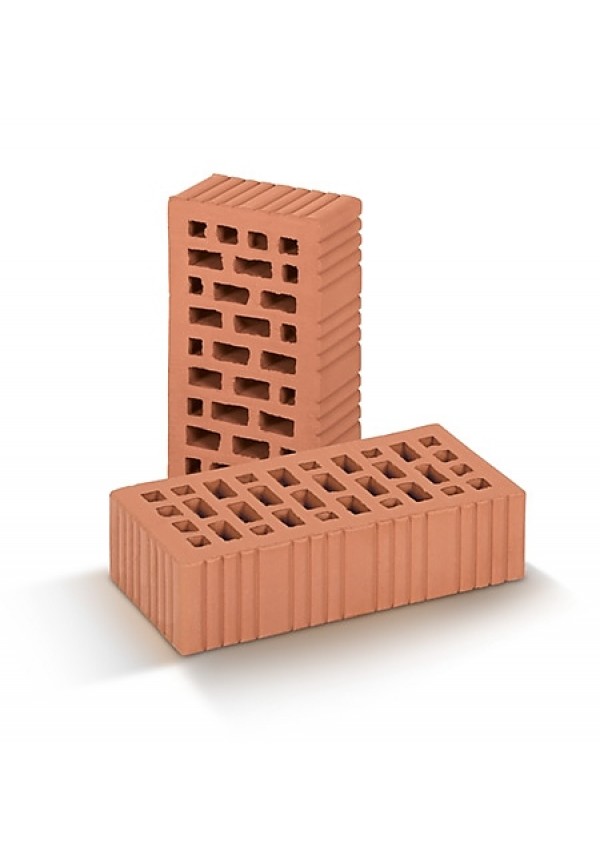

In the field of house construction, solid and hollow materials are used. The latter are characterized by maximum heat-insulating characteristics, concentrating heat energy. They are used in the construction of houses to reduce the force of impact on the base.

The percentage of voids often varies in different types of bars. A bar of the fourteenth class, with thirty percent of voids, is emitted by increased heat conductivity. Thanks to this, it is used for masonry work.

The main advantage of the white bar is obvious. Even load-bearing structures of minimal thickness, laid out in one ball, are distinguished by the same characteristics of thermal and acoustic insulation. They are often compared to thick ceramic materials that are laid out in several rows.

Description of silicate one-and-a-half brick

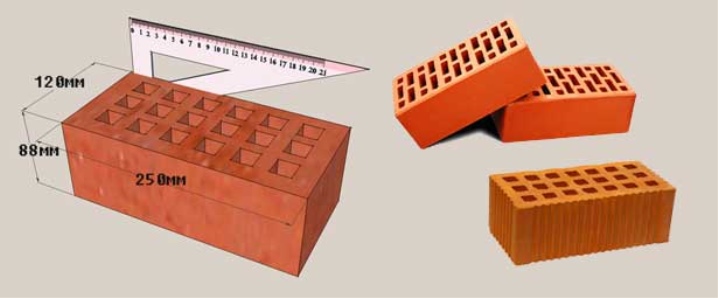

Silicate one-and-a-half, the dimensions of which are also characteristic of a full-bodied one, allows you to lay structures very quickly and easily. The reason for this convenience is its low weight. Silicate brick has voids, which can be through or blind, made in the form of a cylinder, and also located perpendicular to the base.

The weight of white sand-lime brick is described in the article.

The presence of voids helps to reduce the weight of the product, and also increases the thermal and sound insulation properties.

In the photo - one-and-a-half silicate brick

Modern technologies for the manufacture of silicate products make it possible to produce a product in unpainted or colored form. The first type is produced in white, but color samples are processed, and the necessary pattern is created on their surface. Silicate brick serves as an excellent protection of walls from the negative effects of the atmosphere. Since the artificial stone is able to "breathe", optimal living conditions are created in the house.

Which brick is best to use for the oven can be found in this article.

The video tells about the size of one-and-a-half silicate brick:

You can find out about the cost of ceramic bricks from the article.

Facing silicate combines excellent external data, as well as reliable performance. When building a house from one-and-a-half silicate bricks, you can shorten the construction time. Also, the building, laid out of completely flat stone, is characterized by a modern style and excellent external design, and it is not necessary to carry out additional finishing here.

Refractory brick sha 8 sizes and other data can be emphasized for yourself from the article.

The presented material has the following advantages:

- The material has low thermal conductivity.

- It can withstand low temperatures, it can withstand 15-50 defrost and freeze cycles.

- Excellent water absorption rates, which reach 14-18%.

- Since the production process of silicate bricks involves the use of only natural natural ingredients, the final product does not adversely affect human health, because it does not emit harmful impurities into the environment.

- Buildings made of this material are characterized by excellent sound insulation and a pleasant microclimate.

- If we compare white with red, then the first has less strength qualities. Also, white brick is not as versatile in terms of its use. It is used only for the construction of walls and partitions. As for the masonry of the foundation, fireplace, pipes and basement, in this regard, silicate brick will not help.

You can learn about the dimensions of chamotte bricks sha 8 from the article.

The video shows the weight of one-and-a-half silicate brick, its pros and cons:

Red pattern

With the help of stoves and fireplaces, it is possible to create cozy and comfortable conditions in the house, give it warmth and pleasant notes. Red stone, the dimensions of which can take on a variety of values, is used not only for the construction of stoves and a fireplace, but also for other structures, which are characterized by the influence of a very high temperature regime.

The red stone is able to easily withstand high temperatures - 1400-1800 degrees.

Red and its dimensions depend on what type of product is used for the construction of a particular structure.

You can learn about the disadvantages of silicate bricks from this article.

There are such varieties of the product in question:

- Simple.Such a stone, in comparison with a refractory one, gains heat very quickly and is able to withstand temperature extremes. A simple stone can be used for the construction of stoves and fireplaces, since they are able to heat a building and give off heat energy perfectly.

- Refractory. The production process of the product in question involves the use of special, high-strength types of clay. After that, the raw material is quenched. The resulting stone perfectly tolerates high temperature indicators, and it can be used in places where there is an effect of too high temperature conditions.

You can find out how much the kiln brick weighs from this article.

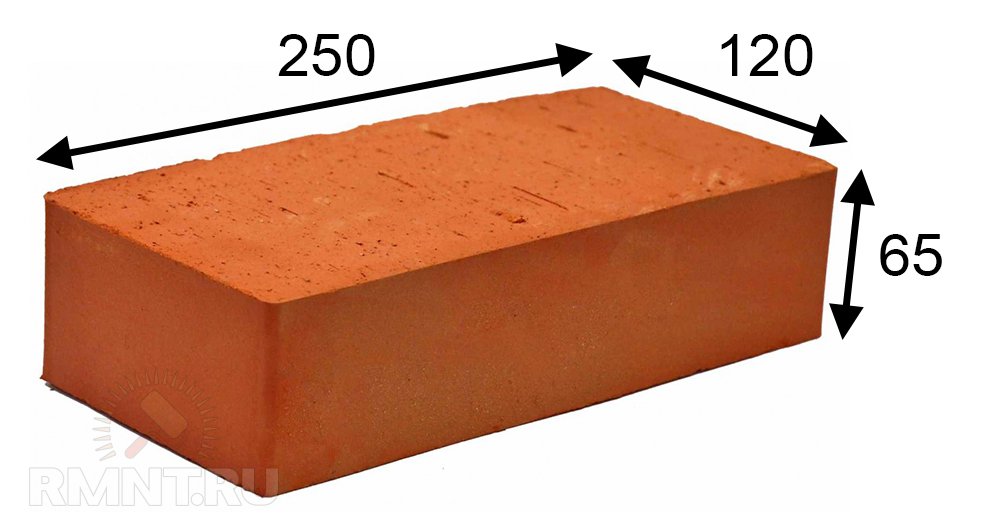

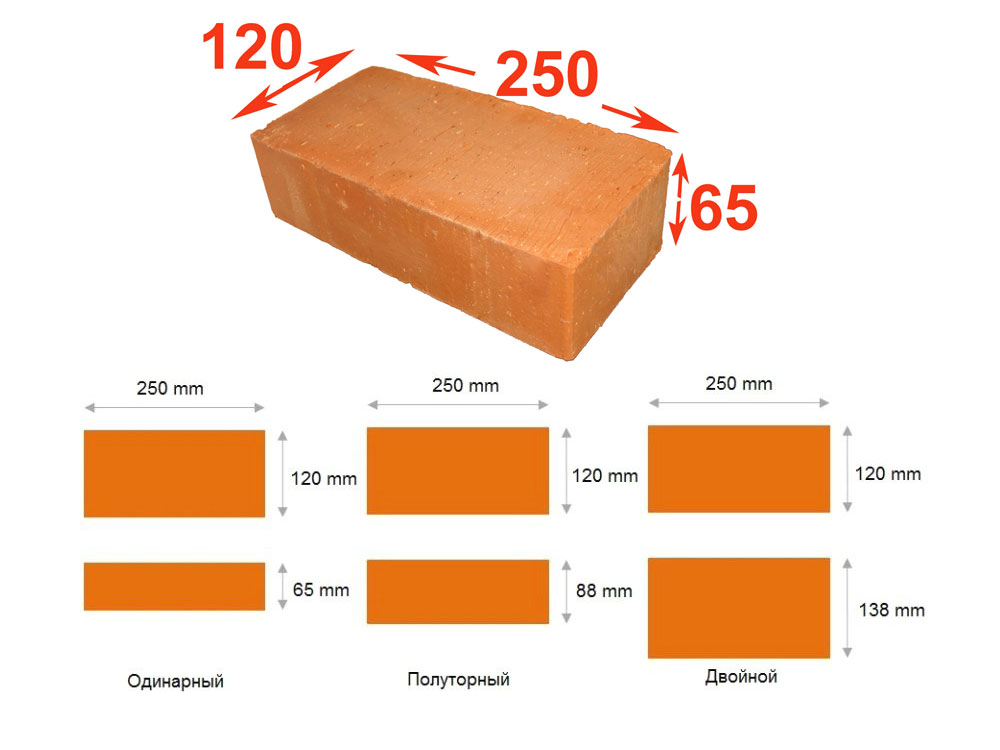

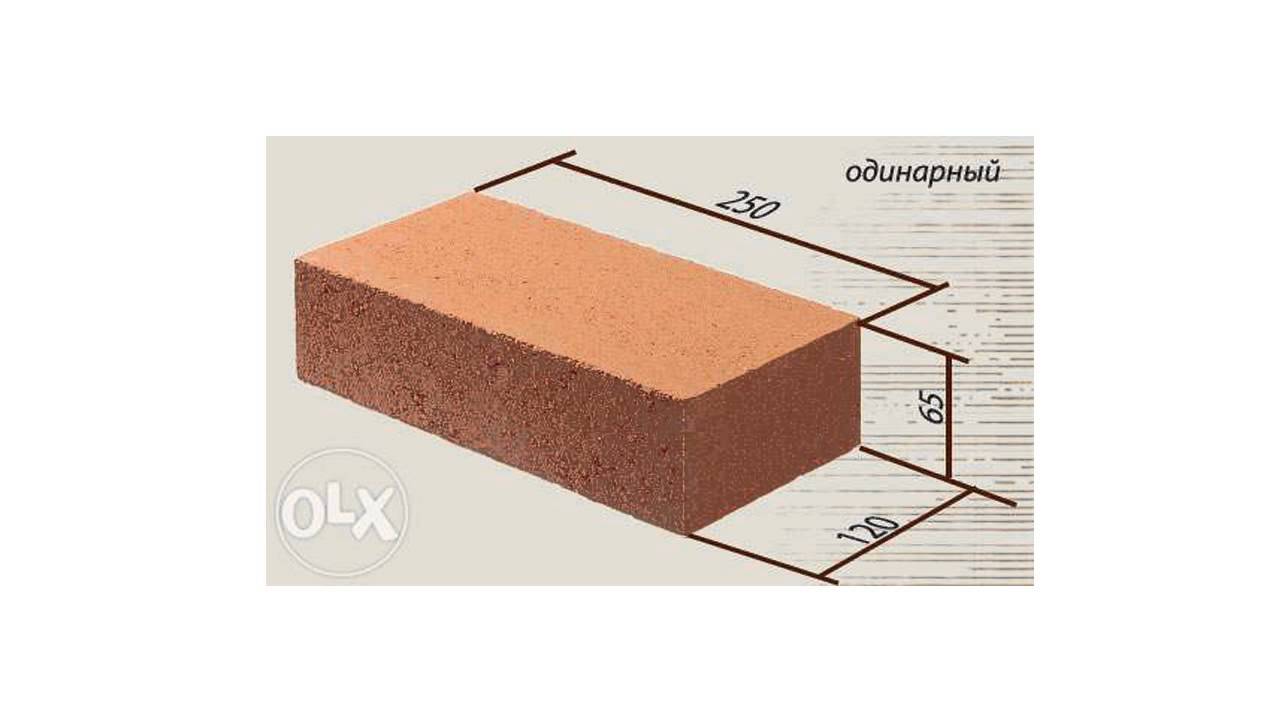

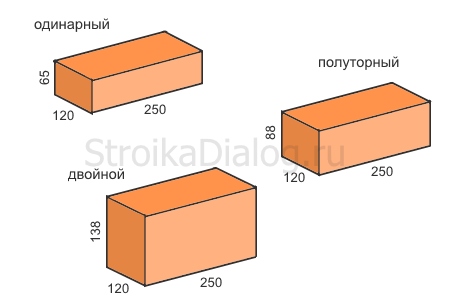

The dimensions of the red material can take on different values. However, the manufacturer can produce a red stone of standard sizes - 65x120x250 mm. This size is considered normal for the product shown. Thanks to them, red brick is one of the most suitable materials for making transverse-longitudinal masonry walls.

Brick yellow facing one and a half price and other technical data of the building material are indicated in the article.

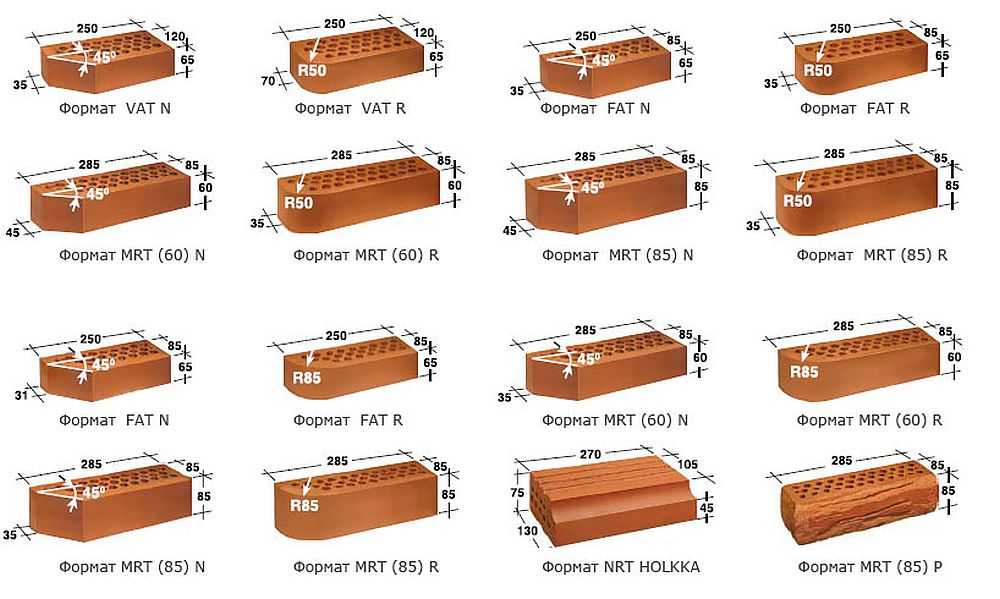

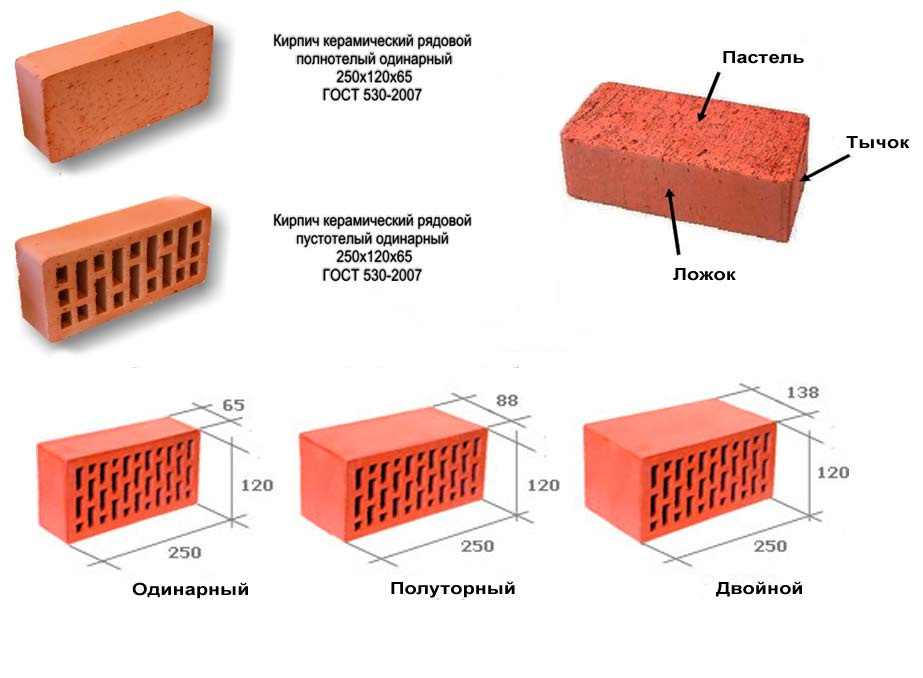

Each facet of the material according to GOST 530-2007 has its own name: poke, spoons and bed. Normal format brick can be divided into the following types:

Table 1 - Sizes of red

Russian briquettes and their dimensions today

Domestic briquettes acquired their modern look only in the 27th year of the last century. A little later, the dimensions of a single ceramic briquette and its value in one and a half and double form appear in regulatory documents. Finally, this information is approved with the introduction of conventional units of measurement of structural parts and building materials, which, according to the latest editions of the state standard, began to be called a module.

White brick is most often sold in lots

White brick is most often sold in lots

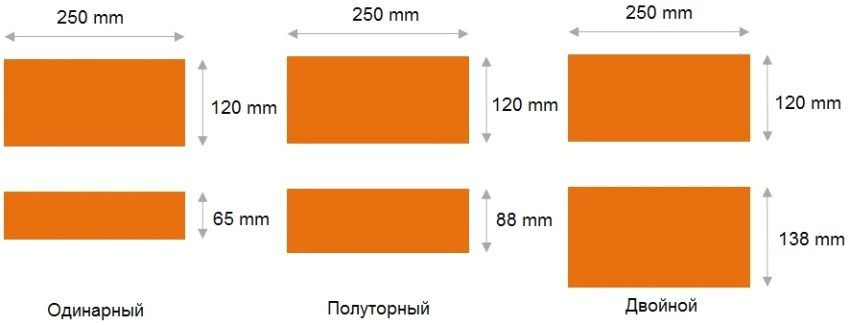

An interesting fact remains that the word "one and a half" cannot be confirmed by mathematical calculations, because its height, in comparison with a single one, is more than 1.3 cm. This name was used most often among builders and since then it has begun to be included in state rules and regulations. This term is incriminated with the size of a silicate briquette, the size of which is 25 * 12 * 8.8 cm.

Building material began to be made from a combination of sand and lime only in the 20th century, after a significant modernization of industrial production in the field of building materials. Then they began to use the method of semi-dry pressing and burning in an autoclave. The dimensions, cost and strength indicators did not cause any complaints from users, the materials became resistant to moisture and increased temperature.

Today, any non-observance of established standards in matters of laying briquettes is allowed only when decorating rooms or supporting structures. The parameters of briquettes for facing are controlled with the utmost rigor. The boundary deviation can vary from 3-4 mm, and in the border of 2 mm in thickness. Therefore, the dimensions of the white briquette are strictly limited and comply with the norms of interstate rules.

There are a number of restrictions regarding the use of briquettes. Reduced resistance to moisture prohibits their use in homes that are exposed to increased moisture (base, basement rooms, water shafts) and maximum temperatures (capsules for the stove, chimney).

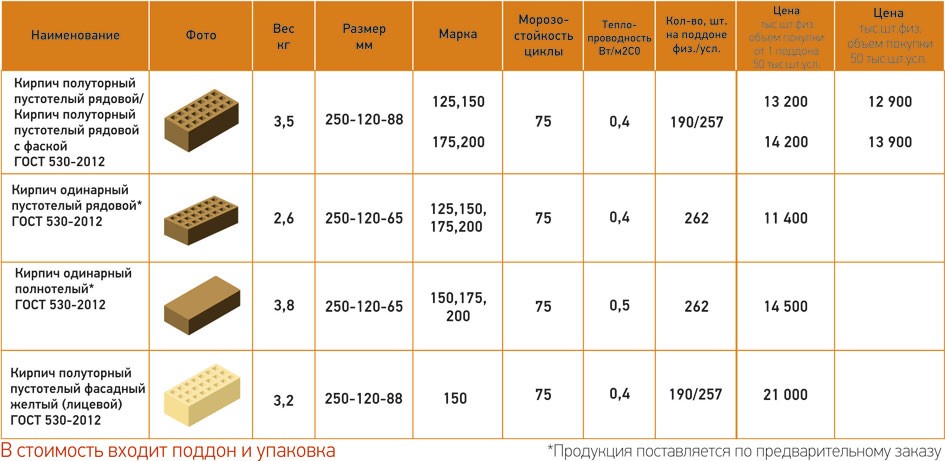

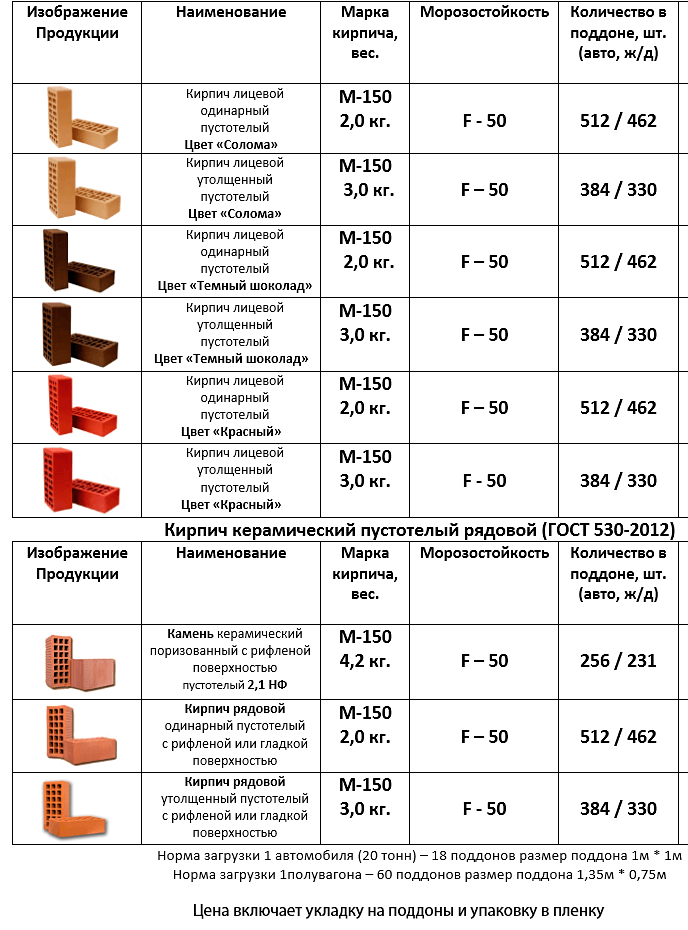

Ceramic brick M-150 and its application

Such material can withstand a load of up to one hundred and fifty kilograms and is suitable for any construction option: for the construction of office premises and buildings. Brick ceramic corpulent ordinary single m 150 is widely used in housing and for utility rooms.

- This material is available in two versions: solid and hollow. They have a fairly high strength, retain heat well, and also have high frost resistance.

- Single solid ceramic brick m 150 is perfectly used for the construction of foundations and plinths of any type. This is a fairly durable material that will withstand floor slabs;

- The corpulent version is also successfully suitable for the construction of fireplaces. it is also often used to install different types of ovens. An excellent solution for the material for the manufacture of a barbecue. in short, suitable for anything where solid fuels are not used. In these cases, it is worth using refractory bricks.

- Ceramic brick m150 is hollow, perfect for installing partitions indoors and for cladding a building. Voids make it not so strong and it may not withstand floor slabs.

- Due to its positive properties, such a material is able to withstand strong pressure. Such a brick is produced with a standard single size, as well as with a double and one and a half. This allows you to significantly save time on construction.

- Brick is subdivided into special, facing and construction, therefore it is used not only for the construction of buildings, but also for facing facades.

- Brick m150, the price is slightly higher than brick M75. But you get a stronger material and it has a wider scope of application.

- Clack of this material may well be carried out independently, this will significantly reduce construction costs.

- The weight of a brick m150 is standard there is nothing new here.

- It is not difficult to buy brick m150, it can be done at any point in the retail trade in building materials or at a manufacturing plant.

When building a solid brick structure, which assumes that it will last up to a hundred years, it is best to purchase a solid ceramic brick. This building material is perfectly suited for the construction of lower floors and foundations that use significant loads on themselves.

It is not enough to take brick in terms of parameters, you still need to take high-quality material. After all, you can simply be deceived

In the video you can see what is worth paying attention to

Delivery and storage of material

Material parameters

The price of a material depends on its size and production. Of course, the more raw materials are spent on it, so the price will be higher... After all, the weight is greater. But sometimes what is more expensive is more profitable. Therefore, when choosing, there can be only one instruction, this is to make the correct calculations.

Attention: when calculating, it is imperative to take into account waste. They will be there anyway

Only unlike clay material, silicate waste can be used in few places.

Silicate brick weight:

Silicate brick

The production of silicate bricks is carried out in autoclaves under high pressure. This is one of the differences from the production of clay material.

- The composition of the brick includes sand, this is in the region of 92-94%. Lime is also used as an additive. Its volume fluctuates around 3-5%. Various additives are also used for the quality of products, which make up about 2%.

- This technology makes it possible to make high-quality and durable material. For example, hollow materials have increased sound insulation and heat insulation. Therefore, they can be perfectly used for the construction of partitions indoors.

- The frost resistance index ranges from 15 to 50 freeze and thaw cycles.

- This material can have almost any color. It all depends on the dye added.

Attention: This material has a significant drawback, it absorbs moisture strongly and therefore cannot be used for the manufacture of the foundation and basement of the room. The weight of the silicate brick depends on several parameters.

In the first place is the composition of the material, in the second place is the manufacturing technology. But the average weight of a brick is around 2.5 kilograms

The weight of a silicate brick depends on several parameters. In the first place is the composition of the material, in the second place is the manufacturing technology.But the average weight of a brick is around 2.5 kilograms.

The volumetric weight of a silicate brick directly depends on its dimensions. They are quite different. There is one and a half material, there is also a single one.

Material selection rules

You make the choice yourself. Here you will need to look at the following components:

First of all, decide on the height of the wall. Here you will need to select a brick not only by weight, but also take into account its height. It will be possible to save on this;

Construction requires the use of quality materials. Therefore, do not take damp bricks on pallets. It dries very badly;

The price of color will be more expensive

Pay attention to this when choosing.

Be sure to take into account the weight, because for partitions it is better to take hollow material. True, here you will use up more solution.

But the wall will be lighter.

If you will be laying bearing surfaces, then it is better to use solid material here. It will withstand heavy loads.

When making a choice, you should never rush. There are always calculations before buying. Look at photos and videos, make an analysis. Construction does not tolerate errors. After purchasing the material you don't need, you will spend not just money, but you can make a poor-quality structure.

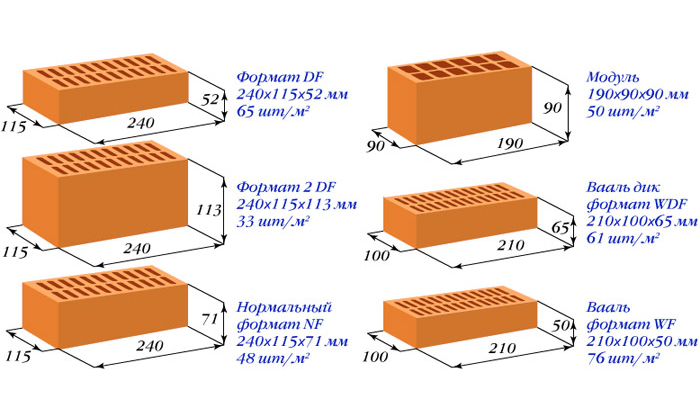

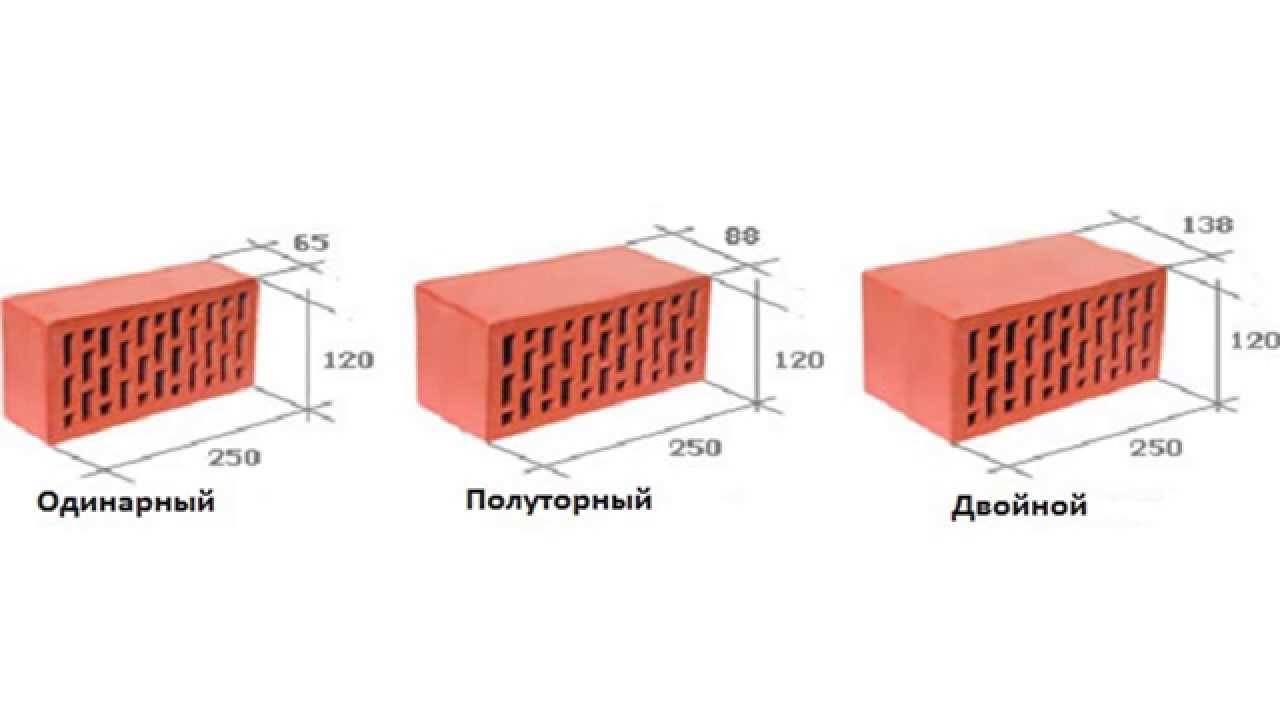

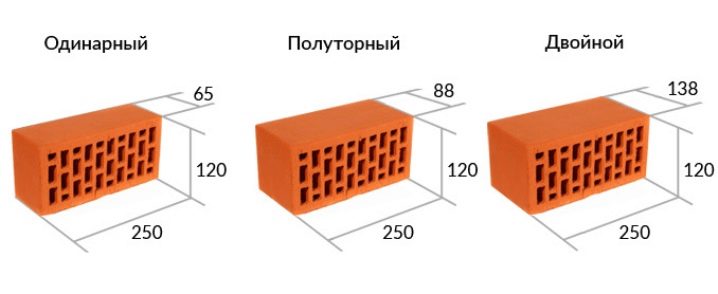

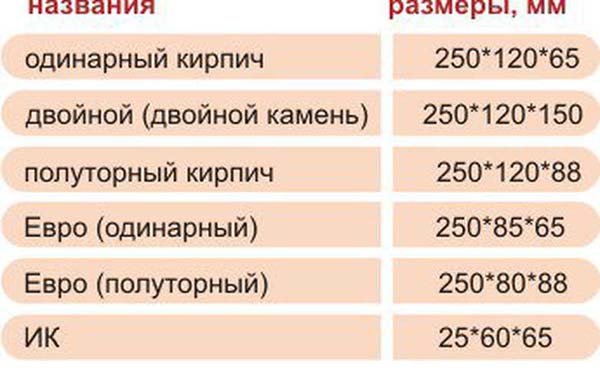

Brick sizes, determined by GOST.

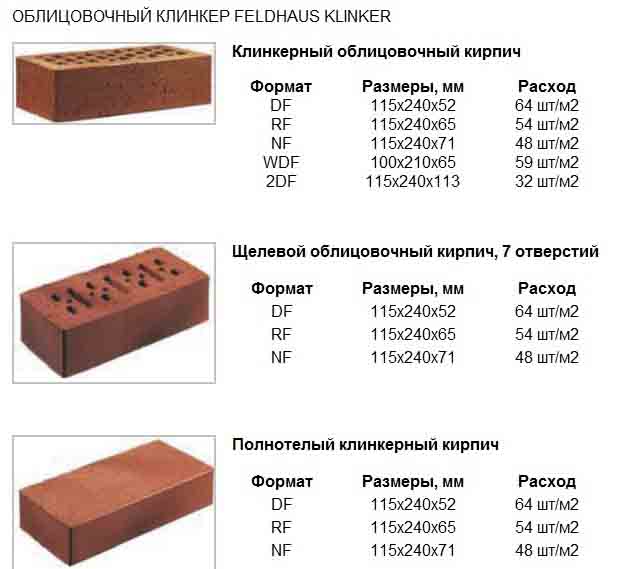

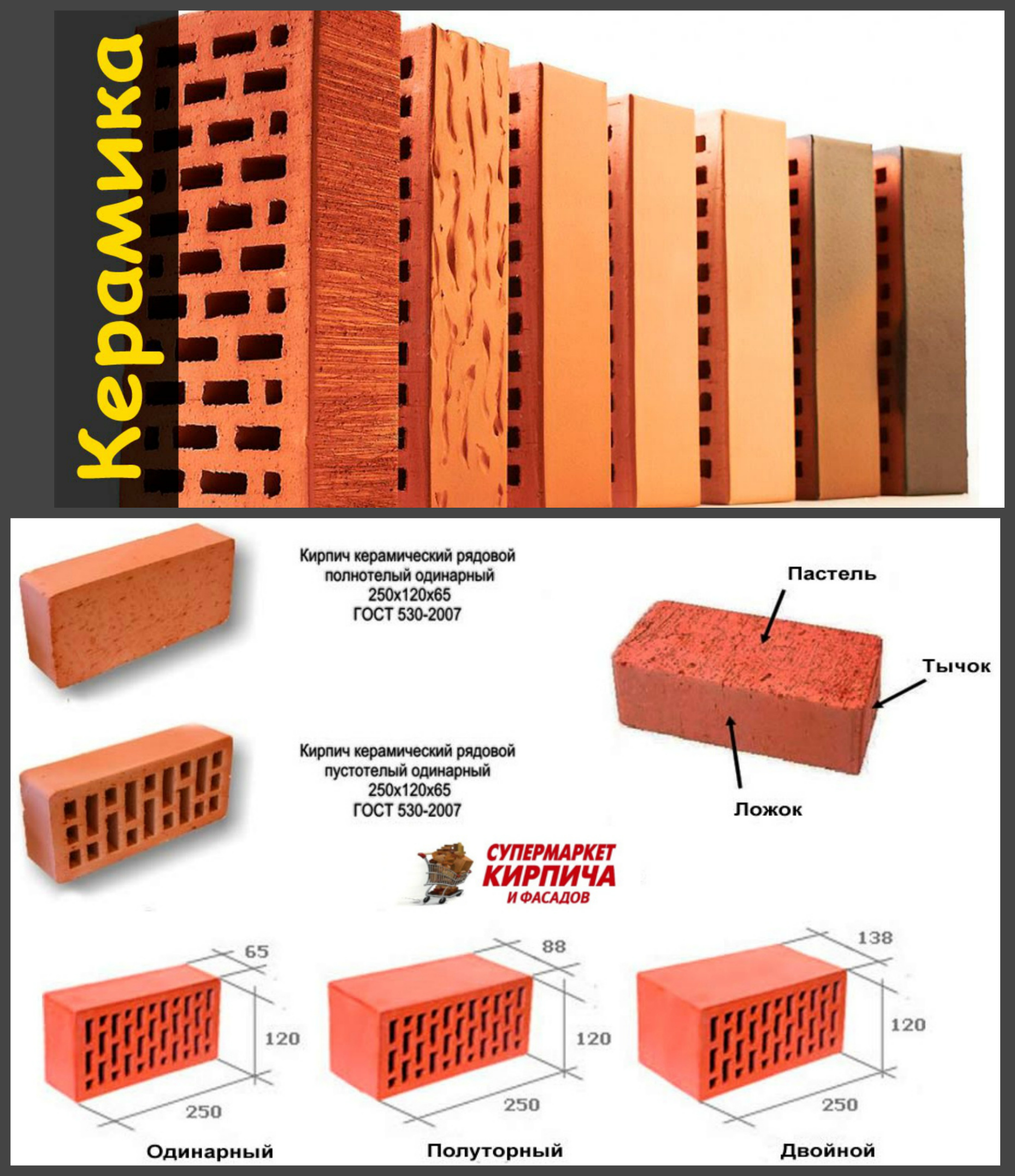

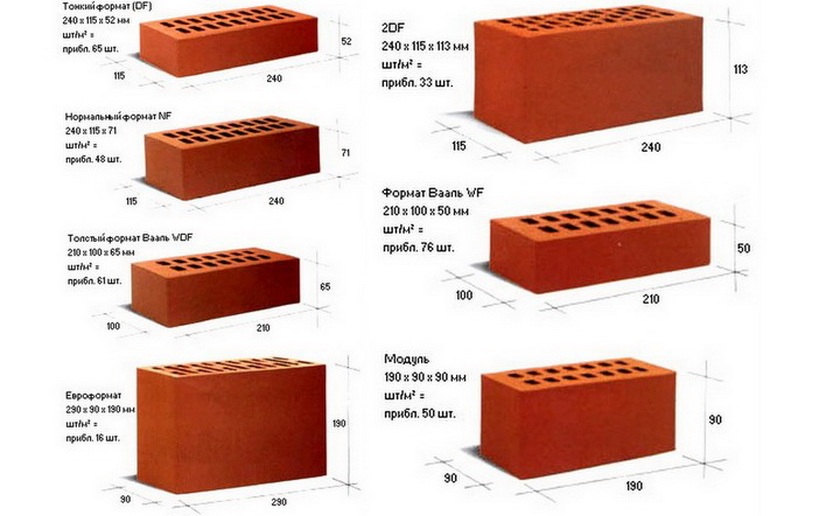

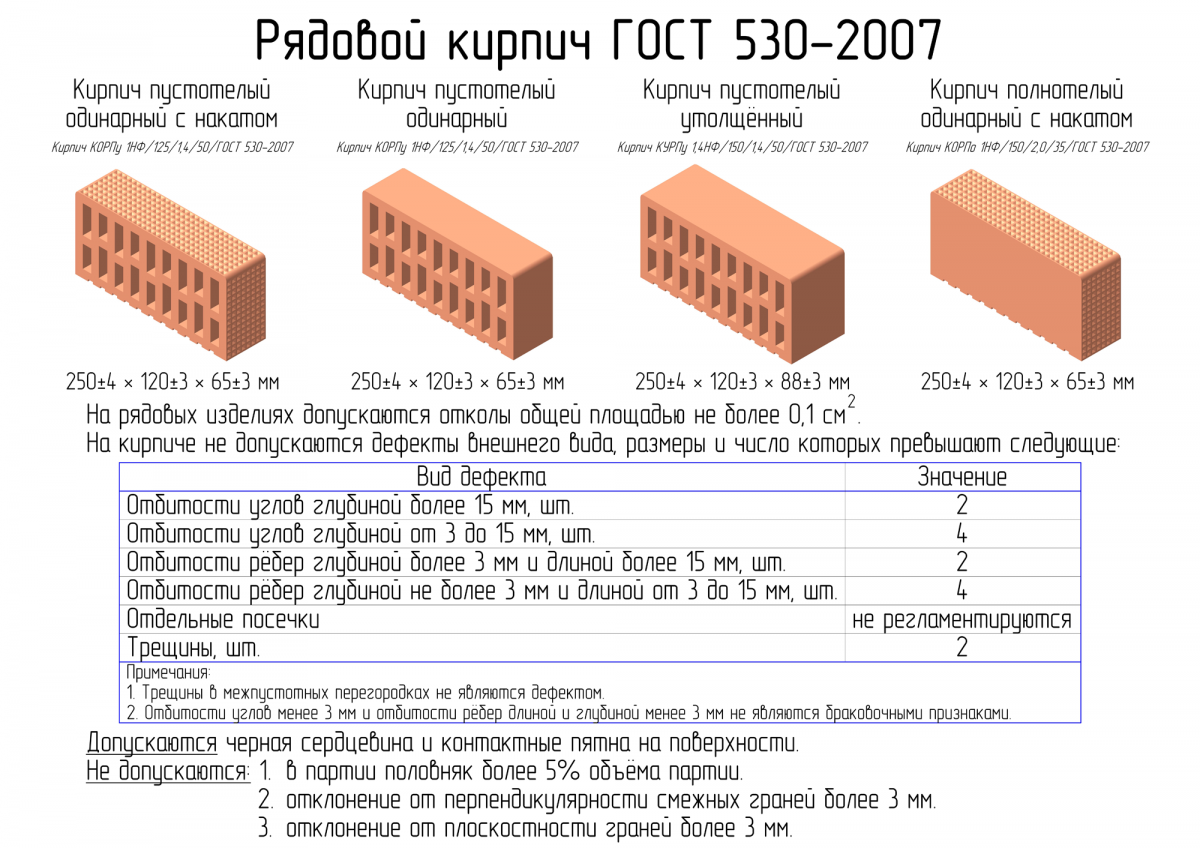

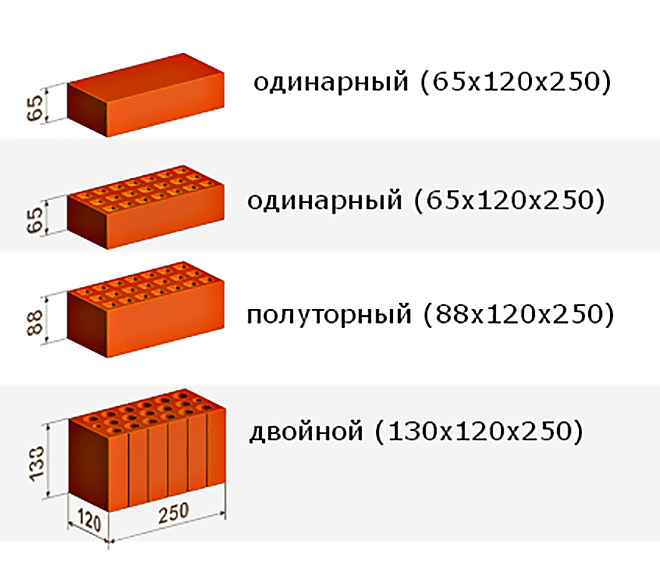

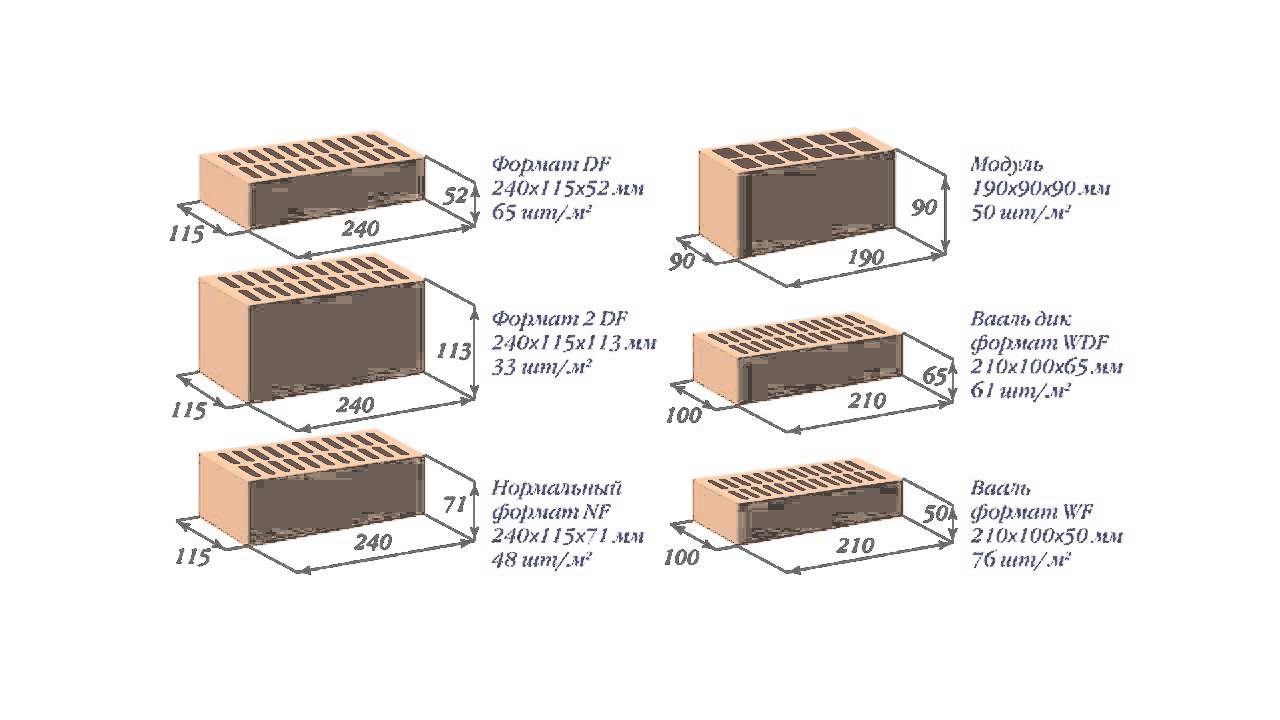

The main GOST, which determines the size of bricks, is GOST 530-2012 "Ceramic bricks and stones". With the increase in regulations and stricter requirements for the construction of houses and other structures, the range of brick sizes has expanded. There are the following main types of bricks:

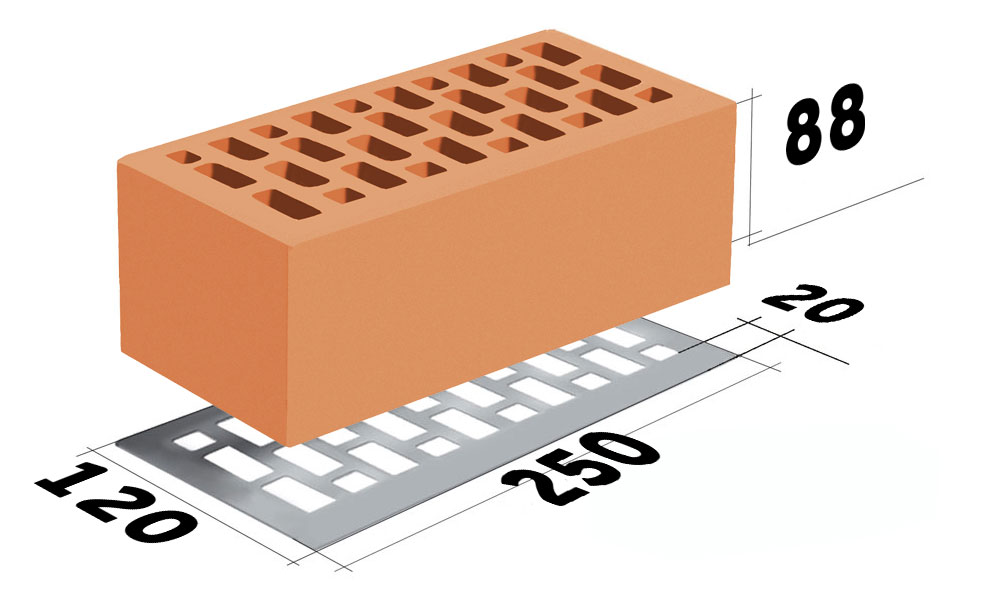

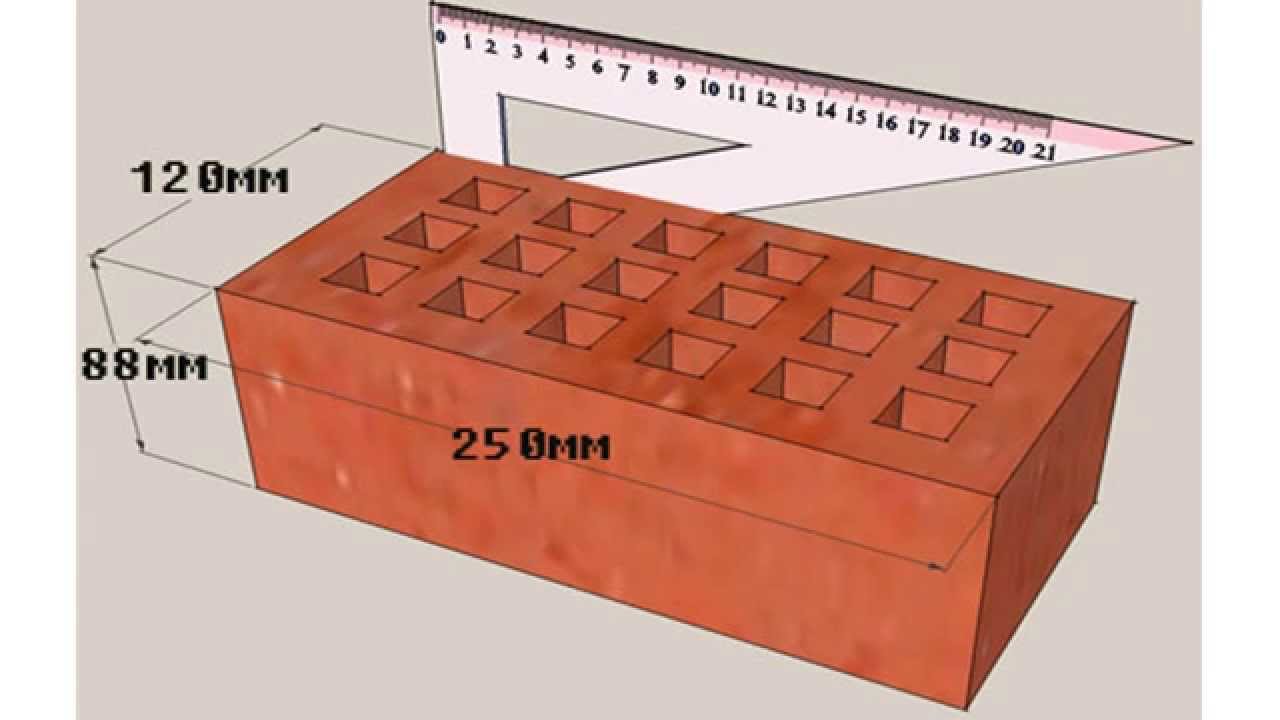

1. Single (250x120x65 mm). Designation for European marking - RF;

2. Double (250x120x138 mm);

3. One and a half (250x120x88 mm);

4. Modular (280x130x80 mm);

5. Euro brick (250x85x65 mm).

In terms of shape, bricks are divided into:

• corpulent;

• hollow (slotted);

In addition to the overall dimensions of the brick, there are certain permissions for deviations from the norm (defects). The size of the deviations depends on the type of building material - building or facing. Stricter measures are imposed on facing materials, because the appearance of the building depends on its properties and characteristics.

For solid bricks, it is allowed:

1) The presence of dullness and chips of ribs and corners (no more than two) and no more than 1.5 cm in length along the rib;

2) Curvature of edges and edges no more than 0.3 cm;

3) On the lateral longitudinal edges, the presence of a crack up to 3 cm long across the width of the brick is allowed.

For hollow bricks, it is allowed:

1) No more than two bumps at corners or edges 1-1.5 cm long, provided that they do not reach the voids;

2) Full thickness cracks in the bed. In width, they can reach the first row of voids;

3) One crack on the butt and spoon edges.

For facing bricks, it is prohibited:

1) Chipped corners, the depth of which exceeds 1.5 cm;

2) The presence of cracks;

3) Chipped ribs, the width of which is more than 0.3 cm, and the length exceeds 1.5 cm.

A facing material is considered the most suitable for work, in which:

1) No more than 1 bit of corners up to 1.5 cm deep;

2) Separation of handwriting, which in total does not exceed the length of 4 cm;

3) No more than 1 chipped ribs, not exceeding 3 cm in depth, and not more than 1.5 cm in length.

Modern architecture projects allow the use of bricks of various shapes and colors. The choice of building materials today is very diverse. There is an opportunity, without harm to the reliability and strength of the structure, to connect in the masonry variants of bricks of different texture, for example, artificially aged, variegated.

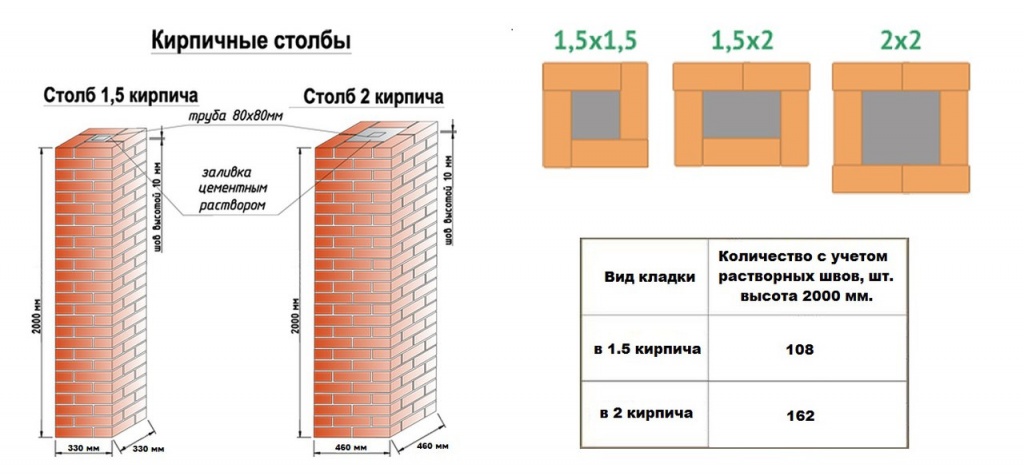

In order to reduce the weight of the structure, bricks of one and a half and double sizes are often made hollow. Large-scale porous blocks have become widespread in modern construction. The use of ceramic bricks simplifies and speeds up the construction process, while allowing to reduce the consumption of masonry composition, since this type of brick is lighter and warmer than usual.

Pallet location

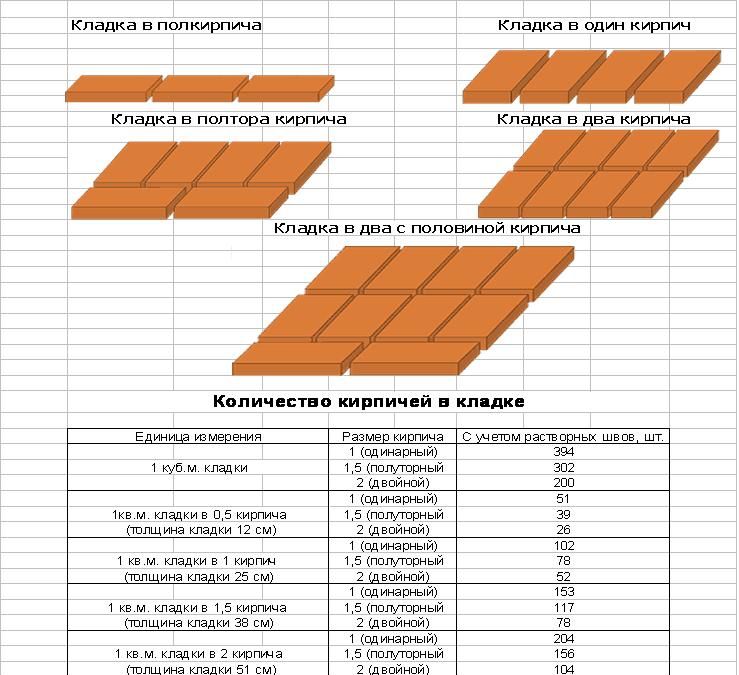

How to calculate how much masonry is in a cube, taking into account the seams, and the volume of brick in m3, is understandable, but in order to avoid excessive overload, it is worth finding out how many products will fit in them and what is the maximum allowable weight

To determine this indicator, pay attention to:

- The material from which the bricks are made: silicate, ceramic.

- Stone sizes approved by state standards.

- The shape of each element: with or without voids inside. In the second option, the voids are contained in an amount of no more than 13%. They are used to lay out various types of walls. The weight of one such ceramic product is 3.3-4.7 kg, and silicate - 3.7-6 kg. Hollow voids represent 13-45% of the total structure. Air gaps are present in the composition of such bricks, due to which their heat transfer properties are reduced. Ceramic hollow stones weigh up to 5 kg, while silicate stones weigh a little more. Therefore, the shape and material of each product plays a role.

To determine how many kilograms a pallet filled with one-and-a-half bricks will weigh, take the weight of one stone and multiply it by the total.

To the general calculations, you need to add the weight of the wooden pallet itself, which is 30-40 kg. Pallets are used to bring materials to the right place. They are made of wood or metal. They can also combine several options. To determine the amount of stone in the pallets, you must first find out the standard dimensions of the products.

Usually, manufacturers in the accompanying documentation indicate information about how many products can be laid out on a pallet as much as possible. To calculate how many elements can be placed on it, you need to divide the maximum number allowed by the manufacturer and divide by the weight of the brick.

If the bricks are laid in an overlap or in the form of a herringbone, then the exact data will not work.

To make the material easier to calculate and transport, they prefer to lay it in the form of a cube. For stability, the structure is tied with a fixing tape. How many stones fit depends on their size.

Masonry features

White brick walls

White brick walls

The peculiarities of the masonry of load-bearing structures made of silicate briquettes completely repeats similar technological rules for shell rock and gas blocks. The briquette is mounted in a bandage with the previous ball. This is done to prevent the joints from overlapping.

After completing the laying of the first ball, it is important to lay the corners, adhering to the stepped technique.

A building thread is pulled from two corners, along which subsequent blocks are laid. They form the rows of the future house. The building level checks all formed rows so that they correspond to the horizon. Do not forget about the joining. The latter is carried out with a seam sealant, and gives the necessary aesthetic appearance.

Video - Laying of silicate bricks. Secrets of craftsmanship

Sheathing of load-bearing structures is carried out in accordance with certain rules and methods. The first rule is a general tape of briquettes 1⁄2 stone thick. The second rule is that the corners of the supporting structure should be laid out from solid briquettes along the entire length (called protrusions, as well as posts). To ensure a tighter attachment of the masonry to the supporting structure, glass mesh or wire loops are used. You can also snap using anchor fasteners. This is done every 5 rows.

Installation of white brick

Installation of white brick

Company overview

The quality of all building materials is influenced by the norms prescribed in the state standard and rules, which are taken into account by the manufacturer. "Yaroslavl Silicate Brick Plant" is a leading manufacturer in the country, which began its work in the 31st year of the last century. Customers buy over one hundred million units of goods per year.

The assortment is complemented by all types of bars, the quality is confirmed by international standards and is constantly monitored by the laboratory at the factory.

Another equally large manufacturer is Borsky silicate plant. The plant supplies goods to all regions of the country and even abroad.Imported equipment and qualified specialists allow us to produce high-quality and affordable goods.