Location and purpose of the structure

When choosing the size of the shelf, its type, consider in which room it will be located in the future

It is important to create a holistic interior with a functional detail.

The main purpose of the shelf is to optimize the space in the house.

Kitchen

It is important for the kitchen that all the necessary items are always at hand, and not hidden in numerous drawers. It is best to use a compact yet roomy wall design

Wooden models are most suitable for the kitchen, as they create an atmosphere of comfort. A variety of designs allows you to choose an option that harmoniously complements the interior of the room.

Not the most practical solution for the kitchen would be models from:

- plastic;

- glass;

- metal.

A good alternative to wood is a decorated gypsum fiber sheet.

In a small kitchen, the shelf has a practical purpose, helping to keep the necessary utensils in order.

Hallway

Using the original hinged shelf, you can easily decorate the hallway. Such furniture can easily fulfill several functions.

- Small shelf suitable for storing keys, small items.

- Larger design allows all bags to fit easily.

- The tall structure, complemented by figurines, will add sophistication to the hallway.

- The hook shelf is easy to use as a hanger.

For the hallway, you should choose wooden furniture. Glass, metal and plastic cannot be called practical, versatile. Consider this when arranging a room.

Corner shoe rack will be a functional addition to the hallway

Bathroom

It is hard to imagine a bathroom without a convenient corner shelf on which all hygiene products are stored. Of course, numerous jars can be neatly folded into the closet, but getting them out of it every time is not very convenient. It is better that they are always at hand.

Most often chosen for the bathroom:

- glass structures with chrome supports;

- plastic shelves with metal racks.

It is important that such an interior detail be distinguished by its laconic execution. This makes it easy to care for it, since the high humidity in the bathroom causes the surfaces to become quickly dirty.

Manufacturers make the design as functional as possible by adding hooks, soap dishes

Living room

The living room is the ideal place to install a functional corner structure. Lovers of reading will adapt the shelving to store the home library. On the shelves you can easily place:

- family photos;

- decor items.

During the installation of the structure, you should definitely think about what kind of load is planned for it. Mounts should be as reliable as possible. The size of the shelf directly depends on the future purpose of the selected shelf. Decorative items look good on compact models, and for a large library or collection, choose a spacious shelving unit.

Small corner shelves with carvings, ornamental wooden details are often used as stands for icons

In many living rooms, wood, metal corner shelves are used as flower stands. Glass specimens are much less common in living rooms. Designers advise not to clutter the shelves with numerous flowerpots, figurines. So the feeling of lightness, which such a structure is intended to add in the room, disappears.

In the spacious interior, the options installed on the outer corners look harmonious. Most often they are made of drywall, chipboard.You can design such an addition to the room yourself, taking into account the features of the place chosen for the shelf.

In a small room, it is better to purchase a compact design.

DIY shelf rack

The functional and minimalist industrial style is very popular today. A do-it-yourself shelf assembled on pipes will bring to your home the same industrial chic that you may be striving for.

Since the number of shelves, as well as the total length of the pipes, is easily adjustable, let us dwell on the general scheme for the manufacture of this designer furniture.

Work begins with the preparation of wood shelves. They are coated with a special oil or wax to obtain a smooth textured surface.

It would be nice if the shelves initially had an interesting texture.

If you also coat the shelves with a water-based polyurethane varnish, they will get an even great shine.

After letting the structure dry, round flanges are installed in each corner of the bottom shelf, about 2 cm from the edge.

The location of the connecting parts is marked with a pencil.

The shelves are stacked and clamped with a clamp.

A pilot hole is drilled through the center of the flange through the first and second shelf. For the next boards in order, the drill size must be changed to a larger one, since pipes will pass through them in the future.

Start assembling.

Each flange is positioned on the bottom flange above the pilot hole and secured to the surface.

Galvanized pipes of the required length are inserted into the holes with threads at both ends and tightened in the flange with a wrench. A clutch is installed in the upper part.

When all the parts are mounted, flanges are screwed to the tops of the pipes and fixed to the upper shelf.

The finished shelf can be made mobile by placing the wheels on the bottom board.

The headset will be more stable if you attach it to the wall with special studs or install an L-shaped bracket.

LED backlit corner bookshelf

A shelf like this will create a cozy and welcoming atmosphere in your room.

You can cut the shelves yourself, or you can simply order at the nearest furniture factory. Just enter in the search the query "sawing chipboard according to the customer's size" and Yandex will give you the companies that are engaged in this. Just tell me what you want and they will cut everything out for you in the best possible way, it will not be expensive. Cheaper than your drinking time!

BUT we advise you to take a responsible approach to the choice of the FONT, it should be so bold that the letters have as much empty space as possible - it is so beautiful.

After you fasten the central boards perpendicularly, it will be possible to determine with the markings for the LED strip, so that the light is evenly distributed. There is nothing difficult about this, just do not miss this moment.

Central boards (corner) should be painted only from the outside, so that the inside retains its reflectivity.

Step-by-step production photos:

Wooden corner shelf in a semicircle

To make such a shelf with your own hands, you need a milling machine and a piece of MDF. To make it aesthetically pleasing, we recommend that you stick a special tape on the ends, this is done with an iron)))

Step-by-step production photos:

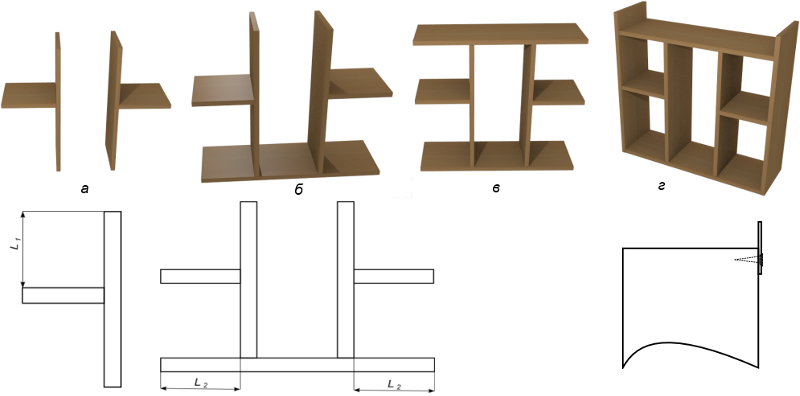

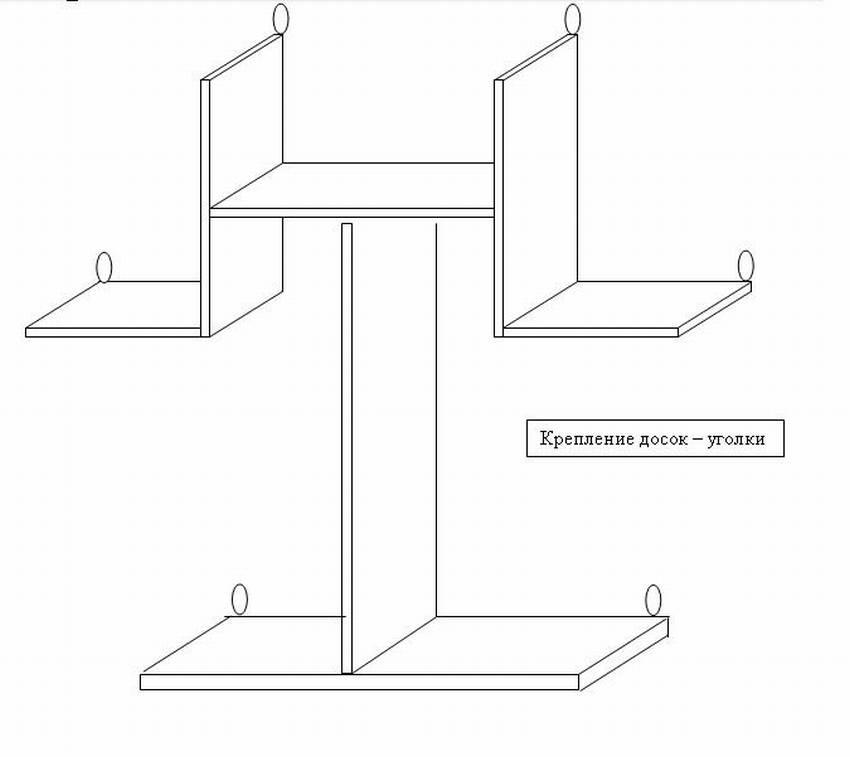

DIY wooden shelving

Fresh, clean lines, simple, solid construction and modern design will fit in any room. The credo of many great architects of the 20th century was "form meets function," the bookcase presented is proof of this. The sturdy shelves are mounted on the same sturdy struts. No decorations, unnecessary details, even the back part does not overshadow the perfect geometry.

The design is really surprisingly simple, so making a modern wooden rack with your own hands is quite possible. Long threaded rods are hidden inside and firmly tie the entire rack.

No corners to cut, no traditional grooves. Finishing is also practically unnecessary, because all parts are processed before assembly. The rack is made of laminated plywood, so it looks solid, as if it were made of solid wood. You will need a saw, a planer, a jointer, a drilling machine, a drill, and you can see the assembly order in the step-by-step photos.

The size of the rack can be made at your discretion. Want it to be a full wall (even around a window) with enough shelves to house an entire library? You can do it! Cabinet shelves can be easily made to any size. Need a small shelving unit? No problem either. Check out the drawings, adhering to the proportions, you can assemble any structure of any size, only by changing the distance between the holes or simply by reducing and increasing the number of shelves.

Floor corner bookshelf (cabinet)

(with your own hands in 2 hours !!! drawings and step-by-step photos of production)

The author claims that he managed to make all the parts of the shelf and assemble the entire structure in 2 hours. The rest of the time was spent painting, varnishing and drying.

The very design of such a shelf shelf assumes that not a single nail is needed to make it.

It is important that all the shelves sit very tightly in their places so that the shelf does not swing. If the connecting holes did not work out and some shelves stagger in their places, then the shelves in these places can be screwed on, or, as the author advises, you can simply drive pieces and fragments of wood into the grooves

We also recommend that you do not forget to screw the shelf to the wall so that it does not accidentally fall)))

Floor shelf or table with shelves in the kitchen

Most likely, this option applies more to tables than shelves. However, we have posted this model here, because We hope that this option for organizing personal will be of interest to you, and most importantly useful, because when arranging a home, you must bear in mind all the options !!!

See below step by step photos of the master class

Large wood shelving for home

Using these step-by-step photos, you can easily make such a huge and simple wooden rack with your own hands, which is suitable for a garage, for a house, for a store, for storing toys, for flowers, for books and storing old unnecessary things in the back room.

DIY portable shelf

A great option for a simple wooden shoe rack, which you can easily make with your own hands from wood. This shelf has a large surface area, which means you can put more of your shoes on it. Also, this shelf is perfect for toys, books, tools, shoes and other things. The shelf is characterized by high mobility, which means that you can put it wherever you need it at any time.

Shelf bench for shoes, toys and books

It will not be difficult for you to make such a simple wooden shelf in the hallway with your own hands. Check out the step-by-step photos below how it's done. The bench shelf is suitable in the hallway for shoes, in the bathroom, in the nursery for toys, in the room for books, magazines and newspapers.

Shelf wardrobe

Many craftsmen, having opted for a shelf - a shoe cabinet, begin to doubt their abilities. And the first question that worries them: "How to make a shelf-cabinet for shoes yourself?"

It's actually not that hard. First you need to prepare all the necessary materials, and you can safely get to work.

And so, for a shoe rack - a cabinet with parameters 1100 * 700 * 250 you will need:

- Chipboard 1.6 cm. Size 110 * 25 cm., 2 pcs.;

- Chipboard 1.6 cm. 66.8 * 25 cm., 3 pcs.;

- Chipboard 1.6 cm.52.6 * 25 cm, 2 pcs .;

- Chipboard 1.6 cm.31.1 * 51.8 cm, 4 pcs .;

- Chipboard 1.0 cm.51.0 * 14.0 cm, 4 pcs .;

- Chipboard 1.0 cm.51.0 * 13.5 cm, 4 pcs .;

- Chipboard 1.0 cm.51.0 * 8.5 cm., 4 pcs.;

- Fiberboard 0.3 cm. 69.6 * 109.6 cm., 1 pc.

List of accessories:

- 4 sets of shoe boxes;

- 4 handles;

- 6 pcs. foot pads;

- self-tapping screws;

- confirms;

- Double-sided tape.

For all this work, you need a tool like this:

- screwdriver;

- corner, screwdriver, tape measure;

- bit for working with confirmants;

- bit for self-tapping screws;

- drill for confirmation;

- awl.

We proceed directly to the assembly of the shoe rack. The first thing to do is to assemble the frame and install the internal parts. Next, we install the back wall of the fiberboard.

Now, the most time consuming part of the assembly is attaching the opening mechanism. On the sidewalls, we mark the places where we will have fasteners and a pin stop, and fasten the panels to the sidewalls.

To attach shoe boxes, it is also better to use the diagram that comes with the kit.

The next step is to fasten the facades, handles and thrust bearings and the assembly is complete.

Schemes and drawings of shelves in the kitchen

To do anything, even a regular kitchen shelf, needs a plan. A diagram or a drawing is already half the battle. Usually difficulties arise with proportions, it is not always possible to rely on your eye, so it is better to use a ready-made, tested scheme.

For example, do you like this cute country-style shelf? Interesting solution, right? Cornice with a decorative pattern in the shape of an apple, the back wall assembled from a lining. If you want the same for your kitchen, use this scheme.

Or another version of a beautiful carved shelf in the same style

This collection contains diagrams and drawings of various shelves and cabinets for the kitchen, as well as methods for attaching the shelf to the wall, assembling the bracket and installing the shelf in the bracket. It will also be easier for you to figure out the proportions if there is a ready-made scheme.

which you can do yourself

You can see the whole variety of kitchen shelves in this gallery.

from beer houses do it yourself to the kitchen

Let's look at how to make a kitchen shelf (rack) from beer glass bottles with your own hands. If you already have four beer bottles (or champagne bottles) and two boards, then consider that you have already done half of the work. Of course, in addition to this, you will also need inexpensive mounts that can be purchased at almost any hardware store.

Opt for beer bottles with an elongated neck.

Shelf boards are sanded and coated with dark varnish.

Surprisingly, these glass bottle kitchen shelves are durable, as they can support the weight of an adult.

By placing one such shelf on another, you get a rack in the kitchen from glass bottles.

See step-by-step photos of the master class:

Save

= What shelves can be made of

|

made of wood Example: DIY flower shelves 230 |

from metal pipes Example: DIY pipe shelves |

made of PVC pipes |

|

made of cardboard Example: Shelf rack made of cardboard boxes |

from paper | drywall |

|

from glass Example: Shelves in Art Nouveau style 180 do-it-yourself photos |

from old boxes Example: Shelves from boxes with your own hands 120 photos |

pallet pallets |

| stainless steel | from glass | from old stairs |

| From bars |

from bottles Example: |

from snags and branches Example: A bookshelf made of twigs and snags |

|

made of bricks Example: |

from newspapers Example: Shelf of newspapers |

From cans Example: Do-it-yourself kitchen shelves: 456 photo drawings instructions |

= Ways of fixing the shelves:

|

On belts Example: |

On brackets Example: Upside Down Bookshelf |

On hinges (hidden shelves) or pivot pins Example: Secret door - wardrobe and bookcase |

| On strings | On the ropes | On pins |

|

Clips Example: A 3-pipe rack from floor to ceiling. |

On perforated rails | |

= What are the shelves:

|

Corner Example: Do-it-yourself corner shelf 230 photos |

Wall mounted Example: Wooden bathroom shelf |

Hinged Example: Art Nouveau shelves 180 do-it-yourself photos |

| Suspended |

Floor standing Example: DIY floor shelf in 45 minutes |

Under the ceiling Example: Making a bookshelf under the ceiling |

|

Racks Example: DIY pipe racks: 180 photos, instructions, diagrams |

Bookcase |

Shelf - Invisible Example: Invisible Bookshelf |

Save

Save

Materials for the manufacture of shelves

If we talk specifically about homemade structures, then wood is most often used. And there are many options.

It can be both ordinary boards and sheet materials in the form of plywood, chipboard or MDF. Someone uses the remnants of OSB (although the material does not differ in aesthetic qualities). Others - specially procured pieces of logs, as well as saw cuts and thick branches of trees.

But the most affordable and popular material is the boards. You can buy them in a store, or you can prepare them yourself by sawing a log.

And also boards can be "obtained" for free by dismantling old wooden pallets. For many, they have been lying around for years.

How to make a shelf with your own hands from wood, you can read in detail on our website in our article.

This is just one of the possible options for using boards and bars. Very simple, by the way. So take note of it.

Another popular material is metal. Most often these are shaped pipes or strips. But you can use any rolled metal that catches your eye.

Metal structures are durable and can withstand significant loads. However, to work with metal, you will need an additional tool in the form of a grinder and a welding machine. However, sometimes it is possible to do without welding, using a bolted connection of parts.

Shelves can also be made from other materials. For example, glass or plastic. In the first case, you will have to sweat a little, because working with glass is another task.

It's not for you to cut a tree "by eye" or to cook metal according to the principle: "Oh, it will do just that!". It requires accuracy, patience and sometimes even jewelry precision in the process of cutting glass.

With plastic, of course, everything is much easier. It will also be much easier to make wood shelves. Someone prefers to make shelves from cement mortar. But most often these are floor structures or small hanging shelves.

DIY wine bottle rack

Here's a concrete example of how to make a large wine storage cabinet in a basement or other appropriately sized room. The dimensions were chosen to match the height of the basement. The width was determined by two factors: no additional support in the center was needed, and the need to remodel a portion of the basement around a pair of these wine racks (an artificial brick lined on the wall was needed between the racks).

This is a relatively complex project, so the author, through step-by-step photos, tried to share his experience as much as possible. If you change the dimensions of the holes, the author of the project suggests making a mock-up and checking the distance between the shelves using various bottles. You may need to change the distance between the shelves. You will also have to do this if you have boards of different different thicknesses. Adjust dimensions for your intended height. In this case, the height is 205 cm, the width is 100 cm and the depth is 25 cm. 7 bottles are placed on the shelf. (70 bottles per rack).

You can see the sketch, if you disassemble something, do not judge strictly, this is just an amateur drawing.

Instruments

- Table saw

- Mitral Saw

- Electric drill

- Right angle adapter

- Roulette

- Drill bits

- Screwdriver

- Clamps

See below for step-by-step photos of sawing parts.

Here's how to assemble a wine rack. First, make a template on cardboard to speed up the process of marking the hole points. Here the shelf stands are located at a distance of 17 cm. With the first shelf 25 mm from the floor. Using a template and starting from the bottom, mark all the holes for the holes. Check all joints with a square to make sure they are square. Install the screws into the shelf support. Start at the bottom and work your way up. The thickness of the shelf boards and the dimensions of the holes must match the template. Use spacers to push the front shelf closer to the rear shelf. This ensures that the bottles are in a stable position. Attach the bottom shelves (one or two) first and then one of the top shelves to make sure the spacing between the uprights is consistent throughout. Then go back and install the remaining shelves. Depending on the floor level, you need to place a spacer or plank under the legs to balance the shelf. This will prevent rocking on uneven ground.

Pallet shoe rack

Unusual furniture and decor items made from pallets are gaining more and more popularity every year. It would seem like a simple transport material, but nevertheless a lot can be made of it, even a shoe rack.

Necessary materials:

- pallet made of wood;

- Sander;

- sandpaper;

- dust mask;

- waterproof wood primer;

- gloves;

- stain or paint;

- brush;

- soft rags;

- Matt lacquer;

- brush.

If necessary, we clean the pallet from dust and dirt. After that, we process it with sandpaper to remove irregularities. We brush away all the dust with a brush and wipe the pallet with a damp cloth.

Apply a primer to the entire surface of the pallet. This is necessary in order to protect it from moisture and prepare it for painting. After complete drying, apply a thin layer of paint and leave for several hours.

We cover the pallet with matte varnish. Once dry, you can apply a drawing or text using a stencil, paint and brush.

If desired, the top of the shelf can be decorated with stones, plants or other decorative items.

How to make a cardboard rack with your own hands

We will conduct a master class on making cardboard shelves with our own hands.

Necessary materials and tools

From the tool you only need a clerical knife or jigsaw, a glue gun, a simple pencil, a tape measure, a plastic or wooden ruler.

The cardboard does not contain harmful, toxic and other hazardous substances.

Materials (part optional):

- Cardboard, thick wrapping paper, tracing paper.

- Moment glue, adhesive tape.

- Plastic clamps.

- Emery for grinding joints and cuts.

You do not have to waste time looking for a practical, vending thing that fits perfectly into the interior.

You can speed up the drying of glued structural elements using an ordinary household hair dryer.

A hairdryer will help dry the cardboard product faster.

Instructions for creating a rack

Let's make the simplest shelving from the same type of cardboard boxes. We don't even need a sketch and drawing. No need to measure and cut grooves. We already have ready-made elements of the storage system.

The service life of cardboard furniture will be long-lasting if it has not been exposed to moisture and has been correctly processed during creation.

Algorithm of actions:

-

Step 1. We take boxes of the same type.

- Step 2. Cut off the lids with scissors.

- Step 3. We connect the boxes to each other. For fastening, you can use glue, tape, plastic clips.

-

Step 4. The lightweight and mobile storage system is ready.

We complicate the design a little.

-

Step 5. We collect and fasten the smaller boxes. We cut a rectangular hole in front of each box.

- Step 6. We get a few more cute drawers for storing shirts, towels and all kinds of small things.

-

Step 7. And if we make (or pick up) boxes in such a way that four pieces can freely enter one compartment of the bookcase we made earlier, then we will supplement the new storage system with drawers. For convenience, they can be signed. It will be easier to look for where what lies.

- Step 8. So we made the simplest cardboard bookcase with our own hands.

Part of the shelves can be omitted with drawers. We will add larger items here.

Decorate the finished rack at your discretion.

The ends can be pasted over with wrapping paper or tracing paper, and then varnish can be applied to all structural elements. Even old newspapers and pages of glossy magazines can become the basis for LKP. A good decor option is vinyl for furniture.

You can decorate cardboard products with your own hands from any materials, it all depends on your wishes and fantasies - there are many options.

How to make a book shelf with your own hands

Furniture manufacturers offer a fairly large assortment of bookshelves, shelves and cabinets of various designs and prices. You can buy shelves for books, or you can make them yourself, which is not difficult at all. To independently make a bookcase, wardrobe or shelf, it is enough to draw up a project, buy material, have the necessary tools and minimal experience with it.

The simplest do-it-yourself shelf

So, in order to make a bookshelf with your own hands, you may need the following materials:

- Chipboard or MDF;

- wood or plywood;

- plastic;

- glass;

- metal.

Related article:

Chipboard is the most common material for the manufacture of bookshelves

You can use one of these materials or combine them to create some pretty original book shelves. As for tools and accessories, you will definitely need:

- tape measure and ruler;

- electric drill and screwdriver;

- screwdriwer set;

- attachments for tightening fasteners;

- stainless steel furniture pipe with Æ16 or 32 mm;

- confirms;

- screws 16 × 3.5, 20 × 3.5, 30 × 3.5 and 50 × 3.5 mm;

- edge;

- iron or hair dryer;

- PVA glue.

Necessary tools for making furniture

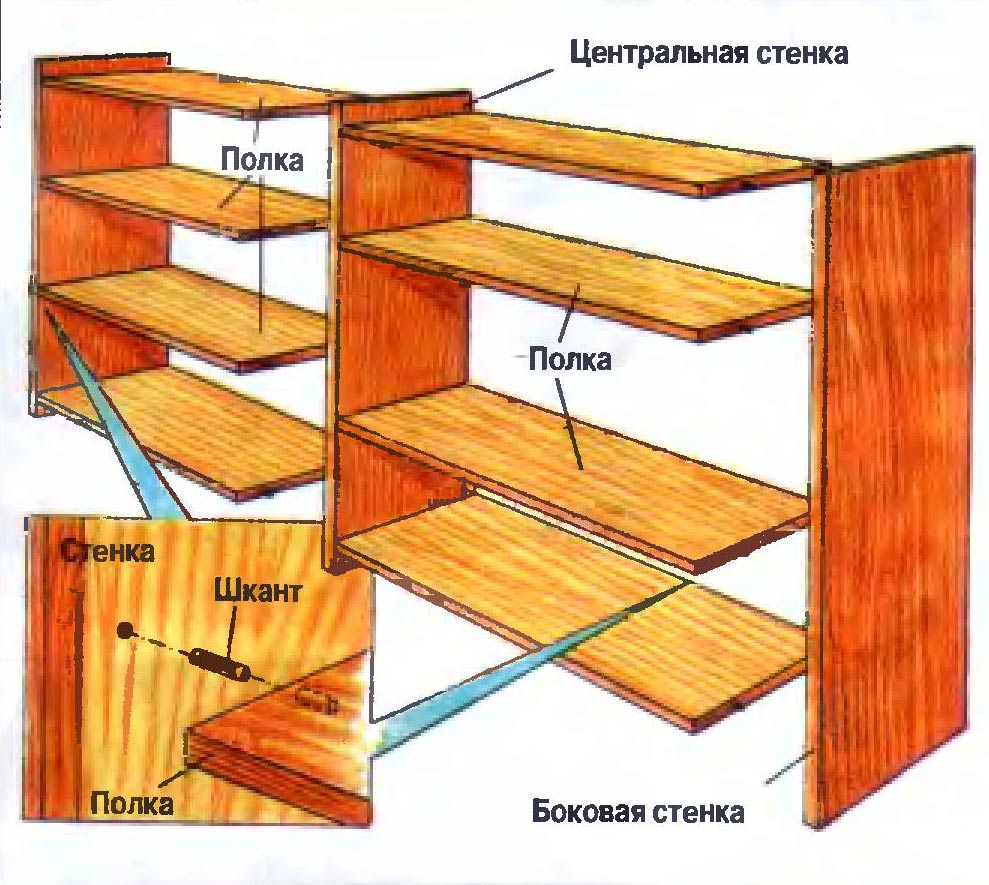

Do-it-yourself bookshelf made of wood or chipboard

In order to make any furniture, you first need to create a sketch and drawing. We have already written about how to do this using the PRO100 program on the pages of our online magazine in the article "How to make a wardrobe with your own hands." If it is not possible to use the program, then the drawing can be made on an ordinary notebook sheet in a box, where each cell will denote 10 mm. We will show you how to make a designer bookshelf using the PRO100 program as an example. As already mentioned, a designer thing is something that is made in very limited quantities.

Photo

Description of work

First, let's model our shelving unit. Such visualization will help to imagine how the finished shelf will look in the interior.

For convenience, you can split the sketch into separate parts. At this stage, you can already accurately determine the size, which means that you can choose the right raw materials and accessories for assembling the shelf.

The sketch shows the base points of the fasteners

Joining with coke (wooden pegs of a cylindrical shape) is the most difficult option, since additional devices are needed and maximum accuracy and attention. Basically, the same can be said about rafixes and minifixes.

Assembly diagram on minifixes

This method is difficult for a novice furniture maker, since you need to make a very accurate marking of the joints of two parts. However, the advantages of this type of fastening are that, if necessary, the shelf can be disassembled and reassembled many times, and the structure does not loosen over time. In addition, the peculiarity of this fastener allows you to make the joint invisible from the side, which cannot be said about confirms.

Assembly scheme using minifix and additional reinforcement with cokes. On narrow parts, when there is only one fastener on each side, additional fastening is needed, which will be provided by wooden pegs (coke), completely hidden.

Beginners can learn this, a simplified version of the shelf. And if you have carpentry experience, if you have material, tools, imagination and desire, you can make the most unusual shelves for books on the wall.

The cost of homemade structures is much cheaper than purchased ones, and you also enjoy the fact that they are made by hand and are unique.

Related article:

DIY Book Racks

By the same principle as described above, you can make book shelves. The difference lies only in the dimensions of the structures.Shelves can be made of almost any size and can be used as partitions, as well as for zoning space in studio apartments. Such systems for storing books can be made of wood, chipboard, metal, and even from scrap materials (pipes, pallets or logs).

Rack detailing The joints of the parts are marked in red

1 of 4

Peculiarities

The most important specificity of plywood shelves is convenience and simplicity. Compressed veneer can be made from both birch and softwood. Plywood of various grades can be used for the manufacture of shelves.

By the marking, you can judge what kind of glue was applied. Depending on its composition, the sheets are:

- flame resistant;

- moisture resistant;

- prone to moisture.

There may be some difference in the processing methods. Sanded plywood is quite widespread. Grinding is done on one or two sides. The last option is optimal.

In the overwhelming majority of cases, plywood is produced by the circular peeling method. But, for reasons of aesthetics, it is more profitable in some cases to use a material that was peeled with eccentric torsion of the workpiece. With flat planing, you can achieve a strictly specified type of pattern in accordance with the course of processing. For the most complex aesthetic effects, veneer is obtained by sawing (this technique removes the requirements for preliminary preparation and ensures the development of natural patterns with a natural range of tones).

For work, you can take plywood brands:

- FSF;

- FC (much better than the previous version, but with less moisture resistance);

- FB;

- FBS (with the maximum level of strength and resistance to moisture);

- FBA (completely natural material).

DIY flower shelf-screen

The shelves can be different, but you can always come up with something original. We suggest you make a flower shelf-screen with your own hands, a very convenient piece to divide the room space. Moreover, this is not just a mobile partition, but also a flower rack, so it will perform two functions at once.

The dimensions of the screen can be chosen arbitrarily, you can do it, for example, according to this scheme. We need:

- two 20 mm boards 2.5 meters long;

- 5 pieces of wooden blocks;

- self-tapping screws, tie screws, beech spikes;

- glue, putty, acrylic paint.

The first step is to make two side frames. Then, in the corners and for the middle shelf, we make holes for confirmations, and at the ends of the bars that will go under the vertical posts, we drill holes for the spikes. At the ends of the crossbars, we also drill holes and glue wooden spikes. We tighten the vertical posts and crossbars with screws, put the short crossbars on spikes. We fill all the cracks with putty. Then these places need to be sanded (when the putty dries). Prepare the shelves. To do this, we cut off the corners at the lower and middle shelves and fasten them to the frame with self-tapping screws. We fasten the partitions using confirmations. Then we screw the crossbars under the wheels. It remains to paint and arrange the pots with flowers. Photo source.

Shelf shelf

We present to your attention two ideas for shelving-shelves, which you can easily implement yourself.

The first of the 40 mm edged boards is extremely simple. Whatnot is assembled:

- from two planks, beveled at the top by 30 ° to provide support;

- shelves cut from furniture board.

The height and width of the structure are arbitrary and can be selected locally. If desired, the bookcase can be fixed in the upper part, and rubber heels can be stuffed along the bottom of the boards.

The second is S-shaped. For manufacturing, you can use trim boards, plywood or chipboard. One section of the structure requires 16 rectangular blanks, for example, 300x150 mm.

The workpieces are installed in a certain order, at each stage, three.

The first piece is placed on the floor. A second is attached to it at a right angle, joining them in width to the left. The third in width is joined with the first along its length, starting from the far right corner.

Fourth, fifth, sixth - assembled symmetrically, exactly the opposite.

It is very simple to check how correctly the figure is formed: the second, third and fourth boards should form the letter S.

Experienced craftsmen advise you to first assemble the structure on a rough basis on wooden pins and adjust the blanks, and when disassembling, number the parts from the end.

Each part is then sanded with sandpaper and they begin to assemble, according to the numbering. On the line of joints and grooves, PVA glue is applied and clamped tightly, holding it in this state for some time.

The assembled bookcase is varnished or painted.

Bookshelves made of obsolete things

If you came up with an idea to make a shelf out of handy things, you have a million options. You can use an old ladder, an interesting box or box, a thick rope, a non-working TV or even a guitar, or a water pipe - your imagination is unlimited.

For a nautical style, a real boat is suitable - a bookcase with built-in shelves. A musician can screw a guitar or cello case to the wall. But from the TV you just need to pull out the filling - and the shelf is ready.

In old drawers, pasted over with wallpaper, ladies' novels will feel good. Making the simplest corner shelves.

Sawing out or ordering wooden corners with sides of 20-25 centimeters. Use them to attach the shelves to the walls. The shelves can be of different sizes, however, it is desirable that their length is no more than 80 centimeters, with a width of 20-25. Shelves larger than the specified sizes do not carry the weight of books well and sag.

If you have an unnecessary interior door with an original relief, cut it lengthwise. Screw the resulting two parts into the walls, make shelves between them, paint - a fantastic door - a wardrobe at your service!