Specifications

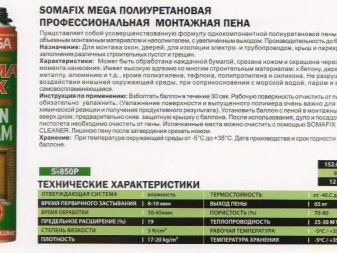

Such a sealant has a number of special characteristics that distinguish it from other compounds used in the process of construction and repair. During the operation of the foam, the volume of the substance release is taken into account, which is measured in liters. This indicator is determined by the consistency of the foam (foaming), as well as the amount of substance that came out of the balloon.

The adhesion index characterizes the adhesion strength to the substrate. Various surfaces can act as a substrate, the most common are brick, concrete, plastic, wood. With these materials the adhesion values are very high, but with substrates such as oily surfaces, silicone, ice and synthetic materials, there is practically no adhesion.

Foaming is characterized by the boiling process of the substance in the container. It occurs due to the difference between atmospheric pressure and the pressure inside the cylinder. When the substance leaves the package, bubbles form. Due to the presence of silicone particles in the composition, the foam mass retains a certain shape. Lack of silicones can lead to a violation of the consistency of the composition when foaming.

The existence of porous components allows the bubbles to burst, while the contents of the bubbles do not leave the foam clot. Only excess propellant is removed naturally. There should always be a balance between the number of closed and open bubbles, its absence can radically change the structure and properties of the composition.

Expansion is a chemical process that occurs after foaming. It is the reaction of the prepolymer to the environment. As a rule, the foam substance comes into contact with moisture, during which carbon dioxide is released and polyurethane compounds are created. It is at this stage that the substance expands, filling the required areas. It is believed that foam manufacturers must carefully control this process so that excessive expansion does not occur, but many think that this property can significantly save material consumption during the repair process.

Secondary expansion is a process that occurs after the substance has polymerized. Most often, this process is precisely negative, since it affects the ease of use of the composition. Re-expansion can most often occur due to the influence of external factors, for example, an increase in temperature. But an important indicator is the origin of the gases that the manufacturer adds to the foam. Quality products, as a rule, are not subject to spontaneous expansion or shrinkage.

Some builders have noticed that the likelihood of secondary expansion increases with products that are produced in cylinders with a tube.

An important indicator of quality is the viscosity of the substance. It significantly determines the consistency of the composition and the degree of influence of temperature factors on it. With a sharp change in temperature, the viscosity is often violated.

The polyurethane foam has special thermal insulation properties. Its thermal conductivity is not very different from that of foam. Foaming agent is great for insulation, but it is usually used on a small area or on certain types of seams, because it will be quite expensive to insulate large spaces with foam.

Depending on the type of composition, the foam can have a different density. It is selected in accordance with the type of work planned, because this indicator varies for different procedures.

The characteristic color of the foaming sealant is light yellow.If the surface is not properly prepared, the color can change under the influence of sunlight and turn orange. This process significantly affects the life of the material. To prolong it, treat the material with putty or plaster.

The shelf life of products depends on the manufacturer. But on average, it varies from one to one and a half years. After this period, it is not recommended to use a sealant, because due to a change in properties, it can present surprises during operation.

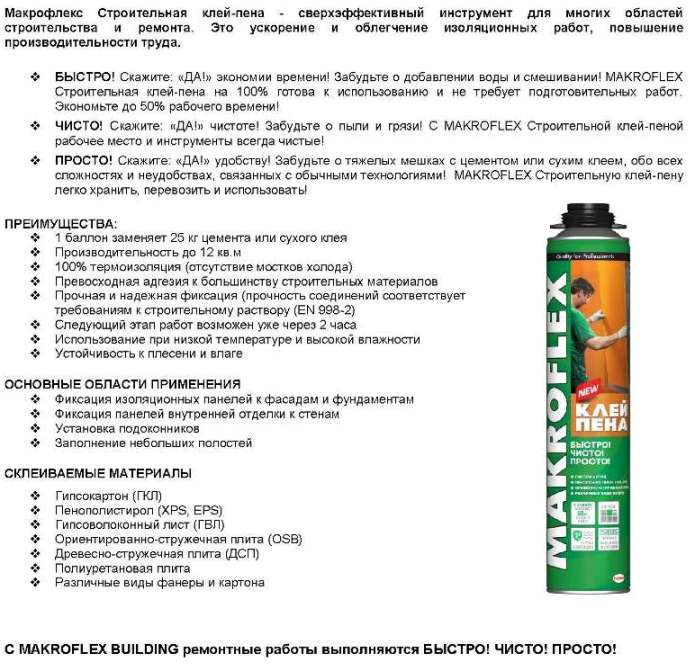

Pros and cons of Macroflex foam

Foam "Macroflex" is a one-component composition that is completely ready to use, it does not need to be mixed or diluted. Thanks to the packaging in the form of a tube, the foam is very convenient to apply - all you need to do is purchase a suitable assembly gun.

To work, you do not have to carry heavy bags, buy expensive tools and equipment, waste electricity, water, dilute dust and dirt. The absence of the need to mix the mortar significantly reduces time costs and helps to carry out construction and repair an order of magnitude faster.

Other properties and advantages of the composition are as follows:

- high strength of any joints (no less than that of standard cement mortars);

- the ability to replace dry building mixtures in many situations;

- effective joining of homogeneous and dissimilar building materials;

- suitability for work with both horizontal and vertical surfaces outside and inside the premises;

- reliable sealing and insulation of seams from moisture and minimization of heat loss;

- short time to complete solidification;

- ability to withstand heat and freezing;

- the ability to carry out work at low temperatures;

- control of foam consumption due to the special design of the package;

- lack of chlorofluorocarbon propellants in the composition;

- low price and low cost of the work performed.

Foam-cement "Macroflex" effectively glues, seals, bridges cracks, strengthens and provides moisture, sound, thermal insulation of structures, therefore it can be called a universal building material.

Despite the impressive list of advantages, foam also has disadvantages. "Macroflex" is a composition that, after hardening, is prone to shrinkage. However, due to the strong expansion after setting, this shrinkage is often unnoticeable.

Under the influence of ultraviolet radiation, the foam gradually collapses, but this minus can be smoothed out by protecting its upper layer with mortars, putties, and sealants. "Macroflex" cannot be used for the installation of load-bearing walls - the composition is suitable only for lighter structures.

Scope of application

The main purpose of the foam is to fill voids, joints, cracks in already mounted structures. It is used for both indoor and outdoor work.

Polyurethane is used:

- when installing windows, insulating frames;

- for insulation of premises, including balconies;

- for roof insulation;

- as an increase in the thermal insulation properties of the floor, foundation;

- when insulating partitions, doors;

- to increase the insulation of heating and water supply systems;

- in the production of furniture, household appliances;

- for fixing wall panels;

- for gluing surfaces;

- for fixing insulating materials such as foam;

- to reduce noise during the operation of air conditioners, heating systems;

- for sealing cavities between pipelines, joints of hoods, split systems;

- in the manufacture of decorative figures;

- polyurethane is part of synthetic fabrics such as spandex, lycra.

With the help of the assembly mixture, surfaces consisting of glass, metal, wood, stone or concrete can be insulated.

What to look for when buying

Of course, you won't be able to evaluate the quality of the material right in the store, but there are several signs that will help you choose a really high-quality product:

Pay attention to the packaging, or rather to its condition. The cylinder should be free of scratches, dents, nicks and other mechanical damage

Their presence indicates improper storage, which will certainly affect the end result, or negligent transportation, which indicates the manufacturer's unreliability.

Be sure to check the expiration date of the composition. The fresher the date, the better the substance has.

Turn the can up and down several times or shake it gently. You should feel how the liquid inside rolls quickly and easily. If there is a feeling that the components "fall" to the bottom of the container, it means that the curing process has begun. Mix as it should, this foam will no longer come out.

According to your feelings, the weight of the cylinder should exceed the volume declared on the packaging. The 500 ml bottle must not weigh exactly 0.5 kg. This means that there is much less liquid inside, and at the exit you will get fewer liters of ready-made foam.

Such a quick visual inspection will already tell a lot about the product that you are holding in your hands, and will protect you from fakes.

Main types

Polyurethane foam is used more and more often in repairs, as it has the following properties:

- Resistant to moisture, heat, sound.

- Poorly conducts current.

- Low flammability.

- Fills any cracks, seams.

- No harmful additives.

- Ease of application, etc.

With the help of foam, windows and doors are installed.

The types of material differ by category. So by way of use:

- Professional. Provides for the use of an assembly gun for ease of application. The composition increases significantly, low shrinkage, is used when filling large openings (window, door, etc.).

- Household. It has a special tip with a handle, foam is fed through it. Such packaging is for single use. They are used for filling cracks, cracks of small value. The filling density of the tube is lower. The outlet pressure is low, which contributes to the incomplete outlet of the mixture. When exiting, there is an increase in two times, shrinkage up to seven percent.

By operating temperature:

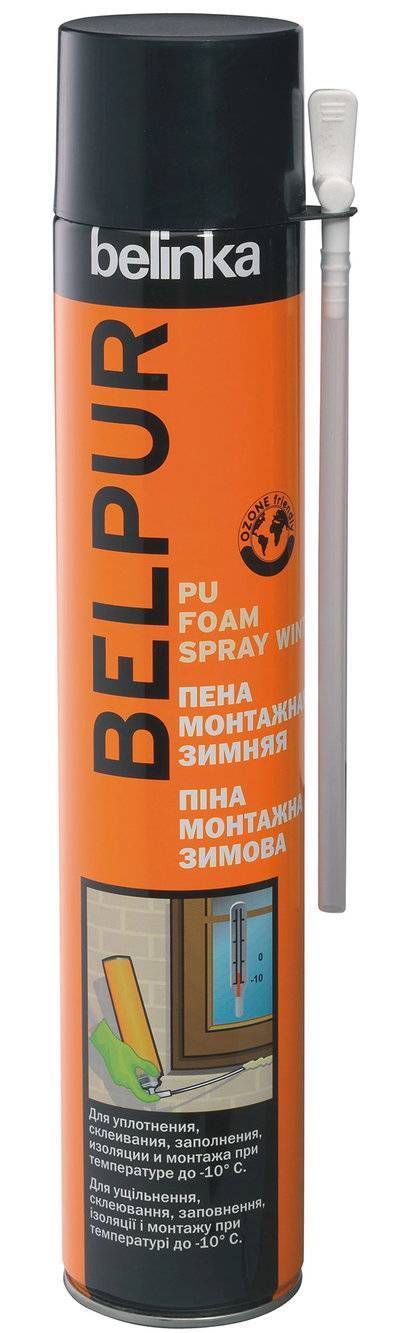

- Winter - possible use at -18 degrees.

- Summer - possible use at temperatures from 5 to 35 degrees.

- All-weather - applied from -100 to +350 degrees, which makes it more in demand.

By composition:

- One-component. The aerosol pack contains a mixture of ready-to-use components. The chemical reaction takes place inside the balloon.

- Multicomponent. The inner part of the package contains two cylinders (components and additives), shaking and stirring is performed immediately before work. The chemical reaction takes place later, but the service life is longer.

Masters advise using foam for the bathroom when renovating the bathroom. Such foam does not interact with polyethylene and silicone, but works with wood, brick, concrete and glass. The material is safe for the body, long-term use.

Waterproof polyurethane foam will glue joints, remove cracks, insulate from moisture, current penetration.

Top best pen

- Tytan Professional is a moisture resistant polyurethane foam for professionals. Use temperature - summer. Available in 750 ml cylinders. Weak re-expansion. Upon application and further drying, it does not emit toxic substances. It is used for the installation of windows, doors, sealing, insulation and more. When applied, it does not spoil the plane, does not deform it. Properties allow using for thermal and sound insulation. Simplicity, accuracy of application. Compatible with all materials except silicone. Manufactured in Poland.

- Ceresit WhiteTeq Thermal & Sound is a component mixture for white color application. Used with a pistol. The temperature of use is from -40 to +90 degrees, therefore it is used for external and internal work. The composition is waterproof. The packaging is convenient and easy to use.It is used for sound and heat insulation. Manufactured in Estonia.

- Construction foam Makroflex Pro - a high degree of adhesion to almost all surfaces for a long period, heat and sound insulation qualities, when using a gun, an accurate dosage is achieved, saving material consumption. After application, a day must pass for complete hardening. If the drying temperature is higher than 20 degrees, then the time will be shortened. The material is resistant to temperature changes from -50 to +100 degrees. Application at low temperatures will lead to partial loss of filling properties. Manufactured in Finland.

Penosil - polyurethane foam adhesive has plastic properties, which eliminates tears after the base dries. Weak smell. Fast setting, high sealing and sound insulating properties. For ease of use and application of an even seam, it is recommended to use a gun. It is based on polyurethane. Requirements for the plane - clean, moist. Manufactured in Estonia.

Akfix 805P is a one-component polyurethane mixture. Moisture is the prerequisite for hardening. The material is moisture resistant, has high adhesion. Constant direct ultraviolet radiation can shorten the working period of the applied raw material. Use temperature 20 degrees. Thorough shaking for half a minute is required before use. It is used with an upside-down assembly gun. The plane is cleared, dust is removed

The foam expands significantly, which is important to consider when foaming. Manufactured in Turkey.

Hauser sealing foam

Manufactured on the basis of polyurethanes. It is produced in several versions: winter, summer, for professional use. Having a low cost, it belongs to an economical type. Does not contain harmful impurities, which is beneficial for the body. Has thermal and sound insulating properties. Manufactured in Russia.

By application temperature

Allocate winter, summer and universal polyurethane foams. Let's start with universal polyurethane foam, it is also called all-season.

Such foam can be used in a wide temperature range from -10 to +25 ° C. It is the most common and used most frequently. However, it is necessary to understand that such an all-season nature is rather arbitrary, the temperature range from +5 to +25 ° C is considered optimal for the use and storage of this type of foam. Now comes the fun part: what is the difference between summer foam and winter foam? In winter, at low temperatures and low air humidity, the course of chemical reactions slows down, the viscosity of the material increases, and the pressure in the cells (structure) of the foam decreases.

It should also be remembered that during the curing of the foam there is an intensive absorption of moisture from the air, and in winter the humidity is lowered.

Winter foams, unlike summer foams, have a different formula - they are modified with special additives that allow you to work with foam in winter at low ambient temperatures and at low air humidity.

Working temperatures of winter foam are in the range from -18 to +25 ° С. It should be noted that the volume of foam after its spraying and expansion decreases in proportion to the decrease in the ambient temperature. For example, the foam output from a 300 ml bottle at a temperature of +20 ° C is 30 liters,

at 0 ° С - about 25 liters, at -5 ° С - about 20 liters, at -10 ° С - about 15 liters.

The operating temperature of summer polyurethane foam is the highest in comparison with winter and all-season foam: from +5 to +25 ° С. This allows you to work even on the hottest days without the fear of changing foam characteristics.

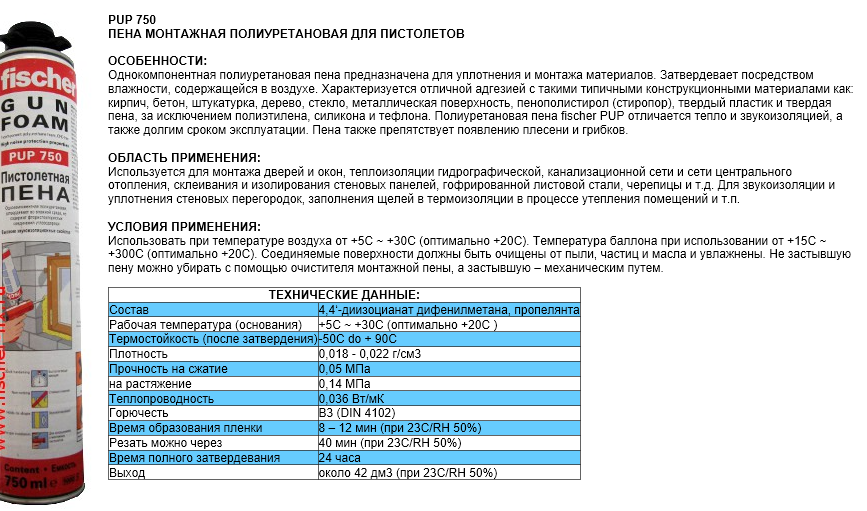

Technical characteristics of polyurethane foam Titanium

Product of the American company Selena. Launched in 1992. Today, production facilities are already available on all continents.

Specifications:

- the output of the polyurethane foam mixture from a 750 milliliter canister - up to forty-five liters (at an air temperature of 23-25 degrees and humidity - 50-70 percent);

- excellent adhesion to a wide range of surfaces;

- resistance to high humidity and mold formation;

- excellent sound and thermal insulation parameters;

- high accuracy of application;

- ready to cut within half an hour after surface treatment with foam;

- the duration of the complete polymerization is twenty four hours;

- density of finished polyurethane - 20-25 kg / m3 (very fine and dense structure);

- has a slight primary expansion;

- secondary expansion and shrinkage are absent;

- guaranteed shelf life - one and a half years;

- flammability class (according to DIN 4102) - B2 and B3.

The line of Titan foams includes household and professional sealants, winter and summer, foams with increased product yield from the cylinder, one-component and two-component, fire-resistant.

Overview of brands and manufacturers

In construction stores, adhesive foam from various manufacturers is sold. Samples differ in price and quality. The highest quality, but also the most expensive options are produced in Germany and Finland. It is definitely not worth buying glue-foam made in China. But between these manufacturers there is still a wide range of products from other suppliers.

T-Vanguard

T-Vanguard combines expanded polystyrene with concrete and brick. It can be used to put insulation on a wall covered with plaster putty. The formulations are available in seasonal versions. They differ in the requirement for temperature conditions. The disadvantage of the adhesive is that it is sold in powder form. Before use, the glue is diluted with water.

Tytan Styro 753

The glue-foam is packaged in cylinders. A distinctive feature is fast setting and complete drying. You can continue grinding and other installation work after a couple of hours after laying the plates.

Ceresite ST 83

Ceresite is sold in bags. It is a powdery mixture. Package weight - 25 kg. The powder is diluted with water. Dilution instructions are on the packaging.

TechnoNIKOL

Glue-foam TechnoNIKOL It is used for fixing XPS and EPS boards for external insulation and interior work. The cracks are sealed with it and expanded polystyrene is glued. The adhesive is resistant to moisture. He is not afraid of mold. The composition is characterized by high adhesion to concrete and other materials. A cylinder with a capacity of 750 mm is enough for 12 m of the working surface.

Macroflex

Glue-foam Macroflex is produced in cylinders. There are two types of glue: for summer and for winter. The disadvantage is the big expansion. When expanding, Macroflex 65 is capable of doubling. Other brands of this adhesive expand less at low temperatures.

When choosing a foam adhesive, you should take into account the environmental conditions and types of finishing materials.

Tips & Tricks

Experienced craftsmen share tips for buying and using foam glue:

- The glue should not be liquid. You can check the consistency at the time of purchase. There are testers in stores. It is enough to squeeze out some glue to evaluate its consistency.

- When buying foam glue, you should look at the package for the density of its composition. The higher this figure, the higher the adhesive consumption will be.

- The label indicates whether it is possible to work with glue in the cold. The lower the number, the better. The fact is that compositions with a low temperature regime tolerate high temperatures just as well.

- When buying foamed glue, be sure to familiarize yourself with the contents of the container. It should not contain carbon dioxide and freons. A good indicator is the presence of isocyanate oligomers.

- The initial setting time is indicated on the packaging. The optimal rate is 10-15 minutes.

- Assess the degree of adhesion. The minimum indicator for concrete is 0.3 MPa, for expanded polystyrene - 0.8 MPa.

There are many tools for joining PVC boards to concrete and other surfaces.Foam adhesive specifically recommended for this purpose is the best solution.

Share link:

Application process

Regardless of environmental factors, the can should always have an average temperature of 23 degrees Celsius. Before starting the procedure, the coating must be prepared in advance, that is, it must be cleaned of dirt and dust. Remember to shake the can. To use professional foam, you need to use a gun with an applicator.

If too much was applied, then it must be eliminated. A rag will help with this, try not to smear the substance. If you did not eliminate the excess part right away, but it hardened, then you need to use acetone or gasoline (or some other solvent).

You can get rid of the remaining foam on your hands using a solution of table salt. For the mixture, prepare warm water, and dissolve the salt in it. Then release your hands there. When doing this, use a washcloth to clean your hands. Laundry soap also helps.

Polyurethane foam is sold on the construction market in a spray can. The balloon can be used to flush the gun. Thorough cleaning of construction tools is a guarantee of long-term work with them.

Polyurethane foam is not as often used as a waterproofing material. Most often it is used to create sound insulation in a room. It is especially used for door sound insulation. Because many external factors can adversely affect the structure of the construction foam.

Therefore, it is better to find a better material for waterproofing. The polyurethane foam does not let water through and keeps it, but this is only temporary. But it also depends on the quality. The product is mainly used for sealing. Sometimes a substance is used for condensation. Therefore, polyurethane foam and water are related concepts.

Types of polyurethane foam

Foam cylinder valve

What is polyurethane foam?

Manufacturers produce different types of polyurethane foam, which differ in composition, performance and scope.

Nevertheless, conditionally, the foam can be divided into (description of polyurethane foam):

Professional.

Cylinders with such foam are equipped with a special ring valve, which serves to screw the container onto the assembly gun. After the cylinder is attached to the tool, the foam under pressure enters the inside of the gun, where it rests on the valve, which is controlled by the trigger. Thanks to the use of a gun, the procedure for applying foam to the work surface is as comfortable and fast as possible. By pressing your finger on the trigger, you can control the pressure and direction.

Household.

The set of such cylinders initially includes a special plastic tube, which allows you to perform work without using an assembly gun. However, despite its simplicity and affordability, it is significantly inferior to professional foam in most parameters. In particular, it has a much higher secondary expansion rate and a lower output volume. Quite often, the gas in such cartridges runs out faster than the prepolymer. In addition, they are considered disposable, so they must be used at the same time, since the next day the containers become completely unusable. Thus, it is best to fork out for the purchase of an assembly gun, which costs in the range of several hundred rubles.

It is worth noting that household foam is categorically not recommended to be used for critical work, such as the installation of window and door structures, as well as window sills.

In addition, the composition of the polyurethane foam may differ in its composition:

One-component is familiar and available for general use.

Two-component - this type has a narrow scope and is not available on the free market.Since for its use it is necessary to mix two different compositions.

Also, depending on the temperature conditions in which the polyurethane foam can be used, it can be:

- Summer.

- Winter.

- All-season.

It should be noted that the composition of winter foam is significantly different from its summer counterparts. In particular, it can be used at low air temperatures, up to -20 ° C inclusive. Naturally, for its application in such frost, care should be taken to ensure that the temperature of the cylinder itself is positive.

In addition, the foam is distributed according to flammability classes and has the appropriate designations:

- B1 - refractory.

- B2 - self-extinguishing.

- B3 is flammable.

Of course, polyurethane foam, which has increased refractory properties, is considered the best.