Dyeing plastic at home

It is possible to cope with painting of plastic materials on your own, this will largely save the budget. Turning to professionals is a very expensive business. To carry out the work at home yourself, you will need to take care of your own safety by preparing protective equipment, also prepare all the necessary tools (listed above), and perform all stages of the work. They will be discussed in detail later.

It is possible to cope with painting of plastic materials on your own, this will largely save the budget.

Painting methods

The paint coat is available either in cans or in aerosols. Which option to choose depends on the size of the product and the experience of the person who will carry out the painting work.

-

Spray cans are more appropriate for a small object to be painted, it is not difficult to work with them, but before starting, you should try it by sprinkling a little paint on an unnecessary surface, this will help you understand how best to spray in order to get the desired result. In general, the aerosol method will give a good even coverage. This method does not allow mixing tones, and thus it will not work to apply clear color boundaries.

-

A can of a larger volume than a can, but storage in it is possible only for a short time. For this reason, it is more often used for a large amount of work. It should also be taken into account that working with a brush is much more difficult and requires skill. Otherwise, an ugly trace of bristles may remain on the product, and stains, the coating will be uneven and aesthetically unkempt.

The use of a spray gun can facilitate the process; a roller is rarely used. For a beginner, the spray method will be more suitable.

Preparing plastics for painting

As mentioned earlier, you should carefully prepare the product before starting work in order to get an excellent result. This stage includes the following steps:

- Get rid of the previous cladding, you can use sandpaper, solvent, construction hairdryer.

- Get rid of contamination.

- The product must be degreased using a solvent.

- Treat the product with an antistatic agent.

- If required, apply a putty.

- To ensure good adhesion, the surface is treated with no more than 180 sandpaper, after the completion of this stage, the object is again cleaned and dried.

- Degreasing is carried out again.

- Carry out priming work, if required.

- Rub and clean again.

The product must be degreased using a solvent.

Plastic dyeing technology

Having chosen the type of coloring agent, it is worthwhile to understand the method of work. The article will discuss two technologies: painting with a brush, and application with an aerosol.

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder, so the coating will become thinner, and the finishing stroke is also done softly to align. If everything is done correctly, then a one-time work with a brush is enough.

General recommendations:

- The brush should not be dipped whole, the tip is enough;

- You should strive to make the layer as thin as possible by pressing on the bristles;

- Maintain a slope in the working position of the hand.

They work with a brush, making wide straight strokes, initially move the brush gently, then press harder.

Spray operation process:

- They put the product on a flat surface, for example, on a chair, mark the part to be painted with paper tape, close the lying objects (with film, newspaper, paper);

- You must first shake the aerosol;

- There should be 20-30 centimeters to the subject;

- Spray paint smoothly in one layer, keeping the balloon straight;

- For complete coloring, it is worth making two or three layers;

- Wait for the time indicated on the package between the application of layers until it dries;

- After completion of the work, the tape is immediately removed.

Once dry, you can varnish the item to increase durability. Acting in the same way as when painting.

Spray paint smoothly in one layer, keeping the balloon straight.

Plastic paint is a great option to freshen up old items and give them new life. The presence of a wide variety of colors allows you to come up with various solutions for decoration. Before painting the plastic, they include all the imagination, they take the tools necessary for this process, as a result, you can perfectly decorate your home yourself.

Properties and composition of epoxy enamels

Epoxy enamels have the properties of epoxy resins. These resins are a synthetic oligomer that is currently used in all existing industries. By themselves, epoxy resins in their pure form are not used anywhere, they receive their valuable and unique properties after the process of connection with a hardener and the complete completion of the polymerization process. Depending on the combination and proportion of different types of resins with hardeners, materials with different properties are obtained, from rigid, like metal, to flexible, rubbery, rubbery materials. Depending on the temperature and type of hardener used, epoxy is divided into hot and cold curing resins.

Paints and varnishes that are based on epoxy resins have excellent adhesion to the painted metal surface, wood, concrete and other types of painted surfaces. In addition, epoxy paints are characterized by increased hardness, chemical resistance and high elasticity.

Epoxy paint is a durable and tough coating that extends the life of the surface to be painted, such as the same floor, ensuring an excellent appearance over time. This type of paint perfectly resists aggressive external irritants and influences - for example, chemicals such as acids, alkalis, salt solutions, fuels and lubricants, withstands heavy loads and has high adhesion to stone building materials containing a binder, aggregates of various size and water, for example, concrete.

Another distinctive feature of epoxy paints and varnishes is its waterproofing property.

Advantages of waterproofing paints:

1). Self-healing, recovery - i.e. under mechanical pressure on such paint, it bends, but does not collapse, eventually restoring its position. This possibility is realized due to the presence of furyl, perchlorovinyl, epoxy and similar resins, consisting of synthetic compounds.

2). The surface painted with this kind of enamel "breathes". That is, if you paint rooms that are devoid of light, with a high moisture content, for example, basements, with such paint, then the walls will breathe thanks to such paint without creating additional condensation.

3). Ease of use. In order to apply paint waterproofing to the surface, before that it is necessary to paint the surface with a bitumen or polymer composition, for this it is enough to use a regular roller, brush, mop or filling with a paddle. Staining must be carried out until a continuous, integral film is formed.

4). Corrosion protection. Surfaces that are painted with waterproofing epoxy enamels reliably resist corrosion.

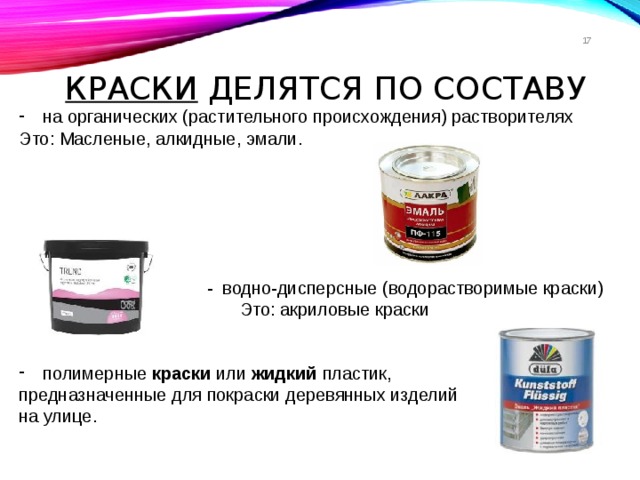

Types of polymer coatings for steel sheet

The following are used as polymer coatings:

- polyester (polyester), designated PE. SP;

- food laminate;

- polyester matt, modified with teflon, PEMA;

- pural - polyamide modified polyurethane, PURAL;

- polyvinyl chloride plastisol, PVS;

- polyvinylidene fluoride, PVDF, consists of 80% polyvinyl chloride and 20% acrylic;

- acrylic, AY.

Polyester is the most popular coating due to its excellent price-performance ratio and has satisfactory UV and corrosion resistance. However, resistance to mechanical damage is higher for Pural and PVDF coatings.

Pural is more expensive than polyester, but it also has a higher chemical resistance, as well as mechanical stress and temperature extremes.

Plastisol is the most resistant to mechanical damage due to thickness, but at the same time the least resistant to temperature extremes and UV radiation.

The most durable and most expensive coating is polyvinylidene fluoride (PVDF).

The least durable and unstable to mechanical and weathering is acrylic coating.

All these coatings can have a different texture, shine, color. Thus, polymer coatings have different resistance to ultraviolet radiation, high and low temperatures, weathering, mechanical damage and others.

The above coatings are initially liquid and are applied by the roller method, which is the most widespread and demanded one both in Russia and in other countries.

The most important requirements for coatings are strong adhesion (adhesion) of individual layers to each other, the lower layer to the substrate, hardness, strength in bending and impact, wear resistance, moisture resistance, weather resistance, a set of decorative properties (transparency or hiding power, color, degree of gloss, pattern, etc. etc.).

The anti-corrosive protective properties of coatings for indoor use are classified according to EU 10169: 2008. The test process in a humid chamber is regulated by the EN 13523-26 standard.

Application technology

Before proceeding to the direct application of the coloring agent to the floor surface, several preparatory steps must be taken. More about them will be discussed in the following chapters.

Before proceeding to the direct application of the coloring agent to the floor surface, several preparatory steps must be taken.

Preparation of concrete pavement

The preparation of the concrete base itself will determine how long and how well the paint will hold. In this case, the actions differ on concrete structures that have just been built, from those that are already standing, for a long period of time.

A fresh screed can be painted five days after creation. At this time, the concrete hardens well enough, and has the necessary moisture for applying paint to it.

This process can be done with a trowel or a stiff brush. All dust should then be vacuumed.

If the painting will be carried out on an old concrete pavement, then, on the contrary, it must be thoroughly dried. Otherwise, the epoxy will begin to flake off. Determination of the moisture content of the base is carried out with a special device. If it is absent, you can glue the film to the surface, after 24 hours they look to see if it is covered with moisture, and if it is wet to the touch. If the film is dry, then you can proceed to painting, if not, you should wait until the floors are completely dry.

Next, an inspection is carried out for flaws. Those places where there are large cracks are expanded to 5 millimeters, such defects will be covered with epoxy putty. Also, the surface is cleaned and vacuumed.

The surface is leveled, all existing defects are removed from it.

Precautionary measures

The two-component formulations, which are the most popular, must be mixed for painting. During this time, they can release substances harmful to human health.Therefore, work must be carried out in protective clothing, special goggles and rubber gloves are worn, and a respirator is also required.

The room must be well ventilated. Do not use utensils that are used for food purposes. If the mixture gets on the skin, it is immediately cleaned with denatured alcohol or white vinegar, it is unacceptable for it to solidify on the skin.

The room must be well ventilated.

Consumption calculation

The consumption of paint for a self-leveling floor is indicated on the packaging, calculated per 1 square meter. Accordingly, in order to find out how much material is needed, you need to calculate the area, and also decide how many layers will be applied to the floor.

When calculating the area, all recesses and notches are taken into account, if the room is complex in structure, then it is divided into several zones, and then their areas are summed up. The average consumption, which is usually 1 mm per 1.5 kg (the exact figure is indicated by the manufacturer on the packaging), is multiplied by the layer thickness and the area of the room.

When calculating the area, all recesses and notches are taken into account.

Can I use a spray gun

The spray gun in many types of painting work simplifies them, and saves paint. But in the case of working with epoxy enamel, its use is impractical. After all, the enamel is distinguished by its fast hardening rate, so it can simply ruin the device itself.

Therefore, it is better to paint with a roller or brush. After painting, they can be thrown away immediately, they will become unusable.

Better to paint with a roller or brush.

Surface paint application

First, a primer mixture is applied to the surface, it serves to improve adhesion to the material. After complete drying, which takes 24 hours. Immediately before painting, the two components of the epoxy (hardener and resin) are mixed, the proportions are indicated on the package, you must strictly adhere to them. Mixing is carried out thoroughly, bringing the composition to homogeneity.

The paint should be applied with a roller or brush, the first layer will be rough. Usually, at least two layers are applied, the second can be applied in a day.

Usually, at least two layers are applied, the second can be applied in a day.

Scope of single component plastic colorant

The constituent elements of a liquid polymer determine its scope and purpose of use.

- Protects the base from the effects of weathering. Plastic is used as a colorant and enamel based on polyurethane, based on acrylic and alkyd. The colors introduced into the composition decorate the surface of different materials.

- The polymer composition protects from UV rays of the sun, from loads, from high humidity, temperature fluctuations. Such technical characteristics extend the service life of structures coated with polyurethane composite materials.

Road markings on highways and pedestrian crossings are considered as an example of the durability of a polymer dye. It does not lose its technological qualities for more than one year.

- In everyday life, such enamels are used to carry out repair work. Stairs on the street, facades, small architectural compositions, surfaces in the bathroom, balconies are covered.

Painting metal with plastic

Metal structures are protected from rust by enamel. It is made on the basis of alkyd resin, organic solvent, polymer filler. It is applied on clean metal and already on areas damaged by corrosion. Problem areas are pre-cleaned from peeling paint. A polymer film is formed. KM painted the lattice on the balcony windows, metal visor over the door, garage doors, various piping systems.

Bathroom application

Elimination of the gap between the bathroom and the wall is carried out with plastic in a liquid form. She renews the coating of the bathtub, the lower bowl of the shower stall.Restoration work is carried out in several ways using the following compounds:

- restoration of the top layer of the bowl with an acrylic mixture;

- enamel of a special composition is applied to the surface. It is made on polymeric materials.

The filling technique is used to update the font with acrylic. KM is sprayed. After that, it spreads along the walls and the bottom of the bowl. A durable film over its entire area is the result of repairs. The font is changing. The new coating strengthens the walls, increases resistance to mechanical stress, the temperature of the liquid in the bowl remains for a long time, and the likelihood of fungal growth decreases.

Thanks to liquid plastic, finances are not spent on the purchase of new plumbing, on the repair of the flooring and walls after the moment when the previous model is dismantled and a new one is installed. The repaired hot tub is ready for use in 36 hours. If the plumbing is used correctly, then after the restoration with liquid plastic, the coating remains for 20 years.

Installation of PVC windows using CM

More recently, the sealing of the gaps during the installation of PVC windows was carried out with a silicone sealant. Currently, liquid plastic or adhesive white liquid is applied to the joint. When it dries, an elastic film is formed that connects the structural elements. The process resembles diffusion welding. The voids are eliminated during the installation of the PVC block. One-piece surface without cracks and voids is the result of work.

Plastic paint for PVC windows is known under the Cocmofen brand. It is easy to use for both professionals and craftsmen at home. The material is colorfast, no shrinkage is observed. The brand is available in 2 types. The joints of PVC window profiles are sealed - the first type is Cosmofen 345. The second Cosmofen Plus HV is used for gluing parts of the window structure and fittings.

Using plastic wood paint

Liquid plastic paint for wood on a water-acrylic basis protects it from the negative weather conditions, which will help to avoid the destruction of the wood inside. KM is used for indoor and outdoor work. The composition is water-based, therefore safe, does not have an unpleasant odor, with a high drying rate.

Wooden housing construction will last longer if the ends of the wreaths of the log house are painted over with plastic CM. The wood is covered with a durable film with elasticity. It repels liquid and living organisms do not penetrate through it. The coating tolerates temperature fluctuations in a wide range, resistant to damage, to the use of detergents.

Any color is chosen when covering a wooden base with a plastic dye. During the period of operation, the brightness of the shade is not lost. This is due to the fact that special substances are added to the composition that strengthen the polymer film and prevent the loss of color brightness. The composition is applied to the wood if it has been outdoors for 12 months (flooring of terraces, staircases, fences).

Interesting: Rubber paint - characteristics and scope

Epoxy polyester paint

Epoxy-polyester paint consists of 50-70% polyester and epoxy resins, as well as hardeners, fillers and pigments. The amount of the latter components in the composition of the paint is about 35-50%. This type of paints and varnishes refers to powder enamels for internal use. Such paints are also called hybrid.

This paint is distinguished by its unique properties, which consist, first of all, in high strength characteristics, such as:

- impact resistance;

- elasticity;

- resistance to the effects on them of various kinds of solvents;

- excellent spreadability.

It should be noted that the field of application of epoxy-polyester paints is quite wide. Such paints and varnishes are used to paint metal products that are inside the premises.These items include various household appliances, electrical equipment, dishes, furniture, car accessories, heating elements, tourism accessories and much more. Due to its properties, paint not only protects products from corrosion, but also significantly improves their appearance. The paint is resistant to high temperatures on the coating, and therefore, does not fade or yellow.

There are two methods available for coating objects:

- Electrostatic spray;

- Tribostatic spray.

The process of painting objects with polyester and epoxy-polyester powder compositions includes the following steps:

- Preparation of the surface of the object for painting, which consists in removing old paint, various defects and irregularities, as well as rust;

- Surface treatment with a primer;

- Powder application to the surface using one of the available methods;

- Polymerization of the coating. To do this, it is necessary to influence the painted object with a sufficiently high temperature, which is in the range of 140-2200C, depending on the type of paint. In the process of heating, the powder slowly melts, which later turns into a sufficiently strong homogeneous coating.

Surfaces painted with these paints can have a glossy or textured appearance. In the first case, the gloss will hide minor irregularities and other defects. The texture, unlike gloss, on the contrary, will emphasize all the advantages of the product.

Advantages of polymer paints

Powder dyes have a number of advantages due to which they can be used to process external and internal products made of different types of metal. The advantages of polymers include: - they are not afraid of mechanical damage: if a metal product is damaged or deformed, the color will simply take on a new shape, remaining on the surface; - water and moisture resistance: the polymer coating does not lose its quality, even if the product is in water or under water for a long time; - resistance to UV rays: while other types of paints from sunlight can fade, deteriorate and lose all their properties, the polymer coating will remain the same strong and bright, nothing will happen to it even on the sunniest day; - they can withstand fire and high temperature: since polymer coloring is produced under strong thermal influence, then in the future, the high temperature regime of the coating is not terrible; you can even paint a brazier and a heating boiler with powder paint. - does not collapse from chemicals.

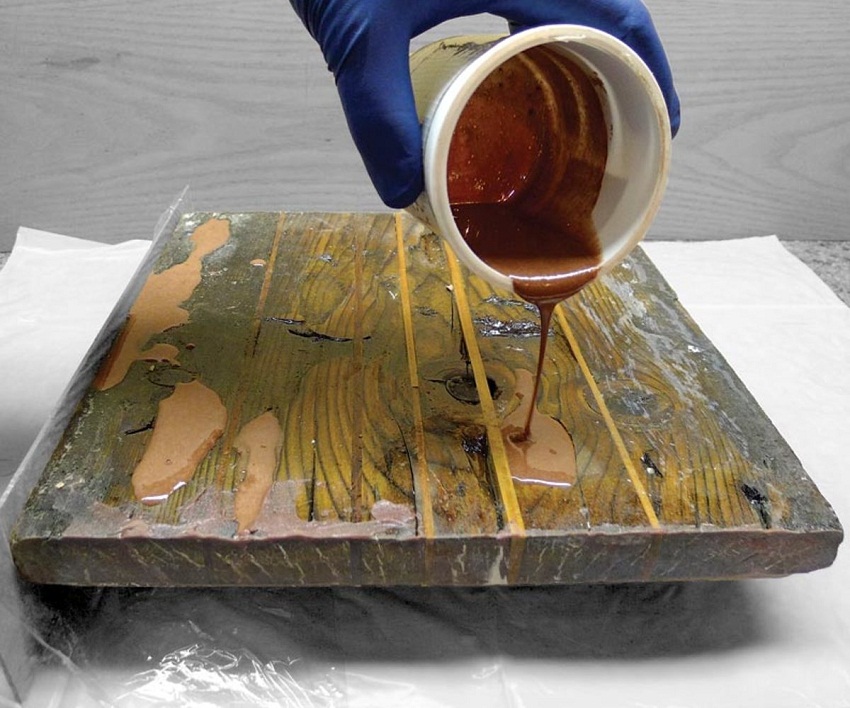

Sample examination

So, meet the test subject. This is polymeric enamel of Ukrainian production PS-160, proudly named "Liquid Plastic". We chose it, first of all, for its availability: the price of a kilogram is about 100 rubles (see also the article "Antique painting of various materials with your own hands").

Composition

The manufacturer announces the composition of the paint in this way:

- Polystyrene.

- Solvent.

- Pigment.

- Special additives.

Simply put, liquid plastic is a solution of crushed foam plastic in toluene or a solvent with the addition of the actual dye. Self-made glue in a similar way was once recommended by the magazine "Young Technician" for gluing plastic.

After evaporation of the solvent, a durable coating is actually formed on the painted surface, which does not peel off under severe mechanical stress, changes in temperature and humidity.

Application area

Since we are examining only coatings for metal, we will restrict ourselves to the corresponding part of the wide scope of PS-160 application.

It can be used:

- For processing pipelines (including heating mains).

- For covering metal floors in industrial premises, warehouses, ships, etc.

- To protect the metal structures of swimming pools, including those constantly in contact with water.

- For painting load-bearing elements of buildings, bridges, viaducts and other critical structures.

The Fort Bridge in Scotland has been continuously painted since its construction in 1890. Sea water destroys any coating throughout the year. The latest project of the authorities is to paint the bridge with a polymer composition, which should be enough for a quarter of a century.

Specifications

Let's pay attention to those characteristics of paint that can be expressed in numbers in one way or another.

- Drying time for one layer is 60 minutes.

- Consumption per square meter of surface when applied with a pneumatic spray gun - 210 grams.

- Mass fraction of non-volatile substances in the supplied paint - at least 23%. It can be diluted if necessary to reduce the viscosity.

After painting, you don't have to worry about the steel supports of the berth.

Surface preparation

The instruction published by the manufacturer for preparing the surface of metal structures for painting looks like this:

- The surface is degreased. For this purpose, gasoline, acetone, white spirit and any other solvents can be used.

- The welded seams are cleaned of slag and scale.

- Then the entire surface is cleaned from rust and other stubborn dirt. The manufacturer strongly recommends the use of sandblasting machines; with a small amount of work, however, it is much easier to use a metal brush or an appropriate attachment for a hand-held power tool.

Part of the corroded surface has been treated with a rust converter.

If the surface for painting PS-160 was previously painted with paints of any type, they are removed. No prior priming is required; painting of the steel surface is carried out no later than 6 hours after it has been cleaned from rust: humid air will very quickly cause its reappearance.

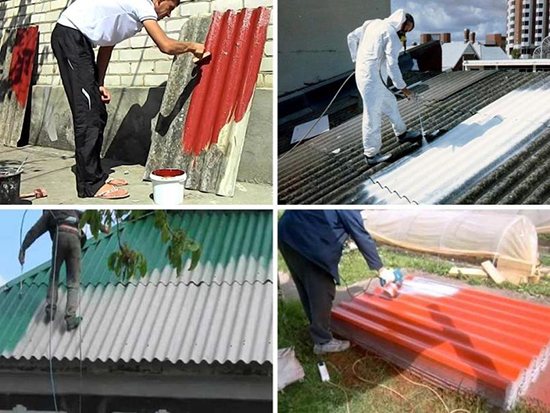

Application

PS-160 is recommended to be applied in at least two layers using a brush, roller or spray. When using spray guns, hoses resistant to organic solvents are used. Painting is carried out at an air temperature and a painted surface not lower than -5 degrees and atmospheric humidity not higher than 70%.

In the photo - painting the metal structure with a spray gun.

It is not recommended to paint in hot sunny weather and with a rapid drop in temperature, which makes possible dew loss. In the first case, uneven drying can cause partial delamination of the coating; in the second, dew can interfere with reliable adhesion of the paint to the surface.