Features of the use of various grades of polymer concrete

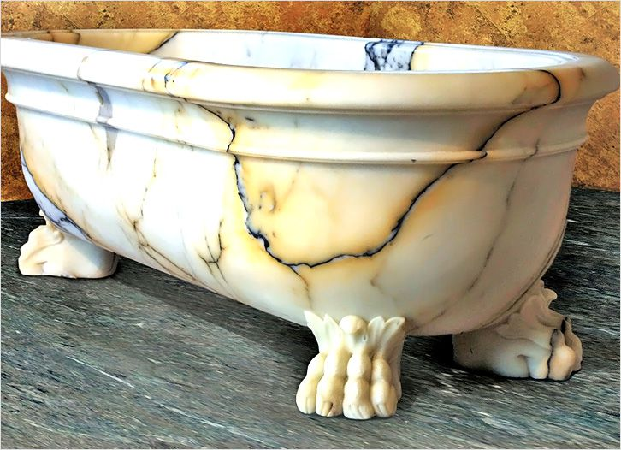

Most people will be surprised to find out how many household items are polymer concrete in their composition. For example, from polyester resin and filler from finely ground natural stone - gabro, basalt, marble, calcite, artificial stones, sculptures, decorative elements and facing tiles are made for finishing like a stone. Countertops and window sills are cast from an inexpensive polymer concrete, the cost of a similar product made of natural marble or granite will cost 2-3 times more.

Elements of communications are made of epoxy polymer concrete - pipes, tanks, wells, gutters and even whole collectors. With the help of polymer cement casting, it is quite easy to repair concrete supporting structures, seal up the screed and restore the tightness of the container. Polymer concretes, which include epoxy resin, have extremely high adhesion, so they are often used to repair holes and joints in concrete panels in high-rise buildings.

From methacrylate filled with ground glass powder and marble dust, it is possible to obtain such a high-quality imitation of natural stone that such a material was borrowed and used for work by professional restorers. Large granules of marble or calcite can be added to the composition. All polymer plasters, putties, tile adhesives, groutings are made on the basis of polymer concrete, that is, almost all materials for decorative finishing of houses.

Separately, it is necessary to remember about self-leveling floors. In this case, instead of glass filler, quartz sand crushed into dust is used. The most expensive grades, which include modified compulsory curing methacrylate, after curing, give an ideally smooth surface, superior in strength to cement screed.

How to make the simplest polymer concrete at home

In order to prepare polymer concrete with your own hands, you will need two components, resin and filler. For the simplest version of polymer concrete, you can use epoxy glue or resin, hardener and filler. It is best to use cement, washed and dried river sand or granite dust in the composition of the material, which can be found in any workshop for the manufacture of monuments.

The resin is diluted with acetone or alcohol-acetone mixture. Different brands of epoxy resin require their own brand of solvent, so a thinner must be selected to prepare polymer concrete. Add a hardener to the resin, stir and add a diluent to the composition. After 10 minutes, a filler can be added to the adhesive mass in small portions. After another 3-10 minutes of mixing, the polymer concrete will be ready for use.

§ 70. Use of polymers in concrete and mortars

Cement concretes - the main building material - are not without drawbacks. In particular, the porosity of concrete makes it insufficiently frost and corrosion resistant and permeable to liquids. Cement concretes are quickly destroyed by acids. In some cases, concrete cannot be used due to its fragility and low wear resistance, in addition, fresh concrete does not adhere well to the surface of old concrete. These disadvantages do not have concretes, in which the mineral binder is partially or completely replaced by polymers: polymer-cement materials, concrete polymers and polymer concretes.

Polymer cement materials obtained by adding the polymer directly to the concrete or mortar mixture.As a polymer additive, water-soluble resins, aqueous dispersions of polymers and liquid water-insoluble thermosetting oligomers (resins) are used; the latter are introduced into the concrete mixture using emulsifiers. The amount of polymer additive is from 1 to 30% by weight of cement, depending on the type of polymer and the purpose of modifying concrete or mortar. The most widespread are polymer-cement mortars and concretes with the addition of aqueous dispersions of polymers (for example, polyvinyl acetate and acrylic dispersions, synthetic rubber latexes). Polymer additives are also used to modify gypsum materials.

Polymer-cement mortars and concretes are distinguished by high adhesion to most building materials, low permeability to liquids, high wear resistance and impact resistance.

Polymer-cement materials are used to cover the floors of industrial buildings, runways of airfields, for exterior finishing on brick and concrete surfaces, and for arranging reservoirs for water and oil products.

Recently, polymer-cement mortars have begun to be used for laying walls of buildings in seismic regions; here the good adhesion properties and high deformability of such solutions are used.

Concrete polymer is concrete impregnated after hardening with monomers or liquid oligomers, which, after appropriate processing, turn into solid polymers that fill the pores of the concrete. As a result, the concrete strength (Rsqueeze = 80 ... 120 MPa) and its frost resistance. Concrete polymers are practically waterproof. To obtain a concrete polymer, styrene and methyl methacrylate are mainly used, which polymerize in concrete to form polystyrene and polymethyl methacrylate, respectively.

A significant drawback of concrete polymer is a significant complication of concrete technology: the hardened concrete product must be dried before impregnation, impregnated under vacuum. In addition, working with monomers requires careful adherence to safety precautions.

Polymer concrete - a kind of concrete, in which thermosetting polymers are used instead of a mineral binder: epoxy, polyester, phenol-formaldehyde. Polymer concrete is obtained by mixing a polymer binder and aggregates. The binder consists of a liquid oligomer, a hardener and a finely ground mineral filler, which reduces polymer consumption and improves the properties of polymer concrete. Polymer concrete hardens at normal temperature for 12 ... 24 hours, and even faster when heated.

The main property of polymer concrete is its high chemical resistance in both acidic and alkaline environments. In addition, polymer concretes have high strength (Rsqueeze = 60 ... 100 MPa, Rexile = 20 ... 40 MPa), density, wear resistance and excellent adhesion to other materials. Along with this, polymer concretes are characterized by increased deformability and low heat resistance.

Although the cost of polymer concrete is much higher than the cost of conventional concretes, its use is economically justified for obtaining protective coatings and entire structures operating in conditions of chemical aggression (chemical and food factories), and for repairing stone and concrete structures (for example, surface restoration, sealing cracks, etc.) . NS.).

Advantages of the material

The main advantage of the composite:

- Increased resistance to moisture penetration into the composite mass. Water droplets quickly evaporate from the surface of the material, I do not have time to saturate it with destructive moisture.

- Resistance to significant temperature changes, allowing polymer concrete to maintain its integrity, regardless of the duration and number of freezing cycles.

This material is one of the new types of concrete mixtures, where a polymer is used instead of silicate or cement (used during the preparation of ordinary concrete)

- Resistance of the material to aggressive substances, chemical reagents, allowing the use of polymer concrete in various areas without surface protection using special coatings.

- Possibility of restoring mechanically damaged areas of the composite array using a restoration mixture.

- Increased strength characteristics with a relatively small mass of the composite, allowing the manufacture of various products with extended operational properties.

- Lack of roughness on a perfectly smooth, absolutely non-slippery surface of the material. This property allows the artificial stone to remain clean for a long time, and, if necessary, various contaminants can be easily removed from the surface of the material.

- Expanded color range of polymer concrete imitating natural marble, malachite, granite. The created artificial stone is difficult to distinguish from the real one, which makes it possible to provide a wide range of applications for the composite.

- The possibility of secondary processing, use in the manufacture of technological waste, which significantly reduces the cost of products manufactured in a waste-free technology.

Pros: strength, light weight, impact resistance, elasticity is several times higher than that of ordinary concrete

DIY polymer concrete manufacturing technology

You can make polymer concrete with your own hands at home. The main thing here is to have all the necessary components and correctly calculate their volume. The work algorithm is simple: first you need to separately mix the resins and fillers, and then pour into the formwork or mold.

The main stages of polymer concrete production:

- Thorough preparation of all components.

- Gentle mixing of the solution according to technology.

- Filling with a liquid mixture.

How to prepare ingredients

First you need to rinse the filler (gravel or crushed stone), thoroughly clean it from dirt. The sand is sieved, any impurities are completely removed. Then everything is dried until a moisture content of 0.5-1% is reached. The moisture content of crushed stone above 1% is unacceptable, as it can significantly reduce the strength of the finished solution.

Preparation of the mixture

The components are loaded into the mixing container in the correct order: crushed stone, sand, filler. They work with the binder separately: they soften it to a certain consistency by heating or using a solvent. A stabilizer, plasticizer and other substances are added to the resin as needed. Everything is mixed separately from the fillers.

Next, mix the binder and filler for 2 minutes, add a hardener to the composition, stir for another 3 minutes and polymer concrete can be used. The resulting mixture can be immediately poured into the formwork or mold, it sets quickly enough, so you need to cook only one pour at a time.

Fill

Before pouring, it is advisable to lubricate the surface of the mold with petroleum jelly or oil to avoid the risk of sticking. The container is filled with composite and then leveled. It is advisable to fill the mold with polymer concrete without air cavities, compact on a vibrating table for at least 2-3 minutes. When a liquid fraction appears on the surface, one can judge the readiness of the material to solidify.

The concrete mixer must be cleaned from the remnants of polymer concrete quickly, until the solution has frozen. The mold can be removed from the finished product in a day. If the layout of the finished mixture is performed several times, it is imperative that each stage is compacted.

Polymer concrete is a high-quality, strong and durable material, which in many respects surpasses the usual cement mixture in characteristics. This leads to the widespread use of polymer concrete in repair, construction, decoration, production of various products.

Casting stone production methods

The process of making concrete polymer can be continuous or batch.

Continuous production

In this case, we are talking about a large-scale production, for which it will be necessary to purchase the appropriate equipment:

- Vibrating table.

- Stirrer.

- Compressor system with a pistol.

- Silicone matrices.

- Extractor hood.

- Grinding and polishing machines.

To purchase everything you need, you will have to spend about 250,000 rubles. Even if you take into account that you will make some of the equipment on your own, the most expensive tools will have to be purchased. Therefore, we will not dwell on this production method and consider a more accessible technology.

Making polymer cement at home

Knowing what polymer concrete is, it becomes obvious why this material is most often used for the production of countertops and decorative elements for a suburban area. Fortunately, you do not need specialized equipment for its "home" production.

To make polymer cement with your own hands:

- Rinse and clean the aggregate. Then dry it until the moisture content of crushed stone or gravel is 0.5-1%. If you use a wet aggregate, the strength of the finished product will decrease.

- Sift the sand and remove impurities from it.

- Pour crushed stone into the concrete mixer first, then sand and aggregate and mix the components for 2 minutes.

- Add water and stir again.

- Soften the binder (resin) with a solvent or simply by heating the solid mass.

- Add plasticizer, stabilizers and other components to the resin. Mix them separately from the aggregate for 2 minutes.

- Add hardener.

- Stir all ingredients for at least 3 minutes until you get a creamy mixture.

- Pour the resulting mixture into a paraffin waxed matrix or prepared formwork. Try to fill immediately the volume of the composition that completely fills the form. Polymer concrete sets very quickly, so you need to act quickly.

- Smooth the surface and compact the mixture on a vibrating table.

- Wait a day and remove the finished product from the matrix.

On this, the production of polymer concrete can be considered finished.

What it is?

Polymer concrete is a relatively new building material that is actively gaining popularity among users. This is primarily due to the large number of positive characteristics that are characteristic of it. The composition of the material (in addition to traditional and familiar sand and crushed stone) includes many additional components that provide such quality properties of polymer concrete as strength, high performance characteristics, decorative effect and many others.

Let's consider in more detail the main advantages of the material.

Stability. Polymer concrete has increased resistance characteristics in relation to various negative environmental influences, for example, excessive moisture, unstable air temperature, chemical aggressive substances, and so on. So, due to the physical and chemical properties of the material, excess water quickly and easily evaporates from its surface. Due to its resistance to unstable temperature conditions, polymer concrete does not crack even after several freezing cycles.

Possibility of quick and easy recovery. In this regard, we mean the fact that even in the case of mechanical damage, polymer concrete can be quickly and easily restored and, if necessary, corrected its shape. This procedure is performed using a specially designed restoration mixture.

Strength. Polymer concrete has high strength characteristics. Accordingly, all products that are made from this material have extended performance properties.

Smooth surface.It should be borne in mind, despite the smooth surface (which does not have any roughness, defects and other shortcomings), it is not slippery. In this regard, polymer concrete can be quickly and easily cleaned from any contamination.

Variety of colors. Depending on your preferences and needs, you can choose polymer concrete that resembles marble, granite, malachite and so on in appearance. At the same time, it is rather difficult to distinguish polymer concrete from real stone. Due to this characteristic of the material, it can be used for a variety of purposes. And also polymer concrete will perfectly fit into almost any interior.

Recyclable. Thus, polymer concrete residues do not pollute the environment. This is primarily due to the fact that the production of the material is waste-free.

At the same time, it should be borne in mind that even despite the presence of such a large number of advantages, polymer concrete is not an ideal material, it also has a number of disadvantages. So, the disadvantages include the following:

- highly flammable;

- relatively high cost (compared to conventional concrete).

The advantages of the material significantly exceed its disadvantages.

Additional elements

It should be noted that all the characteristics of the polymer-cement mortar can be lost if, during the addition of the polymer dispersion, a process such as coagulation or curdling of the mortar occurs. Most often, to avoid such negative consequences, various stabilizers are used. Surfactants (surfactants) - OP-7 or OP-Yu are usually chosen as them. It is also possible to replace them with a small group of electrolytes, for example, liquid glass. Without the addition of a stabilizer, only a polymer-cement solution, which was mixed on the basis of a plasticized PVA dispersion, can do.

However, the introduction of surfactants does not go unnoticed. Most often, these substances act as powerful foaming agents, and they are also able to draw air into the mortar mixture. If this happens, then the smallest air bubbles that have been entrained can amount to 30% of the total mass of the solution.

Types of polymer systems

The term polymer concrete means a wide group of building mixtures, differing in composition and production methods.

Group of plastoconcrete

Plastoconcrete is a mixture based on artificial resins. Cement is not used in its manufacture.

Plast concrete is used in the production of finishing materials.

Plast concrete is used in the production of finishing materials.

There are 2 types of material:

- Filled. The amount of the binder is 20-50%. Resin fills the space between filler and aggregate.

- Wireframe. Has a porous structure. The polymer is used to bond the core of the core. The volume of the binder in the mixture does not exceed 6%.

Material properties are determined by the type of added fillers, polymers, auxiliary additives. Furfural acetone mixtures cannot be used for finishing the premises. Epoxy and methacrylate compounds are safe for humans and animals.

Compared to classic concrete, plastic concrete has higher moisture resistance, frost resistance and elasticity. The disadvantage is fast wear.

Polymer cement systems

These materials include cement.

Polymer cement floors.

Polymer cement floors.

A mixture is obtained in 3 ways:

- Mixing the base with aqueous solutions of polymers - polyvinyl acetate or synthetic rubber.

- Introduction of a dispersion of polymers or monomers. The most commonly used furan alcohol and epoxy resins.

- ... Polymeric components, such as urea or styrene, are introduced to the required depth.

The recommended volume of the binder is 15-20%. This allows you to maintain the structure of the cement composition. With an increase in the polymer content, the products lose their strength.Sand or fine crushed stone is used as a filler. Polymer-cement mixtures are used to create wear-resistant floor coverings.

Concrete-polymer compositions

Concrete polymer is a hardened cement mixture, on the surface of which a liquid impregnation is applied. The composition of the material includes metal acrylate resins and catalysts, which solidify in the structure of the mineral framework.

Such defects reduce strength and resistance to aggressive substances. Filling the pores with polymer helps to improve the performance of the formulation.

Column made of polymer concrete.

Geo-concrete

In construction, materials are increasingly beginning to be used, in the production of which natural components are used. Geopolymer concrete is similar to classic concrete, but the performance characteristics are somewhat different. The structure resembles that of natural stone.

Low cost makes the material in demand among individual developers. Geo-concrete is used for the construction of multi-storey buildings and the creation of decorative elements.

Requirements for reinforcing plastics

It is recommended to use polyolefin grades (polyethylene, polypropylene) as a reinforcing component. They successfully combine strength and flexibility, which allows them not to break when exposed to stress.

Polyolefins are frost-resistant, which will allow the reinforcing additive to withstand weathering and even work at low temperatures.

Therefore, a high-quality and correct reinforcing material can be obtained by extrusion and cutting of the corresponding polymer on a chipper.

This technology is more costly and laborious, but the reinforcing plastic obtained in this way can be used even in industrial construction.

If the task is not to get a concrete mixture for fundamental building, then you can use plastic crushed into a fine fraction.

For even distribution of the polymer over the matrix, it is better to pre-treat it with a lubricant.

These are silicone compounds, for example, a water repellent or a silane-based primer. They cover the crushed with a thin layer, preventing clumping.

Concrete blocks in construction and their functions

The installation of walls made of modern concrete blocks is quite convenient due to the size of the blocks; moreover, modern technologies for creating slabs and blocks significantly improve their quality and period of operation. If polymer concrete blocks are used for interior work more often, then in outdoor construction, walls are laid from expanded clay concrete blocks. These are also high-quality blocks that retain heat better than ordinary concrete, are convenient in construction and operation. Expanded clay concrete wall can be insulated both inside and outside. If this is a living space, it can be insulated at the request of the owner, and if it is a utility room, interior decoration or plaster without insulation is sufficient. Installation of concrete walls involves the use of cement mortar for masonry. If decorative finishes are being installed indoors, use glue, silicone or cement mortar.

Having a concrete surface of the walls in the house, you need to know how to properly install and install technical elements in the walls: sockets, plinth, cornice, etc.

Technical composition of the solution

Polymer cement mortar for concrete consists of certain compositions suitable for decorative finishing. They include:

- Mineral astringent product;

- High calcium ash;

- Portland cement;

- Low-fired clay;

- Placeholders;

- Latex;

- Water.

When choosing other manufacturers, the composition may vary slightly. Compared with conventional cement mortar, such mixtures have a fine pore structure, increased elasticity, bending resistance and adhesion.If the addition of polymers to the cement is observed correctly, then the mixture is saturated with properties for less shrinkage.

Most polymer additives have an air entraining function. Therefore, when mixing such a solution, oxygen penetrates into the composition and the polymer-cement solution is saturated with air, becoming more porous than conventional cement mixtures.

Penetrating into the pores of the composition, polymer additives narrow them, because of this, a fine-grained structure is achieved. The polymer has a strong binding agent, it combines the filler and cement, while hardening the future stone.

Spheres of application of polymer concrete

Polymer concrete is used today in a variety of areas - both for basic building tasks and structures, and for the production of certain items. The material is used to make kitchen countertops, bathrooms, sinks, fireplaces, window sills, balusters, railings, sinks, steps, columns, vases, floors, monuments, fences, facade moldings, fountains, etc.

Kitchen countertops

Polymer concrete countertops look very stylish, expensive, and can be of any color and texture. At the same time, such products are quite inexpensive (in comparison with natural stone, which they can imitate, for example), practical, wear-resistant, durable.

There is a huge selection of options on the market, among which it will not be difficult to choose the one suitable for the decor of the room. The worktops are comfortable in use: pleasant to the touch, easy to clean, do not require special care.

Visually, such a tabletop is practically no different from natural stone, but in terms of characteristics and resistance to aggressive influences, it is much superior.

Floors

Polymer concrete floors are created quickly and easily - they are poured in the same way as ordinary concrete floors, quickly and easily. But such floors are already ready for use, as they are smooth, even, do not generate dust, and are easy to clean. The coating is not afraid of high loads, is plastic, its minimum warranty period is 10 years, provided that the coating is 2 millimeters thick. The thicker the layer, the stronger and more durable it will be.

Polymer concrete floors look very nice and stylish, they can be of different colors and textures. Often they are made not only in residential premises, but also in industrial workshops, warehouses, hangars, garages, airports.

Facade decor

Compared to natural stone, the advantages of polymer concrete in the creation of facade structures are significant. Externally, the material imitates any texture - be it granite or marble, but at the same time its weight is much less, which makes the cladding simple and quick, without the need for the formation of a serious foundation and auxiliary fortifications.

Polymer concrete easily withstands frost and precipitation, is easy to install, has a large color palette and original texture, durability and reasonable cost. Columns, bas-reliefs, pilasters, cornices and other elements of facade decoration are made of the material. Finished products are obtained with clear shapes, strong and reliable, easily attached to the surface of the facade.

Monuments

Monuments made of polymer concrete are as strong and durable as marble or granite. Polymeric concrete is good because it better tolerates negative influences - precipitation, frost, snow, without being covered with cracks and other damage. The shiny and smooth surface makes the product aesthetically pleasing and provides maximum definition of the pattern.

Advantages and disadvantages

Unlike grades M200, M300 and others, concrete M500 demonstrates very high strength, durability, resistance to various environments and influences. But the cost of the material is also high, therefore, before using it in construction, it is necessary to carefully study all the properties and determine the feasibility of preparing the solution.

The main advantages of concrete M500:

- High compressive strength, different types of mechanical stress - damage to the material can only be done with a special tool with diamond coating

- A high hardening rate is not a quick-drying cement, of course, but the mixture still sets quickly, even in conditions of high humidity

- Excellent indicators of resistance to moisture - due to the fact that the composition uses fine sand, which does not give a chance for water to enter the pores of the monolith: thanks to this, the structure can be operated even under water

- The composition of M500 concrete guarantees its resistance to strong winds, ultraviolet radiation, atmospheric precipitation, etc.

- Long service life - structures and objects made of material are not subject to independent deformations at all

Of the shortcomings, it is worth noting, first of all, that the M500 is very expensive and its increased characteristics are not relevant in everyday life, since they remain unclaimed. And the preparation of the solution will require considerable costs and efforts. In Moscow and the region, other regions, you can purchase a dry mixture (there is only no crushed stone in it), but special equipment is required for kneading.

Composition of polymer concrete

The composition of the building mixture includes the following components:

- Coarse filler. Broken glass, crushed stone, sand are used as this element.

- Fine-grained filler. The introduction of such a component reduces the cost of the product. The filler is graphite or quartz.

- Connecting link. A polymer resin is introduced into the mixture, for example, polyester, furan, urea-formaldehyde or epoxy. Polymer concrete contains 5% binder.

- Additional additives. These include substances that increase elasticity and frost resistance, giving the composition the desired color.

Composition

One of the most important components of polymer concrete is fly ash. This substance is a product of coal combustion. The use of ash as an additive has a filling effect on the fresh concrete mix. The filling effect is based on the ability of the smallest coal particles to fill all voids and porous formations. The smaller the ash particles are, the more fully this effect is observed. Thanks to this feature of fly ash, the cured concrete becomes much stronger and stronger than usual.

Another important component of the concrete mix is water glass. It has excellent adhesion and low cost. Its addition to polymer concrete will be very useful if the finished structure will be outdoors or exposed to constant exposure to water.

The technical characteristics of polymeric concrete are higher than those of other standard concrete and, moreover, it is environmentally friendly - it can be used in the construction of buildings in the food industry. The averages are as follows:

- linear shrinkage 0.2-1.5%;

- porosity - 1-2%;

- compressive strength - 20-100 MPa;

- heat resistance - 100-180С;

- creep measure - 0.3-0.5 kg / cm2;

- aging resistance - 4-6 points.

This type of mixture is used as a structural and decorative finishing material.