Variety of assortment

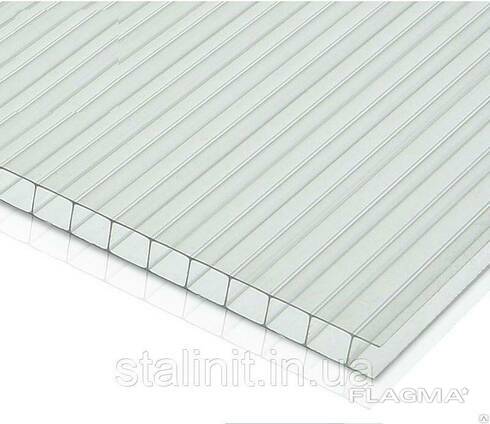

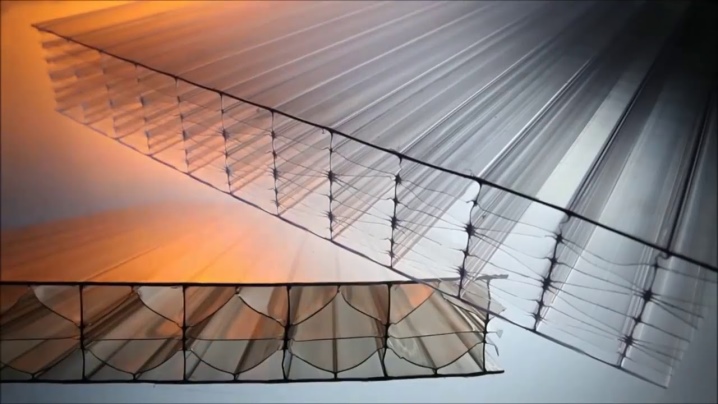

Cellular

It is worth starting the review with cellular polycarbonate, which is more applicable in a domestic environment. The main advantages of the material are low specific gravity, as well as high strength, which makes these products very convenient to use.

Transparency (82% light transmittance) is very important for greenhouses, as the plants need to get enough solar radiation. It is worth noting the wide temperature range, when working in which you will not have any problems with the material. The lower mark from -40 and the upper to +120 degrees will allow you to use this polycarbonate even at elevated temperatures, which significantly expands the scope.

Considering that it is a chemical polymer, it is quite environmentally friendly, fire resistant and flexible due to its structure, so the main physical damage is not terrible for a material with similar characteristics.

Further, it is worth considering certain types of this material.

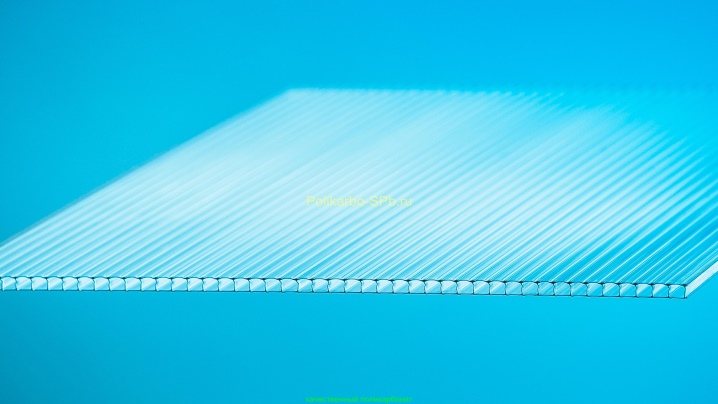

"Standard" is the basic model that became known all over the world. Strength, lightness, accessibility, versatility - all this applies to this polycarbonate. Allowing you to create high-quality and reliable structures, this option is most applicable in construction, where the material does not require specific or additional properties.

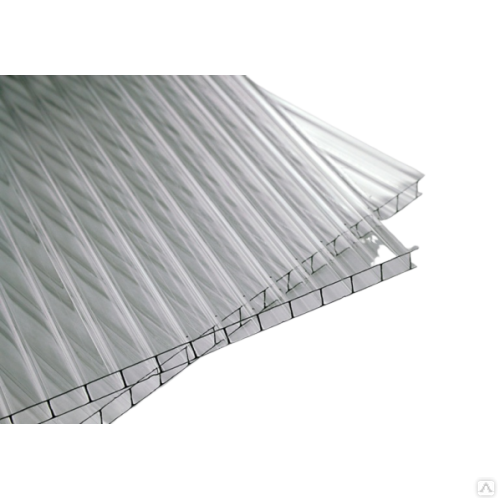

Monolithic

Now it is necessary to say about monolithic polycarbonate, which has its own characteristics. It is high impact resistance, 2-sided UV layer, low flammability. Excellent transparency at the level of glass, good sound insulation, low weight compared to similar chemical materials, and resistance to extreme temperatures.

The first model of this type is "Monogal", which, due to its properties, is very effective for use in places with a high level of hooliganism and vandalism. Given the strength of this product, it can last a long time even in difficult conditions. Good flexibility and high quality sound insulation make Monogal suitable for many glazing projects.

Polygal polycarbonate has a wide range of applications and is actively used in architecture, agriculture, lighting engineering, road construction, light industry and various designs.

What characteristics should you pay attention to when buying cellular polycarbonate

All the data indicated by the supplier in the passport of the goods can be divided into important for the buyer (UV resistance, light transmission, impact and chemical resistance, sheet size) and secondary (weight, distance between ribs, type of honeycomb, etc.) ... It is necessary to choose cellular polycarbonate when buying precisely according to the first technical characteristics, since they determine the performance of the material.

Pay attention first of all to these characteristics:

- UV protection. Most manufacturers cover sheets of cellular polycarbonate with a special protective layer, which ensures the safety of the material in direct sunlight. The absence of this layer means that it is impossible to use the sheet outdoors or you need to apply a protective coating yourself;

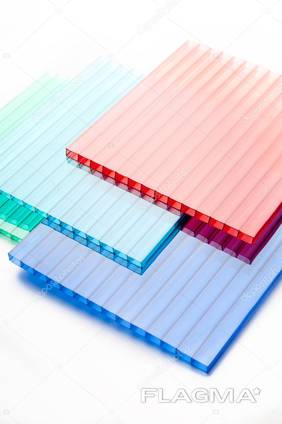

- The transparency of the sheet. It can vary depending on the thickness and structure of the material. If you plan to install cellular polycarbonate on the roof of a pavilion, transparency is not so important, but it is critical for a greenhouse. The average indicator required for plant growth is at least 80%. It can be provided by a colorless sheet of medium thickness without a matte finish.Colored sheets are not suitable for greenhouses. Due to toning, the light transmission parameter can drop to 40, or even up to 20%;

- Resistance to aggressive influences. All polycarbonate is highly chemical resistant. It is not affected by boric acid, oil, sulfuric acid, formalin, ethyl alcohol, etc. Also, most sheets do not break or deteriorate from shock;

- Sheet size. Most often it is determined by other characteristics (for example, panel thickness), but sometimes the cellular polycarbonate manufacturer offers a choice. In general, be guided by the fact that it is easier to cover a large space with large sheets.

In addition to the actual characteristics of a sheet of cellular polycarbonate, some experts also highlight the energy saving parameter. It is determined in comparison with the cost of heating or cooling the room (depending on the season) when using other materials (glass, fiberglass, acrylic panels). The average savings rate is 40% or more. In some cases, it reaches 50%.

Performance properties

Real customer reviews:

What do we know about Israeli Polygal? With all the declared characteristics identical with the Russian Polygal, they still have operational differences:

- Israeli Polygal is denser (than Russian) and does not give any deviations during installation (installers will understand).

- The Russian Polygal does not withstand such rigidity as the Israeli one.

- In 2013, the Odessa hurricane tested the strength of the Israeli Polygal. Qualitatively mounted ceilings made of this material withstood hurricane winds, heavy rain and hail without any problems. In the worst case, the owners of the torn off floors had only to pick up intact Polygal sheets and attach them back to their rightful place.

- Israeli Polygal is the only polycarbonate presented in Ukraine that can boast real examples of compliance with the warranty and operation (Polygal (Israel) has been operating since 1976; Polygal Vostok - since 2006; Soton - since the end of 2010):

| Characteristic | Polygal | Polygal East | Soton |

| Manufacturer | Polygal, Israel | Polygal, Russia | Tagol, Ukraine |

| Thickness | 4-32 | 4-16 | 4-20 |

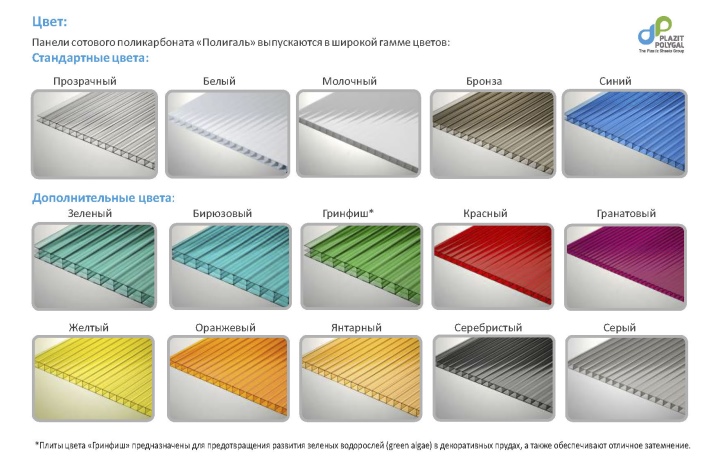

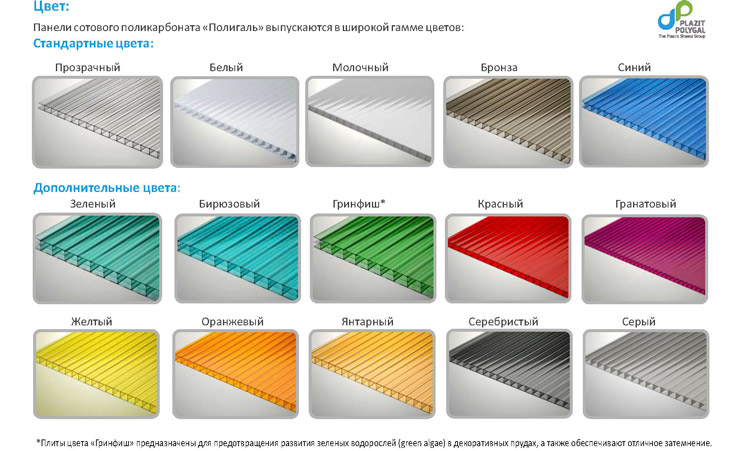

| Colors | Transparent,

bronze, turquoise, blue, yellow, green, Red, ice, opal, Gray |

Transparent,

opal (snow), bronze, blue, green, turquoise, Red, yellow, Orange, silver, pomegranate, amber |

Transparent,

White, lactic, bronze, turquoise, blue, green, Red, Garnet, yellow, Orange, silver, Gray |

| Warranty, years | 10 years | 10 years | 10 years |

| Special species | Polyshade (gray and green), Primalite, Silhouette Gold, Termogal transparent, Titan Sky (bronze, transparent, blue), Titan light blue, Polygal transparent with antifog | Titan Sky (bronze, transparent, blue, green, ice) | Reinforced Titan Solidprof (clear, bronze, blue, silver) |

|

The weight

4 mm 6 mm 8 mm 10 mm 16 mm |

0,8 1,3 1,5 1,7 2,7 |

0,8 1,3 1,5 1,7 2,5 |

0,8 1,3 1,5 1,7 2,7 |

| UV protection | 50 | 50 | 40 |

| Plant history | Since 1976 | Since 2006 | Since 2010 |

| Original profiling systems | + | – | + |

Advantages and disadvantages

Polygal has the following advantages:

- Durability. It is one of the most durable types of polycarbonate. With proper installation and maintenance, it can last from 15 to 23 years, while the sheets of some other brands lose their performance after 3-4 years. The manufacturer gives a 10-year warranty.

- Reliable UV protection. Many manufacturers add a UV stabilizing agent to the material itself. However, with an excessive amount of it, the sheet loses its flexibility, moreover, such protection is insufficient and can be uneven. In "Polygal" the sheet contains a moderate amount of stabilizing granules, while its surface is additionally covered with a protective film. This provides a high level of UV resistance and at the same time allows the sheet to remain flexible.

- Good performance. The honeycomb type allows you to save up to 50% of heat.The performance of impact resistance and flexibility is higher than that of many other brands.

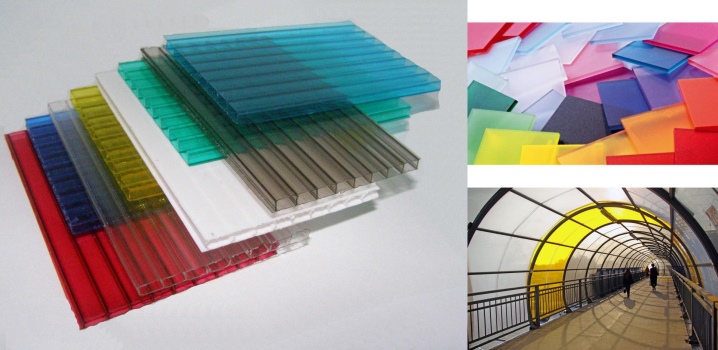

- External appeal. Polygal's sheets have a particularly smooth, beautiful surface. With a wide range of colors, you can find the perfect shade for your garden or home.

Good to know: How to remove the film from polycarbonate correctly.

"Polygal" has no specific drawbacks, they all relate to polycarbonate in general. Among them:

- poor resistance to a number of chemicals, including mineral and organic acids, salt solutions, ammonia, solvents, and some types of adhesives;

- poor resistance to abrasive substances and scratches.

The quality of this material allows it to be successfully used for the construction of greenhouses, polycarbonate fences, gazebos, facade walls and many other objects.

Specifications

The table below shows sheet thicknesses for different types:

|

Type of |

View |

Thickness, mm |

|

Monolithic |

"Standard" |

3, 4, 5, 6, 8, 10, 12, 15 |

|

"Premium" |

2, 3, 4, 5, 6, 8, 10, 12, 15 |

|

|

Cellular |

"Standard" double-walled |

4, 6, 8, 10 |

|

"Standard" three-walled |

16 |

|

|

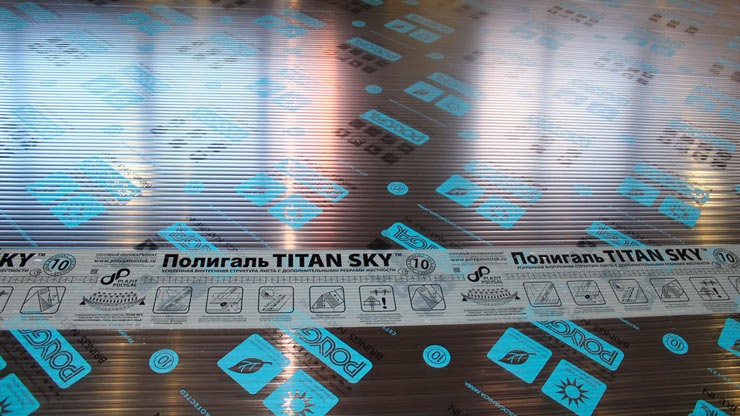

Titan sky |

10, 16 |

|

|

Selectogal |

16 |

|

|

Thermogal |

25, 32 |

Consider the performance characteristics of this material:

- The light transmittance of the monolithic type is up to 92%, of the cellular type - from 50 to 80%.

- Impact strength meets all required standards and depends on the thickness of the sheet. For example, a 6 mm panel can withstand shock loads of up to 2.10 J. Tests using the Gardner method have shown high resistance to falling objects, including hail.

- Temperature resistance standard: -40 to +120 ° C.

- Sound absorption depends on the thickness of the sheet and is 18 to 23 dB.

- The material is classified as hardly flammable and moderately flammable. Does not spread fire. Smoke-generating ability is moderate. Combustion products are moderately hazardous.

- The bending radius of the honeycomb type is from 70 to 437 cm, depending on the type and thickness of the sheet.

Read more: Safe bending radius of polycarbonate.

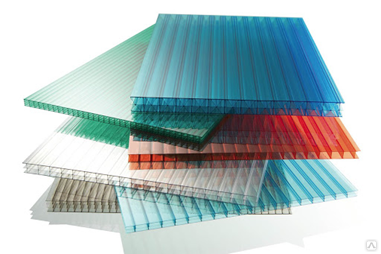

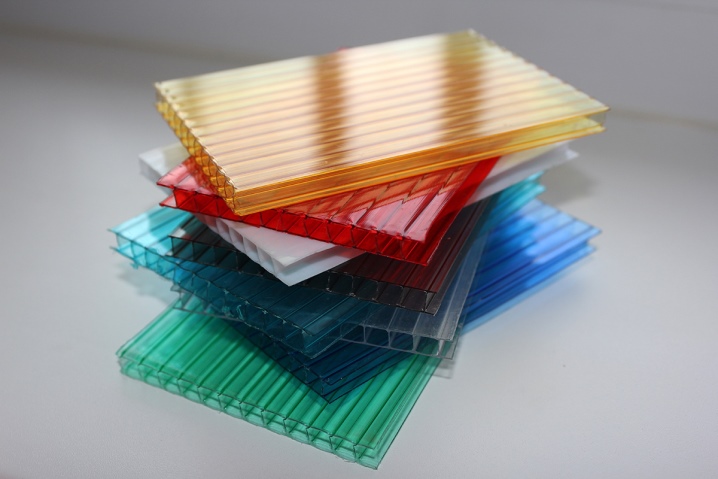

Both monolithic and honeycomb types can be made in different colors. The most popular options are clear, gray, matt white, bronze, yellow, orange, green, blue, turquoise, red and black polycarbonate.

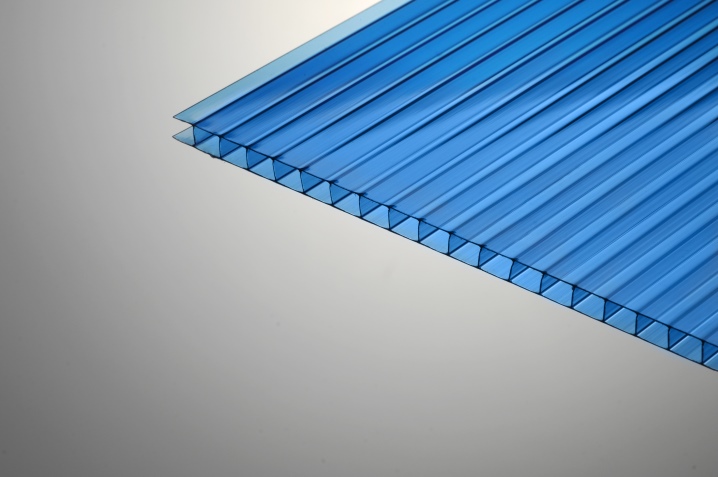

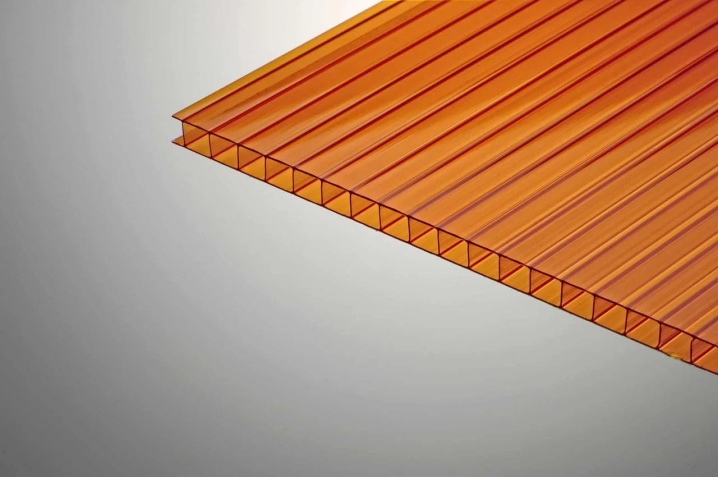

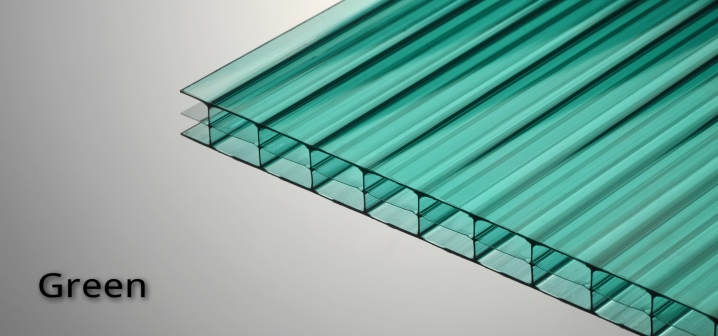

Polycarbonate Polygal is available in a wide range of colors

3 ways to visually distinguish Israeli Polygal from Russian

The abundance on the market of Polygal polycarbonate, produced by the Israeli concern, more than eloquently speaks of the popularity of this material: the highest quality standards, the most guaranteed operational reliability.

There are 3 visual signs that distinguish Polygal made in Israel from Polygal made in Russia:

1. Information on a special tape on Israeli-made Polygal sheets is provided only in Ukrainian ("Products of the company" Polygal "). On sheets produced by Polygal Vostok - in Russian

Israeli Poligal on the left, Russian Poligal on the right

2. On the computer marking indicating the extruder number, date and time of production of a given batch of plates, the manufacturer of Israeli material is designated exclusively as "Polygal", Russian - "Polygal Vostok"

Israeli Poligal on the left, Russian Poligal on the right.

3 The language of information on a blue-and-white sticker on Israeli polycarbonate is English, Russian - Russian

Israeli Poligal on the left, Russian Poligal on the right.

Review overview

Before purchasing a product from any manufacturer, it is necessary to study the reviews of real buyers who used the material for its intended purpose and can draw a conclusion about its main properties declared by the supplier.

Among the advantages of Polygal polycarbonate, people note the high quality of products, which is achieved through high-tech production. In addition, the versatility of standard polycarbonate models is mentioned. A wide range of applications is considered the main advantage of the product, according to consumers.

Users believe that another positive side is good feedback, which is achieved due to the presence of 11 branches throughout Russia, located most optimally in different regions. You can choose a distributor based on your location, which is very convenient, say large buyers.

Of the shortcomings, it can be noted, perhaps, not the lowest price on the polycarbonate market in Russia. Some consumers argue that such material can be purchased much cheaper without losing quality.

For more detailed information on Polygal cellular polycarbonate, see the next video.

Classification

Polygal is produced in both monolithic and honeycomb forms.

The monolithic form is divided into classes "Standard" and "Premium".

Polygal carbonate is produced according to Israeli technology and is considered the best in the domestic market.

Cellular is divided into the following types:

- "Standard". It can be two- and three-walled.

- Titan Sky. The variety is reinforced with diagonal ribs that provide resistance to snow and wind loads. The outer walls are homogeneous, smooth, very aesthetic. Thanks to the strength of the sheet, they can cover a large area without the support of the rafters.

- Selectogal. The outer layer is complemented by prisms that enhance the light in the morning and evening hours and partially absorb it at noon. In winter, when the sun rises low, the illumination also increases. Thus, the light inside turns out to be bright, at the same time soft and uniform, not scalding. It is an excellent choice for both greenhouses and residential or commercial buildings. Due to its flexibility, this variety can be used for highly curved structures.

- Thermogal. The variety is resistant to extreme wind and snow loads. Its strength is provided by a multi-cell structure with three internal partitions and diagonal stiffening ribs. Can be used as doors.

How to store and cut?

For proper storage of polycarbonate, make sure it is not under excessive physical stress. It is best to leave the material in its original packaging, if not, then cover it with polyethylene. The stack height should not exceed 2 meters. Place the plates horizontally, watch the ends so that dirt and moisture do not get into them. The storage area must be cleared in advance, and all heating devices that may be nearby must be removed.

You can cut polycarbonate with various tools, for example, a simple grinder with a 125th circle - a quick and time-tested method. You can also use a thick stationery knife, jigsaw, metal hacksaw, or even a laser

It is important that the process itself is the most correct, for which it is worth making smooth movements, thereby preserving the structure of the material and making even cutting. It is also worth saying that everything that can be used to cut metal is suitable for cutting, if you do not have from the example tools