Properties

In order to familiarize yourself with the material in more detail, you should analyze its distinctive characteristics (including physical and chemical). After all, polyethylene has special properties that distinguish it from any other compound.

So, the main features of the material include:

- as a general rule, polyethylene is transparent (this applies only to a pure chemical compound, devoid of any impurities), during the dyeing process, the material can acquire any other shades (black, white, red and many others);

- the material is solid in structure;

- the crystallization process of the material is carried out at a temperature from -60 to -369 degrees Celsius;

- lack of smell;

- small indicators of mass;

- the density of the material is unstable, it depends on how the polyethylene was obtained;

- chemical compounds have the properties of a shock absorber;

- low level of adhesion;

- low coefficient of friction;

- waterproofness;

- polyethylene undergoes softening processes at temperatures from +80 to +120 degrees Celsius;

- resistance to low temperatures;

- flexibility;

- dielectric characteristics;

- steam and waterproofing;

- biological inertness;

- thermal conductivity;

- during decomposition, polyethylene does not emit substances that are harmful to humans;

- resistance to aggressive chemical compounds.

The properties of polyethylene for the most part determine the areas of its use.

Polypropylene: chemical properties, advantages, disadvantages

| Name | Indicators |

|

Density of polypropylene |

0.90-0.92 (g / cm3) |

|

Thermal conductivity of polypropylene |

0.00033 cal / sec (cm × deg) |

|

Shelf life of polypropylene |

3 years |

|

Specific gravity of polypropylene |

0.91 (g / cm3) |

|

Polymerization degree of polypropylene |

Depends on the molecular weight of the substance |

| Average relative molecular weight of polypropylene |

(75-300)•103 |

|

Specific heat of polypropylene |

0.40-0.50 (cal / (g ° C)) |

|

Polypropylene melt flow rate |

≤0-15-25 (g / 10 min) |

| Coefficient of friction of polypropylene |

0.30-0.40 (µ) (for metal) |

|

Net calorific value of polypropylene |

43.0 MJ / kg |

|

Heat of combustion of polypropylene |

46.5 MJ / kg |

|

Linear expansion coefficient of polypropylene |

0.15 mm / mK |

|

Dielectric constant of polypropylene |

2.2 (at 106 Hz) |

|

Frost resistance of polypropylene |

not lower than -5 (° C) |

Synthetic plastic, in addition to excellent electrical insulating properties, has such advantages as:

- high strength;

- elasticity;

- wear resistance;

- vapor tightness (can be hot sterilized);

- low moisture absorption;

- non-toxicity;

- transparency;

- ease of processing.

Polypropylene has a high chemical resistance to the action of solutions of salts, alkalis, acids, vegetable oils and other inorganic compounds. Easily crystallizes, recyclable, miscible with dyes, weldable. Products made of polymer plastic do not change their shape and performance under the influence of hot water and steam.

The disadvantages of polypropylene are low frost resistance, UV sensitivity. At elevated temperatures, it can swell in ether, benzene, carbon tetrachloride. The technical qualities of the plastic are improved by the introduction of appropriate stabilizers.

Important: when in contact with copper, synthetic material forms chips, cracks, and at low temperatures, its fragility increases.Depending on the production technology, polypropylene has different physical properties and field of application.

It is subdivided into:

Depending on the production technology, polypropylene has different physical properties and field of application. It is subdivided into:

- atactic;

- syndiotactic;

- isotactic.

Atactic - high flow polypropylene similar to rubber. It can take a liquid or waxy form due to its softness, plasticity, high melting point. Easily served with modifications, interacts with various chemicals. It is considered a by-product (waste), therefore it is most often disposed of. Due to oxidation, it has good prospects in the production of bituminous, adhesives, waterproof compounds, anti-corrosion coatings. About 2% of modern chemical producers are engaged in its processing.

Products made from oxidized atactic PP:

- construction mastics for airfields;

- polymer-mineral compositions;

- bitumen-polymer binders;

- adhesive for adhesive tapes;

- anti-corrosion primers, waterproof compounds, putties;

- multifunctional additives for diesel fuel, lubricating oils;

- compounds for rubber compounds.

Syndiotactic is a representative of polymers with high resistance to bending and wear resistance. Used in the manufacture of toys, consumer, medical products. On its basis, fiber is obtained. It requires the addition of stabilizers, is sensitive to low temperatures, and gives a slight shrinkage.

Isotactic is a dense, crystalline material with excellent mechanical properties. It is used in the manufacture of building products, as well as for cold or hot water supply as polymer pipes.

Thermoplastic finished products are manufactured using several methods:

extrusion (office supplies, packaging materials, fibers, films, pipes);

blowing out (cosmetic bottles, flasks, cans, barrels, tanks);

casting (fittings, auto parts, household products, plastic furniture);

foaming (insulating materials);

rotomolding (septic tanks, road barriers, children's playgrounds).

What is LDPE waste?

Several tons of plastic products are produced annually. We use goods and packaging made of polymers every day, these are:

- packing bags in shops and homes;

- colored bags for collecting and recycling garbage;

- soft packaging for drinks, fermented milk products;

- household containers;

- pipes;

- covering, insulating materials;

- pallet or shrink film;

- stretch film is a well-stretching packaging material that easily restores its original shape, resistant to mechanical damage.

Waste polyethylene of high density is divided into three groups:

- From primary raw materials. Polymers are transparent, do not contain impurities, intended for food packaging.

- Recycled. This is a technical color film (gray, blue, light blue) used in industry, agriculture, and other areas where there is no contact with food. Polyethylene accessories, household containers.

- Construction waste is a black dense film, pipes, plastic containers.

Where does LDPE waste come from?

Main properties and characteristics

Polyethylene terephthalate, the properties of which are not limited to light weight and plasticity, has the following characteristics:

- not affected by water. One of the main properties of the polymer, which made it possible to revolutionize the production of food containers for drinks, juices and other food products;

- the material is not affected in any way by organic solvents;

- the polymer melts at a temperature of +260 degrees Celsius. This provides ample opportunities for the use of PET in various industries;

- low production cost.

Despite the rather significant advantages, the polymer is not devoid of disadvantages, the main of which is the transmission of ultraviolet radiation and the release of carbon dioxide inside. These processes prevent the use of plastic for long-term contact with food, reducing their shelf life. On almost any plastic bottle, you can find an inscription recommending storing the product in this container in a dark place. In America and Europe, all PET containers are considered disposable and are not allowed to be reused without recycling.

It is also worth considering the fact that the polymer cannot decompose on its own in natural conditions, which poses a threat to the environment.

There are entire factories for the processing of this material, because new containers obtained by recycling do not differ in their properties from the original material, which expands the possibilities of using PET.

There are two main ways of processing:

- mechanical. Plastic is crushed on special machines, turning it into granules of the required diameter. In the future, new products will be produced from them using the thermal casting method;

- chemical. In this case, there are several options - modification of the polymer by introducing additional components to obtain other materials, obtaining a powder coating or obtaining monomers from secondary raw materials.

Production

Stitching technologies

Polyethylene crosslinking is carried out chemically or physically using one of the following technologies:

- The chemical peroxide method (PEx a) produces very high-quality, but rather expensive products. Hydrogen peroxide is used as a reagent. The process takes place at a temperature of about 200 0C. The crosslinking is the most uniform, since the amount of crosslinked molecules in the total amount will be up to 85%.

- Cross-linked polyethylene is obtained by the chemical silane method (PEx b) in the presence of silane, catalysts and water. This method is the most common, although the percentage of stitching here is only 65-70%.

- Physical radiation (PEx c). This stitching is carried out by passing the polyethylene mass through an electron accelerator, where it is exposed to X-ray or gamma radiation. In this case, free atoms enter into a reaction, but not carbon with hydrogen, but like atoms with each other, forming new bonds. The degree of crosslinking is approximately 60%.

- With chemical nitrogen (PEx d), with the help of nitrogen radicals, a crosslink quality of up to 70% is obtained. This method is rarely used, since it requires sufficient time and certain reaction conditions.

Comparison of properties by stitching type

Crosslinked polyethylene, having passed any of the mentioned crosslinking technologies, obtains an ordered network structure, similar in properties to the crystal lattice of solids. However, in each case, the resulting material has its own slight differences:

- As already noted, the most uniform crosslinking is peroxide, although less productive and more expensive,

- The peroxide method is not applicable to the manufacture of multilayer pipes,

- Finished products are obtained most quickly with the silane method,

- The simplest process and the cheapest raw materials are used in the radiation method,

- The silane method produces the most dense, but also the least flexible material.

Types of polystyrene

By mixing polystyrene with other polymers and styrene copolymers, materials with excellent heat resistance and impact resistance are obtained. Of the greatest industrial importance are block copolymers and graft copolymers, as well as random copolymers. There are three main types of industrial polystyrene: general-purpose, impact-resistant and extruded.

General purpose polystyrene

General purpose polystyrene is a transparent material that is stiff and brittle. It has the following markings: PS, PS-GP, GPPS, Crystal PS and XPS.Produced in accordance with GOST 20282-86 using the suspension and block method, intended for the manufacture of products by various methods of thermoforming.

Specifications:

- maximum operating temperature - 75 - 105 Сº;

- glass transition - 80 - 113 Сº;

- fragility limit - 60 - 70 Сº;

- density - 1.04 - 1.06 g / cm3;

- tensile modulus - 2 850 - 2 930 MPa;

- bending strength - 80 - 104 MPa;

- ultimate tensile strength - 3%.

- transparency;

- hardness;

- low moisture absorption;

- excellent dielectric performance;

- radiation resistance;

- low resistance to UV radiation.

It is mainly used for the production of household goods, food packaging and food packaging, and children's toys. It is used in lighting engineering, in the manufacture of outdoor advertising billboards, for decorative and finishing construction work.

High impact polystyrene

High-impact polystyrene is a copolymerization product of styrene with butadiene and styrene-butadiene rubber. Its properties largely depend on the volume of the rubber phase. Processing methods are injection molding at high temperatures and sheet extrusion with vacuum or pneumatic forming.

The ratio of styrene to rubber determines the performance of the plastic. The following types of high-impact polystyrene are distinguished:

- extra-impact resistant - rubber content 10 - 15%;

- high impact strength - the share of rubber is 7.5 - 9%;

- average impact strength - rubber is 3.5 - 4.5%.

Specifications:

- tensile strength - not less than 21 MPa;

- tensile modulus - not less than 1,800 MPa;

- relative elongation - not less than 45%;

- bending strength - not less than 35 MPa;

- modulus of elasticity - not less than 50 MPa;

- gloss at an angle of 60º - not less than 100.

High-impact plastic has similar values to general-purpose polystyrene in terms of heat resistance, hardness, and dielectric properties. It is used in instrument making, furniture making, household appliances, lighting fixtures, dishes and toys. The breadth of application is explained not only by its high performance properties, but also by its low price. It is currently one of the cheapest plastics.

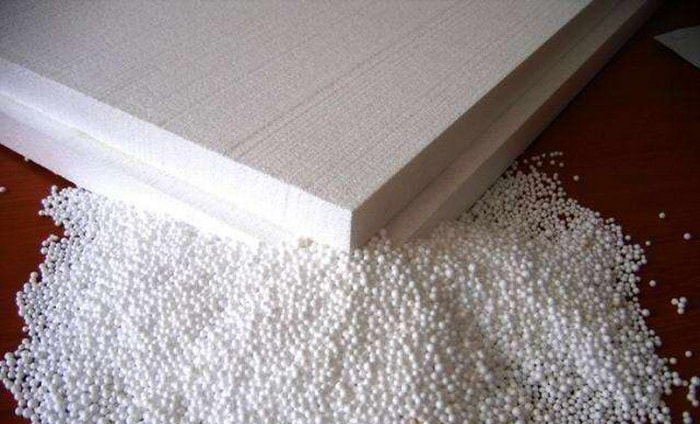

Extruded polystyrene

Extruded polystyrene is made from polymerized styrene by extrusion. Despite the fact that it was invented in the first half of the 20th century, it still has no analogues that would surpass it in terms of performance and availability. It is a versatile insulation. It is used for thermal insulation in industrial and civil construction, as well as in the production of refrigeration equipment, sound insulation of sports and ice arenas.

Specifications:

- density - 1.05 g / cm3;

- elongation - 1.3%;

- tensile strength - 45 - 55 MPa;

- transparency - 90%;

- bending strength - 75 - 80 MPa;

- modulus of elasticity - 3,200 - 3,500 MPa;

- impact strength - 14 kJ / m2;

- linear expansion coefficient - 8 × 10-5 1 / 0С °.

This versatile synthetic material has unique performance properties:

- low thermal conductivity;

- resistant to aggressive chemicals;

- high strength;

- frost resistance;

- moisture resistance;

- immunity to fungus;

- environmental friendliness;

- durability.

The material lends itself well to processing, easy to install, which is important for any construction work. It is absolutely non-toxic, which allows it to be used for both exterior and interior decoration of residential premises.

Differs in an affordable price, which varies depending on the manufacturer, size and density of the boards.

Industries of application

Unique physical and consumer properties made it possible to use the polymer in many areas of production, science and everyday life.

Polyethylene terephtolate - properties and applications:

- chemical fibers are used most massively in comparison with other polymers in the production of clothing and household appliances;

- due to thermoplasticity, the lion's share of the market for plastic containers is made of PET. First of all, it is the mass production of bottles for water and drinks;

- Due to its mechanical strength, plastic is an excellent reinforcement material. This made it possible to use the polymer as an additional reinforcement for hoses, car tires, and conveyor belts;

- transparent sheets that transmit sunlight well are widely used in agriculture or construction.

In addition, due to its dielectric properties, the material is used as electrical insulation for certain elements - capacitors, relays and coils.

The polymer in the countries of the former Soviet Union is mainly used for the manufacture of containers, in the world in the production of polyethylene terephthalate its main purpose is to obtain fibers and threads for their subsequent use in all available areas of production.

Material production technology

To obtain foamed polyethylene, processed high-pressure polyethylene is used, which is subjected to physical expansion or direct extrusion. Material production technology includes a number of stages:

- at the first stage, thermoplastic low density polyethylene granules are fed into the hopper of the injection equipment, where they are melted at a temperature exceeding the melting point of polyethylene - 115 ° C.

-after the formation of the molten mass, liquefied gas (carbon dioxide or nitrogen) is fed into the chamber. He is the very foaming agent, thanks to which the structure of the future product is formed. The creation of a gaseous medium is carried out in two ways: chemical or physical.

So, chemical gas generators are various substances that are capable of releasing gas under the influence of high temperature. Depending on the type of material used and the desired properties of the resulting polyethylene, their compounds can be very different. The use of chemical blowing agents is possible on standard equipment, while special fire safety measures are not required.

Physical gas generators are liquids with low boiling points - they release gas during evaporation. Despite the fact that from an economic point of view, the use of physical additives is more profitable, the process of obtaining foamed polyethylene becomes explosive and fire hazardous. This, in turn, requires strict adherence to precautionary measures and the use of specialized equipment.

- as a result of continuous rotation of the hopper, the polymer mass acquires a homogeneous structure, including at the molecular level. The fluidity of the melt in comparison with the initial values increases by almost 2 times, while the pour point decreases. Depending on the degree of pressure and temperature in the chamber, the size of the cells of the material changes.

- the final stage of polyethylene production involves injecting a liquid mass into an injection mold and its subsequent cooling. This avoids shrinkage and possible deformation of the finished material when removed from the mold.

Polyethylene foam is most often produced with a one-sided or double-sided coating, which is used as foil, metallized film or lavsan. Foamed polyethylene foam, which is usually used for insulation, is also called reflective insulation.

The form of production of products from foamed polyethylene can be very different - sheets, plates, films, threads, tubes, etc. The density of such products is from 5 to 800 kg / cubic meter, and the mesh size is from 0.05 to 15 mm.

As a rule, the production of foamed polyethylene is based on the use of polyethylene waste, which makes the work process cheaper and at the same time avoids serious environmental problems. Of course, recycling of secondary raw materials imposes a number of restrictions on its use. For example, if the material created as a result of primary processing can be used as packaging for various goods, then polyethylene, which has undergone several processing cycles, can only be used as a covering garden film.

Classification of polymers

There are quite a number of indicators by which synthetic polymeric materials can be classified. In this case, the classification also affects the basic performance characteristics. That is why we will consider the types of polymeric materials in more detail.

The classification is carried out according to the state of aggregation:

- Solid. Almost all people are familiar with polymers, as they are used in the manufacture of housings for household appliances and other household items. Another name for this material is plastic. In solid form, the polymer material has a fairly high strength and ductility.

- Elastic materials. The high elasticity of the structure is used in the production of rubber, foam rubber, silicone and other similar materials. Most of it is found in construction as insulation, which is also associated with basic performance.

- Liquids. A fairly large number of various liquid substances are produced on the basis of polymers, most of which are also applicable in construction. Examples include paints, varnishes, sealants, and more.

Different types of polymer materials have different performance characteristics. That is why their features should be considered. There are commercially available polymers that are in a liquid state before being combined, but after entering into a reaction they become solid.

Classification of polymers by origin:

- Artificial substances characterized by high molecular weight.

- Biopolymers, which are also called natural.

- Synthetic.

Polymeric materials of synthetic origin are more widespread, since exceptional performance is achieved by mixing a wide variety of substances. Artificial polymers are found in almost every home today.

The classification of synthetic materials is also carried out according to the characteristics of the molecular network:

- Linear.

- Branched.

- Spatial.

Polymer structure options

Classification is also carried out by the nature of the heteroatom:

- An oxygen atom can be included in the main chain. This chain structure makes it possible to obtain complex and simple polyesters and peroxides.

- IUDs, which are characterized by the presence of a sulfur atom in the main chain. Due to this structure, polythioethers are obtained.

- You can also find compounds in the main chain of which there are phosphorus atoms.

- Both oxygen and nitrogen atoms can be included in the main chain. The most common example of such a structure is polyurethanes.

- Polyamines and polyamides are bright representatives of polymeric materials that have nitrogen atoms in their main chain.

In addition, there are two large groups of polymeric materials:

- Carbochain - a variant that has the main chain of the IUD macromolecule with one carbon atom.

- Heterochain - a structure that, in addition to a carbon atom, also has atoms of other substances.

There are just a huge number of varieties of carbon chain polymers:

- High molecular weight compounds called Teflon.

- Polymer alcohols.

- Structures with rich main chains.

- Chains with saturated basic bonds, which are represented by polyethylene and polypropylene.Note that today these types of polymers are just widespread, they are used in the production of building materials and other things.

- IUDs, which are obtained on the basis of the processing of alcohols.

- Substances obtained from the processing of carboxylic acid.

- Substances obtained on the basis of nitriles.

- Materials that have been obtained on the basis of aromatic hydrocarbons. The most common representative of this group is polystyrene. It is widely used due to its high insulating qualities. Today, polystyrene is used to insulate residential and non-residential premises, vehicles and other equipment.

Polymers

All of the above information determines that there are simply a huge number of varieties of polymeric materials. This point also determines their widespread use, application in almost all industries and areas of human activity.

Corona treatment of the film after extrusion

There are special devices - corona wires, which are used to process the outer surface of film sleeves. They shower the film with corona current discharges. This procedure is necessary if the produced film will be flexo printed.

The structure of any polymer is not fibrous, so the paint will easily adhere to the film without additional processing (gluing, stimulation, etc.). But the use of corona wires is mandatory, because without them the paint will peel off the film within a few seconds. The paint, whatever it is, will turn into a drop and will calmly move along the polymer film. Corona current discharges provide a valence bond for the film and ink, and the original shape is retained for a long time.

The structure of any polymer is not fibrous, so the paint will easily adhere to the film without additional processing (gluing, stimulation, etc.). But the use of corona wires is mandatory, because without them the paint will peel off the film within a few seconds. The paint, whatever it is, will turn into a drop and will calmly move along the polymer film. Corona current discharges provide a valence bond for the film and ink, and the original shape is retained for a long time.